Topway LMT035KDH03-NJN User manual

URL: www.topwaydisplay.com

Document Name: LMT035KDH03-NJN -Manual-Rev0.3

Page: 1 of 12

LMT035KDH03-NJN

LCD Module User Manual

Prepared by:

Caiwei

Checked by:

Approved by:

Date: 2022-06-08

Date:

Date:

Rev.

Descriptions

Release Date

0.1

New release

2021-10-09

0.2

Add LCD Module design picture

2021-01-04

0.3

Updata Outline Dwg

2022-06-08

TOPWAY

LCD Module User Manual

LMT035KDH03-NJN

URL: www.topwaydisplay.com

Document Name: LMT035KDH03-NJN -Manual-Rev0.3

Page: 2 of 12

Table of Content

1. General Specification ............................................................................................................3

2. Block Diagram........................................................................................................................3

2.1 Terminal Functions...............................................................................................................4

3. Absolute Maximum Ratings..................................................................................................4

4. Electrical Characteristics......................................................................................................4

4.1 DC Characteristics ...............................................................................................................4

4.2 AC Characteristics................................................................................................................5

4.2.1 8080 Mode Timing....................................................................................................... 5

4.2.2 Reset Timing ............................................................................................................... 6

5. Optical Characteristics..........................................................................................................7

6. Function Specifications.........................................................................................................9

6.1 Command Summary ............................................................................................................9

7. LCD Module Design and Handling Precautions.................................................................10

TOPWAY

LCD Module User Manual

LMT035KDH03-NJN

URL: www.topwaydisplay.com

Document Name: LMT035KDH03-NJN -Manual-Rev0.3

Page: 3 of 12

1. General Specification

Note:

*1. For saturated color display content (eg. pure-red, pure-green, pure-blue or pure-colors-combinations).

*2. For “color scales” display content.

