EngA AF Series User manual

IOM-52 Apr 13 R2

INSTALLATION, OPERATION

AND MAINTENANCE MANUAL

FOR

AF / DCU SERIES

AIR COOLED CONDENSERS and FLUID COOLERS

UNIT MODEL NO. _________________

UNIT SERIAL NO. _________________

SERVICED BY: ___________________

TEL. NO: ________________________

CANADIAN

HEAD OFFICE

AND FACTORY

USA

HEAD OFFICE

AND FACTORY

CANADIAN

EASTERN FACTORY

1401 HASTINGS CRES. SE

CALGARY, ALBERTA

T2G 4C8

Ph: (403) 287-4774

Fx: 888-364-2727

32050 W. 83rd STREET

DESOTO, KANSAS

66018

Ph: (913) 583-3181

Fx: (913) 583-1406

1175 TWINNEY DRIVE

NEWMARKET, ONTARIO

L3Y 5V7

Ph: (905) 898-1114

Fx: (905) 898-7244

SALES OFFICES ACROSS CANADA AND USA

Retain instructions with unit and maintain in a legible condition.

Please give model number and serial number when contacting

factory for information and/or parts.

www.engineeredair.com

AAF / DCU MANUAL

IOM-52 2 of 23 Apr 13 R2

TABLEOFCONTENTS

Safetyprecautions.............................................................................................................................................................................3

Youhaveresponsibilitiestoo.............................................................................................................................................................3

Introduction.......................................................................................................................................................................................3

Warranty............................................................................................................................................................................................4

Parts...................................................................................................................................................................................................5

Receiving............................................................................................................................................................................................5

Temporarystorage.............................................................................................................................................................................5

Installation..........................................................................................................................................................................................6

Codes..................................................................................................................................................................................................6

Clearanceforairflow.........................................................................................................................................................................7

Qualifiedinstaller...............................................................................................................................................................................7

Refrigerationpipingrecommendations.............................................................................................................................................7

Undergroundrefrigerantpiping...............................................................................................................................................7

Pipingconnectionsizes.............................................................................................................................................................8

Traps.........................................................................................................................................................................................8

Liquidline.................................................................................................................................................................................8

Dischargeline...........................................................................................................................................................................8

Refrigerationspecialties(byothers).........................................................................................................................................9

Servicevalves(recommended).................................................................................................................................................9

Sightglass/moistureindicator(required).................................................................................................................................9

Liquidlinefilter‐drier(required)...............................................................................................................................................9

Liquidlinesolenoidvalve(required)......................................................................................................................................10

Thermostaticexpansionvalve(required)...............................................................................................................................10

Dischargecheckvalves...........................................................................................................................................................10

Refrigerationtable1equivalentlength..................................................................................................................................10

Refrigerationtable2(R410A)pipingguidelinesfornormalairconditioningduty................................................................11

Refrigerationtable2(R407C)pipingguidelinesfornormalairconditioningduty.................................................................12

Refrigerationtable2(R134a)pipingguidelinesfornormalairconditioningduty.................................................................13

Refrigerationtable3...............................................................................................................................................................14

Refrigerationtable4...............................................................................................................................................................14

Refrigerationpipingmaterialsandprocedures...............................................................................................................................15

Tubing.....................................................................................................................................................................................15

Leakchecking..........................................................................................................................................................................16

Evacuationanddehydration...................................................................................................................................................16

Refrigerantcharging.........................................................................................................................................................................17

Flushinganddegreasingofwaterandglycolcoils...........................................................................................................................18

Heattransferfluids.................................................................................................................................................................18

Shutdownprocedure.......................................................................................................................................................................18

Maintenance....................................................................................................................................................................................19

Heresite®maintenance.....................................................................................................................................................................19

Electrical...........................................................................................................................................................................................20

Beltadjustment................................................................................................................................................................................20

Setscrews.........................................................................................................................................................................................20

Motorlubrication.............................................................................................................................................................................21

Dampers...........................................................................................................................................................................................21

Controls............................................................................................................................................................................................21

Refrigeration....................................................................................................................................................................................22

Seasonalmaintenance............................................................................................................................................................22

Condenserfancontroltypicalsettings.......................................................................................Error!Bookmarknotdefined.

Troubleshootingchart.....................................................................................................................................................................22

©AirtexManufacturingPartnership.Allrightsreserved.

AAF / DCU MANUAL

IOM-52 3 of 23 Apr 13 R2

SAFETYPRECAUTIONS

Read,understandandfollowthecompletemanualbeforebeginningtheinstallation,includingallsafety

precautionsandwarnings.

Warning:

Improperinstallation,adjustment,alteration,serviceormaintenancecancause

propertydamage,injuryordeath.Readtheinstallation,operatingandmaintenance

instructionsthoroughlybeforeinstallingorservicingthisequipment.

Warning:Thisunitisconnectedtohighvoltages.Electricalshockordeathcouldoccurif

instructionsarenotfollowed.Thisequipmentcontainsmovingpartsthatcanstart

unexpectedly.Injuryordeathcouldoccurifinstructionsarenotfollowed.Allwork

shouldbeperformedbyaqualifiedtechnician.Alwaysdisconnectandlockoutpower

beforeservicing.DONOTbypassanyinterlockorsafetyswitchesunderany

circumstances.

YOUHAVERESPONSIBILITIESTOO

Thisinstallation,operationandmaintenancemanualcannotcovereverypossibility,situationor

eventuality.Regularservice,cleaningandmaintainingtheequipmentisnecessary.Ifyouarenotcapable

ofperformingthesetasks,hireaqualifiedservicespecialist.Failuretoperformthesedutiescancause

propertydamageand/orharmtothebuildingoccupantsandwillvoidthemanufacturers’warranty.

INTRODUCTION

EngineeredAirunitsarehighqualityproductsdesignedandmanufacturedtoprovidemanyyearsof

trouble‐freeoperation.Werecommendthatthismanualbereadthoroughlytoensureproperinstallation,

efficientoperationandpropermaintenanceofthisequipment.Thesubmittalrecordisconsideredtobe

partoftheInstallation,OperationandMaintenanceManual.Pleasereportanyomissionstothenational

servicemanager.

