EnerSys Wi-iQ 4 User manual

Wi-iQ®

BATTERY MONITORING DEVICE

www.enersys.com

4

Owner’s Manual

WI-IQ®4 BATTERY MONITORING DEVICE

OWNER’S MANUAL

3

TABLE OF CONTENTS

1. Features................................................................................3

2. Technical Specifications......................................................3

3. Dimensions ..........................................................................5

4. Installation............................................................................5

5. Communication ...................................................................6

6. Service and Troubleshooting..............................................9

1. FEATURES

The Wi-iQ®4 battery monitoring device is the fourth generation of battery sensor

technology, providing incremental features such as Bluetooth and CAN-Bus connectivity

to improve communication and integration with other devices and external equipment.

Features added to the new compact design include three LEDs to communicate status,

a new LCD display to show important battery information and an audible alarm.

• Programmable

• Wi-iQ4 device can be assembled on batteries from 24V to 80V

• Small and slim fit

• IP65 enclosure

• Available for flooded lead acid and NexSys®TPPL battery chemistries

• Single or dual cable current sensors

• LCD display and low voltage alarm buzzer

• Memory capable of more than 8,000 events

• Multiple communication channels

• Zigbee®wireless to Wi-iQ Report PC software and charger

• Bluetooth to E Connect™ mobile app and Truck IQ™ smart battery dashboard

• Newly designed E Connect mobile app enables fast and easy check-up of battery

fleet and data sharing

• Connection with our external Truck iQ device that shows real time data to operator

about battery status, alarms and remaining working time

• Optional CAN-Bus module provides State of Charge (SOC) and other data to any

CAN network (e.g. lift trucks, AGVs)

• Compatible with Xinx™ warehouse management efficiency system to simplify both

data collection and reporting

• Wireless communication with EneSys®modular charger allows for better asset

control

• Adjustable SOC Warning and provides an audible alarm

• Eliminates need for separate Low Voltage Alarm (LVA) device

NOTE: The Wi-iQ4 device is designed to install only on a battery and will not

function properly if mounted on the truck side of battery connector for a power

study.

2. TECHNICAL SPECIFICATIONS

Item Description

Nominal Battery Voltage 24VDC to 80VDC

Operating Voltage 15V-120V

Operating Temperature 4ºF (-20ºC) – 140ºF (60ºC)

Bi-directional Current

Measurement

Allows for throughput data collection using a

Hall effect sensor which can measure up to +/-

1000A.

1A resolution

Voltage Measurement Continuous monitoring of overall battery voltage

and half battery voltage

Voltage Accuracy 0.1V

Temperature External thermistor

Altitude <2,000m (<6,561ft)

Electrolyte Level Detection With electrolyte sensor

Wireless Interface Zigbee (SMAC -2.4Ghz), Bluetooth BLE

Real Time Clock Time keeping and stamping of data

Data Storage Upload data to PC via Dongle, to Cloud server via

E Connect mobile app

Data Collection Up to 8,000 event log records

Wireless Range Up to 10m (32ft) (Zigbee); up to 5m (16ft) (BLE)

CAN Communication 2 different CAN protocols: CANOpen or J1939

Power Consumption 1 Watt

Protection Over voltage

Reverse Polarity Protection

Packaging

Water and acid resistant

UL 94V-0

Pollution level 3 protection (dusty environment)

IP65 enclosure

Physical Dimensions 40,07mm L x 19,5 mm W x 107,97mm H

Compliance

Electrical Equipment (Safety) Regulations

2016 (S.I. 2016/1101)

Directive 2014/35/EU :

Safety

BS EN 61010-1 : 2010 / A1 : 2019

EMC Regulations 2016 (S.I.2016/1091)

Directive 2014/30/EU :

Electromagnetic compatibility

BS EN 12895 : 2015 / A1 : 2019

Directive 2011/65/EU

RoHS

Radio Equipment Regulations 2017

(S.I.2017/1206)

Directive 2014/53/EU

ETSI EN 301 489-1 V2.2.3 (2019)

ETSI EN 301 489-17 V3.2.2 (2019)

ETSI EN 300 328 V2.2.2 (2019)

THIS DEVICE COMPLIES WITH PART 15 OF THE FCC RULES. OPERATION IS

SUBJECT TO THE FOLLOWING TWO CONDITIONS:

(1) THIS DEVICE MAY NOT CAUSE HARMFUL INTERFERENCE

(2) THIS DEVICE MUST ACCEPT ANY INTERFERENCE RECEIVED, INCLUDING

INTERFERENCE THAT MAY CAUSE UNDESIRED OPERATION.

IN ACCORDANCE WITH FCC REQUIREMENTS, CHANGES OR MODIFICATIONS NOT

EXPRESSLY APPROVED BY ENERSYS COULD VOID THE USER’S AUTHORITY TO

OPERATE THIS PRODUCT.

Technical support: Reference www.enersys.com to find your local contact.