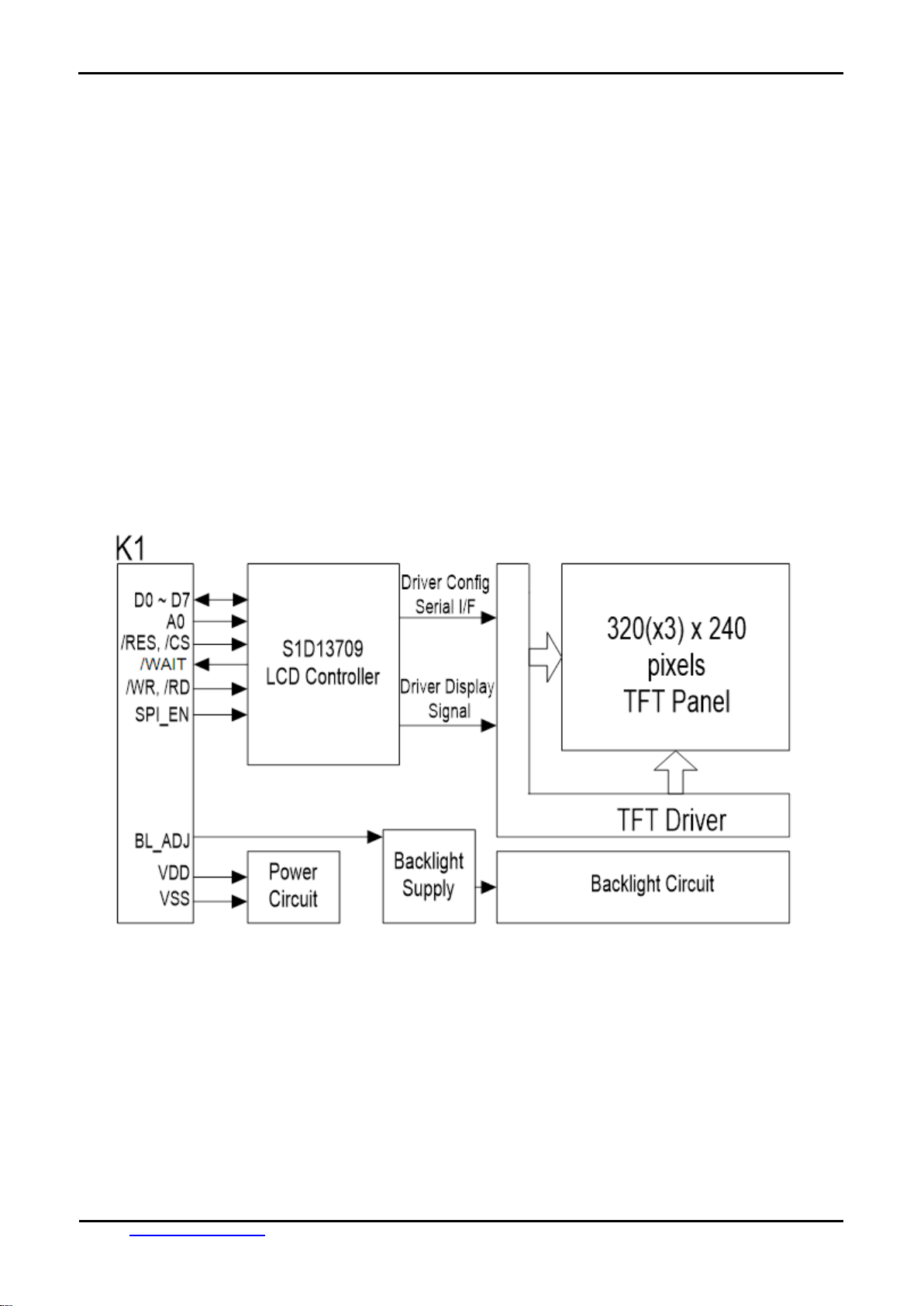

2. Block Diagram

Figure 1

Screen Size(Diagonal) :

3.5 inch

Active Area :

70.08 x 52.56 (mm)

Number of dots :

320(RGB) x 240

Pixel Pitch:

0.219 x 0.219 (mm)

Color Depth:

2bpp

Display Technology :

a-Si TFT active matrix

Display Mode :

Normal White, Transmissive

Display Interface :

MCU Interface

Viewing Direction :

6 o’clock(Gray scale Inversion) (*1)

12 o’clock (*2)

Operating Temperature :

-20 ~ +70°C

Storage Temperature :

-30 ~ +80°C

TOPWAY

LCD Module User Manual

LMT035KDH03-NJN

URL: www.topwaydisplay.com

Document Name: LMT035KDH03-NJN -Manual-Rev0.3

Page: 4 of 12

2.1 Terminal Functions

Terminal (K1/K2)

Pin

No.(K1)

Pin

No.(K2)

Pin

Name

I/O

8bit MCU Mode (Default)

Description

1

1,2

VSS

Power Input

Power Supply GND (0V)

2

3,4

VDD

Power Input

Positive Power Supply

3

NC

-

No Connect

4

18

/WR

Input

Write Enable, active Low

5

17

/RD

Input

Read Enable, active Low

6

6

/CS

Input

Chip Select /CS=Low: Data IO is enabled

7

5

A0

Input

Access Mode

A0=High: Accessing Data

A0=Low: Accessing Address

8

7

/RES

Input

Reset

/RES=Low: Reset

/RES=High: Normal operation

9

8

DB0

Bi-directional

I/O

8-bit Bi-directional data bus

:

:

DB1

14

13

:

15

14

DB6

16

15

DB7

17

16

/WAIT

Output

WAIT Signal

18

NC

-

No Connect

19

19

BL_ADJ

Input

Backlight Driver enable signal, active High, PWM(*1) can be possible

20

20-24

NC

-

No Connect

Note:

*1. The PWM frequency is between 200Hz and 500Hz

3. Absolute Maximum Ratings

Items

Symbol

Min.

Max.

Unit

Condition

Supply Voltage

VDD

-0.2

3.6

V

VSS = 0V

Input Voltage

VIN

-0.2

VDD

V

VSS = 0V

Operating Temperature

TOP

-20

+70

℃

No Condensation

Storage Temperature

TST

-30

+80

℃

No Condensation

Caution:

Any Stresses exceeding the Absolute Maximum Ratings may cause substantial damage to the device. Functional

operation of this device at other conditions beyond those listed in the specification is not implied and prolonged exposure

to extreme conditions may affect device reliability.

4. Electrical Characteristics

4.1 DC Characteristics VSS=0V, VDD =3.3V, TOP =25℃

Items

Symbol

MIN.

TYP.

MAX.

