www.enersys-emea.com

04.2008 - Subject to revisions without prior notice.

2. Operation

EN 50272-3 “Traction batteries for industrial trucks” is the standard

which applies.

The nominal operating temperature is 30°C. The optimum lifetime of the

battery depends on the operating conditions (temperature and depth of

discharge). The temperature range of use for the battery is between

+15°C and +35 °C, any use outside of this range must be approved by the

EnerSys Technical department. Optimal battery life is obtained with the

battery at a temperature of 25-30°C. Higher temperatures shorten the life

of the battery (according to IEC1431 technical report), lower temperatu-

res reduce the available capacity. The upper temperature limit is 45°C

and batteries should not be operated above this temperature.

The capacity of the battery changes with temperature and falls consider-

ably under 0 °C. The optimum lifetime of the battery depends on the

operating conditions (moderate temperature and discharges equal to or

lower than 80% of the nominal capacity C5). The battery obtains its full

capacity after about 3 charging and discharging cycles.

2.1. Discharging

The valves on the top of the battery must not be sealed or covered.

Electrical connections (e.g. plugs) must only be made or broken in the

open circuit condition. Discharges over 80% of the rated capacity are

categorised as deep discharges and are not acceptable as they reduce

considerably the life expectancy of the battery. Discharged batteries

MUST be recharged immediately and MUST not be left in a discharged

condition.

Note: The following statement only applies to partially discharged

batteries.

Discharged batteries can freeze.

Limit the discharge to a maximum of 80% DOD.

The cycle life of the battery will depend on the DOD,

the higher the DOD, the shorter the cycle life.

The presence of a discharge limiter on the vehicle is imperative,

The following energy cut-off settings must be used :

• 60% DOD set at 1.93 Volts per cell.

• 80% DOD set at 1.88 Volts per cell.

when discharged with I5(or higher currents).