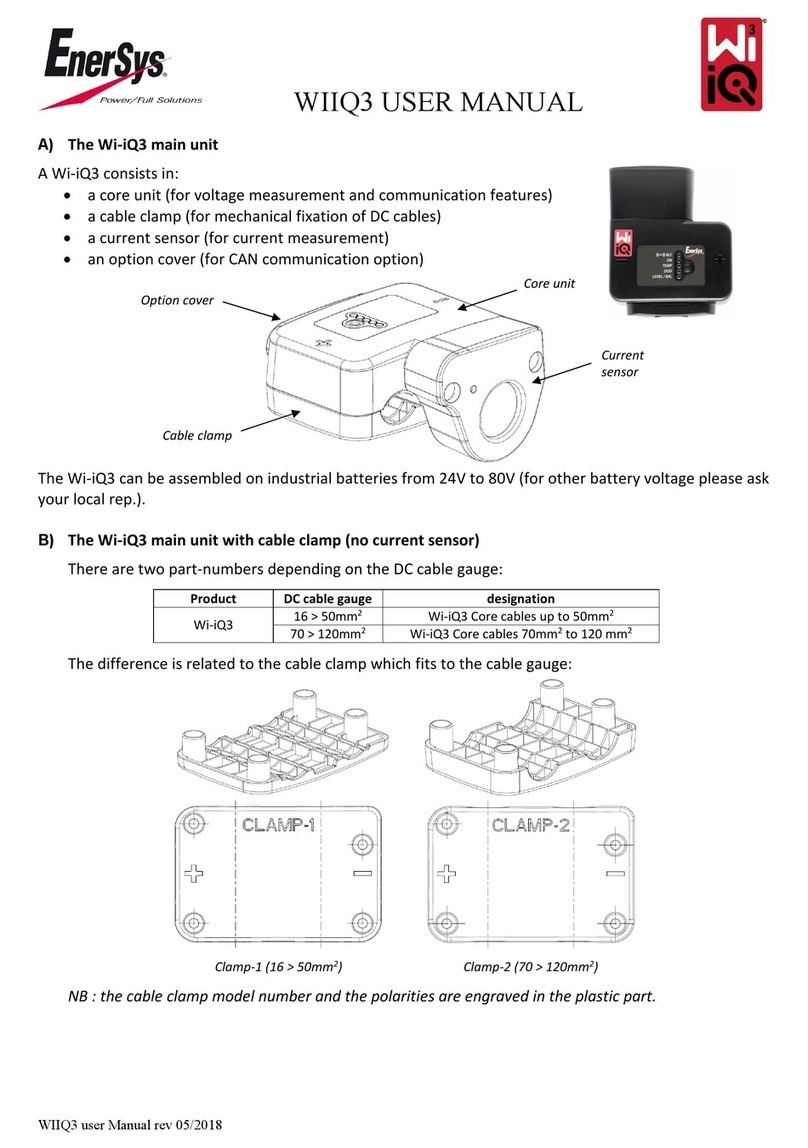

2.1 Components

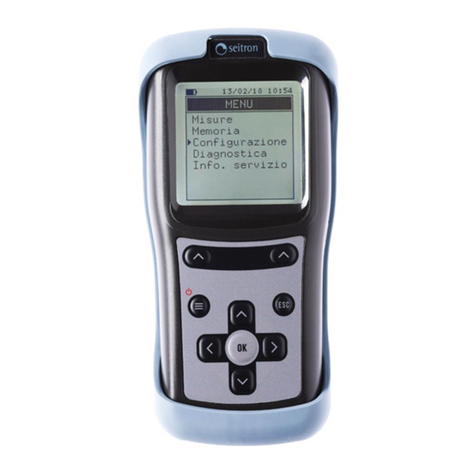

Figure 1: Wi-iQ4 Device for Flooded Batteries with Electrolyte Probe

4

4

2. TECHNICAL SPECIFICATIONS (CONTINUED)

2.2 The Wi-iQ®4 Battery Monitoring Device

2.2.1 The Wi-iQ®4 battery monitoring device consists of:

• A main unit (for voltage measurement, display, LEDs, buzzer and

communication features)

• 1 or 2 current sensors

• A CAN connection (Use is optional)

