HANDLING AND INSTALLATION

Installation into Industrial Truck

Mechanical Installation

• This battery is designed to be a drop-in

replacement of a lead-acid battery intended to

power an electric industrial truck. Modications

of truck rmware, truck settings, or truck

hardware may be necessary to accommodate the

lithium-ion battery. Consult with industrial truck

OEM for required modications. Depending on

the intended application, connectors, ballast, tray

size, etc., must be customized to ensure the

drop-in compatibility.

• Upon receipt of the battery, it must be checked

for any obvious signs of damage to both battery

and all cables, plugs, and accessories.

• Before installation, check that the battery is

supplied with the appropriate cable harness to

connect the battery to the industrial truck.

• Ensure that the battery weight and center of

gravity requirements per the truck manufacturer

are followed. Weight and overall dimensions are

listed on the type label located on the battery

pack.

• The battery must be handled in a way to mitigate

the risk of drop events and crashes.The correct

tools, lifting points, and method should be used.

• After placement of the battery into the truck’s

battery compartment, the technician must ensure

that the battery is mechanically xed in the

truck against the movement as specied by the

industrial truck manufacturer. After the battery

is xed in the truck’s battery compartment, all

cabling must be checked once again in order to

ensure that no cables, wires, or plugs have been

crushed, pinched, or cut.

Electrical Installation

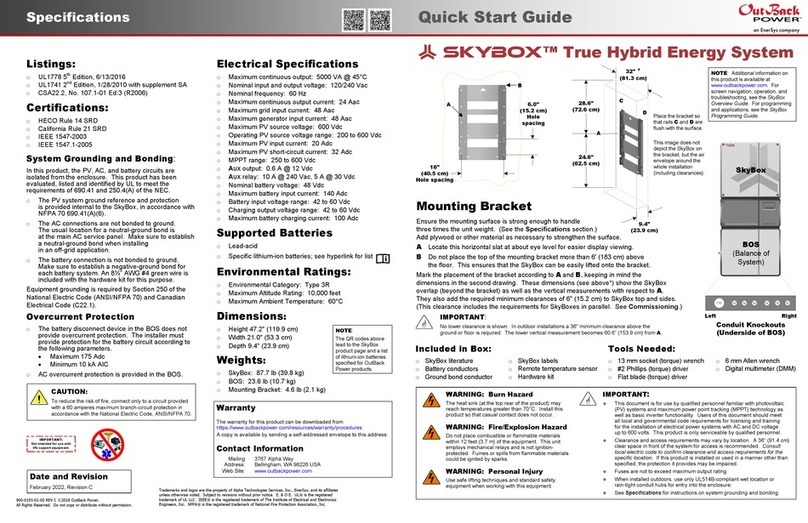

• The model number for this battery begins with

a 24, 36, 48, or 80 for batteries intended to

replace 24 V, 36 V, 48 V, or 80 V nominal lead-acid

batteries respectively.

• The battery must be connected with the

appropriate cables and connector to the

industrial truck per the truck manufacturer’s

recommendation.

• Only use EnerSys®-approved fasteners,

connectors, cabling, and plugs with this battery.

• The cable dimensioning and DC connecting plug

will vary depending on the truck and end-user

requirements.The truck harness shall comply

with relevant requirements for current carrying

capability and truck interface requirements.

Compliance shall be conrmed by the truck OEM.

NOTE: Defective cables and connectors can result

in functional issues and/or severe safety hazards

such as short circuits and/or re. Cables and

connectors must be regularly inspected for any

damage or issues. Cables and connectors should

only be repaired or replaced by an authorized

EnerSys®representative using the correct factory

replacement parts. No substitution is allowed.

Handling (cont.)

Preparing Battery without Outer Tray for Handling

• Remove the sealing bolts from the threaded

mounting holes on the inner tray.

• Install the EnerSys®-supplied lifting attachments

for the battery.

• After handling the battery, the lifting interface

on the four-point connection on the battery must

be removed and the sealing bolts must be tted

again to seal the thread holes.The acceptable

torque is based on the bolt size: M8 bolts should

be torqued to 34 Nm ± 2 Nm; M12 bolts should

be torqued to 66 Nm ± 4 Nm.

NOTE: For transportation and storage safety

reasons, all NexSys iON batteries are shipped at a

partial SoC. Before the rst operation (refer to page

12: Operation) or further storing the battery (refer

to page 16: Storage) it is required to check the SoC

(refer to page 6: Operator Interfaces) and recharge

the battery if needed (refer to page 13: Battery

Charging).

11