EnerSys Alpha TRD User manual

TRD™

VRLA Battery Thermal Runaway Detection System

for DCX™Series Battery Disconnect Systems

Technical Manual

Effective: March 2021

2C048-702-30 R02, Rev. B (03/2021)

The following sections contain important safety information that must be followed during the installation and maintenance

of the equipment. Read all of the instructions before installing or operating the equipment, and save this manual for future

reference.

There may be multiple warnings associated with the call out. Example:

ATTENTION provides specic regulatory/code requirements that may aect the placement of equipment and /or

installation procedures.

ATTENTION:

NOTICE provides additional information to help complete a specic task or procedure.

NOTICE:

ELECTRICAL HAZARD WARNING provides electrical safety information to PREVENT INJURY OR DEATH

to the technician or user.

WARNING! ELECTRICAL HAZARD

FUMES HAZARD WARNING provides fumes safety information to PREVENT INJURY OR DEATH to the

technician or user.

WARNING! FUMES HAZARD

FIRE HAZARD WARNING provides ammability safety information to PREVENT INJURY OR DEATH to the

technician or user.

WARNING! FIRE HAZARD

This WARNING provides safety information for both Electrical AND Fire Hazards

WARNING! ELECTRICAL & FIRE HAZARD

CAUTION provides safety information intended to PREVENT DAMAGE to material or equipment.

CAUTION!

GENERAL HAZARD WARNING provides safety information to PREVENT INJURY OR DEATH to the

technician or user.

WARNING! GENERAL HAZARD

Safety Notes

Alpha Technologies Services, Inc. considers customer safety and satisfaction its most important priority. To reduce the

risk of injury or death and to ensure continual safe operation of this product, certain information is presented dierently in

this manual. Alpha®tries to adhere to ANSI Z535 and encourages special attention and care to information presented in

the following manner:

3C048-702-30 R02, Rev. B (03/2021)

TRD™

VRLA Battery Thermal Runaway Detection System

for DCX™Series Battery Disconnect Systems

Technical Manual

C048-702-30 R02, Rev. B

Eective: March 2021

©2021 by Alpha Technologies Services, Inc.

Disclaimer

Images contained in this manual are for illustrative purposes only. These images may not match your installation.

Operator is cautioned to review the drawings and illustrations contained in this manual before proceeding. If there are

questions regarding the safe operation of this powering system, please contact Alpha Technologies Services, Inc. or your

nearest Alpha representative.

Alpha®shall not be held liable for any damage or injury involving its enclosures, power supplies, generators, batteries or

other hardware if used or operated in any manner or subject to any condition not consistent with its intended purpose or is

installed or operated in an unapproved manner or improperly maintained.

Contact Information

Sales information and customer service in USA

(7AM to 5PM, Pacic Time): 1 800 322 5742

Complete Technical Support in USA

(7AM to 5PM, Pacic Time or 24/7 emergency support): 1 800 863 3364

Sales information and Technical Support in Canada: 1 888 462 7487

Website: www.alpha.com

4C048-702-30 R02, Rev. B (03/2021)

Table of Contents

1.0 Purpose and Applicability � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 5

1�1 Product Model � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 5

2.0 Theory of Operation � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 5

2�1 Features � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 5

3.0 Unpacking and Inspection � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 6

3�1 Package Contents � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 6

4.0 Installation � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 6

4�1 Installation Preparation� � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 6

4�1�1 Elevated Operating Ambient Temperature � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 6

4�1�2 Reduced Air Flow� � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 6

4�1�3 Mechanical Loading � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 6

4�1�4 Circuit Overloading � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 6

4�1�5 Reliable Earthing � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 6

4�1�6 Disconnect Device � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 6

4�2 Installation Procedure� � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 7

5.0 Operation� � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 9

5.1 Conguration and Alarm Wiring � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 9

5�1�1 Alarm Connections� � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 9

5�2 Control Options� � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 10

6.0 Product Specications � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 11

7.0 Ordering Information� � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 11

5C048-702-30 R02, Rev. B (03/2021)