Unit

Applicable Pin

Operating Voltage

VDD

3.0

3.3

3.6

V

VDD

Input High Voltage

VIH

0.8VD

D

-

VDD

V

Input pins, Bi-direction pins

Input Low Voltage

VIL

VSS

-

0.2VDD

V

Input pins, Bi-direction pins

Operating Current

IDD

-

155

200

mA

On Backlight Power on status

TOPWAY

LCD Module User Manual

LMT035KDH03-NJN

URL: www.topwaydisplay.com

Document Name: LMT035KDH03-NJN -Manual-Rev0.3

Page: 5 of 12

4.2 AC Characteristics

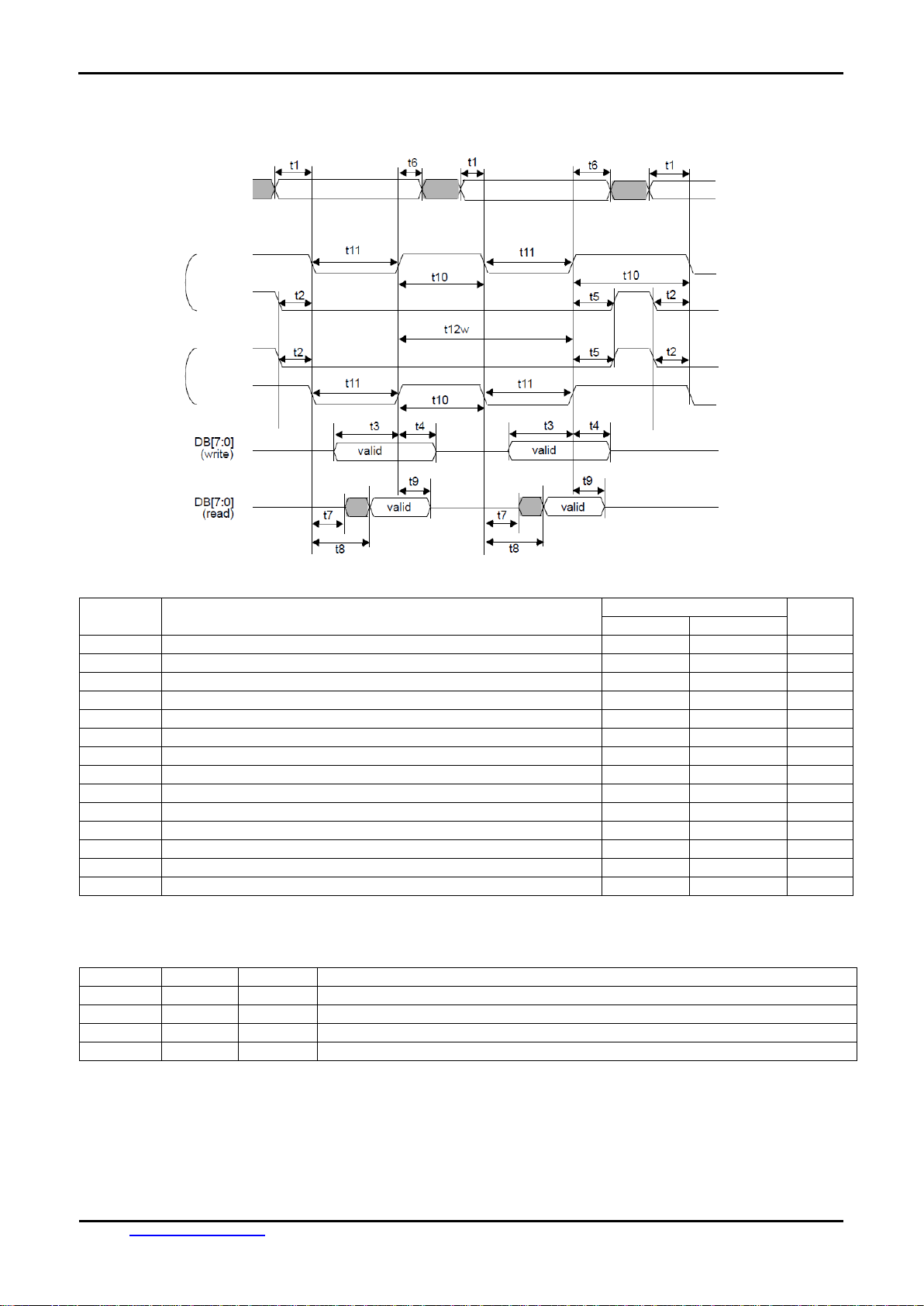

4.2.1 8080 Mode Timing

Figure 2

Symbol

Parameter

3.3 Volt

Units

Min

Max

t1

A0 setup time to /CS (/WR, /RD)