• Red/Black cables to power the Wi-iQ4 device

• Balance/Gray wire for mid battery voltage

• Temperature probe

• Electrolyte level probe for flooded battery version

• 3 crimping splices + 3 cable ties

• Installation hardware

Figure 2: Wi-iQ4 Device for Thin Plate Pure Lead (TPPL) or Valve Regulated Lead

Acid (VRLA) with CAN Connector; without Electrolyte Probe

2.3 The Wi-iQ4 Device Part Numbers

2.3.1 There are four part numbers available.

Table 1: Part Numbers

Part Number Reference P/N Description Battery Type

WIIQ4 6LA20743-E0E Wi-iQ4 monitor Basic flooded

single sensor Flooded

WIIQ4DUAL 6LA20743-E3E Wi-iQ4 monitor Basic

VRLA single sensor Gel, TPPL

WIIQ4F 6LA20743-E1E Wi-iQ4 monitor Premium

CAN single sensor All with CAN

WIIQ4DUALF 6LA20743-E2E Wi-iQ4 monitor Premium

CAN dual sensor All with CAN

6LA20761 6LA20761

Electrolyte sensor (replacement

part only) do not use this

number when ordering

part number WIIQ4 and

WIIQ4DUAL

Flooded

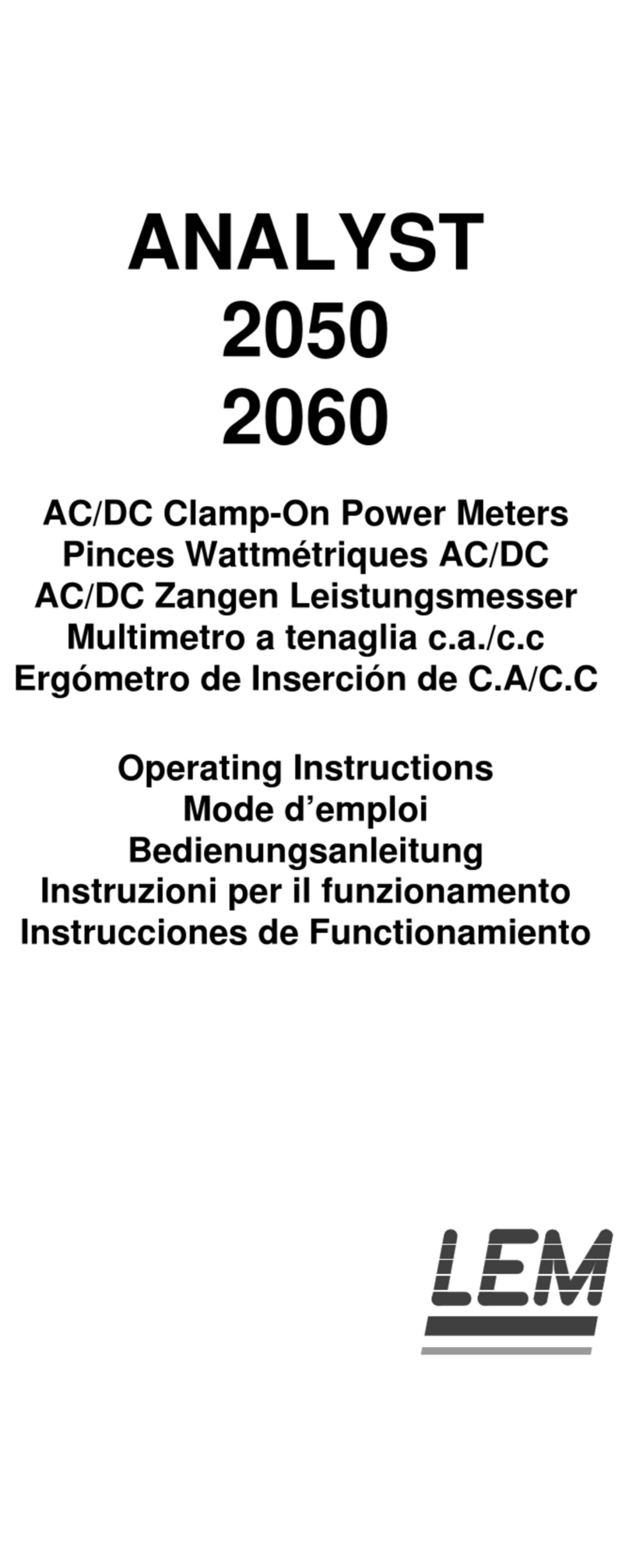

2.4 The Wi-iQ4 Device Display and LEDs

2.4.1 An LCD display and three LEDs on the Wi-iQ4 device provides status

indication. The display is turned OFF after 15 minutes of no activity

(sleep mode). A small touch to the Wi-iQ4 display will turn the display

back ON.

Figure 3: Display and LEDs

2.4.2 Parameters displayed.

Table 2: Parameters

Description Value Comment

SOC 0-100% State of Charge of the battery

Battery Voltage Ex: 27.2V Overall battery voltage (V)

Temperature Ex: 64°F (18°C) Battery Temperature

Current Ex: 10.4A Current value in A (+ charge, - discharge)

Bluetooth

Connected

When the smartphone is connected

to the Wi-iQ4 device

Warning

Level Blue LED ON

Temperature Red LED Flashing or ON

Low SOC Warning Buzzer ON

Low SOC Alert

Unbalance Blue LED flashing

No Current Sensor CURRENT/SENSOR

NO/SIGNAL

No Temperature

Sensor

TEMP/SENSOR

NO/SIGNAL

2.4.3 LED Colors and Functions

Table 3: Colors and Functions

LED Color Lit Fast blinking

(0.5s ON / 0.5s OFF)

Left Red High Temperature Warning Temperature

Center Orange Alert DOD Warning DOD

Right Blue Low level Unbalance

All Fast blink every 5 seconds

(for normal operation)

NOTE: When the Wi-iQ4 device is first connected to the battery voltage, all

LEDs are flashing and Firmware revision is shown on the display (initialization

sequence). The SOC shown will be a reloaded value from the manufacturer. To

start, please set the device and reset the value (refer to the configuration section

of the manual).

2.5 Buzzer

2.5.1 There is a buzzer located inside the main unit. The buzzer is activated

when the SOC of the battery is low and the battery needs to be

charged. Reference Table 5.

Table 4: Warning and Alert Time Frequency

Normal SOC Warning SOC Alert SOC

Buzzer OFF 2 chirps every 20 seconds 1 chirp every 5 seconds

Table 5: Default value of the buzzer vs. battery type

Battery Type* Warning SOC Alert SOC

NexSys TPPL NXS models 30% 20%

NexSys TPPL NXP models 50% 40%

Others 30% 20%

*Adjustable

2.6 The Wi-iQ4 Device Current Sensor(s)

2.6.1 The current sensor is a solid core hall effect device.

Table 6: Current Sensor Technical Specification

DC Cable Gauge* AWG Internal

Diameter

Truck Class

Recommendation Max DC Current

Up to 120mm2Up to 4/0 20.1 mm Class 1, 2 & 3 1000A

NOTE: The DC cable gauge does not consider the terminal lug or contact

dimensions. Terminal lugs or contacts may need to be assembled after inserting

the cable in the current sensor. Mostly for the 4/0 cables.