1.01.0 Purpose and ApplicabilityPurpose and Applicability

The purpose of this document is to detail the installation and operation instructions for the Alpha® TRD™Battery Thermal

Runaway Detection System�

1.11.1 Product ModelProduct Model

This document applies to the TRD Battery Thermal Runaway Detection System� This kit may have been supplied pre-

installed on your DCX™Series battery disconnect system, or was sold separately�

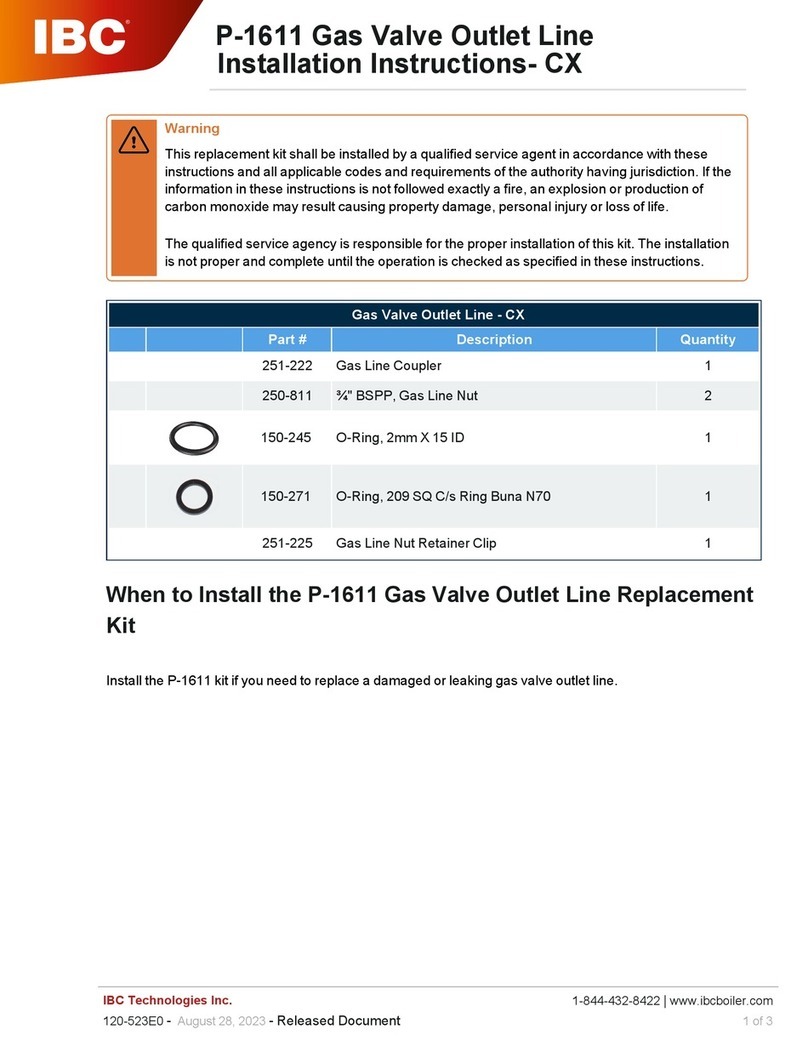

Table 1. GMT 125 Series Fuse Panel Congurations

PART NUMBER DESCRIPTION

C016-934-10 TRD - VRLA Battery Thermal Runaway Detection System

2.02.0 Theory of OperationTheory of Operation

The DCX Series top terminal mount DC disconnect product family consists of an internal magnetic trip DC rated circuit

breaker and control circuit to provide remote status monitoring, remote trip and provides an interface expansion connector

to allow optional circuit modules to plug into the DCX Series system� DCX units are available in 400, 600, 800, 1,000

and 1,200 ampere rated versions with a multitude of adapter termination copper bus and mounting kits to support many

battery types�

The standard DCX Series disconnect comes with circuit breaker status monitoring via both LED indicators as well as

form-c alarm contacts for remote breaker status detection. In addition, a remote EPO (Emergency Power O) input circuit

is provided to allow for use of EPO wall mounted switches, remote trip supervisory controllers or other options to comply

with applicable re or building codes for remote trip function.