1

-

ns

t2

/WR, /RD (/CS) setup time to /CS (/WR, /RD)

1

-

ns

t3

DB[7:0] setup time to /CS (/WR) rising edge: write cycle

1

-

ns

t4

DB[7:0] hold time from /CS (/WR) rising edge: write cycle

7

-

ns

t5w

/WR (/CS) hold time from /CS (/WR) rising edge: write cycle

3

-

ns

t5r

/RD (/CS) hold time from /CS (/RD) rising edge: read cycle

0

-

ns

t6

A0 hold time from /CS (/WR, /RD) rising edge

4

-

ns

t7

/CS (/RD) falling edge to DB[7:0] driven: read cycle

-

15

ns

t8

/CS (/RD) falling edge to valid Data: read cycle

-

4xTmclk+17

ns

t9

DB[7:0] hold time from /CS (/RD) rising edge: read cycle

2

12

ns

t10w

End of write to next read/write

5

-

ns

t10r

End of read to next read/write

Tmclk+9

-

ns

t11w

/CS (/WR) pulse width for write cycle

3

-

ns

t12w

/CS (/WR) rise to next /CS (/WR) rise: write cycle

3xTmclk+6

-

ns

Note: Tmclk = period of internal MCLK clock signal.

Indirect 8-bit Function Select:

A0

/WR

/RD

Comments

0

0

1

Command Write (register address)