5

2. TECHNICAL SPECIFICATIONS (CONTINUED)

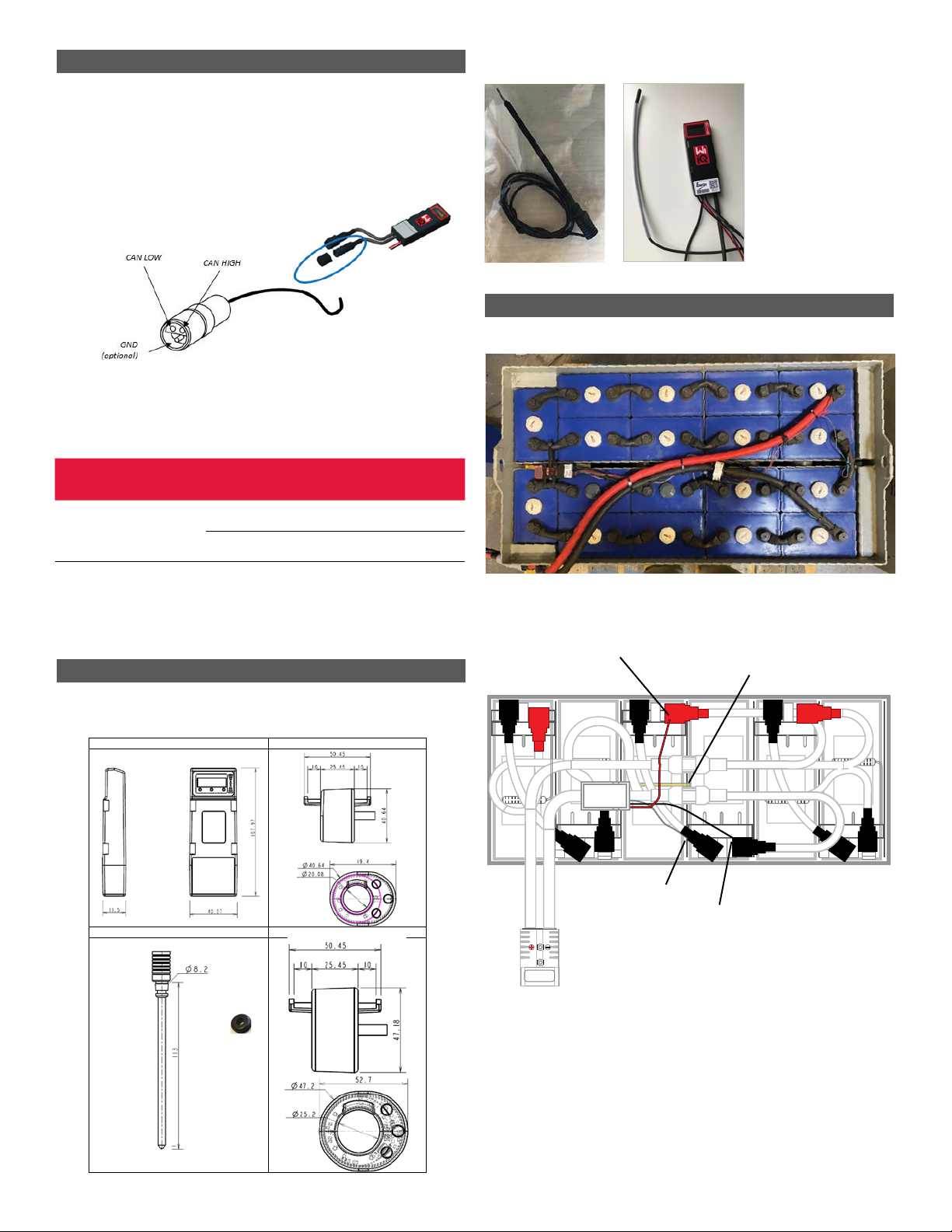

2.7 Wi-iQ®4 Device CAN option

2.7.1 If equipped, the Wi-iQ®4 device communicates via CAN protocol.

2.7.2 The Wi-iQ4 device main unit is delivered with a protective plastic cap

that needs to be removed to use the CAN option.

2.7.2.1 The female connector pinout is described below.

Figure 4: Female Connector

2.7.2.2 Male connector is NOT included (ITT-CANON SURE-SEAL IP68

3-contact receptacle with two pins and one socket adapted for

0.75-1.5mm2wires).

Table 7: CAN Connector Specification

Product Receptacle

Part Number

Contact Part Number

Wire Gauge Pin (qty 2) Socket (qty 1)

ITT-CANON

SURE-SEAL

120-8551-001

(SS3R)

0.5–1.0mm2330-8672-001

(SS20)

031-8703-001

(SS20)

0.75–1.5mm2330-8672-000

(SS10)

031-8703-000

(SS10)

2.7.3 The Wi-iQ4 device CAN communication adopts two different CAN

protocols:

2.7.3.1 CANOpen

2.7.3.2 J1939

2.7.4 Refer to section 5.7 for proper documentation.

3. DIMENSIONS

3.1 Wi-iQ4 Device and Hall effects overall dimensions (mm)

Figure 5: Dimensions

Figure 6: Probes and Sensors

4. INSTALLATION

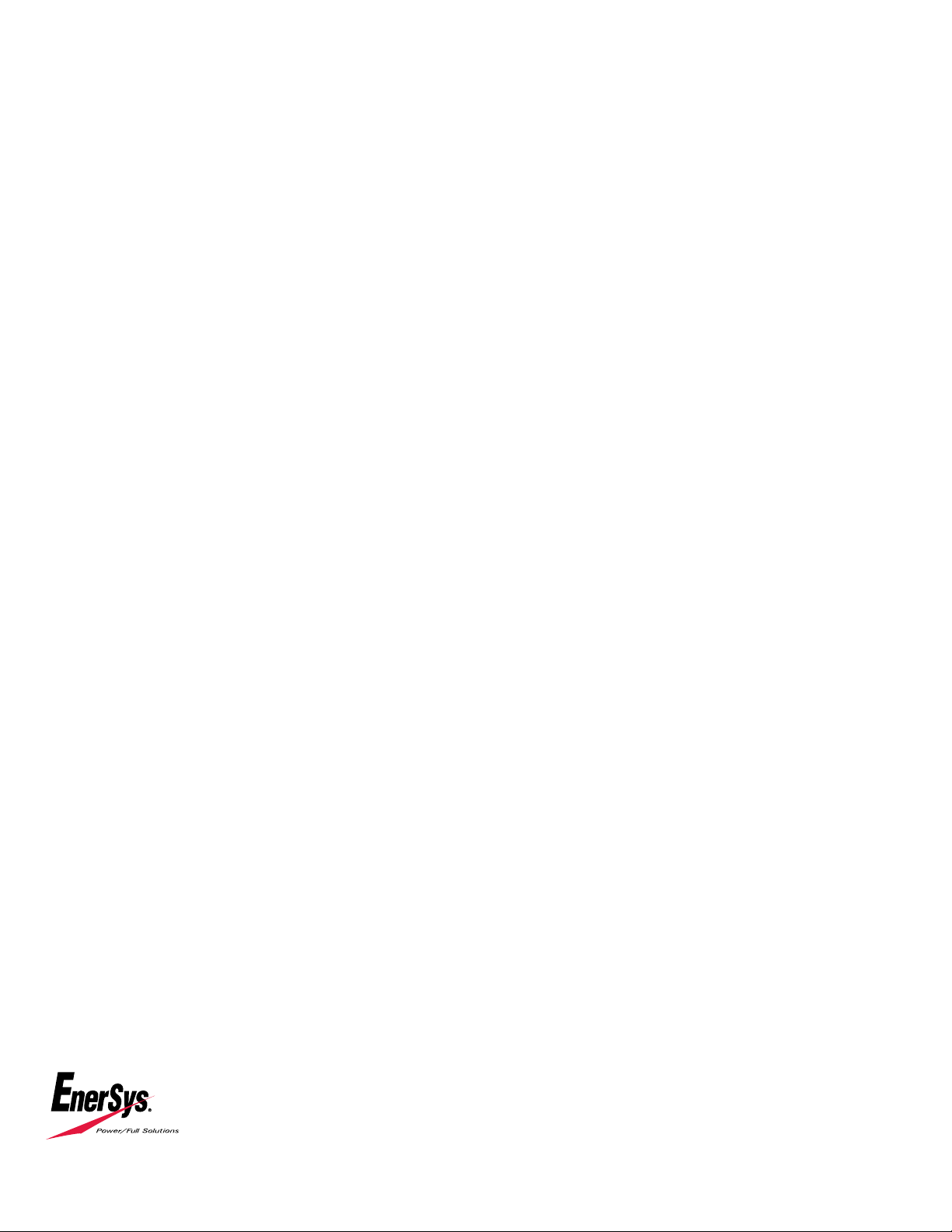

Figure 7: Wi-iQ4 Device Final Assembly on 2V Cell Tray

Figure 8: Wi-iQ4 Device Final Assembly on 12V Block Tray4.

(CONTINUED4. IN

NOTE: The stack order on the stud is: Battery Cable, Wi-iQ4 Device Ring Terminal,

Flat Washer, Lock Washer and Nut.

4.1.1.1 Ensure the threads on the nut and stud are clean,

place a drop of blue Loctite™ on the stud and

tighten the nut in place.

4.1.1.2 Torque the nut to the proper specification (above).

Ensure the battery cable lug is flat against the

plate.

Red wire

Temperature sensor

Gray wire

Black wire

Wi-iQ4

Temperature SensorElectrolyte Probe

1. Dimensions

Wi-iQ4

Current sensor USA

Level sensor 6LA20761

Current sensor EMEA/APAC

NB: All dimensions are given in mm.

6

5. COMMUNICATION

There are two modes of communication (Wireless and CAN) available on the Wi-iQ®4

device:

5.1 Wireless

5.1.1 BLE

5.1.1.1 Connect to a smartphone via E Connect mobile app

5.1.1.2 Connect to Truck iQ™ smart battery dashboard

5.1.2 Zigbee®(legacy protocol in use with previous generations of Wi-iQ

device)

5.1.2.1 Connect to chargers (NexSys®+ battery charger)

5.1.2.2 Connect to Wi-iQ Report software

5.1.2.3 Connect to Xinx™ software

5.2 The Wi-iQ4 device can be configured and provide data via Zigbee®(Wi-iQ

Report – v5.4.5 minimum) or BLE (E Connect app – v2.16 minimum).

5.3 CAN (Controller Area Network)

5.3.1 CANOpen Cia 418 or J1939

5.3.1.1 Interface with truck using an Original Equipment

Manufacturer (OEM) proprietary CAN protocol implemented.

5.3.1.2 Interface with AGV using EnerSys proprietary CAN protocol.

5.4 Configuring Wi-iQ4 Device within Wi-iQ Reporting Suite

5.4.1 Once the device is installed, it must be set-up in the software. Plug

a dongle (Wi-iQ antenna) into the USB port of a PC with the Wi-iQ

Reporting Suite installed. Start Wi-iQ Report software.

5.4.2 Click on the Software menu item in the upper left corner; click

“Language” and select “US” (not English). This is necessary to ensure

all the battery technologies (Bat. Techno) are available later in the

software setup.