A terminal block is provided for remote switch contact or relay contact closure to EPO trip the DC circuit breaker and

disconnect the battery string from the load and rectier system. Manual disconnect is always available via simply turning

o the circuit breaker handle.

The TRD option (Thermal Runaway Detector) is a kit that consists of a plug-in circuit card and control panel assembly,

two remote temperature sensors, and cable� The TRD can be installed in any DCX Series disconnect unit� The TRD

control board assembly simply plugs into the DCX Series circuit board expansion connector and is secured with mounting

screws to hold it in position�

The TRD controller circuit monitors temperature in three locations to analyze and determine if the VRLA battery system

is approaching or is in thermal runaway condition� Two remote battery terminal sensors are compared against an internal

reference temperature sensor and dierential is analyzed and if a thermal fault is detected, the system alerts this status.

New NFPA and local state re codes now specify use of a thermal runaway detection system for VRLA batteries to

provide the ability to detect and alert if the battery system has a thermal fault developing or in process� In addition,

many local municipalities have added the requirement that if thermal runaway is detected, the battery system must

automatically be disconnected from the charging and load circuit without requiring manual intervention�

The DCX Series battery disconnect and TRD system is the only self-contained telecom grade thermal runaway detection

and auto-disconnect system that complies with both NFPA and state/local re codes for VRLA battery installations.

2.12.1 FeaturesFeatures

yModular, hot-swap circuit card assembly

yTwo remote temperature sensor probes

yPre-alert and Thermal Runaway alarm relay contacts

yTemperature display

yOptional self disconnect feature

yKit retrots in any existing DCX Series battery disconnect system

6C048-702-30 R02, Rev. B (03/2021)

3.03.0 Unpacking and InspectionUnpacking and Inspection

The TRD was carefully packaged at the factory to withstand the normal

rigors of shipping� However, you should carefully inspect the box and

contents to conrm that no damage has occurred in transit. Most

shipping carriers require notication of shipping damage within twenty-

four hours of delivery, and it is the responsibility of the recipient to

inspect the shipment immediately upon receipt�

3.13.1 Package ContentsPackage Contents

Included with your product are the following items:

yTRD control board

yTwo remote temperature sensors with LED status

yMounting hardware kit

yTemperature sensor cables

4.04.0 InstallationInstallation

Installation of the TRD kit is typically performed as a retrot for existing

DCX Series battery disconnect systems in communications battery

rooms or similar -48VDC power plants� Orders direct to the factory for

new systems where the TRD option is specied on the order are factory

installed prior to shipment. This procedure denes the retrot process

to install the TRD kit in an existing DCX Series disconnect system�

Figure 1. TRD board

Figure 2. Battery temperature sensor for

TRD

4.14.1 Installation PreparationInstallation Preparation

When selecting an installation location, ensure that all of the following conditions are met before proceeding.

4.1.14.1.1 Elevated Operating Ambient TemperatureElevated Operating Ambient Temperature

If you install the product in a closed or multi-unit rack assembly, the operating ambient temperature of the rack

environment may be greater than room ambient� Therefore, take care to install the equipment in an environment

compatible with the maximum ambient temperature (TMA) specied in Section 6.

4.1.24.1.2 Reduced Air FlowReduced Air Flow

Installation of the equipment in a rack should be such that the amount of air ow required for safe operation of the

equipment is not compromised�

4.1.34.1.3 Mechanical LoadingMechanical Loading

Mounting of the equipment in the rack should be such that a hazardous condition is not achieved due to uneven

mechanical loading�

4.1.44.1.4 Circuit OverloadingCircuit Overloading

Give consideration to the connection of the equipment to the supply circuit and the eect that overloading of the circuits

might have on overcurrent protection and supply wiring� Use appropriate consideration for equipment nameplate ratings

when addressing this concern�

4.1.54.1.5 Reliable EarthingReliable Earthing

Maintain reliable earthing of rack-mounted equipment� Pay particular attention to supply connections other than direct

connections to the branch circuit (e.g., use of power strips).