1

0

1

Data (Parameter) Write

0

1

0

inhibit

1

1

1

Data (Parameter) Read

A0

/CS Control

cONTROL

/RD,WR/ Control

cONTROL

/CS

/WR

/RD

/WR

/RD

/CS

TOPWAY

LCD Module User Manual

LMT035KDH03-NJN

URL: www.topwaydisplay.com

Document Name: LMT035KDH03-NJN -Manual-Rev0.3

Page: 6 of 12

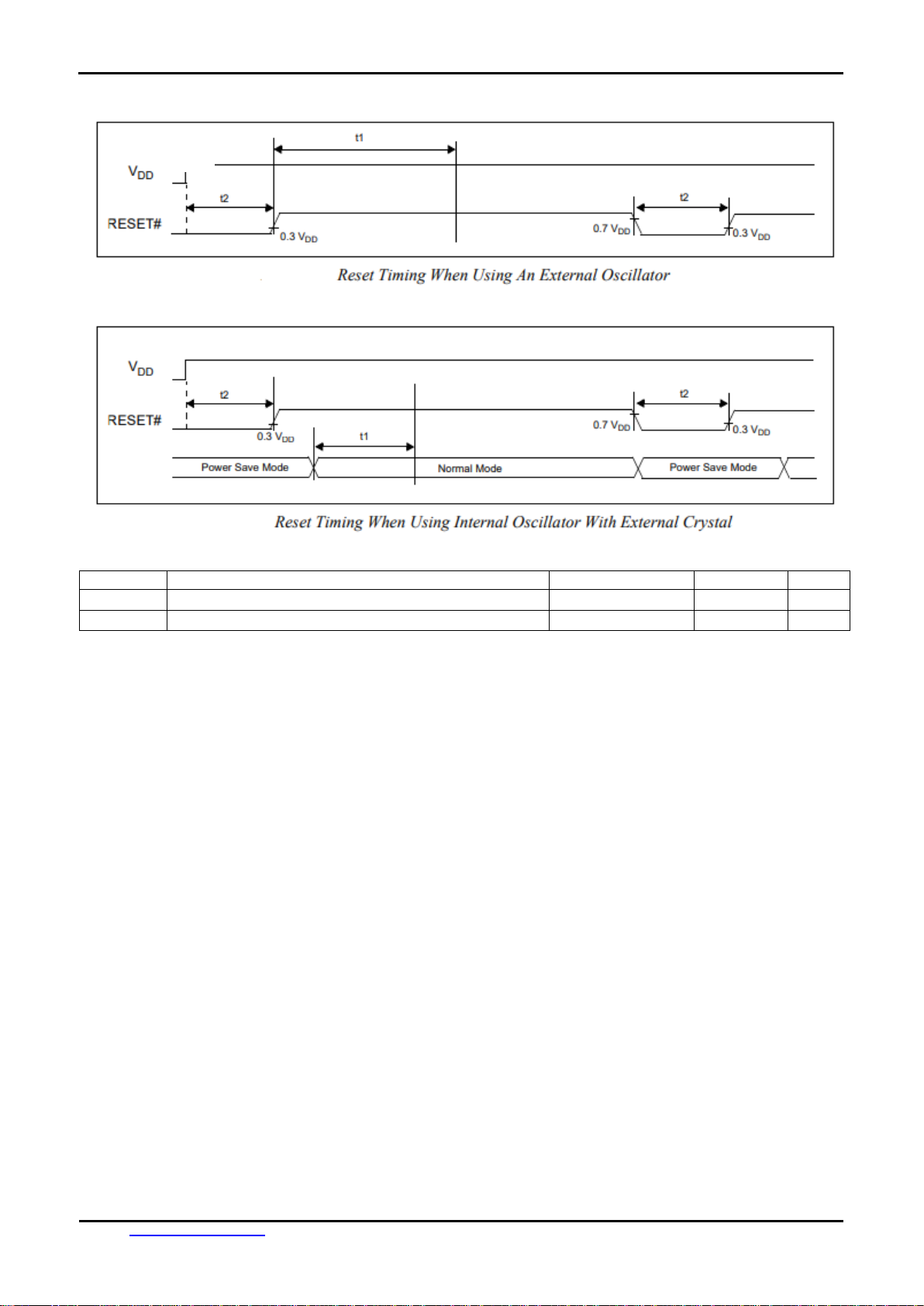

4.2.2 Reset Timing

Figure 3

Symbol

Parameter

Min

Max

Units

t1

Oscillator stable delay

Note 1

-

ms

t2

Reset pulse duration

100(Note 2)

-

ns

Note:

1. When using an external oscillator, a delay is required following the rising edges of both RESET#

and VDD to allow for system stabilization. This delay allows the clock used by the internal

oscillator circuit to become stable before use. The delay time depends on a crystal. The

S1D13709 must not be accessed before the oscillation circuit is stable.

When using the internal oscillator with an external crystal, a delay is required after exiting power

save mode. For direct mode, writing REG[08h] bit 0 will exit power save mode and start the

internal oscillator. For indirect mode, writing the SYSTEM SET command will exit power save

mode and start the internal oscillator.

2. The S1D13709 requires a reset pulse of at least 100 ns after power-on in order to re-initialize its

internal state. For maximum reliability, it is not recommended to apply a DC voltage to the LCD

panel while the S1D13709 is reset. Turn off the LCD power supplies for at least one frame

period after the start of the reset pulse.

Note that during the reset period the S1D13709 cannot receive commands. Commands to

initialize the internal registers should be issued soon after a reset. During reset, the LCD drive

signals FPDAT, LP and FR are halted.

For more information and details please refer to LCD controller (S1D13709) datasheet.

