Presys PCON-Y18-LP User manual

Technical Manual

EM0345-02

PCON-Y18-LP

www.presys.com.br

Desktop

version

Field

Service

version

Rack Mounting

version

Automatic Low Pressure Calibrator

presys

PRESYS Instruments PCON-Y18-LP

WARNING!

The instruments described in this technical manual are equipments for

use in specialized technical area. The user is responsible for the

configuration and selection of values of the parameters of the

instruments. The manufacturer warns against the risk of incidents with

injuries to both persons and property, resulting from the incorrect use of

the instrument. Use the instrument only according to this technical

manual. Any operation not described here is not allowed.

WARNING!

Other pressure equipments and accessories (such as hose, reservoirs,

protection devices) connected to the calibrator must be appropriate to the

working pressure.

WARNING!

During startup, do not connect any instrument to the output port of the

Pressure Control Module. Before making connections to the Pressure

Control Module, enter the CALIBRATOR menu and wait for the automatic

VENT and RESET operation.

WARNING!

The calibrator discharges gas to the atmosphere through the vent port.

Leave this port free.

WARNING!

Before connecting the instrument under test to the output port, make a

VENT operation to discharge any gas inside the controller.

WARNING!

Before connecting the instrument under test to the output port it is

recommended to configure the output range parameters. These

parameters limit the controller output range, in order to protect the

instrument under test.

ATTENTION!

To prevent damage to the connected instrument to be calibrated, do not

turn off the PCON-Y18-LP with the CONTROL mode selected. Before

turning off, select MEASURE or VENT mode.

presys

PRESYS Instruments PCON-Y18-LP

WARNING!

Avoid electric shock risk when touching the equipment. Use only suitable

power cable with earth connection and never power up the equipment to

the mains socket without an earth connection (DT and RM Version).

For FS Version, use only the charger provided by the manufacturer.

WARNING!

High voltage is present inside these equipments. It can cause great

damages and injuries. Do not make any repair service inside the

equipment without removing the plug from the supply (DT and RM

version).

NOTICE!

High level of electromagnetic noise can cause instability to the

equipment. The equipment is provided with electromagnetic interference

filters that protect not only the mains but also the equipment itself against

noise. These filters have no function if the unit/charger is not earthed

properly.

IMPORTANT!

All pressure equipment and accessories (such as hoses, connections,

adapters, etc.) connected to the calibrator must be clean, free of residues

such as oil, dirt, dust etc. These residues can cause irreversible damage

to the internal system of the pressure control module. It is mandatory to

use filters in out port (HI).

ATTENTION!

Whenever you change the inclination of the PCON-Y18-LP, it is important to

perform the RESET operation of the pressure again.

CAUTION: Damage caused by failure to observe the above recommendations

results in total or partial loss of the equipment warranty.

The warranty conditions are available in our sites:

www.presys.com.br/warranty

Do you have any doubt?

Press HELP or icons to have information about the function.

presys

EC Declaration of Conformity

We declare under our sole responsability that the CE marked products, are in conformity

with the essential requirements of the following EC Directives when installed in

accordance with the installation instructions contained in the product documentation:

Series

PCON-Y18-LP

Description

Automatic Low Pressure Calibrator

LVD

Low Voltage Directive

2014/35/EC of the European Parliament and of the Council of 12 December 2006 on

the harmonization of the laws of Member States relating to Electrical Equipment

designed for use within certain voltage limits.

EN 61010-1:2011

Safety requirements for electrical equipment for measurement, control and laboratory

use

EN 61010-2:010

Safety requirements for electrical equipment for measurement, control and laboratory

use - Part 2-010: Particular requirements for laboratory equipment for the heating of

Materials.