AAF / DCU MANUAL

IOM-52 4 of 23 Apr 13 R2

WARRANTY

LIMITEDWARRANTYENGINEEREDAIRwillfurnishwithoutcharge,F.O.B.factory,freightcollect,

replacementpartsfor,orrepairstoproductscoveredhereinwhichprovedefectiveinmaterialor

workmanshipundernormalandproperuseforaperiodoftwelve(12)monthsfromtheinitialstart‐upor

eighteen(18)monthsfromthedateofshipment,whicheverexpiressooner,providedthecustomergives

ENGINEEREDAIRwrittennoticeofsuchdefectswithinsuchtimeperiodsandprovidedthatinspectionby

ENGINEEREDAIRestablishesthevalidityoftheclaimandallpertinentinvoiceshavebeenpaidinfull.The

repairsorreplacementswillbemadeonlywhenthecompleteproduct(s)orpart(s)claimedtobedefective

arereturnedtoENGINEEREDAIRoradepotdesignatedbyENGINEEREDAIR,transportationcharges

prepaid.Repairsorreplacementsasprovidedforbythisparagraphshallconstitutefulfillmentofall

ENGINEEREDAIR'sobligationswithrespecttothiswarranty.Therefrigerantchargeisnotincludedinany

partofthiswarranty.Thiswarrantydoesnotapplytoanyproductsorpartsthereofthathavebeensubject

toaccident,misuseorunauthorizedalterations,orwhereENGINEEREDAIR'sinstallationandservice

requirementshavenotbeenmet.

Theforegoingwarrantyisinlieuofallotherwarranties,expressorimplied.ENGINEEREDAIRspecifically

disclaimsanyimpliedwarrantyofmerchantabilityand/orfitnessforpurpose.Undernocircumstances

shallENGINEEREDAIRbeliableto,norberequiredtoindemnify,Buyeroranythirdpartiesforanyclaims,

losses,labor,expensesordamages(includingspecial,indirect,incidental,orconsequentialdamages)of

anykind,resultingfromtheperformance(orlackthereof)ofthisAgreementortheuseof,orinabilityto

usethegoodssoldhereunder,including,butnotlimitedto,damagesfordelay,temporaryheating/cooling

costs,lossofgoodwill,lossofprofitsorlossofuse.Furthermore,thepartiesagreethattheBuyer'ssole

remedyunderthisagreementshallbelimitedtothelimitedwarrantysetforthintheprecedingparagraph

relatingtotherepairorreplacementofanydefectivegoods.Undernocircumstancesshallanyclaimor

awardagainstENGINEEREDAIRexceedtheoriginalcontractpricewhetherawardedthrougharbitration,

litigationorotherwise.

ENGINEEREDAIRWarrantyisvoidif:

1. Theunitisnotinstalledinaccordancewiththismanual.

2. Thestart‐upandoperationoftheunitisnotperformedinaccordancewiththismanual.

3. Theunitisoperatedinanatmospherecontainingcorrosivesubstances.

4. Theunitisallowedtooperateduringbuildingconstruction.

AAF / DCU MANUAL

IOM-52 5 of 23 Apr 13 R2

PARTS

Warning:

Anyreplacementpartmustbeofequivalentlistingorcertificationandbefunctionally

equivalent.Thereplacementpartmustmeettheoriginal’sspecificationintermsof

functionalityincludingcertifications,timing,inputandoutputrange,accuracyand

operation.

Failuretoreplacepartsorcomponentswithequivalentpartscancauseproperty

damage,injuryordeath.

1. Motors:

Motormanufacturershaveservicecentersthatwillrepairorreplacemotorsasrequired.

2. PartsOtherThanMotors:

ContactthenearestEngineeredAirsalesofficeorfactory.BesuretoincludeModelNumber,Serial

Number,dateofinstallationandnatureoffailurealongwiththedescriptionofthepartsrequired.

Somepartsmaynotbestockeditemsthatmustbemadeorordered.

RECEIVING

Refertothebackofthepackingslipforreceivingunitinstructions.

Onreceiptoftheunit,checkfordamage.Inspectprotectivecoversforpuncturesorothersignsthatthere

maybeinternaldamage.Removeprotectivecoversandcheckforinternaldamage.Replacecoversifthe

unitisnotbeingassembledorinstalledatthistime.Openaccessdoorsandcheckforinternaldamage.

Closeaccessdoorswhentheinspectioniscomplete.Ifdamageisfoundfollowtheinstructionsonthe

packingslip.

Onreceiptoftheunit,checkelectricalcharacteristics(seeratingplate)tomakesuretheunitvoltageis

compatiblewiththatavailablefortheunit.Allpartsforfieldinstallationarelistedontheshippingorder

form.

TEMPORARYSTORAGE

Ifaunitistobestoredpriortoinstallationthefollowingprecautionsarerequired:

• Storeinawelldrainedareathatwillnotaccumulatesurfacewater.

• Storeinanareawheretheunitwillnotgetdamaged.

• Theentireperimeterandanyfullheightcrossmembersoftheunitmustbesupportedbyalevel

surfaceandthesupportingsurfacemustbeadequateforsupportingtheentireweightoftheunit.

• Allprotectivecoveringsthatwereprovidedforshippingmustbeinplace.

AAF / DCU MANUAL

IOM-52 6 of 23 Apr 13 R2

INSTALLATION

Warning: Thisunitisnotratedforhazardouslocationsandcannotbeinstalledinareasrequiring

anyhazardouslocationrating.

Caution: Allwiringandpipinginstallationmustbecompletedbyqualifiedpersonsin

accordancewithallfederal,state,provincialand/orlocalcodes.

Note: Installationshallbeinaccordancewiththismanualandallotherassociated

componentandcontrolInstallation,OperationandMaintenanceManuals.

