3

NOTES:

• During adaptor installation, extend the plunger

and apply approximately 1500 to 2000 psi

[103 to 138 bar] of hydraulic pressure. This will

help keep the plunger from turning inside the

cylinder base.

• Do not allow the plunger to rotate during

adaptor installation. Plunger rotation may

damage the internal seals and/or the plunger

return spring (if equipped).

• Hand-tighten adapters and attachments until

full thread engagement occurs and the item

can no longer be turned by hand. Do not use

tools.

• Always check for full thread engagement.

Thread damage may occur if cylinder is

loaded and threads are not fully engaged.

• Note that the plunger threads on single-acting

cylinders are not rated for the full cylinder

load.Forces must betransferreddirectly from

theadapteror attachment to the face of the

plunger, and not through the threads.For this

reason, it is very important to verify that the

adapter or attachment is fully installed on the

plunger.

• Use care when installing adaptors and

attachments. Be careful not to nick or mar the

plunger rod surface.

• Collar threads are rated for the full capacity of

the cylinder when fully engaged in attachments.

WARNING: Some cylinder attachments

require that the cylinder be used at no

more than 50% of its rated capacity. Refer

to the accessory instruction sheet for

additional information.

4.0 OPERATION

Operate the hydraulic pump to advance and retract

the cylinder. Some single-acting cylinders are spring-

return, others are load-return. The speed of retraction

is aected by the length of the hose and other

restrictions in the line. Double-acting cylinders are

powered in both directions by the pump.

The cylinder stop ring is designed to take the full load.

However, to reduce cylinder wear, use less than full

stroke and pressure when possible.

5.0 RELIEVING TRAPPED PRESSURE

Pressure can sometimes become trapped in a

hydraulic cylinder if a hose is disconnected before

pressure is completely relieved.

If a trapped pressure condition occurs, always use the

Enerpac model CT-604 coupler bleed tool (available

from your Authorized Enerpac Distributor) to safely

relieve the remaining pressure.

DANGER: Never attempt to relieve hydraulic

pressure by loosening a coupler. Trapped

hydraulic pressure can cause a loosened

coupler to dislodge unexpectedly with great force.

Serious personal injury or death will result if the

coupler becomes a projectile and strikes persons

working in the area.

WARNING: Loosening a coupler may

result in an escape of high pressure oil

that can penetrate the skin. Serious

personal injury or death could result.

WARNING: Never use a hammer and

punch (or other similar method) to unseat

a coupler check ball that is under

pressure. Serious personal injury or death

could result due to the sudden and uncontrolled

escape of high pressure oil.

6.0 MAINTENANCE

1. Use only Enerpac oil with the cylinder. The use of

any other oil may invalidate your warranty.

2. Use dust cap(s) when cylinder is disconnected

from the hose(s). Keep the entire cylinder clean to

prolong its life.