EMC directive

2004/108/EC of the European Parliament and of the Council of 15 December 2004

on the approximation of the laws of the Member States relating to electromagnetic

compatibility and repealing Directive 89/336/EEC

EN 61326-1:2003

Electrical equipment for measurement, control and laboratory use - EMC requirements

São Paulo, 8 September 2015

Vinicius José Gomes Nunes

Antonio Rafael Sito Antunes

CEO

Engineering Manager

presys

PRESYS Instruments PCON-Y18-LP

Table of Contents

1 - Introduction ................................................................................................................................. 1

1.1. General Description ................................................................................................................. 1

1.2. Technical Specifications .......................................................................................................... 2

1.3. Special Software Features....................................................................................................... 4

1.4. Order Code ............................................................................................................................. 5

1.5. Parts Identification ................................................................................................................... 6

2 - Calibrator Operation ................................................................................................................... 8

2.1. Calibrator Menu ....................................................................................................................... 9

2.1.1. Pressure Control Module – Connections ..........................................................................10

2.1.2. Measure Mode ................................................................................................................12

2.1.3. Control Mode...................................................................................................................14

a) Range Parameters ............................................................................................................15

b) Changing the setpoint .......................................................................................................16

c) Stabilization Settings .........................................................................................................17

d) Control Settings ................................................................................................................17

e) Preset Setpoints................................................................................................................19

f) Step Function.....................................................................................................................19

g) Nudge Function ................................................................................................................20

2.1.4. Vent Mode .......................................................................................................................21

2.1.5. Changing the Engineering Unit .......................................................................................24

2.1.6. Filter Intensity ..................................................................................................................24

2.1.7. Auxiliar Input ...................................................................................................................25

2.1.8. Transmitter Power Supply (TPS) .....................................................................................28

2.1.9. Auxiliary Input Scale Function ..........................................................................................28

2.1.10. Calibration Examples .....................................................................................................30

a) Pressure Transmitter Calibration .......................................................................................30

b) Pressure Switch Verification ..............................................................................................31

2.1.11. Leakage / Stability Test .................................................................................................33

2.2. HART® ...................................................................................................................................35

2.2.1. HART® Connections ........................................................................................................35

2.2.2. Starting Communication ..................................................................................................37

2.2.3. Adjusting the Measurement Range of a HART® Transmitter (CH Option) .........................38

2.2.4. Adjusting the Measurement Range of a HART® Transmitter with Reference (CH Option) .39

2.2.5. Checking / Adjusting HART® Transmitter mA Output (CH Option) ....................................40

2.2.6. Full-Hart Configurator (FH Option) ...................................................................................41

2.3. Automatic Tasks .....................................................................................................................43

2.3.1. Creating Tasks ................................................................................................................43

2.3.2. Performing Tasks ............................................................................................................45

2.3.3. Viewing Results ...............................................................................................................46

2.4. Data Logger ...........................................................................................................................48

2.5. Videos ....................................................................................................................................49

2.6. Settings ..................................................................................................................................50

2.7. Built-in Web Server ................................................................................................................51

2.8. SCPI Commands Set .............................................................................................................52

3 - Maintenance ...............................................................................................................................54

3.1. Replacing the Current Input Fuse ...........................................................................................54

3.2. Replacing the Power Supply Fuse ..........................................................................................54

4 - Pressure Units Conversion .......................................................................................................55

presys

PRESYS Instruments PCON-Y18-LP

Page 1

1 - Introduction

1.1. General Description

The PCON-Y18-LP Automatic Low Pressure Calibrator enables the control of

pneumatic low pressure from -100 to 100 Pa up to -35000 to 35000 Pa. Due to its

integrated electrical pump, there is no need of a pressure supply, providing a complete

solution for the test and calibration of low pressure and differential gauges, transmitters

and switches.

It has a high level of accuracy, including aspects relating to changes in room

temperature, and it maintains the specifications over long periods of time. Besides that, it

also allows the measurement of signals generated by the instrument under test which is

being calibrated. This is possible due to an embedded calibrator specific for these

types of signal, including current 4-20 mA. Thus, PCON-Y18-LP incorporates the

functions of pressure controller, digital pressure standard and calibrator for mA, V, mV,

ohms and RTD.

It is also a Hart® Communicator (optional) with a configurable internal

resistance, transmitter power supply and latest DD as optional, in order to easily

configure and calibrate Hart® pressure transmitters.

A highly visible 5.7” touch screen display allows easy configuration and user-

friendly operation.