/RES

TOPWAY

LCD Module User Manual

LMT035KDH03-NJN

URL: www.topwaydisplay.com

Document Name: LMT035KDH03-NJN -Manual-Rev0.3

Page: 8 of 12

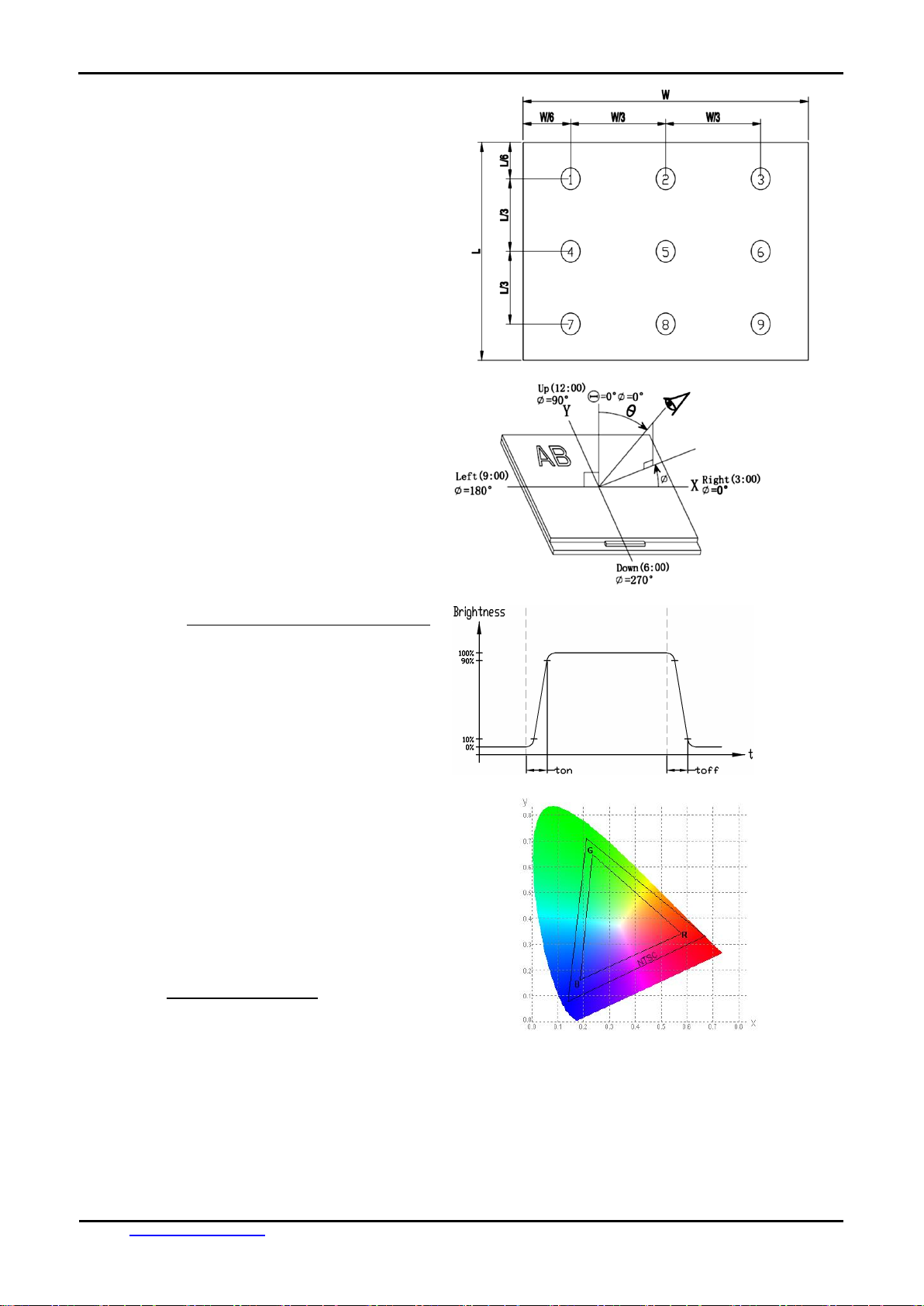

Note 1:

The data are measured after LEDs are turned on for 5

minutes. LCM displays full white. The brightness is the

average value of 9 measured spots. Measurement

equipment PR-705 (Φ8mm)

Measuring condition:

- Measuring surroundings: Dark room

- Measuring temperature: Ta=25℃.

- Adjust operating voltage to get optimum

contrast at the center of the display.

Measured value at the center point of LCD panel after more

than 5 minutes while backlight turning on.

Note 2: reference Figure4

The luminance uniformity is calculated by using following

formula.

△Bp = Bp (Min.) / Bp (Max.)×100 (%)

Bp (Max.) = Maximum brightness in 9 measured

spots Bp (Min.) = Minimum brightness in 9 measured spots.

Note 3: reference Figure5

The definition of viewing angle:

Refer to the graph below marked by

θ

and

Ф

Note 4:

The definition of contrast ratio (Test LCM using PR-705):

Contrast

Ratio(CR)=

Luminance When LCD is at “White” state

Luminance When LCD is at “Black” state

(Contrast Ratio is measured in optimum common electrode

voltage)

Note 5: reference Figure6

Definition of Response time. (Test LCD using DMS501):

The output signals of photo detector are measured

when the input signals are changed from

“black” to “white”(falling time)

and from “white” to “black”(rising time), respectively.

The response time is defined as

the time interval between the 10% and 90% of

amplitudes.Refer to figure as below.

Note 6: reference Figure7

Definition of Color of CIE Coordinate and NTSC Ratio.

Color gamut:

S=

Area of RGB triangle

X100%

Area of NTSC triangle

Figure 4

Figure 5

Figure 6

Figure 7

TOPWAY

LCD Module User Manual

LMT035KDH03-NJN

URL: www.topwaydisplay.com

Document Name: LMT035KDH03-NJN -Manual-Rev0.3

Page: 10 of 12

7. LCD Module Design and Handling

Precautions

7. 液晶显示模块设计和使用须知

-Please ensure V0, VCOM is adjustable, to enable LCD module get

the best contrast ratio under different temperatures, view angles

and positions.