5.4.3 Create a new site if one does not already exist. The naming of the site

is not important for installation purposes.

Figure 9: Wi-iQ Report Website Configuration Page

5.4.4 Double-click on the Site Name to open it. Previously added devices may

be shown. To add a new device, click on the scan button at the top left.

The software will scan for all available devices. Check the “Add” box

for all devices you wish to configure and hit the “+ Add” button on the

right. The devices can be identified by matching the Address (HEX) field

to the S/N on the device.

Figure 10: HEX Address Match5. COMMUNICATION (CONTINUED)

5.4.5 The devices you have added should now be added to the site view.

If you have added multiple devices at once and you are unsure which

device is on each battery, click on the eye icon in the left column. This

will make all the LEDs on that device blink for 15 seconds. The device

will also beep during the same period. Double click anywhere along

the line of the device the device you wish to configure to open the

configuration window.

5.4.6 **If at any time the Laptop version will not pick up the Wi-iQ®4

device or find correct serial number of device, configure correctly

through Econnect app on appropriate serial number, scan again

and it will now show up in your Wi-iQ Suite on your laptop.

Figure 11: Wi-iQ4 Report Website Homepage

7

Figure 12: Wi-iQ®4 Report Website Device Configuration Page

5.4.8 Battery SN# – Enter the battery serial number (9 digits).

5.4.9 Fleet number – As required

5.4.10 Model – Enter the battery type, ex: 18-E100-21

5.4.11 Cells – Enter the number of cells on the battery

5.4.11.1 For NexSys®TPPL 2V batteries, use total voltage divided by

2 to determine number of cells. Example – The battery type is

36NXS700. 36 describes the total voltage of the battery. Take

this number and divide by 2 to get “Cells”; in this example,

36 / 2 = 18 cells.

5.4.12 Cells Bal. – Enter the cell number where the gray wire was installed,

counting from the positive post.

5.4.12.1 For NexSys TPPL Bloc Battery: The black Wi-iQ4 device

wire and the gray Wi-iQ4 device wire should be attached to

the negative and positive posts of the same bloc as described

in section 4.1.13. In this configuration “Cells Bal.” will always

be 6.

5.4.13 Battery Technology – Select the appropriate type of battery.

Refer to line-item notes on BaaN order requesting any

specific Battery Technology setting by customer or sales

representative. If nothing is requested in the line item notes,

refer to Table 8.

Table 8: Charge Profiles

Battery Technology Battery Types

COLD STORAGE All Flooded with average battery temperature below

59°F (15°C)

FAST US 85P(FC), 125P(FC), E100X, E140X

HG FLOODED* E55L, E75L, E110, E155

LOW MAIN* Deserthog (E90D, E100D, E125D)

NexSys 2V NexSys TPPL 2V (NXS)

NexSys BLOC NexSys TPPL Bloc (NXS)

NexSys TPPL 2V Not used in North America

NexSys TPPL Bloc NexSys TPPL Bloc (NXP)

OP CHARGE All Flooded

STD FLOODED All Flooded

*NOTE: The charge profile will be STD FLOODED when HG FLOODED, or LOW

MAIN are selected. The purpose of selecting HG FLOODED, or LOW MAIN is to

inform the Data Analyst of the specific type of battery being reviewed.

5.4.14 Capacity (Ah) – Enter the nominal Ah of the battery.

5.4.14.1 NexSys TPPL Bloc Battery: Determine total battery Ah.

Example: 24-12NXS186-3. 186 describes the amp hour rating

of each block and 3 describes the number of parallel strings.

Multiply these two numbers to get “Capacity (Ah)”; in this

example 186 X 3 = 558 Ahrs.

5.4.14.2 NexSys TPPL 2V Battery: Determine total battery Ah.

Example: 18-NXS770. The 770 describes amp hour rating.

5.4.15 (+) cable/(-) cable – Select the cable the Wi-iQ4 device has been

installed on. In most cases, (-) cable should be selected.

5.4.16 Equal. Period (hours) – Enter 186. This is the time in hours to request

equalization charge (only available with Wi-iQ4 device firmware v4.0

and higher). If equal time is set to 0 hours, this disables the feature

and critical faults are not recorded on reports. This feature is not

programmable for NexSys battery profiles.

5.4.17 Balance – Check this box for all batteries.

5.4.18 Water Level Probe – Check this box for all batteries with an electrolyte

probe installed.

5.4.19 Mode – Leave as default – CYCLES, unless line-item notes on Order

Acknowledgement requires an alternative mode setting by customer

or sales representative. Note: Click on the “WRITE IDCARD” button

prior to changing the mode. If mode is changed first, then restart

configuration from step 5.6.1.

5.4.19.1 Xinx™ Systems require the Mode to be EVENT.

5.4.20 Dates – Enter the date from the battery date code for the “Date

Manufac. Bat.” Field. Enter the date the battery is placed in service for

the “Date Inst. serv.” field. Leave all other date fields blank.

5.4.21 Owner – Leave as default – ENERSYS.

5.4.22 Battery Group – Enter truck type – Sit Down, Reach, etc., or as

designated by customer.

5.4.22.1 For Xinx, refer to the Xinx set-up worksheet.

5.4.23 Charger Group – Charger Model or Charger Max Output

5.4.24 Summertime Setting: OFF/Europe/Australia.

5.4.25 Once you have entered all of the required information, click on the

“WRITE IDCARD” button. Select the “Write” button and confirm

settings are written.

5.4.26 Click on the “CYCLES” tab. Find the button called “Reset Cycles” and

click on it, select “Continue” when the warning message appears. This

will erase any memory in the device. Installation is now complete. It is

important to reset the data on a new installation for proper averaging

calculations.

