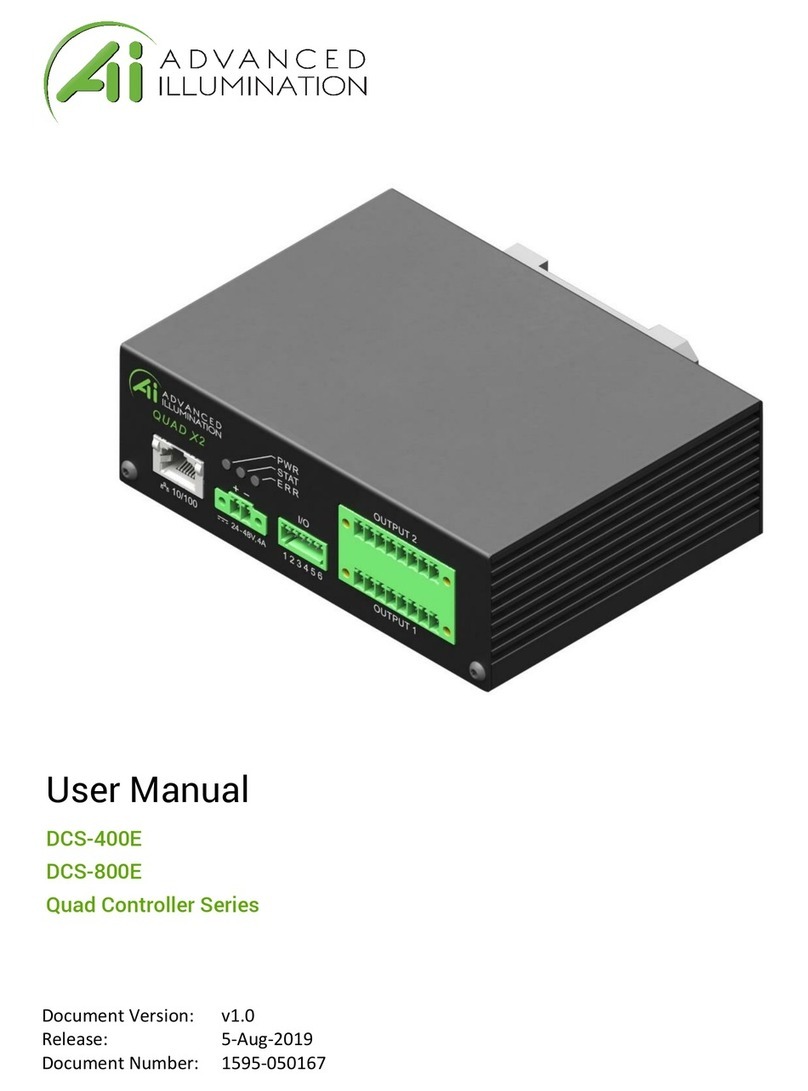

Advanced Illumination DCS-400E User manual

Photometric Stereo with the

Ai DCS-400E Quad Controller

User Guide

Mounting Bracket

DIN Rail Compatible

Input Power

24 V DC Nominal, 4.5 A

Vmin = 22 V DC

Vmax = 48 V DC

External Trigger

Input/Output

5V, TTL Compatible

Overtvoltage Protected,

Safe up to 30 V DC

Communication/Software

10/100 Ethernet Standard TCP-IP, UDP

.NET Library Compatible with C#, F#, and VB

Windows Software

Channel Control

DCS-400E: 4 Independent Channels, 1 Output

DCS-800E: 8 Independent Channels, 2 Outputs

Introduction

Hardware & Setup

Hardware Overview

Setup Diagram

DCS-400E & DCS-800E General Specs

DCS 400E Overview

Modes

Standard

Sequenced

Connections

Camera Setup

Design Assistant Software Setup

Application Examples

Threaded Metallic Part Inspection

Glossy Vitamin Bottle Inspection

2

2

2

3

3

4

4

4

5

6

6

7

8

8

9

Table of Contents

Page 1

Hardware Overview

Hardware & Setup

The following hardware are used in the examples featured in this user guide.