CODES

InCanada:

1. TheinstallationofthisunitshallbeinaccordancewiththelatesteditionoftheCanadianElectrical

Code,Part1–C.S.A.StandardC22.1,ProvincialandLocalCodes,andinaccordancewiththelocal

authoritieshavingjurisdiction.

2. ThisunitshallbeelectricallygroundedinaccordancewiththelatesteditionoftheCanadianElectrical

Code,Part1–C.S.A.StandardC22.1,ProvincialandLocalCodes,andinaccordancewiththelocal

authoritieshavingjurisdiction.

3. TheinstallationofthisunitshallbeinaccordancewiththelatesteditionoftheCanadianNaturalGas

andPropaneInstallationCode,C.S.A.StandardB149.1,ProvincialandLocalCodes,andinaccordance

withthelocalauthoritieshavingjurisdiction.

4. TheinstallationofthisunitshallbeinaccordancewiththelatesteditionoftheNationalPlumbingCode

ofCanada,ProvincialandLocalCodes,andinaccordancewiththelocalauthoritieshavingjurisdiction.

5. TheinstallationofthisunitshallbeinaccordancewithallotherNational,ProvincialandLocalCodes,

andinaccordancewiththelocalauthoritieshavingjurisdiction.

InUSA:

1. TheinstallationofthisunitshallbeinaccordancewiththelatesteditionoftheNationalElectrical

Code(ANSI/NFPA70),StateandLocalCodesandinaccordancewiththelocalauthoritieshaving

jurisdiction.

2. ThisunitshallbeelectricallygroundedinaccordancewiththelatesteditionoftheNational

ElectricalCode(ANSI/NFPA70),StateandLocalCodesandinaccordancewiththelocalauthorities

havingjurisdiction.

3. Iftheunithasnotbeenprovidedwithanelectricdisconnectswitch,oneofadequateampacity

shallbeinstalledinaccordancewithArticle430oftheNationalElectricalCode(ANSI/NFPA70).

4. TheinstallationofthisunitshallbeinaccordancewiththelatesteditionoftheNationalFuelGas

AAF / DCU MANUAL

IOM-52 7 of 23 Apr 13 R2

CodeANSI/Z223.1/NFPA54,StateandLocalCodesandinaccordancewiththelocalauthorities

havingjurisdiction.

5. TheinstallationofthisunitshallbeinaccordancewiththelatesteditionoftheNationalStandard

PlumbingCode(NSPC),StateandLocalCodesandinaccordancewiththelocalauthoritieshaving

jurisdiction.

6. TheinstallationofthisunitshallbeinaccordancewithallotherNational,StateandLocalCodes,

andinaccordancewiththelocalauthoritieshavingjurisdiction.

CLEARANCEFORAIRFLOW

Properairflowisessentialfortheoperationofthisequipment.Maintainatleast60”(1500mm)clearance

betweenthecoilandanyobstruction.Maintainatleast96”(2400mm)betweenadjacentsections.Donot

placeinawell.Wellscreateasituationwhereairre‐circulatesfromthefanbacktothecoil.Enclosures

mustbedesignedforproperairflowandtopreventblockageorre‐circulatedair.

QUALIFIEDINSTALLER

Tocompletetheinstallation,arefrigerationcontractorexperiencedandqualifiedinsystempipingis

required.Thecontractorisresponsibleforthedesign,selectionandinstallationoftherefrigeration

specialtiesandrefrigerantpipingforthisequipment.Thefollowinginformationisintendedtoprovide

generalinformationandguidelinesforthesuccessfulinstallationofthisequipment.

FordetailedinformationaboutinstallationpracticesconsultASHRAEhandbooks,ANSI/ASMECodes,

ANSI/ASHRAESafetyCodeforMechanicalRefrigeration,CAN/CSAB52MechanicalRefrigerationCodeand

anylocalauthoritieshavingjurisdiction.

Note:

Componentselection,pipingdesignandinstallationoftheairconditioningsystemarethe

responsibilityoftheinstallingcontractor.Thismanualisdesignedtoprovidegeneral

guidelinesandrecommendationsonly.Itisnotintendedtobeacompletemanualforair

conditioningdesign.

REFRIGERATIONPIPINGRECOMMENDATIONS

UNDERGROUNDREFRIGERANTPIPING

Caution:

Undergroundcondenserrefrigerantpipingisnotrecommended.

Improperinstallationofacondensingunitwithundergroundpipingwillresultin

equipmentfailure.

ConsultFactoryonallsystemswithundergroundrefrigerantpiping.

Undergroundpipingwillvoidcompressorwarrantyunlessspecificallyauthorizedby

EngineeredAir.

Intheoffcycle,therefrigerantchargewillmigratetothecoldestlocation.Typically,groundtemperatures

arecoolerthanairtemperatures,andtheundergroundpipingbecomesthecoolestlocation.Inthiscase

therefrigerantchargewillmigratetoundergroundpiping.Whenthecompressorstarts,anyliquid

refrigerantinthedischargelinecouldcausenuisancetrippingonhighheadpressure.

AAF / DCU MANUAL

IOM-52 8 of 23 Apr 13 R2

PIPINGCONNECTIONSIZES

Refrigerantpipingmustbeselectedtomeettheconditionsrequiredforyourspecificinstallation.The

tubingconnectionsizesontheequipmentmayormaynotbethecorrectsizeforyourspecificapplication.

Note:

DONOTselecttubingsizesbasedonthesizeoftheconnectionstubs.

Thecorrecttubingsizeforyourinstallationmustbecheckedandselectedforeachandevery

job.

TRAPS

Itisrecommendedthattrapsbeinstalledonallsuctionordischargegasrisers.

LIQUIDLINE

Selectthelinesizeusingpipingtables.

Liquidlinesshouldhaveamaximumrefrigerantvelocityof350feetperminute(1.78m/s)toavoidliquid

hammer.Selectpressuredropforatemperaturepenaltyoflessthan2°F(1°C).Ifaliquidlinetravels

throughawarmarea,suchasaboilerroom,insulatethelinetopreventheatgain.