PCON-Y18-LP features full advanced documenting capabilities. It enables the

creation and execution of automatic calibration procedures (Tasks). After completing a

task, a Calibration Report is issued and it can be printed directly on a USB connected

printer or a PDF document can be generated.

Communication with the computer through SCPI commands for on-line data

acquisition and control of the calibrator.

presys

PRESYS Instruments PCON-Y18-LP

Page 2

1.2. Technical Specifications

1.2.1. Pressure Control Module

Choose one range for the Pressure Control Module between -100 to 100 Pa

(-1 to 1 mbar) and -35000 to 35000 Pa (-350 to 350 mbar).

SI-Pascal

bar

Resolution

Control Stability

Accuracy

(0) -100 to 100 Pa

-1 to 1 mbar

0.001 Pa

1000 ppm

0.1 Pa

0.50 % FS*

(1) -1000 to 1000 Pa

-10 to 10 mbar

0.01 Pa

100 ppm

0.1 Pa

0.075 % FS

(2) -2500 to 2500 Pa

-25 to 25 mbar

0.01 Pa

100 ppm

0.25 Pa

0.050 % FS

(3) -7000 to 7000 Pa

-70 to 70 mbar

0.1 Pa

40 ppm

0.28 Pa

0.025 % FS

(4) -35000 to 35000 Pa

-350 to 350 mbar

1 Pa

40 ppm

1.4 Pa

0.025 % FS

(*) FS = Full Scale.

Accuracy values are valid within one year and temperature range from 20 to 26 °C.

Outside these limits add 0.005 % FS / C, taking 23 °C as the reference temperature.

These values are obtained through algorithms of temperature compensation on pressure

measurements.

1.2.2. Auxiliary Input

Input Ranges

Resolution

Accuracy

Remarks

millivolt

-150 mV to 150 mV

0.001 mV

0.01 % FS*

Rinput > 10 M

auto-ranging

-500 mV to -150 mV

0.01 mV

0.02 % FS

150 mV to 2450 mV

0.01 mV

0.02 % FS

volt

-10 V to 11 V

11 V to 45 V

0.0001 V

0.0001 V

0.02 % FS

0.02 % FS

Rinput > 1 M

mA

-5 mA to 24.5 mA

0.0001 mA

0.02 % FS

Rinput < 120

resistance

0 to 400

400 to 2500

0.01

0.01

0.01 % FS

0.03 % FS

Excitation current

0.85 mA, auto-ranging

Pt-100

-200 to 850 C

-328 to 1562 F

0.01 C

0.01 F

0.1 C

0.2 F

IEC 60751

Pt-1000

-200 to 400 C

-328 to 752 F

0.1 C

0.1 F

0.1 C

0.2 F

IEC 60751

Cu-10

-200 to 260 C

-328 to 500 F

0.1 C

0.1 F

2.0 C

4.0 F

Minco 16-9

Ni-100

-60 to 250 C

-76 to 482 F

0.1 C

0.1 F

0.2 C

0.4 F

DIN-43760

(*) FS = Full Scale.

Accuracy values are valid within one year and temperature range from 20 to 26 °C.

Outside these limits add 0.001 % FS / C, taking 23 °C as the reference temperature.

presys

PRESYS Instruments PCON-Y18-LP

Page 3

1.2.3. General Specifications

Thirty minutes warm-up time.

Transmitter power supply (TPS): 24 Vdc, with protection from short circuit (30 mA).

Contact input for calibration of pressure switches.

Operating temperature range: 0 to 50 C.

Relative Humidity: 0 to 90 % RH.

Engineering units – psi, bar, mbar, MPa, kPa, Pa, atm, at, mmH2O, cmH2O, ftH2O,

inH2O, inH2O@60°F, torr, mmHg, cmHg, inHg, inHg@60°F, gf/cm2, kgf/cm2, kgf/m2 (see

section 4 – Pressure Units Conversion).

Temperature: °C, °F, K, °R.

Built in Web Server.

Ethernet communication. USB port for software/firmware upgrade.

HART® Communication Protocol (optional).

Includes technical manual and test leads. For FS Version (Field Service) a battery

charger is also included (100 to 240 Vac 50/60Hz).

Pneumatic Connection: connector for hose diameter 6 mm.

