10

Building a ventilation ductwork

Ventilation ducts must be closed until the

ventilation system is commissioned, so that warm

air does not ow into the ducts. Condensation

water is formed when warm air mixes with

cold outdoor air or the cold surface of the duct.

Shutdown prevents dirt and particles from

contaminating the system.

NOTE

Insulation of ventilation ducts

The ventilation ducts must be appropriately insulated.

Insulation is especially important, if the unit has a cooling

function.

Ventilation ducts must be insulated so that no water can

condense on the outer or inner surface of the duct under

any circumstances. Air must not cool or warm too much in

the ductwork due to external factors. Ventilation designer

will proportion the insulation on a case-by-case basis,

depending on the duct placements and temperatures.

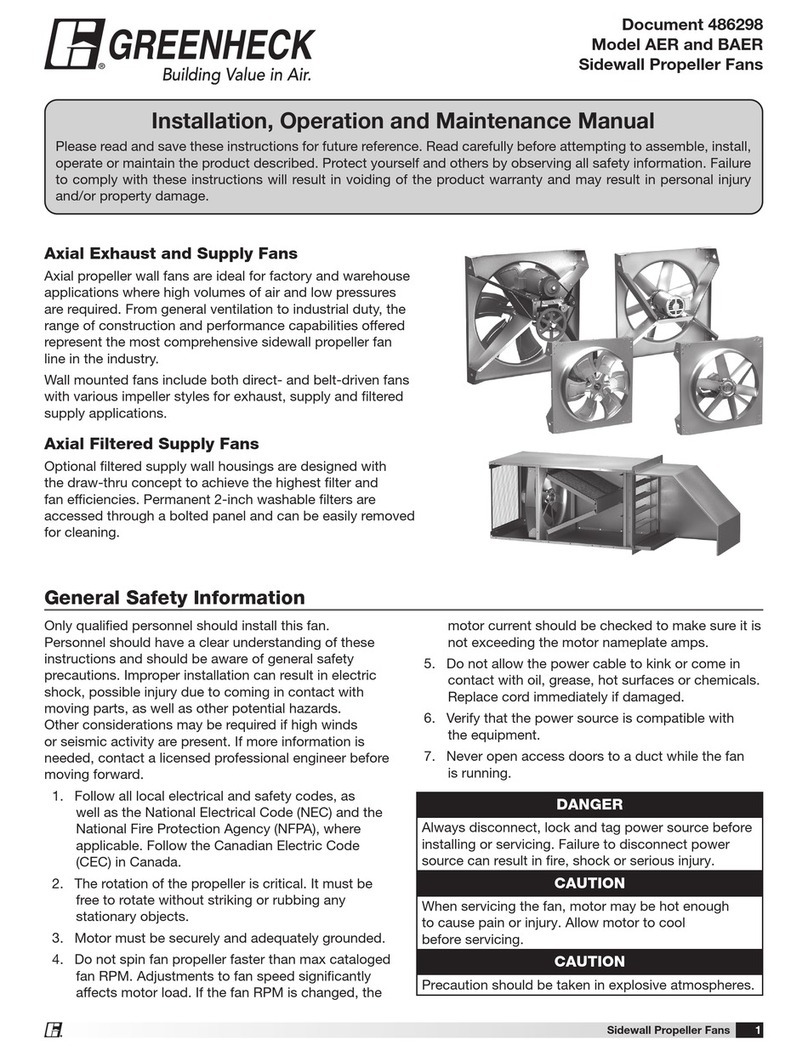

Ventilation duct insulation in heating

Supply air duct from

ventilation unit to inlet

valve

Insulation must be planned and

implemented so that changes in

the temperature of airow are 1°C

at most.

Extract air duct from

extract valve to

ventilation unit

Insulation must be planned and

implemented so that changes in

the temperature of airow are 1°C

at most.

Insulation of ventilation ducts in cooling use

Supply air duct from

ventilation unit to inlet

valve

Insulation must be planned and

implemented so that changes

in the temperature of airow are

1°C at most. A cellular rubber

insulation with a thickness of at

least 19 mm is needed for the

surface of the duct, together with

a sucient additional insulation.

Extract air duct from

extract valve to

ventilation unit

Insulation must be planned and

implemented so that changes in

the temperature of airow are 1°C

at most.

Planning a ventilation ductwork is a task for professionals.

When building a ductwork, it is crucial to follow the

plan exactly. Following the plan ensures operationality

and customer satisfaction. The performance capacity

of the ventilation unit and its evaluated heating or

cooling power can be calculated with the Enervent

Energy Optimizer program on the Enervent website. We

recommend reading the planning guide on the Enervent

website for professionals.

• Type-approved, factory-made materials are used for

building a ductwork.

• The intended valves must be suitable for mechanical

ventilation.

• The outer louvre must not be covered with an anti-

insect netting, as it will impede with maintenance.

• Snow and rainwater must be prevented from entering

the outside and exhauts air ducts.

• The ductwork must have enough inspection hatches

through which the ducts can be cleaned.

• The locations of inspection hatches have to be marked

on the roof framework, for example, so that they are

easier to nd.

• Each re zone must have its own, separate ventilation

system. Dierent re zones are garage and living

quarters, for example. These dierent re zones cannot

share a ventilation system.

• The kitchen must have a range hood with its own fan

above the stove. The range hood must have its own

exhaust duct that goes straight out of the house. A

range hood without a motor can be connected to a

ventilation unit only if the unit has a connection for a

range hood.

• Cabinet dryers with integrated fan can be indirectly

connected to the extract valve with the dryer’s own

connecting system. A portion of extract air is taken

from the surrounding room and a portion from the

cabinet dryer. Extract air must ow through the valve

at a rate of 12 liters per second.

• Silencers are needed for supply and extract ducts, at

the very least.

• Silencers are dimensioned on a case-by-case basis.

• Installing automatically closing dampers in outdoor

and exhaust air ducts is recommended. In case of a

blackout, the dampers will close and prevent cold

air from entering the duct, which in turn prevents

any water coils from freezing. If cold air enters the

ventilation ductwork, condensation water can form

when cold air mixes with warm air.

• If the unit has a constant duct pressure control,

dierential pressure transmitters must be installed.