Ensurethetemperaturepenaltydoesnotexceedthesubcoolingprovidedbythecondensingunit.

AsightglassshouldbeinstalledattheTXvalvetoensurethevalveisreceivingasolidcolumnofliquidif

adequatesubcoolingisaconcern.AnEngAIntercoolermaybeorderedandinstalledtohelpreducethe

effectsofinadequatesubcooling.

DISCHARGELINE

Dischargelinesmustbeselectedtobalancetworequirements;minimizepressuredropandensure

adequatelinevelocitytoallowforoilreturn.Horizontaldischargelinesshouldbeslopeddowninthe

directionofflow.Usesizingtablestoselecttubingsizesbasedoncapacity,equivalentlengthand

maximumsizeforoilreturn.

A

AF / DCU MANUAL

IOM-52 9 of 23 Apr 13 R2

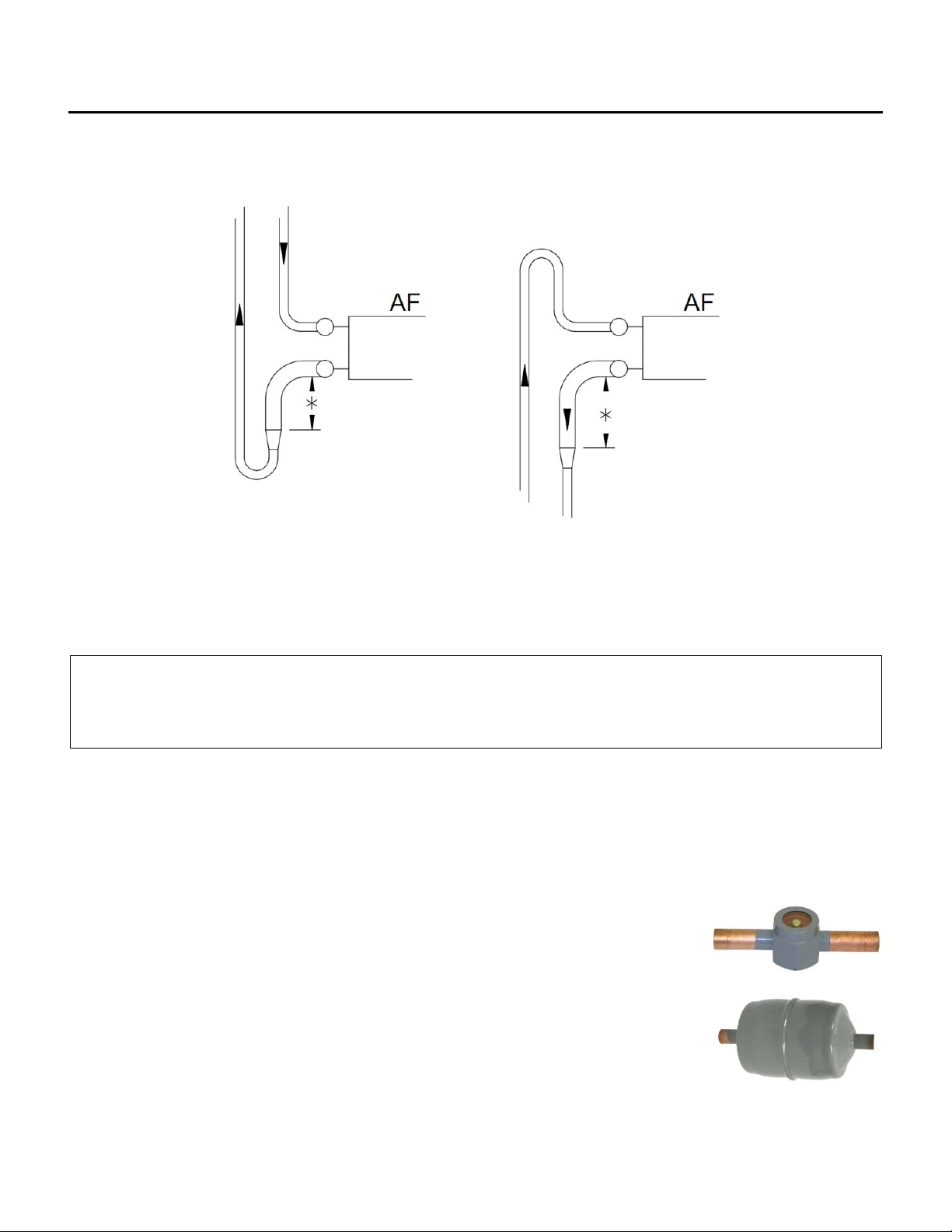

Thesketchbelowdescribesaboveandbelowpipingconnectionsandtraprequirements.Onlyinstall

reducersontheverticalline,atleast12”(300mm)belowtheheaderconnection.

*12”(300mm)minimumheightbeforereducingsize.

REFRIGERATIONSPECIALTIES(BYOTHERS)

Note:

Refrigerantspecialtiesareselected,suppliedandinstalledbytheinstallingcontractor.

Mostofthesedeviceshavespecifieddirectionsofflowandmaybepermanentlydamagedif

notinstalledcorrectly.Alwaysfollowtheinstallationinstructionsprovidedwiththe

components.

SERVICEVALVES(Recommended)

Servicevalvesshouldbeinstalledtoallowservicingoftheequipment.Aliquidlineservicevalveatthe

condensingunitisconsideredaminimumrequirement.

SIGHTGLASS/MOISTUREINDICATOR(Required)

Sightglassesareinstalledintheliquidlinetogiveavisualindicationofthe

refrigerantcharge.Themoistureindicatorgivesanindicationofthemoisture

contentoftherefrigerant.

LIQUIDLINEFILTER‐DRIER(Required)

Thefilter‐drierisinstalledintheliquidlinetofilterparticulateandforeignmatter

fromtherefrigerant.Filter‐driersalsoabsorbsmallamountsofmoistureandacid.