DT and RM Version: Power Supply: 100 to 240 Vac 50/60Hz

FS Version: Lithium Polymer 4200 mAh rechargeable battery.

Dimensions: 135 mm x 350 mm x 270 mm (HxWxD) - DT Version – Desktop.

132 mm x 483 mm x 255 mm (HxWxD) - RM Version – Rack Mounting.

200 mm x 300 mm x 260 mm (HxWxD) - FS Version – Field Service

Weight: 6.2 kg approx. (DT Version – Desktop)

8.5 kg approx. (RM Version – Rack Mounting)

6.0 kg approx. (FS Version – Field Service)

One-year warranty.

Calibration Certificate (optional).

Notes:

* Changes can be introduced in the instrument, altering specifications in this manual.

* HART® is a FieldComm Group trademark.

presys

PRESYS Instruments PCON-Y18-LP

Page 4

1.3. Special Software Features

- PRESET POINTS: edit your most frequently used setpoints and access them quickly.

- STEP: steps or setpoints with configurable time.

- STABILITY/LEAK TEST: measures the variation of the signal (be it Pressure or an

Auxiliary Input signal) within a configurable period.

- PRESSURE SWITCH TEST: automatic testing of pressure switches.

- AUTOMATED TASKS: create calibration work orders and automatic execution of

calibration services, storage of data and generation of calibration report to a directly

connected USB printer or PDF file.

- DATA LOGGER: monitoring of input or output signals, storage and visualization of data

in chart or table.

- VIDEOS: storage and viewing videos on the calibrator screen.

- MEMORY MANAGER: stores configuration types predefined by the user.