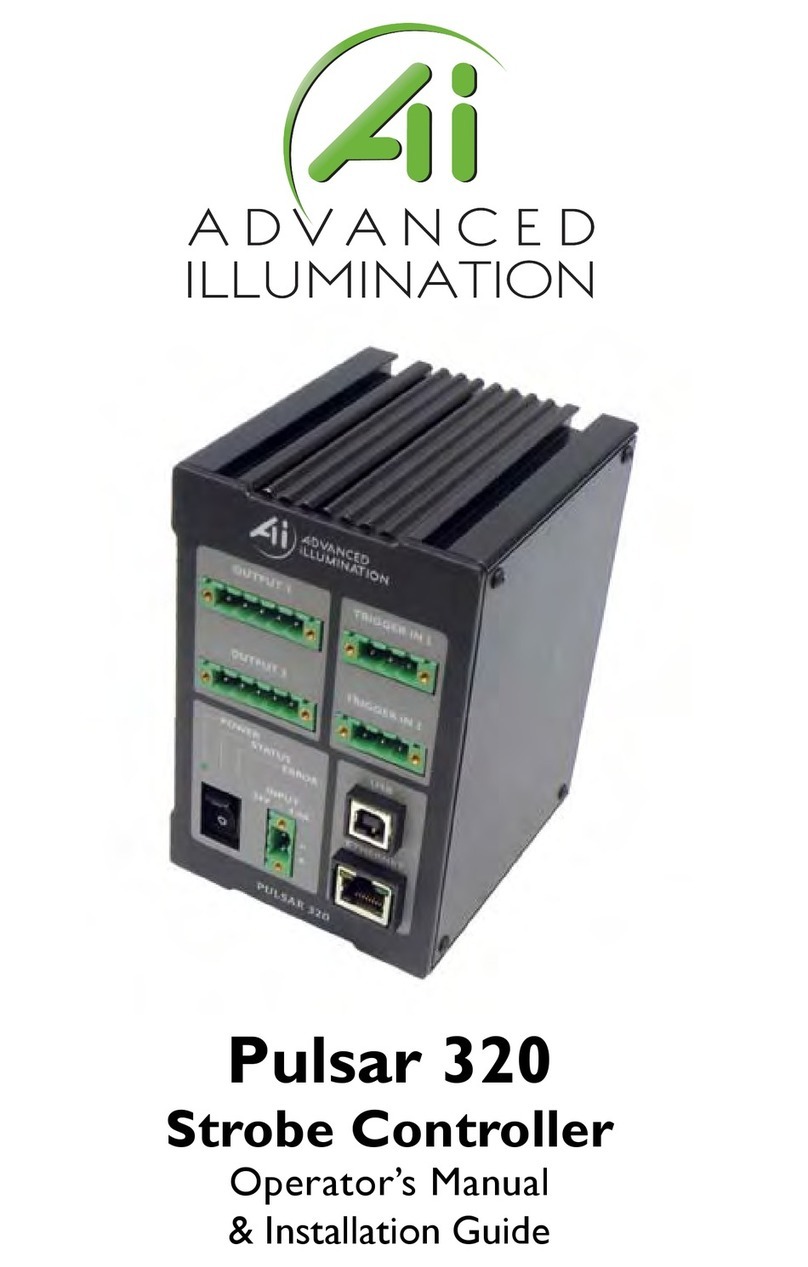

DCS-400E

Quad Controller

DF198 Dark Field Ring Light

DF198-WHIQ1

USB 3 Camera

Standardized Camera Interface

MIL Compatible

Introduction

Challenging machine vision inspection requirements often call for more sophisticated imaging

techniques, like those employed with Photometric Stereo. The DCS-400E (Quad Controller,

4-channel) and DCS-800E (Quad X2, 8-channel) lighting controllers provide multi-channel

lighting and sequenced, multi-image captures that produce compelling inspection results when

processed with photometric stereo imaging software libraries.

A typical photometric stereo imaging application uses two or more channels of lighting to

sequentially illuminate the target from different directions. The DCS-400E and DCS-800E allow

up to 4 or 8 potential channels, respectively, which can be used in any combination of quadrants

or colors, or even different light types. To meet the inspection requirements, these combinations

can be mixed and matched to create the ultimate multi-dimensional lighting effects.

The Quad Controllers allow independent brightness, pulse width, and pulse delay across all

channels, affording maximum flexibility. Congurable output signals are available to provide

frame start and stop control over the camera, as well as the ability to save and load channel

recipes on the fly.