AAF / DCU MANUAL

IOM-52 10 of 23 Apr 13 R2

LIQUIDLINESOLENOIDVALVE(Required)

Theliquidlinesolenoidvalveisinstalledtocontrolliquidrefrigerantintheoff

cycle.ThesolenoidvalvemustbeinstalledclosetotheTXvalveattheevaporator

coil.Severaldifferentcontrolmethodsareusedtocontrolliquidlinesolenoid

valves.Seewiringdiagramandunitfunctionfordetails.

Note:

Liquidlinesolenoidvalvesmustbeinstalledattheevaporatorcoil,closetotheTXvalve.

THERMOSTATICEXPANSIONVALVE(Required)

Thethermostaticexpansionvalveissizedtomatchthecapacityofthesystem.The

TXvalveshouldbebalancedordualportedandmustbeexternallyequalized.One

valveisrequiredperdistributor.Theequalizationtubeconnectstothesuctionline

attheoutletoftheevaporatordownstreamofthebulb.TheTXvalvesensingbulb

isinstalledatthesamelocationtightlystrappedtothesuctionline.Suggested

positioningisatthesideofthepipe,atthe4:00o’clockor8:00o’clockposition.InsulatetheTXbulbafter

installation.

DISCHARGECHECKVALVES(Required)

Providedischargecheckvalve(s)totheinletoftheAF.Thiscontrolsliquidmigrationtothecompressorin

theoffcycle.

RefrigerationTable1EquivalentLength.

ACR(OD) Approximatepressurelossoffittings

(equivalentfeetoftubing)

Tubing

Size

90°

Std

90°

Long

Radius

90°

Street

45°

Std

Return

Bend

Tee

Branch

Flow

Tee

Straight

Through

Ball

Valve

Globe

Valve

Angle

Valve

1/2"OD 1.4 0.9 2.3 0.7 2.3 2.7 0.9 0.9 17 6

5/8”OD 1.6 1.0 2.5 0.8 2.5 3.0 1.0 1.0 18 7

7/8”OD 2.0 1.4 3.2 0.9 3.2 4.0 1.4 1.4 22 9

11/8”OD 2.6 1.7 4.1 1.3 4.1 5.0 1.7 1.7 29 12

13/8”OD 3.3 2.3 5.6 1.7 5.6 7.0 2.3 2.3 38 15

15/8”OD 4.0 2.6 6.3 2.1 6.3 8.0 2.6 2.6 43 18

21/8”OD 5.0 3.3 8.2 2.6 8.2 10.0 3.3 3.3 55 24

25/8”OD 6.0 4.1 10.0 3.2 10.0 12.0 4.1 4.1 69 29

AAF / DCU MANUAL

IOM-52 11 of 23 Apr 13 R2

RefrigerationTable2(R410A)PipingGuidelinesforNormalAirConditioningDuty.

R410A

Net

Evaporator

Capacity

EquivalentLength

(Actuallengthplusfittingsandvalves) Maximum

RiserSize

Tons Line 30feet 50feet 100feet 150feet

3tons Suction 3/4”(7/8”) 3/4”(7/8”) 7/8” 7/8” 7/8"

Discharge 1/2" 1/2" 5/8" 5/8" 5/8"

Liquid 3/8" 3/8” 1/2" 1/2"

Condensate 5/8" 5/8"

4tons Suction 3/4”(7/8”) 7/8" 7/8” 11/8” 7/8"

Discharge 1/2" 5/8" 5/8” 3/4”(7/8”) 5/8"

Liquid 3/8" 1/2” 1/2" 1/2"

Condensate 5/8" 5/8"

5tons Suction 7/8" 7/8" 11/8" 11/8" 11/8"

Discharge 5/8" 5/8” 3/4”(7/8”) 3/4”(7/8”) 5/8"

Liquid 1/2" 1/2" 1/2" 1/2”

Condensate 3/4”(7/8”) 3/4”(7/8”)

7.5tons Suction 7/8" 11/8" 11/8" 13/8" 13/8"

Discharge 5/8" 3/4”(7/8”) 7/8" 7/8" 3/4”(7/8”)

Liquid 1/2" 1/2" 1/2" 5/8"

Condensate 7/8” 7/8”

10tons Suction 11/8" 11/8" 13/8" 13/8" 13/8"

Discharge 3/4”(7/8”) 3/4”(7/8”) 7/8" 7/8" 7/8"

Liquid 5/8" 5/8" 5/8" 5/8”

Condensate 11/8” 11/8”

12.5tons Suction 11/8" 13/8" 13/8" 15/8" 15/8"

Discharge 7/8" 7/8" 7/8" 11/8" 7/8"

Liquid 5/8” 5/8" 5/8” 5/8”

Condensate 11/8" 11/8"

15tons Suction 13/8" 13/8" 15/8" 15/8" 15/8"

Discharge 7/8" 7/8" 11/8" 11/8" 11/8"

Liquid 3/4”(7/8”) 3/4”(7/8”) 3/4”(7/8”) 7/8"

Condensate 13/8" 13/8"

20tons Suction 13/8" 13/8" 15/8" 21/8" 15/8"

Discharge 7/8" 11/8" 11/8" 11/8" 11/8"

Liquid 7/8” 7/8” 7/8” 7/8”

Condensate 13/8” 13/8”