presys

PRESYS Instruments PCON-Y18-LP

Page 5

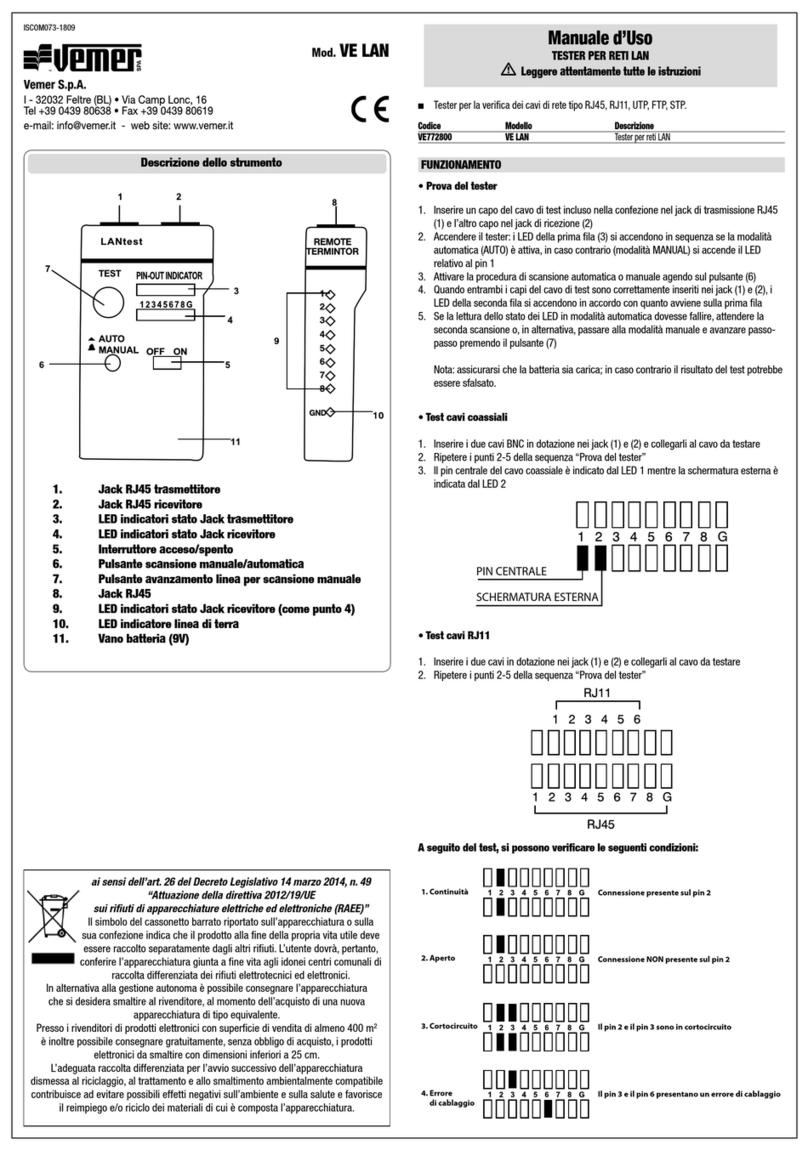

1.4. Order Code

presys

PRESYS Instruments PCON-Y18-LP

Page 6

1.5. Parts Identification

DT Version - Desktop

Fig. 01 – DT Version

presys

PRESYS Instruments PCON-Y18-LP

Page 7

RM Version – Rack Mounting

Fig. 02 – RM Version

Fig. 03 – FS Version

Notes:

On the FS Version, the VENT is an internal port, not accessible to the user.

presys

PRESYS Instruments PCON-Y18-LP

Page 8

2 - Calibrator Operation

Turn on the PCON-Y18-LP by pressing the power switch (located on the rear

panel for the DT version, and on the front panel for the RM and FS version).

When powered on, the calibrator goes through a self-test routine. In case of

failure, it displays a message to indicate the error; if that occurs, please contact the

Presys Technical Assistance department.

After the self-test is completed, the display shows the main menu, as showed

below.

Fig. 04 - Main Menu

WARNING!

During startup, do not connect any instrument to the output port of the

Pressure Control Module. Before making connections to the Pressure

Control Module, enter the CALIBRATOR menu and wait for the automatic

VENT and RESET operation.

The main menu is divided in the following functions:

CALIBRATOR – selects the input/output functions (Pressure Control Module and

Auxiliary Input Signals), see section 2.1.

HART® – optional module that allows communication with devices that have Hart®

Communication Protocol, see section 2.2.

TASKS – performs calibrations automatically, see section 2.3.

DATA LOGGER – record measurements, enabling visualization on chart or table, see

section 2.4.

VIDEOS – features videos made by Presys to assist in the use of the calibrator, and can

also store videos made by the user, see section 2.5.

SETTINGS – general instrument settings, see section 2.6.

presys

PRESYS Instruments PCON-Y18-LP

Page 9

2.1. Calibrator Menu

To select the Pressure Control Module and the Auxiliary Input functions press

the CALIBRATOR button from the main menu.

When first entering the CALIBRATOR menu, the PCON-Y18-LP executes a

VENT operation and an AUTO RESET of the pressure read in the Pressure Control

Module. When it is done, it goes to CONTROL mode. The following screens are

displayed.

Fig. 05 - Calibrator initialization

The Pressure Control Module has three operation modes: MEASURE, VENT and

CONTROL (see sections 2.1.2, 2.1.3 and 2.1.4). To select an operation mode, press one

of the buttons indicated below. The current state is indicated by the symbol.

Fig. 06 - Pressure Control Module - Operation Modes

presys

PRESYS Instruments PCON-Y18-LP

Page 10

2.1.1. Pressure Control Module – Connections

PCON-Y18-LP controls the pressure in the output port with high precision and

stability. To control the pressure, an integrated electric pump for positive and negative

pressure generation supplies the pressure for the controller. When the calibrator is

switched on, the electric pump is turned on and provides the required pressure for the

entire range of the calibrator.

The presence of water, oil or particles in the pressure control module can cause

irreparable damage to the system. Equipment and connections must be clean and dry when

connected to output. The use of impurities filters is necessary to protect the system.

Fig. 07 - Pressure Control Module

Fig. 08 – Output Connections (Rear Panel – Dt / RM Version)

- For the RM and DT version, the VENT port is located on the rear panel; HI and LO ports (Pressure output) are

located on the front panel.

- For the FS version, HI and LO ports (Pressure output) are located on the front panel; VENT port is an internal port

(not accessible by the user).

presys

PRESYS Instruments PCON-Y18-LP

Page 11

WARNING!