4.1.64.1.6 Disconnect DeviceDisconnect Device

A readily accessible disconnect device must be incorporated in the building installation wiring�

7C048-702-30 R02, Rev. B (03/2021)

4.24.2 Installation ProcedureInstallation Procedure

THIS PRODUCT MUST BE INSTALLED WITHIN A RESTRICTED ACCESS LOCATION WHERE ACCESS IS

THROUGH THE USE OF A TOOL, LOCK AND KEY, OR OTHER MEANS OF SECURITY, AND IS CONTROLLED

BY THE AUTHORITY RESPONSIBLE FOR THE LOCATION� THIS PRODUCT MUST BE INSTALLED AND

MAINTAINED ONLY BY QUALIFIED TECHNICIANS�

NOTICE:

WARNING! ELECTRICAL HAZARD

VRLA BATTERY STACKS CAN PROVIDE THOUSANDS OF AMPERES OF DISCHARGE CURRENT INTO

A SHORT CIRCUIT, IN ADDITION, PARALLELED BATTERY STACKS AND LARGE RECTIFIER SYSTEMS

CAN ALSO DISCHARGE EXTREMELY HIGH CURRENTS INTO A SHORT CIRCUIT FAULT� THERE IS

AN EXTREME SAFETY HAZARD WHEN WORKING ON LARGE SYSTEMS WITH THIS DISCHARGE

AMPACITY POTENTIAL� EYE PROTECTION, SAFETY GLOVES AND PROTECTIVE SHIELDS ARE

REQUIRED ENTIRELY DURING THE TRD INSTALLATION PROCESS�

Step 1. Unpack and inspect contents of TRD kit. See "3.1 Package Contents" on page 6 for more information. Conrm

all parts are present and no shipping damage has occurred�

Step 2. Installation into the DCX unit technically can be performed with the battery disconnect circuit breaker on and

connected to the rectier and load system in extreme cases but is not recommended for safety reasons and due

to the fact that battery bus bar connections must be loosened as part of the temperature sensor installation

process. It is recommended that the battery disconnect circuit breaker be turned o for the installation process.

Step 3. Locate the DCX unit to be retrotted with the TRD kit. Turn o the DCX circuit breaker and tape in the o position

as a reminder during the work process and as a notication to co-workers that may be present. Ensure that eye

protection, safety gloves, long sleeve shirts are used as a precaution�

Step 4. Open the ip-up DCX unit lid/door and conrm that it latches in the secure upright position.

Step 5. Install the TRD circuit board and control assembly from the left of the DCX unit and move toward the right to plug

into the expansion connector on the existing circuit board assembly inside of the DCX unit� Ensure that there is a

secure connection with full alignment and seating of the connectors� Align the mounting holes of the TRD board

assembly with the existing threaded metal stand-os inside of the DCX unit. Install the screws provided in the kit

to secure the TRD board module assembly to the DCX metal housing�

Step 6. Locate the temperature sensor kit which consists of two remote terminal temperature sensors and cable

assemblies� Note that one cable may be shorter than the other� One temperature sensor and cable is intended to

mount on a battery terminal near the top of the battery stack which requires a shorter cable, while the other

sensor is intended to be installed on the lower section of the battery stack, requiring the longer cable to route to

this location�

Step 7. Installation of the temperature sensor modules requires that the bolt connecting the copper bus strap that will be

used to mount the sensor be removed and replaced with a longer bolt to mount the TRD sensor module� This

requires access to the battery terminals and is a safety hazard area� Ensure that insulated tools, safety gloves,

and eye protection are used�

Step 8. To install the temperature sensor modules, two mounting locations must be conrmed: one at the top of the

battery stack to monitor the upper section of the stack and one near the lower third of the stack to monitor lower

stack temperature�

These two temperature sensing points are compared to an ambient temperature sensor in the TRD unit to

determine the temperature rise of the battery sensors compared to ambient and compared to each other� The

temperature sensor module has a copper lug with a clearance hole for a 1⁄4-20 bolt which is the typical size bolt

used in the strapping kit from the battery manufacturer. Conrm that the DCX circuit breaker is in the OFF

position, then remove the appropriate clear cover from the battery stack that is covering the bolt location desired

for installation� Ensure that insulated tools, safety gloves, and eye protection are used� Carefully loosen and

remove the bolt while being extremely careful to not contact adjacent battery terminal posts or strap locations�

Remove this bolt and washers and nut and set aside�

8C048-702-30 R02, Rev. B (03/2021)

Step 9. Top sensor: select a bolt location in the top battery string

shelf or second shelf from the top� Locate the temperature

sensor module and lengthened bolt kit� Locate the sensor

module lug clearance hole on the battery terminal post and

slide the new bolt in from the bottom up through the battery

post and strap assembly and new nut� The hardware order

from bottom up should be bolt, at washer, battery terminal

post and strap then at washer, split lock washer, second nut,

temperature sensor lug and nal nut. Finger tighten this

assembly and check to ensure that the sensor lug and PCB

assembly are not pinched or pressed against adjacent

terminals, bus bars etc�

Figure 3. Temperature sensor cable

connected to battery terminal

The sensor module is designed to sit above the rst nut so that the sensor lug is not in compression with the bolt

assembly required for correct tight torque for current carrying capacity of the battery strap system� Tighten the

hardware on the battery post and strap to the battery manufacturers correct torque setting� Typically this is about

100 inch pounds� Use a torque wrench with insulated feature to avoid potential for short circuit� Locate the

temperature sensor lug and tighten top nut carefully on top of lug to hold the sensor to the bolt� This connection

does not need to be over tightened� Take caution as to not rotate or stress the sensor circuit board while

tightening� This is intended as a temperature measurement connection and not a high current connection

requiring extreme torque to hold the sensor module in place�

Step 10. Bottom sensor: Select a bolt location in the second or third battery shelf from the bottom of the stack and

repeat the installation procedure from Step 9 for this sensor. Conrm all connections are tight.

Step 11. Locate temperature sensor cables and conrm that they are dierent lengths: the shorter cable is for the top

sensor and the longer cable is for the bottom sensor� Plug the sensor cable into the jack of the sensor module

securely and ensure that it latches� Route the sensor cable up the face of the battery stack carefully around the

battery posts and straps� It is not recommended that this cable be allowed to chafe on these bus bars or be

cable-tied to the bus bars� Use double-sided tape cable tie anchors or route cable directly up to the top of the

stack in such a manner that it is not contacting battery straps or terminal posts to avoid a potential short circuit�

Plug in both cables at the sensor ends and conrm correct routing of the cables safely up the stack to the DCX

unit mounted on the top of the battery stack�

Step 12. Replace all of the battery terminal plastic cover shields

removed for access for the sensor installation. Conrm all are

mounted correctly�

Step 13. Route the two sensor cables up to the bottom of the DCX

housing through the black plastic grommet hole and into the

control panel assembly and plug in the cables into the jacks

provided on the DCX control circuit board� The sensor on the

top of the stack is TEMP 1 and the sensor on the bottom of

the stack is TEMP 2. Conrm this by reading the label on the

DCX PCB next to the jacks� These are clearly marked and it

is important to ensure that the correct sensor cable is

plugged into it's correct jack� Store any excess sensor cable

by carefully coiling and secure with a cable tie� This

concludes the TRD control and temperature sensor

installation procedure�

Figure 4. Temperature sensor cable

routing through DCX chassis via grommet

hole and up to DCX control PCB jack

locations

9C048-702-30 R02, Rev. B (03/2021)

5.05.0 OperationOperation

5.15.1 Conguration and Alarm WiringConguration and Alarm Wiring

The TRD system is congurable in several ways to provide remote

alarm monitoring and either local or remote battery breaker trip

disconnection if either terminal runaway is detected or a ventilation

system fails etc�

The TRD PCB assembly includes the control circuit to monitor, analyze

and detect thermal faults via three sensor systems� The alarm output

of this circuit assembly includes LED indicators as well as two alarm

contact relays that can provide remote alarm detection�

5.1.15.1.1 Alarm ConnectionsAlarm Connections

The alarm connections are provided on a 6-position terminal block and

on an 8p8c (RJ-45) jack (see Figure 5).