AAF / DCU MANUAL

IOM-52 12 of 23 Apr 13 R2

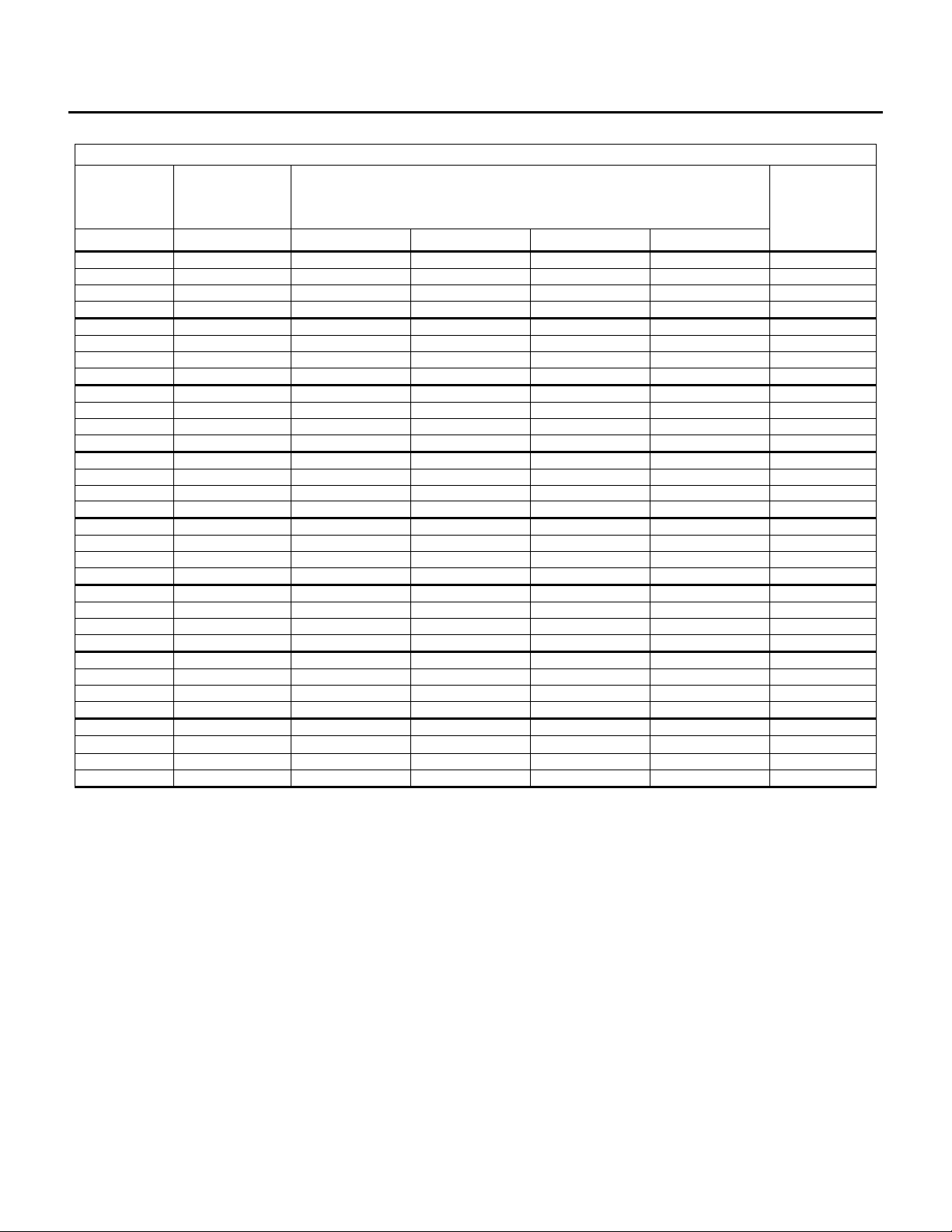

RefrigerationTable2(R407C)PipingGuidelinesforNormalAirConditioningDuty.

R407C

Net

Evaporator

Capacity

EquivalentLength

(Actuallengthplusfittingsandvalves) Maximum

RiserSize

Tons Line 30feet 50feet 100feet 150feet

3tons Suction 3/4”(7/8”) 7/8" 11/8” 11/8” 11/8"

Discharge

1/2" 5/8" 5/8" 3/4" 7/8"

Liquid 3/8" 3/8” 1/2" 1/2"

Condensate 5/8" 5/8"

4tons Suction 7/8" 7/8" 11/8” 11/8” 13/8"

Discharge

5/8" 5/8" 3/4”(7/8”) 7/8" 11/8"

Liquid 1/2” 1/2” 1/2" 1/2"

Condensate 5/8" 5/8"

5tons Suction 7/8" 11/8" 11/8" 13/8" 13/8"

Discharge

5/8" 3/4”(7/8”) 7/8" 7/8" 11/8"

Liquid 1/2" 1/2" 1/2" 5/8”

Condensate 3/4”(7/8”) 3/4”(7/8”)

7.5tons Suction 11/8" 11/8" 13/8" 13/8" 15/8"

Discharge

3/4”(7/8”) 7/8" 7/8" 11/8" 13/8"

Liquid 1/2" 5/8" 5/8" 5/8"

Condensate 7/8” 7/8”

10tons Suction 11/8" 13/8" 15/8" 15/8" 15/8"

Discharge

7/8" 7/8" 11/8" 11/8" 15/8"

Liquid 5/8" 5/8" 5/8" 3/4”(7/8”)

Condensate 11/8” 11/8”

12.5tons Suction 13/8" 13/8" 15/8" 21/8" 21/8"

Discharge

7/8" 7/8" 11/8" 11/8" 15/8"

Liquid 5/8” 5/8" 3/4”(7/8”) 3/4”(7/8”)

Condensate 11/8" 11/8"

15tons Suction 13/8" 15/8" 15/8" 21/8" 21/8"

Discharge

7/8" 11/8" 11/8" 13/8" 15/8"

Liquid 3/4”(7/8”) 3/4”(7/8”) 3/4”(7/8”) 7/8"

Condensate 11/8" 11/8"

20tons Suction 15/8" 15/8" 21/8" 21/8" 25/8"

Discharge

11/8" 11/8" 13/8" 13/8" 21/8"

Liquid 7/8" 7/8" 7/8" 11/8"

Condensate 13/8" 13/8"

AAF / DCU MANUAL

IOM-52 13 of 23 Apr 13 R2

RefrigerationTable2(R134a)PipingGuidelinesforNormalAirConditioningDuty.