Page 2

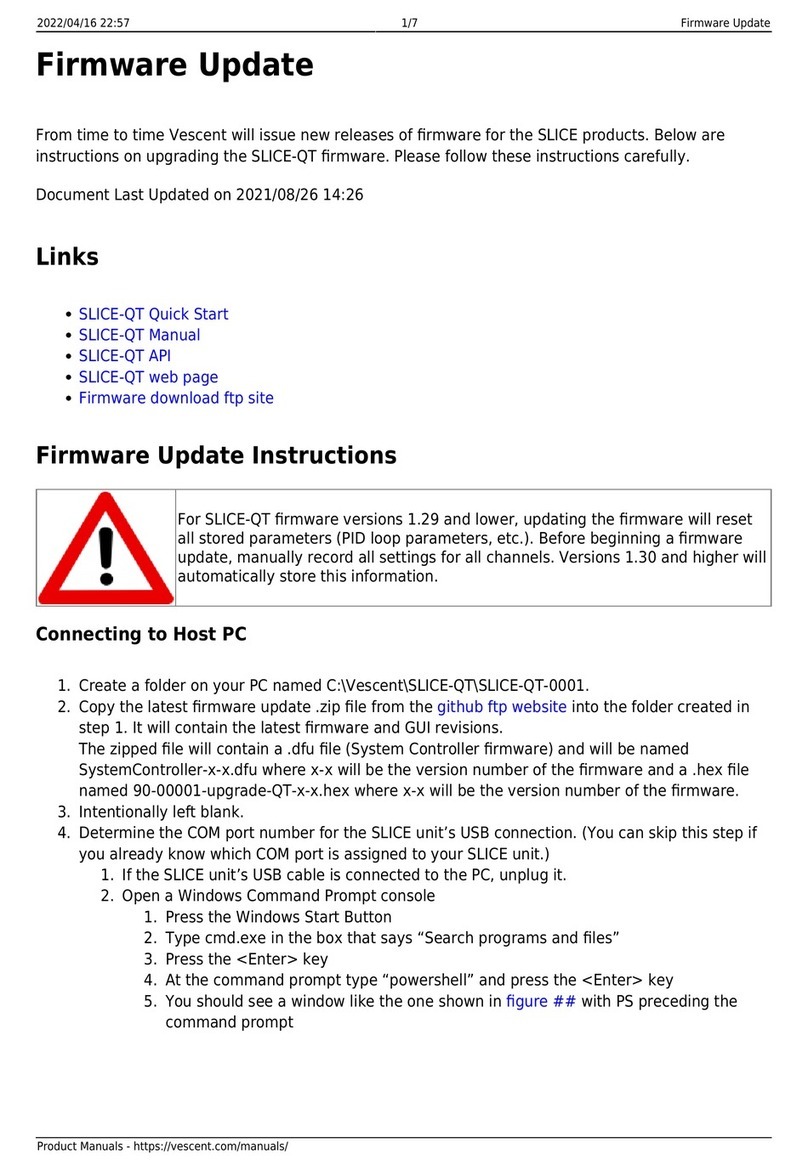

Trigger Setup Diagram

Camera

External Trigger

24 V DC

Trigger

Connector

Q1 Connector

X4 / X8 Channels

SignaTechTM EEPROM

DCS-400E Quad Controller

or DCS-800E Quad X2

Vision Software

Q1 Light

Single Cable, up to

4 Channels per Connector

DCS-400E & DCS-800E Specications

Modes

Power Requirements

Output Power

Pulse Width Range

DCS-400E

500mA Continuous per Channel; Up to 50W Total,

5A Pulsed per Channel; 12.5W per Channel

24V DC Nominal, 4.5A Maximum

Pulsed, Continuous, Gated Continuous

30 μsec - 3600 msec

DCS-800E

Strobe Frequency Limit

2KHz

Trigger Latency

30 μsec Typical

Channel Control

8 Independent Channels,

2 Outputs

4 Independent Channels,

1 Output

500mA Continuous per Channel; Up to 100W Total,

5A Pulsed per Channel; 12.5W per Channel

Download the User Manual for the DCS-400E & DCS-800E here:

https://www.advancedillumination.com/quad-controllers-manual

Page 3

Standard mode works like a traditional strobe controller where all channels re with a xed delay

and pulse width. There is no modied channel sequencing that occurs, and all channels re from

a single trigger edge.

Figure 1 - DCS-400E Standard Channel Settings, Single Event. If using DCS-800E, Channels 1-8 will be visible.

Modes: Standard

Figure 2 - A Single Trigger Flashes each channel, with or without independent delay. Note: delay is not to scale with the

channel settings shown in Figure 1.

DCS-400E Overview

Page 4

Sequenced mode allows the user to synchronize each channel flash with a camera exposure

to create a multi-dimensional acquisition. Channel recipes can be congured by the user,

depending on the application needs.

A Sequence is made up of a series of Events. Events can be thought of as "recipes" that contain

all the channel settings (pulse delay, current, pulse width, etc.) associated with the receiving

trigger.