The instruments described in this technical manual are equipments for

use in specialized technical area. The user is responsible for the

configuration and selection of values of the parameters of the

instruments. The manufacturer warns against the risk of incidents with

injuries to both persons and property, resulting from the incorrect use of

the instrument. Use the instrument only according to this technical

manual. Any operation not described here is not allowed.

WARNING!

Other pressure equipments and accessories (such as hose, reservoirs,

protection devices) connected to the calibrator must be appropriate to the

working pressure.

WARNING!

The calibrator discharges gas to the atmosphere through vent port. Leave

this port free.

WARNING!

Before connecting the instrument under test to the output port, make a

VENT operation to discharge any gas inside the controller. Before turning

the calibrator off, it is recommended to vent the gas inside the controller.

ATTENTION!

To prevent damage to the connected instrument to be calibrated, do not

turn off the PCON-Y18-LP with the CONTROL mode selected. Before

turning off, select MEASURE or VENT mode.

IMPORTANT!

All pressure equipment and accessories (such as hoses, connections,

adapters, etc.) connected to the calibrator must be clean, free of residues

such as oil, dirt, dust etc. These residues can cause irreversible damage

to the internal system of the pressure control module. It is mandatory to

use filters in out port (HI).

presys

PRESYS Instruments PCON-Y18-LP

Page 12

2.1.2. Measure Mode

In Measure mode, the calibrator shows the pressure measurement in the Control

Module. In this state, the control mode is disabled.

Fig. 09 - Measure mode – screen

Note: The FS Version (Field Service) has an internal VENT port, not accessible to the user.

Fig. 10 - Measure mode – state of the valves

presys

PRESYS Instruments PCON-Y18-LP

Page 13

The state of the output isolation valve is user configurable. To change the state of

the valve, press the SETTINGS button shown below and change the Output

Parameters (OPEN / CLOSED) in the ADVANCED tab.

The valve symbol appears on the calibrator screen indicating that the Isolation

valve is OPEN. This valve is used to isolate the unit under test from the pressure control

module.

Fig. 11 - Output Isolation Valve Status

To zero the current pressure measurement, press the RESET PRESS button.

Whenever this function is used, the PCON-Y18-LP executes a VENT operation and an

AUTO RESET of the pressure read in the Pressure Control Module and returns to the

control mode.

ATTENTION: Whenever you change the inclination of the PCON-Y18-LP, it is

important to perform the RESET operation of the pressure again.

Fig. 12 - Reset of the current pressure measurement

presys

PRESYS Instruments PCON-Y18-LP

Page 14

2.1.3. Control Mode

In this mode, the calibrator controls pressure at the output port through the

admission and exhaustion control valves.

Fig. 13 - Control mode – screen

Note: The FS Version (Field Service) has an internal VENT port, not accessible to the user.

Fig. 14 - Control mode – state of the valves

presys

PRESYS Instruments PCON-Y18-LP

Page 15

a) Range Parameters

WARNING!

Before connecting the instrument under test to the output port it is

recommended to configure the output range parameters. These

parameters limit the controller output range, in order to protect the

instrument under test.

To change the pressure controller output range press the SETTINGS button

shown below and edit the Min and Max values in the RANGE tab. All parameters set in

these menus are the same engineering unit of the execution mode (measure / control).

The engineering unit used is indicated in the upper right corner of the screen. To change

the unit, return to the execution mode (measure / control) and touch on the unit (Pa, psi

etc) and select the desired unit.

Fig. 15 - Range parameters

Changing the output range is useful when the pressure range of the instrument

under test is lower than the control module range, to protect against overpressure at the

instrument.

presys

Table of contents

Other Presys Test Equipment manuals

Presys

Presys T-1200PH User manual

Presys

Presys T-350P User manual

Presys

Presys PC-507-IS User manual

Presys

Presys TA-1200P User manual

Presys

Presys PCA-570-RM User manual

Presys

Presys MCS-12-IS User manual

Presys

Presys MCS-XV User manual

Presys

Presys T-25N User manual

Presys

Presys T-500PIR User manual

Presys

Presys TA-1200PLAB User manual