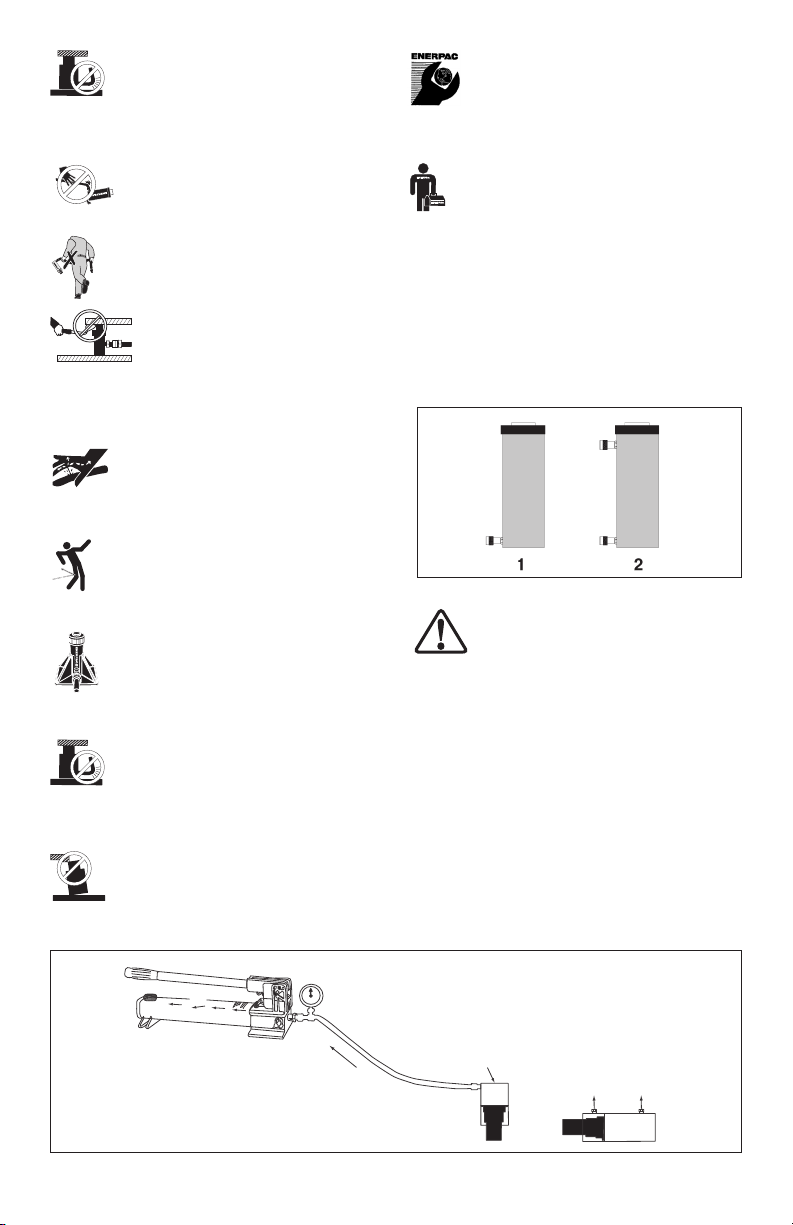

3. Store cylinders upright to prevent seal distortion.

4. Single-acting cylinders only: Before long term

storage, fully extend and retract the plunger once.

Then, store the cylinder upside-down. This will

help protect the cylinder from corrosion and seal

distortion.

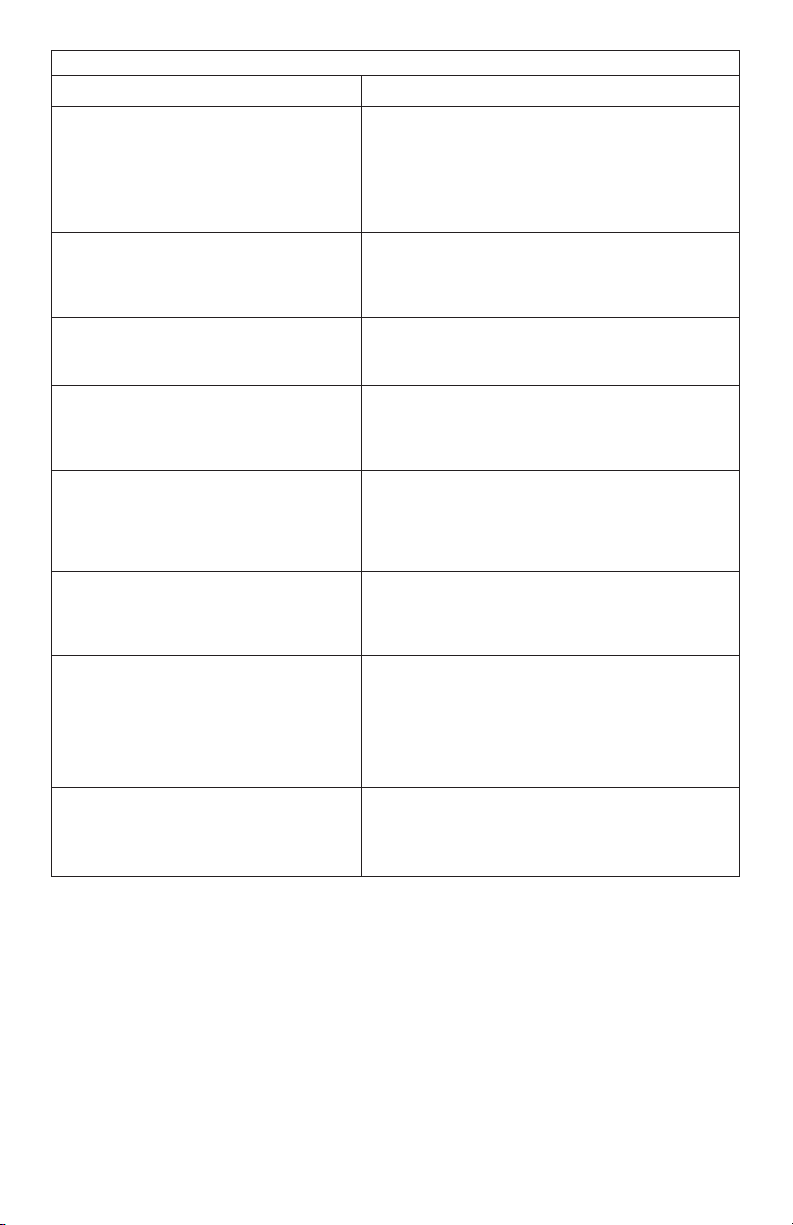

7.0 TROUBLESHOOTING

Refer to the troubleshooting chart for a list of

typical cylinder problems and possible causes. The

troubleshooting chart is not all-inclusive, and should

be considered only as an aid to help diagnose the

most common problems.

The cylinder should be repaired only by trained and

experienced hydraulic technicians.

WARNING: Single-acting cylinders are

spring-loaded and require special

disassembly techniques to prevent

personal injury.