R134a

Net

Evaporator

Capacity

EquivalentLength

(Actuallengthplusfittingsandvalves) Maximum

RiserSize

Tons Line 30feet 50feet 100feet 150feet

3tons

Suction 7/8” 11/8" 11/8” 13/8” 13/8"

Discharge 5/8" 3/4”(7/8”) 3/4”(7/8”) 7/8" 7/8"

Liquid 3/8" 3/8” 1/2" 1/2"

Condensate 5/8" 5/8"

4tons Suction 11/8” 11/8" 13/8” 13/8” 13/8"

Discharge 3/4”(7/8”) 3/4”(7/8”) 7/8” 7/8" 7/8"

Liquid 1/2" 1/2” 1/2" 1/2"

Condensate 7/8" 7/8"

5tons Suction 11/8" 13/8" 13/8" 15/8" 15/8"

Discharge 3/4”(7/8”) 7/8” 7/8" 11/8" 11/8"

Liquid 1/2" 1/2" 5/8" 5/8”

Condensate 7/8” 7/8”

7.5tons Suction 13/8" 13/8" 15/8" 15/8" 15/8"

Discharge 7/8" 7/8" 11/8" 11/8" 11/8"

Liquid 1/2" 1/2" 5/8" 7/8"

Condensate 7/8” 7/8”

10tons Suction 13/8" 15/8" 21/8" 25/8" 21/8"

Discharge 7/8” 11/8" 11/8" 11/8" 11/8"

Liquid 5/8" 5/8" 5/8" 3/4”(7/8”)

Condensate 11/8” 11/8”

12.5tons Suction 15/8" 15/8" 21/8" 21/8" 21/8"

Discharge 11/8" 11/8" 11/8" 13/8" 13/8"

Liquid 5/8” 5/8" 7/8” 3/4”(7/8”)

Condensate 11/8" 11/8"

15tons Suction 15/8" 21/8" 21/8" 21/8" 21/8"

Discharge 11/8" 11/8" 1 3/8" 13/8" 13/8"

Liquid 3/4”(7/8”) 3/4”(7/8”) 7/8” 7/8"

Condensate 13/8" 13/8"

20tons Suction 21/8" 21/8" 25/8" 25/8" 25/8"

Discharge 11/8" 13/8" 15/8" 15/8" 15/8"

Liquid 7/8” 7/8” 7/8” 7/8”

Condensate 13/8” 13/8”

AAF / DCU MANUAL

IOM-52 14 of 23 Apr 13 R2

NOTES:

1. SizesareODdimensions,TypeL,ACRrefrigerationtubing.

2. 3/4”(7/8”)notedabove:7/8”ACRtubingmayreplace3/4"asrequired.

3. Selectionsarebasedonequivalentlength.Equivalentlengthistheactuallengthplustheadditional

lossesinfeetduetofittings.SeeTable1forpressurelossesduetofittings.

(Ifnumberoffittingsisunknownanequivalentlengthestimatecanbemadebymultiplyingtheactual

pipingrunbyacomplexityfactorof1.5to2timestheactuallength.1.5timesforasimplesystemor

longrunsand2timesforaclosecoupledsystemoronewithalotoffittings.)

4. Forcompressorsorcircuitswithunloading(tandemcompressorsincluded).Alwayschecktubingsizes

foroilreturnattheunloadedconditions.Determinetheunloadedcapacityintonsandverifythatthe

selectedtubingisnotlargerthanmaximumrisersizeattheunloadedcapacity.

5. SelectionCriteriatodeveloptable.

Suctionline ‐ PDlessthan2°Ftemperaturepenalty.

Dischargeline‐ PDlessthan2.5°Ftemperaturepenalty.

Liquidline ‐ PDlessthan2°Ftemperaturepenalty,withvelocitylessthan350fpmtoavoidliquid

hammer.

Condensateline(condensertoreceiverifequipped‐velocitylessthan115fpm.(twophaseflow)with

notraps.

Maximumrisersizesarethelargestrecommendedtubingsizesforoilreturn.Sizesarebasedon75%

capacitytoallowforlowloadconditions.

Fordetailedevaluationofpipingsystems,guidelinesandpressurelossesconsultASHRAEhandbooks.

RefrigerationTable3

Approximateeffectofgaslinepressuredropon

compressorcapacityandpower(ASHRAE

REFRGERATION2.3)

LineLoss Capacity RequiredPower

Suction % %

0°F 100 100

2°F 96.4 104.8

4°F 92.9 108.1

Discharge % %

0°F 100 100

2°F 99.1 103.0

4°F 98.2 106.3

RefrigerationTable4

Weightofrefrigerantinliquidlinesper100ftoftubing(100°F)

Liquid

Line

R134a

Lbs(kg)

R407C

Lbs(kg)

R410A

Lbs(kg)

3/8” 3.9(1.8) 3.6(1.6) 3.4(1.5)

1/2” 7.3(3.3) 6.8(3.0) 6.2(2.8)

5/8” 12(5) 11(2.3) 10(4.5)

7/8” 24(11) 23(10.4) 21(9.5)

11/8” 41(19) 39(18) 36(16)

13/8” 63(29) 59(27) 54(24)

AAF / DCU MANUAL

IOM-52 15 of 23 Apr 13 R2

REFRIGERATIONPIPINGMATERIALSANDPROCEDURES

Note:

Aqualifiedrefrigerationcontractorexperiencedinrefrigerantpipingmustcompletethe

installation.Theinstallationmustbecompletedusingindustry‐acceptedmethodsand

materials.

WARNING:

TheAFunitisshippedwithaholdingchargeofdrynitrogen.

Thispressureshallbereleasedsafelybeforeopeningsystemorconnectingtubing.

TUBING

UseNitrogenizedACRgrade,‘TypeL’or‘TypeK’coppertubingonly.Allrefrigeranttubingshallbeclean

anddry.Thetubingshallbenitrogenpurgedduringthebrazingprocess.Thispreventsharmfulcopper

oxidesfromforminginthetubing.