2.2. Charging

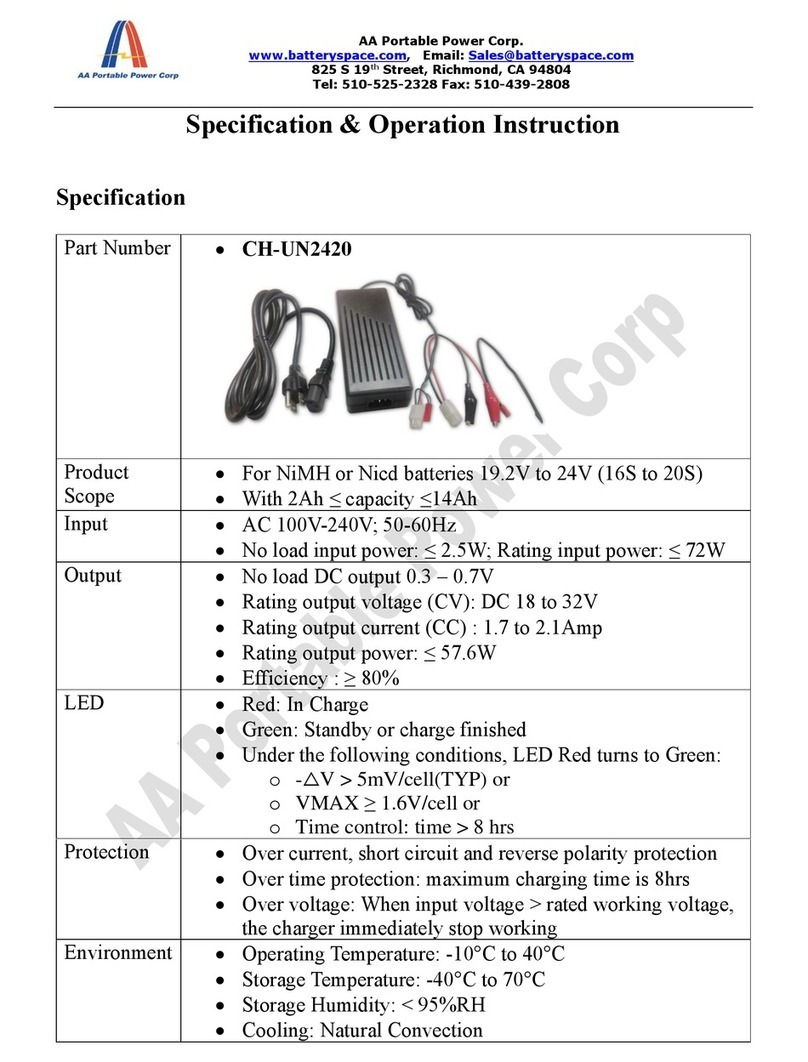

Powerbloc dry XFC batteries must be charged using an approved speci-

fied EnerSys XFC charger. An approved charger MUST be used on these

batteries; failure to do so will affect the performance and life of the bat-

tery and invalidate any warranty.

The specific charging profile developed for recharging the powerbloc dry

XFC blocs allows a rapid recharge in 3 hours from 60% DOD and oppor-

tunity charging as often as needed without damaging the blocs.

The powerbloc dry XFC batteries have an extremely low gas emission.

Nevertheless, provision must be made for venting of the charging gases.

Battery container lids and the covers must be opened or removed.

With the charger switched off, connect the battery to the charger, ensu-

ring that the polarity is correct. (Positive to positive, negative to negati-

ve). Now switch the charger ON.

2.3. Equalising Charge

Equalising charge is not necessary for this technology of battery.

3. Maintenance

The electrolyte is immobilised. The density of the electrolyte can not be

measured.

Never remove the safety valves from the monobloc.

In case of accidental damage to the valve, contact our After Sales

Service for replacement.

3.1. Daily

• Recharge the battery after every discharge.

• Check the condition of the plugs, cables and that all insulation covers

are in place and in good condition.

3.2. Weekly

• Visual inspection for signs of dirt and mechanical damage.

3.3. Quarterly

At the end of the charge, carry out end of charge voltage readings,

measure and record:

• The voltage of the complete battery

• The voltages of each monobloc

If significant changes from earlier measurements or differences between

the monoblocs are found, please contact our Service Department.

If the discharge time of the battery is not sufficient, check:

• That the required work is compatible with the battery capacity

• The settings of the charger

• The settings of the discharge limiter on the vehicle.

3.4. Annually

Internal dust removal from the charger.

Electrical connections: test all connections (sockets, cables, and contacts).

Monoblocs having terminals with insert: Check the torque loading of the

bolts/screws.

According to EN 1175-1 when necessary, but at least once a year, the

insulation resistance of the vehicle and of the battery must be checked

by an electrical specialist.

4. Storage

Batteries are despatched from the manufacturer in a fully charged

condition. The state of charge will decrease with storage.

All batteries lose their stored energy when allowed to stand open-circuit,

due to parasitic chemical reactions.

The rate of self-discharge is non-linear and decreases with decreasing

state of charge. It is also strongly influenced by temperature.

High temperatures greatly reduce storage life.

It is recommended that the fully charged battery should be stored in a

cool dry place, ideally below 20°C.

The battery has a maximum inspection-free storage life of 2 years, if sto-

red at or below 20°C, after which a refresh charge should be administe-

red. However, it is advisable to conduct an inspection and open circuit

voltage check after 12 months and recharge if the OCV is less than 2.10

Volts per cell.

The battery may be stored for up to 5 years without degradation of per-

formance provided that an open circuit voltage (OCV) check is conducted

every 12 months. When stored in temperatures in excess of 30°C (86°F),

the battery should be OCV checked every 6 months.

The graph below shows the relationship between temperature, storage

time and OCV.

5. Disposal

Powerbloc dry XFC batteries are recyclable. Scrap batteries must be

packaged and transported in accordance with prevailing transportation

rules and regulations. Scrap batteries must be disposed of in compliance

with local and national laws by a licensed or certified lead acid battery

recycler.

Back to the manufacturer!

Batteries with this sign must be recycled.

Batteries wich are not returned for the recycling process must be disposed of as hazardous waste!