5.4.26.1 “Reset Events” for Xinx or any setup requiring EVENT Mode.5.

COMMUNICATION (CONTINUED)

Figure 13: Reset Cycle Button

5.4.27 Xinx™ System Setup

5.4.27.1 Change mode to EVENT

5.4.27.2 The Battery Group must be set for the correct Pool Name in

accordance with the note on the order and/or the Xinx BOM

profile; e.g. Dock Stockers, Pallet Jack, etc. If you use all

capital letters for one pool, make sure all the pools are named

using all caps. This will be provided via a custom note on the

order and/or the Xinx BOM profile. Any typo may result in the

Xinx system failing to recognize the battery.

5.4.28 Use the “MEASURES” tab to verify setup

5.4.28.1 Select the “MEASURES” button to read Wi-iQ®4 device

real-time data

5.4.28.1.1 Measure voltage from the positive terminal of the

battery to the VBAL/CEL gray wire with a calibrated

voltmeter. Divide the reading by the number of

cells between the positive terminal and the balance

wire. Compare this value to the “VBAL/CEL”

reading and confirm is within a tolerance of (+/- .02

VDC). Deviation from this value indicates the wrong

number of cells was input into the “Cells Bal” field,

or the Balance Wire is in the wrong location.

5. COMMUNICATION (CONTINUED)

5.4.38.1.2 Measure the voltage between the positive and

negative battery post with a calibrated voltmeter.

Divide the number of cells in the battery and

confirm this value is within a tolerance of (+/- .03

VDC) of the value in “VBAT/CEL”. Deviation from

this value may indicate a bad electrical connection.

Clean and grease the battery post and terminal lug.

5.4.28.1.3 Measure the temperature near the Temperature

Probe on the battery. Verify the value in the

“Temp” field is near the as read value. Large

deviations indicate a bad thermal sensor.

5.4.28.1.4 If possible, operate the equipment or charge the

battery. Measure the current with a calibrated

clamp-on ammeter and confirm the value is within

(+/- 2%) tolerance of the value in “CURRENT”.

Deviation from this value indicates a bad Hall Effect

Sensor.

5.4.28.1.4.1 Also verify the current is in the proper

direction, (-) for discharger and (+) for

charge. Deviation from this indicates

the Hall Effect Sensor was installed

backwards.

5.4.28.1.5 Verify the electrolyte indicates properly. If the

probe is covered and the indication in “Measures”

is not green, verify the balance wire is on the

negative post of the same cell the electrolyte probe

is installed.

Figure 14: Live Readings on Wi-iQ4 Report

5.5 Configuring Wi-iQ®4 device within the E Connect™ mobile app

5.5.1 A mobile app called “E Connect” is developed for iOS®and Android®

operating systems (will not work on Windows platforms), available for

download for free from App Store and Play Store. Access is protected

by login/password. Different access levels will be granted through

different access codes.

5.5.2 The E Connect mobile app allows mainly:

5.5.2.1 Scanning and then associate the Wi-iQ4 device to a customer

site (list of devices will be automatically recorded on a remote

server).

5.5.2.2 Setting the Wi-iQ4 device battery parameters (such as

technology, capacity…).

5.5.2.3 Quick review of historical parameters such as SOC, voltage

and temperature.

5.5.2.4 Downloading the Wi-iQ4 device history data (data downloaded

are automatically transferred to a remote server* - there is no

data stored on the Smartphone).

Notes:

(1) When launching the mobile app, Bluetooth is automatically activated.

(2) If the Smartphone is not connected to Internet during scan and data download,

the transfer to the remote server will be done as soon as the Internet connection

is restored.

5.5.3 The main screens of the E Connect mobile app with the main

parameters are shown below.

Figure 15: E Connect Mobile App Screens

5.5.4 Refer to 5.4 “Configuring Wi-iQ®4 Device within Wi-iQ Reporting Suite”

to configure the battery parameters in the Wi-iQ4 device settings page

of the app. The info required is the same (ie battery s/n, customer info,

battery technology, battery capacity, number of cells, etc).

Figure 16: E Connect™ Mobile App Available Menu Options

5. COMMUNICATION (CONTINUED)

8

9

5.6 Truck iQ™ smart battery dashboard

5.6.1 The Truck iQ™ smart battery dashboard is one of the latest “iQ”

devices from EnerSys®.

5.6.2 The device consists of a display powered by the battery via the truck

cables. It reads in real time and wirelessly data from the Wi-iQ®4

device, displaying alerts, alarms, SOC and other useful parameters to

optimize the operation of the battery.

Figure 17: Wi-iQ4 Device Communicates with Truck iQ Smart Battery Dashboard to

Display Critical Battery Information

5.6.3 Pairing Truck iQ dashboard with Wi-iQ4 device

5.6.4 The Truck iQ dashboard can be paired with the Wi-iQ4 device either

manually or automatically.

5.6.4.1 Manual Procedure

Figure 18: Wi-iQ4 Device and Truck iQ Dashboard Pairing Instructions

5.7 CAN (Controlled Area Network) Communication

5.7.1 EnerSys®allows integration via CAN supported protocols interfacing

with the following:

5.7.1.1 Trucks using OEM’s proprietary CAN protocol implemented in

the Wi-iQ4 device firmware.

5.7.1.2 AGVs (Automated Guided Vehicle) using EnerSys proprietary

CAN protocol (CANOpen Cia 418 or J1939).

