EnerPro VR31 User manual

http://www.enerpro-inc.com

99 Aero Camino

Goleta, California 93117

Ph: (805) 683-2114 / (877) 648-2114

Operating Manual: OP-0116

Date: July 2019

Enerpro Document No: OP-0116, Rev.A Page 1 of 3 ECO #19-11073; Release Date: 07/23/2019

OPERATIONS MANUAL

VR31 Troubleshooting Guide

Purpose

The purpose of this document is to outline on locomotive troubleshooting of the VR31. The information in

this report should be used to incorporate into locomotive maintenance manuals.

Reference

1. PD773, VR31 Auxiliary Generator Regulator Product Guide

Test Equipment

1. Digital Multimeter (DMM)

2. Banana jack test leads

Description of VR31

1. The VR31 system is an upgraded Auxiliary Generator regulator that provides 3-stage battery

charging for legacy EMD locomotives. It works in conjunction with the EBCS-3 current sensor that

provides battery charging current feedback to the VR31. After each engine start, the VR31

transitions through the 3 stages with each stage being indicated by an LED on the front panel.

2. Test jacks provide measurement of AuxGen voltage, battery voltage, battery current, AuxGen

field voltage, and AuxGen AC1, AC2, and AC3 voltage.

3. If the VR31 detects a current sensor or wiring fault, a fault LED is illuminated and transition to

stage 3 is made. This is done in order to prevent battery overcharging. This fail-safe mode allows

continued locomotive operation until the EBCS-3 and associated wiring can be evaluated and

repaired.

4. The EBCS-3 is powered from the VR31 through pin 9 and protected by a 2 amp mini-fuse, CP1.

Fuse CP1 and a spare are located near the back of the regulator module.

5. VR31 output voltage is calibrated at the factory and is not adjustable in the field.

Normal Operation

Normal operation is indicated by illumination of one of the 3 charge stage LED’s and a nominal

AuxGen voltage range output. Stage 1 is constant battery current and Stage 2 and 3 are constant

rectifier voltage. AuxGen voltage output is measured between jacks RP (rectifier positive) and BN

(battery negative). Battery voltage is measured between jacks BP (battery positive) and BN. Battery

voltage can be 1-6 VDC lower than rectifier voltage depending on battery charging current. Battery

current is measured between jacks +IB and BN with 100 ADC scaled to 1 VDC. Nominal range output

for each stage is outlined below:

Stage 1 (Bulk): Rectifier Voltage ~68-78 VDC

Battery Current 80-95 amps (0.80 – 0.95 VDC on front panel)

Stage 2 (Absorption): Rectifier Voltage 77.5 - 78 VDC

Battery Current 25 to 95 amps (0.25 - 0.95 VDC on front panel)

Stage 3 (Float): Rectifier Voltage 72 - 72.8 VDC

Battery Current 0 to 25 amps (0- 0.25 VDC on front panel)

Enerpro Document No: OP-0116; Rev. A Page 2 of 3 ECO #19-11073; Release Date: 07/23/2019

Troubleshooting

1. General. For any abnormal AuxGen issues on AC AuxGen locomotives, verify AuxGen AC

outputs. Measure the 3 AuxGen phase to phase AC voltages (AC1 to AC2, AC2 to AC3, and AC1

to AC3). If measurements are not equal, troubleshoot AuxGen.

2. Current Sensor Fault. Current sensor fault is indicated by the Current Sensor Fault and Stage 3

LEDs being illuminated. RP voltage should be 72-72.8 VDC. If fuse CP1 is open, RP will read 0

VDC even with good output.

a. Verify EBCS-3 current sensor wiring on back panel: white wire to Pin 3, red wire to Pin 9,

black wire to Pin 14.

b. If wiring incorrect, correct per above, check fuse CP1, restart engine and re-evaluate

VR31.

c. If wiring correct, check fuse CP1 and replace EBCS-3.

3. No LEDs and no Output. Temporarily increase engine RPM. If VR31 begins operation as

indicated by Stage 1 LED illuminating, note idle RPM. If idle RPM is below normal range, correct

idle. If idle RPM is normal, replace VR31 with one that has the low-idle upgrade modification. The

low idle upgrade is identified by components R11 and R2 on the upper back of the circuit board.

On a standard VR31, R11 is light blue and RT2 is small. On a modified VR31, R11 is tan and

RT2 is larger as shown below.