-Normally display quality should be judged under the best contrast

ratio within viewable area. Unexpected display pattern may come

out under abnormal contrast ratio.

-Never operate the LCD module exceed the absolute maximum

ratings.

-Never apply signal to the LCD module without power supply.

-Keep signal line as short as possible to reduce external noise

interference.

-IC chip (e.g. TAB or COG) is sensitive to light. Strong light might

cause malfunction. Light sealing structure casing is recommended.

-Make sure there is enough space (with cushion) between case and

LCD panel, to prevent external force passed on to the panel;

otherwise that may cause damage to the LCD and degrade its

display result.

-Avoid showing a display pattern on screen for a long time

(continuous ON segment).

-LCD module reliability may be reduced by temperature shock.

-When storing and operating LCD module, avoids exposure to direct

sunlight, high humidity, high or low temperature. They may damage

or degrade the LCD module.

-Never leave LCD module in extreme condition (max./min

storage/operate temperature) for more than 48hr.

-Recommend LCD module storage conditions is 0 C~40 C

<80%RH.

-LCD module should be stored in the room without acid, alkali and

harmful gas.

-Avoid dropping & violent shocking during transportation, and no

excessive pressure press, moisture and sunlight.

-LCD module can be easily damaged by static electricity. Please

maintain an optimum anti-static working environment to protect the

LCD module. (eg. ground the soldering irons properly)

-Be sure to ground the body when handling LCD module.

-Only hold LCD module by its sides. Never hold LCD module by

applying force on the heat seal or TAB.

-When soldering, control the temperature and duration avoid

damaging the backlight guide or diffuser which might degrade the

display result such as uneven display.

-Never let LCD module contact with corrosive liquids, which might

cause damage to the backlight guide or the electric circuit of LCD

module.

-Only clean LCD with a soft dry cloth, Isopropyl Alcohol or Ethyl

Alcohol. Other solvents (e.g. water) may damage the LCD.

-Never add force to components of LCD module. It may cause

invisible damage or degrade the module's reliability.

-When mounting LCD module, please make sure it is free from

twisting, warping and bending.

-Do not add excessive force on surface of LCD, which may cause

the display color change abnormally.

-LCD panel is made with glass. Any mechanical shock (e.g.

dropping from high place) will damage the LCD module.

-请注意 V0, VCOM 的设定, 以确保液晶显示模块在不同

的使用温度下以及在不同的视角和位置观察模块显

示,均能达到最佳对比度,请务必将应用电路上设置

为对比度可调。

-请注意液晶显示模块的显示品质判定是指在正常对比

度下以及视窗(V.A)范围内进行的,非正常对比度下液

晶可能会出现非预期的显示不良,应注意区分。

-请勿在最大额定值以外使用液晶显示模块。

-请勿在没有接通电源的条件下,给液晶显示模块输送

信号。

-请尽可能缩短信号线的连接,以避免对液晶显示模块

的信号干扰。

-集成电路因 IC 芯片(如TAB 或COG)对紫外线极为敏

感,强光环境下可能会引起液晶显示模块功能失效,

故应采用不透光的外壳。

-请在液晶显示模块与外壳之间保留足够的空间(可使用

衬垫),以缓冲外力对液晶显示模块的损坏或因受力不

均而产生的显示不匀等异常现象。

-避免液晶显示屏在某一画面下长时间点亮,否则有出

现残影的风险;请通过软件每隔一段时间改变一次画

面。

-液晶显示模块的可靠性可能因温度冲击而降低。

-请勿在阳光直射、高湿、高温或低温下储存和使用液

晶显示模块,这将造成液晶显示模块的损坏或失效。

-请勿在极限环境(最大/最小存储/工作温度)下使用或

放置液晶显示模块超过 48 小时以上。

-液晶显示模块建议存储条件为: 0 C~40 C <80%RH。

-请勿让液晶显示模块存储于带有 酸性, 碱性, 有害气

体环境之中。

-在运输过程中, 请勿让液晶显示模块跌落与猛烈震动,

同时避免 异常挤压, 高湿度, 与阳光照射.