Pre-alert

Form-C. NO (normally open), NC (normally closed), C (common). Max 1

ampere, 30VDC�

yActuates rst if a thermal fault is initially detected. Can be wired to a

remote strobe, lamp, horn etc� to notify alert condition locally� Can

be wired to remote monitoring or re suppression control panel.

Thermal Runaway Detect

Form-C. NO (normally open), NC (normally closed), C (common). Max 1

ampere, 30VDC�

yActuates second if a thermal runaway is detected� Can be wired

to a remote strobe, lamp, horn etc� to notify alert condition locally�

Can be wired to remote monitoring or re suppression control

panel� This signal is typically used for a remote monitoring and

control system to detect thermal runaway and then to send a DCX

battery breaker disconnect signal�

Table 2. P-Terminal Alarm Outputs

PIN # DESCRIPTION

1N�O� PRE-ALERT

ALARM

2N�C�

3COM

4N�O� THERMAL

RUNAWAY

ALARM

5N�C�

6COM

Figure 5. Alarm connections

Table 3. RJ-45 Alarm Outputs

PIN # DESCRIPTION

1COM PRE-ALERT

ALARM

2N�C�

3N�O�

4COM THERMAL

RUNAWAY

ALARM

5N�C�

6N�O�

7RESERVED N/A

8RESERVED

10 C048-702-30 R02, Rev. B (03/2021)

5.25.2 Control OptionsControl Options

Option A: Internal TRD detect and self-

disconnect

This option does not require an external monitoring or

control system such as a re suppression controller and

simply uses the thermal runaway detect relay output of

the TRD module to connect into the EPO switch input of

the DCX control PCB� Essentially the TRD alarm relay

closes and sends an EPO signal to the DCX which trips

the battery circuit breaker and isolates the batteries from

the charging system� This approach is viable for small

systems with a single battery stack, remote sites such

as cell sites, cabinets or equipment rooms where a re

suppression system may not be present or where there

may not be sucient supervisory control functions in the

re suppression or monitoring controller. Figure 6. Internal TRD detect and self-disconnect

Figure 7. Internal TRD detect and remote disconnect control

Option B: Internal TRD detect and remote disconnect control

This option requires use of a remote controller device of some kind such as a re control panel or supervisory controller

or PLC etc� This device can monitor both the pre-alert and TRD relays of the TRD module and provide remote

monitoring, send an alarm to a call center, send a re department alarm and/or provide an EPO trip signal back to the

DCX unit after a programmable time delay after waiting for manual intervention rst etc.

The remote controller device provides the control monitoring and trip control� The advantage of this approach is that

the controller device can also monitor other site conditions to determine if the DCX breaker should be EPO tripped o.

Examples include EPO wall switches pushed, remote hydrogen sensors detecting out gassing, ventilation – cooling

system failure etc� Any one of these conditions can be programmed to send an EPO trip signal to the DCX including the

thermal runaway detection from the TRD module�

11 C048-702-30 R02, Rev. B (03/2021)

6.06.0 Product SpecicationsProduct Specications

Table 4. Specications

Input Voltage -48V DC (supplied by DCX unit term board)

Width 7� 25 i n�

Height 5�5 in�

Operating Temperature 0 to 50°C

Elevation -500m to 2800m

7.07.0 Ordering InformationOrdering Information

Table 5. Kit Conguration

DESCRIPTION PART NUMBER

TRD - VRLA Battery Thermal Runaway Detection System C016-934-10

Alpha Technologies Services, Inc. | 3767 Alpha Way, Bellingham, WA 98226, USA

Tel�: Toll Free North America: +1 800 322 5742 | Outside US: +1 360 647 2360 | Technical Support: +1 800 863 3364

For more information visit our website at: www�alpha�com

© 2021 Alpha Technologies Services, Inc� All Rights Reserved� Trademarks and logos are the property of Alpha

Technologies Services, Inc. and its aliates unless otherwise noted. Subject to revisions without prior notice. E.&O.E. C048-702-30 R02, Rev. B (03/2021)

This manual suits for next models

1

Table of contents

Other EnerSys Control Unit manuals