With the DCS-400E, each Event can include anywhere from 1-4 channels (DCS-800E includes 1-8

channels), with their respective settings (pulse delay, current, pulse width). For example, to set

up a quadrant imaging application, the user should create x4 Events, one for each quadrant. An

Event can contain any number of channels.

The example Sequence in Figure 3 shows Event 2 thru 5 in its series. This setup will require x4

triggers from the camera to complete the Sequence.

Figure 3 - Dening a Sequence using four Events with the DCS-400E .

Figure 4 - Visual representation of each trigger initiating the next Event in the Sequence.

Modes: Sequenced

Page 5

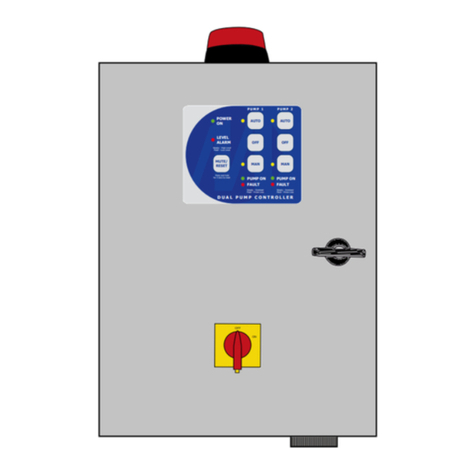

Basic Camera to LC (Light Controller) Connections.

Figure 5 - Camera Exposure Triggers LC Channels.

Connections

Figure 6 - LC Triggered Externally, Frame-Start Triggers Camera Exposure.

In the following examples, we are using a typical USB 3.0 camera with Matrox Design Assistant.

The Quad Controllers are compatible with any camera and software combination that is capable

of Photometric Stereo.

Camera Setup

Page 6

The full extent of using Matrox Design Assistant is beyond the scope of this User Guide.

However, included in this document is a broad overview of how the DCS-400E Quad Controller

and Ai lights work in conjunction with the Photometric Stereo library functions.

Visit this URL to Access the Matrox MIL:

https://www.matrox.com/imaging/en/products/software/design-assistant-machine-vision-software/

Design Assistant Software Setup

Page 7

The following threaded metallic part presents a challenge for standard vision light and camera

congurations. The varying heights of the object’s threads create signicant shadowing, making

it very difcult to visually inspect for defects. The metallic surface also presents a challenge

with unwanted specular reflections. We independently control the quadrants of a DF198-115

MicroBriteTM Diffuse Ring Light with the DCS-400E Quad Controller to illuminate the threaded part

from four directions.

The input images in Figure 7 highlight the inspection challenges created by the shadowing

and reflections of the part’s 3D surface characteristics. However, by processing the images in

the Matrox Design Assistant and Imaging Library, the nal flattened shape image removes the

specular reflections and severe shadowing. This results in an image more easily inspected for

damaged threads or other imperfections.

Application Examples

Figure 8 - MIL Operator View.

Figure 7 - Input images of the inspected threaded metallic part.

Threaded Metallic Part Inspection Example

Page 8

In this example, we are inspecting a printed lot code on the bottom of a bottle. Due to the

reflective and concave characteristics of the bottom of the bottle, it is difcult to illuminate the

printed lot code without excessive specular reflections.

However, by using a DF198 MicroBriteTM Diffuse

Ring Light with each of its four quadrants

independently controlled with the DCS-400E Quad

Controller, we are able to capture four images with

illumination at the same angle of incidence, but

from multiple directions.

Using the Matrox Design Assistant and Imaging

Library (MIL) to process the images, the nal

albedo of the image is flat – resulting in an easily

identiable printed lot code.

Figure 9 - Input images of the glossy vitamin bottle.

Figure 10 - Final processed image.

Glossy Vitamin Bottle Inspection Example

For additional application examples and detailed Photometric Stereo information, visit our website:

https://www.advancedillumination.com/photometric-stereo-technique/

Page 9

www.advancedillumination.com | 440 State Garage Rd., Rochester, VT 05767

Other manuals for DCS-400E

1

This manual suits for next models

1

Table of contents

Other Advanced Illumination Controllers manuals

Popular Controllers manuals by other brands

Intel

Intel 845PE Thermal Design Guide

Kübler

Kübler 573 Series operating instructions

Heatcraft Refrigeration Products

Heatcraft Refrigeration Products 25001501 Installation & operating instructions

Sony

Sony JunboTron JME-SA200 operating instructions

Cypress

Cypress UNIVERSAL CAPSENSE quick start guide

Weathermatic

Weathermatic PROLINE PL800 owner's manual