5.7.1.3 List of parameters communicated via CAN to trucks as

specified by OEMs proprietary protocol, but not limited to:

5.7.1.3.1 USOC (Usable State of Charge)

5.7.1.3.2 DC Bus Voltage

5.7.1.3.3 DC Bus Current

5.7.1.3.4 System temperature ( battery temperature)

5.7.1.3.5 Lift Lock-out trigger

5.7.1.3.6 Limited Operation trigger

5.7.1.4 For more details, please refer to CAN Interface Specification

provided with the truck’s user manual for each specific OEM.

5.7.1.5 Parameter communicated via CAN to AGV as specified by

EnerSys proprietary CAN protocol, but not limited to:

5.7.1.5.1 USOC (Usable State of Charge)

5.7.1.5.2 DC Bus Voltage

5.7.1.5.3 DC Bus Current

5.7.1.5.4 System temperature (battery temperature)

5.7.1.6 For more details, please refer to EnerSys Global: CAN Open

and CAN J1939 specification for battery controller document

ENER-CO-002’ and document EnerSys_J1939.

6. SERVICE AND TROUBLESHOOTING

6.1 Displayed error messages

Figure 19: Wi-iQ4 Device LEDs6. SERVICE AND TROUBLESHOOTING )

6.1.1 Check the LED indicators on the device. Fast blinking every five

seconds of all LEDs indicates successful setup and normal operation.

Refer to the table below for troubleshooting other indicators:

Table 9: Diagnostic Table

LED Indicator LCD Display Meaning

Fast blink every

5 seconds Installation OK

Flashing Blue Balance installed or programmed

incorrectly

No temp sensor Level probe not inserted or incorrectly

programmed

No current sensor Hall effect not connected or not reading

Flashing Red Temperature Possible bad thermal probe (if persistent)

6.1.2 Connect to the device with the E Connect™ mobile app

6.1.2.1 If it won’t connect, verify no other devices are connected, such

as another App or Truck iQ™ dashboard. It can only connect to

one device at a time.

6.1.2.2 Try to connect with a computer and Wi-iQ®Report

6.1.2.3 If it doesn’t connect to either device. Move the Wi-iQ4 device

to another area, preferably outdoors.

6.1.2.3.1 If it connects in another location, the problem is

radio magnetic interference.

6.1.2.3.2 If it does not connect, replace the Wi-iQ4 device

6. S6.1.3 Perform the following quality checks to confirm proper installation.

Compare values displayed on the LCD with variables measured from the

battery (i.e., voltage, temperature, etc.).

6.1.3.1 Select the “MEASURES” button to read Wi-iQ4 device real-

time data

6.1.3.1.1 Measure voltage from the positive terminal of the

battery to the VBAL/CEL gray wire with a calibrated

voltmeter. Divide the reading by the number of

cells between the positive terminal and the balance

wire. Compare this value to the “VBAL/CEL”

reading and confirm is within a tolerance of (+/- .02

VDC). Deviation from this value indicates the wrong

number of cells was input into the “Cells Bal” field,

or the Balance Wire is in the wrong location.

Pairing

Setting -> I/O -> Pairing -> Disable Auto pairing.

Select the appropriate Wi-iQ4 device by clicking on the BLE

(Bluetooth) icon.

NB: The Wi-iQ4 device is normally equal to the battery name.

Auto Pairing

24V30T3AH

5. COMMUNICATION (CONTINUED)

10

6.1.3.1.2 Measure the voltage between the positive and

negative battery post with a calibrated voltmeter.

Divide the number of cells in the battery and

confirm this value is within a tolerance of (+/- .03

VDC) of the value in “VBAT/CEL”. Deviation from

this value may indicate a bad electrical connection.

Clean and grease the battery post and terminal lug.

6.1.3.1.3 Measure the temperature near the Temperature

Probe on the battery. Verify the value in the

“Temp” field is near the as read value. Large

deviations indicate a bad thermal sensor.

6.1.3.1.4 If possible, operate the equipment or charge the

battery. Measure the current with a calibrated

clamp-on ammeter and confirm the value is within

(+/- 2%) tolerance of the value in “CURRENT”.

Deviation from this value indicates a bad Hall Effect

Sensor.

6.1.3.1.4.1 Also verify the current is in the proper

direction, (-) for discharger and (+) for

charge. Deviation from this indicates

the Hall Effect Sensor was installed

backwards.

6.1.3.1.5 Verify the electrolyte indicates properly. If the

probe is covered and the indication in “Measures”

is not green, verify the balance wire is on the

negative post of the same cell the electrolyte probe

is installed.

6.1.3.1.5.1 If installed correctly, inspect the

probe for corrosion. Replace probe if

damaged.

6.2 For service, contact your EnerSys sales represeentative or visit

www.enersys.com.

6. SERVICE AND TROUBLESHOOTING (CONTINUED)

EnerSys World Headquarters

2366 Bernville Road

Reading, PA 19605, USA

Tel: +1-610-208-1991 /

+1-800-538-3627

EnerSys EMEA

EH Europe GmbH

Baarerstrasse 18

6300 Zug, Switzerland

EnerSys Asia

152 Beach Road

#11-08 Gateway East Building

Singapore 189721

Tel: +65 6416 4800

© 2023 EnerSys. All rights reserved. Trademarks and logos are the property of EnerSys and its aliates except Bluetooth, Loctite, Noalox,

CE, UKCA, Zigbee, iOS and Android, which are not the property of EnerSys. Subject to revisions without prior notice. E.&O.E.

EMEA-EN-OM-ENS-WIQ-1023

Table of contents

Other EnerSys Measuring Instrument manuals