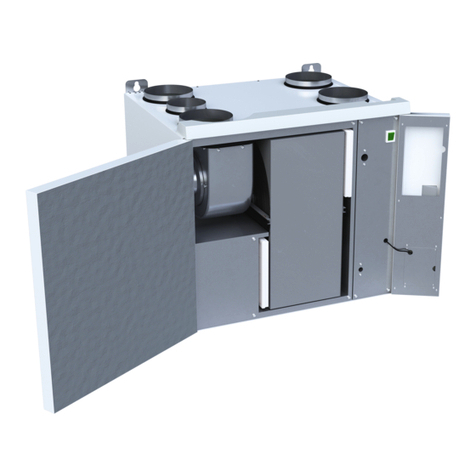

enervent LTR-3 Series Technical manual

This manual suits for next models

6

Table of contents

Other enervent Fan manuals

enervent

enervent LTR-5 Z eWind User manual

enervent

enervent LTR-5 Z eAir User manual

enervent

enervent Salla eAir User manual

enervent

enervent Neo eWind User manual

enervent

enervent Pinion Troubleshooting guide

enervent

enervent eWind Pinion User manual

enervent

enervent EDX Quick start guide

enervent

enervent Pelican Z eWind Manual

enervent

enervent eWind Pelican User manual

enervent

enervent Alta eWind User manual

enervent

enervent LTR-5 Z eWind Manual

enervent

enervent Pallas HP eAir Series User manual

enervent

enervent Pingvin XL eAir User manual

enervent

enervent Pingvin XL eWind User manual

enervent

enervent eWind Pinion Manual

enervent

enervent Pegasos Z eWind User manual

enervent

enervent Pelican eAir User manual

enervent

enervent greenair Plaza eco EC Quick start guide

enervent

enervent eWind Pelican Manual

enervent

enervent Salla eWind User manual

Popular Fan manuals by other brands

Harbor Breeze

Harbor Breeze 40045 manual

Greenheck

Greenheck PVE-20 Installation, operation and maintenance manual

Haier

Haier FDPH112 user manual

Gaggenau

Gaggenau AL 400 use and care manual

QUORUM INTERNATIONAL

QUORUM INTERNATIONAL The Angel installation instructions

ZIEHL-ABEGG

ZIEHL-ABEGG ECblue Assembly instructions

Ventamatic

Ventamatic MaxxAir HVFF 20 Instruction & owner's manual

AmazonBasics

AmazonBasics B07YJD9K21 manual

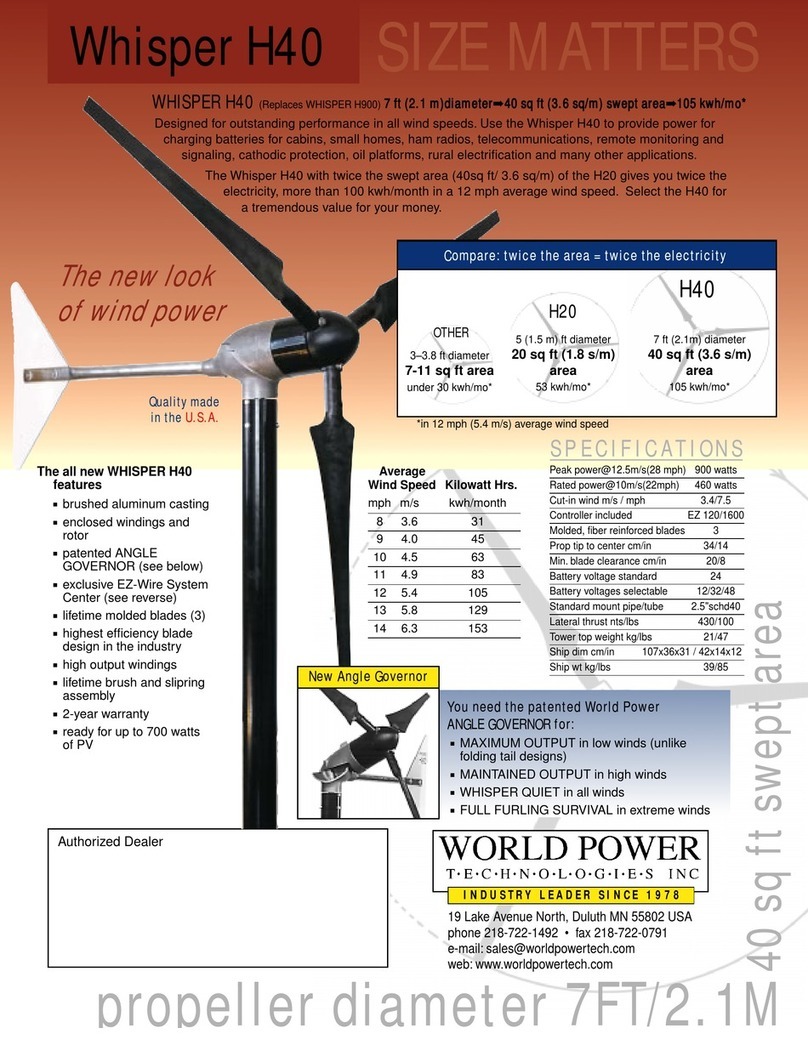

World Power Technologies

World Power Technologies WHISPER H40 datasheet

Kichler Lighting

Kichler Lighting BASICS PRO SELECT 330017MWH instruction manual

Faro Barcelona

Faro Barcelona lombok installation guide

Craftmade

Craftmade FRM52 installation guide