-液晶显示模块极易受静电损坏,请务必保证液晶显示

模块在防静电的工作环境中使用或保存。(如: 烙铁正

确接地,等)

-拿取液晶显示模块时需注意操作人员的接地情况。

-请手持液晶显示模块的边沿取放模块,防止热压纸或

TAB 部位受力。

-焊接液晶模块时,请注意控制烙铁的温度、焊接时

间,以免烫坏导光板或偏光片,导致显示不匀等不良

现象发生。

-请勿使用洗板水等腐蚀性液体接触液晶模块,以免腐

蚀导光板或模块电路。

-仅可使用柔软的干布, 异丙醇或乙醇清洁液晶屏表

面,其他任何溶剂(如:水)都有可能损坏液晶模块。

-请勿挤压液晶显示模块上的元器件,以避免产生潜在

的损坏或失效而影响产品可靠性。

-装配液晶显示模块时,请务必注意避免液晶显示模块

的扭曲或变形。

-请勿挤压液晶显示屏表面,这将导致显示颜色的异

常。

-液晶屏由玻璃制作而成,任何机械碰撞(如从高处跌

落)均有可能损坏液晶显示模块。

TOPWAY

LCD Module User Manual

LMT035KDH03-NJN

URL: www.topwaydisplay.com

Document Name: LMT035KDH03-NJN -Manual-Rev0.3

Page: 11 of 12

-Protective film is attached on LCD screen. Be careful when peeling

off this protective film, since static electricity may be generated.

-Polarizer on LCD gets scratched easily. If possible, do not remove

LCD protective film until the last step of installation.

-When peeling off protective film from LCD, static charge may cause

abnormal display pattern. The symptom is normal, and it will turn

back to normal in a short while.

-LCD panel has sharp edges, please handle with care.

-Never attempt to disassemble or rework LCD module.

-If display panel is damaged and liquid crystal substance leaks out,

be sure not to get any in your mouth, if the substance comes into

contact with your skin or clothes promptly wash it off using soap

and water.

-液晶屏表面带有保护膜, 揭除保护膜时需要注意可能

产生的静电。

-因液晶显示屏表面的偏光片极易划伤,安装完成之前

请尽量不要揭下保护膜。

-请缓慢揭除保护膜,在此过程中液晶显示屏上可能会

产生静电线,此为正常情况,可在短时间内消失。

-请注意避免被液晶显示屏的边缘割伤。

-请不要试图拆卸或改造液晶显示模块。

-当液晶显示屏出现破裂, 内部液晶液体可能流出; 相

关液体不可吞吃, 绝对不可接触嘴巴, 如接触到皮肤

或衣服, 请使用肥皂与清水彻底清洗.

Warranty

This product has been manufactured to our company’s specifications as a part for use in your company’s general

electronic products. It is guaranteed to perform according to delivery specifications. For any other use apart from general

electronic equipment, we cannot take responsibility if the product is used in medical devices, nuclear power control

equipment, aerospace equipment, fire and security systems, or any other applications in which there is a direct risk to

human life and where extremely high levels of reliability are required. If the product is to be used in any of the above

applications, we will need to enter into a separate product liability agreement.

-We cannot accept responsibility for any defect, which may arise form additional manufacturing of the product

(including disassembly and reassembly), after product delivery.

-We cannot accept responsibility for any defect, which may arise after the application of strong external force to the

product.

-We cannot accept responsibility for any defect, which may arise due to the application of static electricity after the

product has passed our company’s acceptance inspection procedures.

-When the product is in CCFL models, CCFL service life and brightness will vary according to the performance of the

inverter used, leaks, etc. We cannot accept responsibility for product performance, reliability, or defect, which may

arise.

-We cannot accept responsibility for intellectual property of a third part, which may arise through the application of our

product to our assembly with exception to those issues relating directly to the structure or method of manufacturing of

our product.

Table of contents

Other Topway Control Unit manuals

Topway

Topway LMT050DNCFWU-NWN User manual

Topway

Topway LMT035KDH03-NHN User manual

Topway

Topway LMT070DICFWD-NJN User manual

Topway

Topway HMT028ATB-C User manual

Topway

Topway LM8053-1 User manual

Topway

Topway LMT080TDGP01 User manual

Topway

Topway LM6093ACW User manual

Topway

Topway LM2088RCW User manual

Topway

Topway LM6020FCW-2 User manual

Topway

Topway LM12864LFC User manual

Popular Control Unit manuals by other brands

SKF

SKF MAXILUBE MAX 230-IF105 Series Assembly instructions

Quectel

Quectel SG560D Series Hardware design

McIntosh

McIntosh MX135 owner's manual

CALEFFI

CALEFFI 523160A Installation, commissioning and service instructions

SKF

SKF Lincoln 85307 installation instructions

Armstrong

Armstrong GP-2000 Installation, operation and maintenance