Standard VR31 Low-Idle Upgrade VR31

Low-Idle Upgrade Marking

4. Tripped Circuit Breaker. A tripped circuit breaker is caused by RP overvoltage or field over

current. An overvoltage may be caused by a locomotive wiring fault, excessive load dump, or a

faulty VR31. Shut down engine, reset circuit breaker and restart engine. If circuit breaker trips

again, verify back panel wiring AC1, AC2, and AC3 inputs. These inputs (pins 4, 6, and 10)

should only have the singe AC inputs connected. If back panel wiring is correct, remove and

replace VR31.

Enerpro Document No: OP-0116; Rev. A Page 3 of 3 ECO #19-11073; Release Date: 07/23/2019

5. Output Out of Range. Voltage outside the ranges listed above may be due to VR31

malfunction, a defective AuxGen (Step 1) or a defective or damaged battery. Note that the output

measured is rectifier voltage, not battery voltage. Because of diode drop and cabling resistance,

battery voltage may be as much as 6 volts lower than rectifier voltage depending on battery state

of charge and health.

a. Stage 1 voltage low. With the Stage 1 LED illuminated, check battery current IB. If IB is

normal (0.8- 0.95 VDC, 80-95 amps), check RP voltage. If RP voltage is 68 VDC or

above, allow to run and check again in 1 hour. If RP is below 68 VDC or does not

increase after 1 hour, test battery for shorted cells or other defects.

b. Stage 1 battery current out of range. If Stage 1 is illuminated and IB is out of range

(0.8- 0.95 VDC, 80-95 amps), remove and replace VR31.

c. Stage 2 or 3 voltage out of range. Remove and replace VR31.

Table of contents

Popular Controllers manuals by other brands

Enttec

Enttec Pixelator 70060 user manual

Allmand

Allmand LSC100 Operation, Testing, and Troubleshooting Information

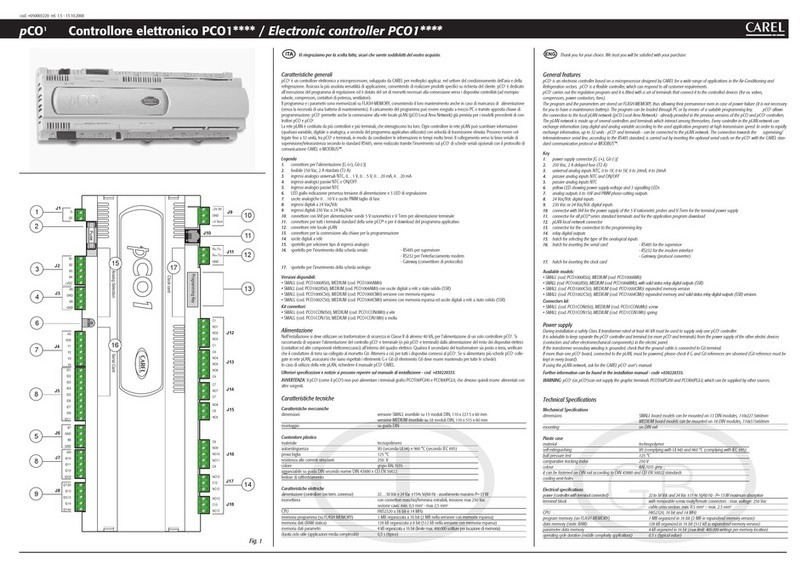

Carel

Carel pCO1 series manual

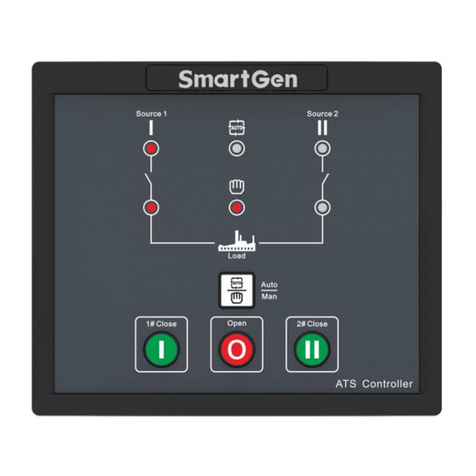

Smartgen

Smartgen HAT530P Series user manual

uAvionix

uAvionix microLink User and installation guide

progressive automations

progressive automations PA-37 User's manual and setup instructions