WARNING:

Nitrogencylindersshallbeequippedwithahigh‐pressureregulatorandflowmeter.Do

notconnecthigh‐pressurecylinderstotherefrigerantcircuitwithoutaregulator.

Failuretodosomayresultinpropertydamage,injuryordeath.

Refrigeranttubingmustbecutwithatubecutterandtheendsdeburredbeforeinstallation.Neverusea

hacksaworabrasivecuttertocutrefrigerationtubing.

Longradiuselbowsshouldbeusedtoreducepressuredrop.

CoppertocopperconnectionsshouldbemadewithSILFOS,orsimilarsilverbearinglowtemperature

brazingmaterial.

Coppertobrassorcoppertosteeljointsshouldbemadewith45%silversolderandtheappropriateflux.

Fluxmustbecleanedfromtubingafterinstallation.

WARNING:

Softsolders(50/50,95/5,etc)arenotsuitableforusewithairconditioningsystems.

Allaccessoriesshallbeproperlyprotectedfromheatduringinstallation.Refertotheinstallationguidelines

suppliedwiththecomponents.Itispreferredtoinstallthefilter/drierlasttoavoidextendedexposureto

atmosphere(moisture).

Pipingshallbeproperlysupportedandallowancesshallbemadeforthermalexpansionorcontractionof

tubing.

AAF / DCU MANUAL

IOM-52 16 of 23 Apr 13 R2

LEAKCHECKING

Afterinstallation,alljoints,bothfactoryandfieldinstalled,shallbepressurecheckedandleaktestedusing

approvedindustrymethods.

WARNING:

Testpressuresmustnotexceedthemaximumpressureratingsspecifiedontheunit

ratingplate.

WARNING:

OxygenmustNEVERbeusedtopressurizeasystem.

Ensureallservicevalvesandmanualvalvesareopen.Ifleaksarelocated,removepressureandrepair

leaks.Recheckasnecessary.

Ifbrazingisnecessarytorepairleaks,adrynitrogenpurgethroughtubingwhilebrazingisrequiredto

preventtheformationofcopperoxides.

EVACUATIONANDDEHYDRATION

Thesystemmustbeevacuatedpriortocharging.Properevacuationwillremovenon‐condensablegasses

andwatervaporfromthesystem.Watervaporinthesystemwillcombinewiththeoilandrefrigerantto

formacidsandotherundesirableby‐products.Non‐condensablegassessuchasairornitrogenwill

increasetheheadpressureandoperatingtemperatureanddegradesystemperformance.

Sketchapipingschematicshowingallvalvesandcomponents.Checkthediagramtoensurethatall

portionsofthesystemwillbeevacuated.Addadditionalhosesorservicefittingsasrequired.

Note:

Ahighvacuumcannotbepulledthroughasolenoidvalvewhetherornotitisenergized.

Ahighvacuumcannotbepulledthroughacheckvalveregardlessofdirectionofflow.

EvacuationProcedure:

1. Removeleak‐testinggassesfromthesystem.Ifrefrigerantwasusedtoleaktest,therefrigerant

shallberecovered.

2. Connectahighvacuumpumptothesystem.Usetheshortestandlargestdiameterhoseavailable.

3. Useasmanyconnectionsasthesystemwillallow.

4. Ifevacuatingthrough‘Schraedervalves’,removetheSchraedervalvecorebeforeevacuation.

5. Openallservicevalves.

6. Useamicrongaugetomeasurethevacuum.

Note:

Astandardrefrigerationgaugewith“inchesofmercury”isnotsuitabletomeasurethehigh

vacuums.AhighvacuumgaugecapableofmeasuringMicronsisrequired.

AAF / DCU MANUAL

IOM-52 17 of 23 Apr 13 R2

7. Tripleevacuationorhighevacuationmethodsarebothacceptable.

8. Evacuatethesystemtoanultimatevacuumof500microns(0.5mmofmercury).

9. Checkunitrating‐plateforcorrectrefrigeranttype.Breakthevacuumwithvirginrefrigerantfroma

sealedcontainer.

10. Pressurizethesystemtoaslightpositivepressure,(oneortwopsig).ReplaceallSchraedervalve

cores.Donotallowairintothesystem.

11. Reinstallgauges,proceedtothestart‐upsectionforcharginginstructions.

CAUTION:

NEVERusesystemcompressorstoevacuateasystem.Operatingacompressorwhilethe

systemisunderahighvacuummaycauseinternalarcingofthewindingsand

compressorfailure.Compressordamagecausedbyhighvacuumoperationisnot

coveredbysystemwarranty.

REFRIGERANTCHARGING

Systemchargewilldependonthelengthandorientationoftheinstalledsystem.

AninitialestimateforanACsystemchargeis1lb.(0.5kg).pertonplustheweightofliquidintheliquid

line(seeTable4Weightofrefrigerantincopperlines).Ideallychargingshouldbedoneinwarmweather.

Iftheambienttemperatureislessthandesign,restricttheairflowacrossthecondensertoincreasehead

pressureto130°F(55°C)saturateddischargetemperatureforcharging.

1. Checkthatallmanualshutoffvalvesintherefrigerationcircuitareinthenormaloperating

position.

2. Weighinaninitialchargeofapproximately75%oftheestimatedcharge.

3. Checktoensureevaporatorsectionhasproperairflow.Checkstaticpressuredropandcompare

withdesignstatic.Checkinletairtemperaturetoevaporator.Ensurethatthereissufficientloadto

operatetheairconditioning.

4. Checkthesupplyvoltageandensurethatiswithin10%ofdesignvoltageonunitratingplate.

5. Checkcontrolvoltageatrefrigerantsolenoidvalvesandensurethatitiswithin10%ofrated

voltage.

6. Setcontrolstocallforcooling.

7. Closethesystemserviceswitch.

8. Withthesaturateddischargetemperatureapproximatelyequalto130°F(55°C),[475psig(R‐410a),

325psig(R‐407C)]Thisstepmayrequireblockingcondenserairflowtoincreaseheadpressure.

Chargesystemslowlyuntilthesightglassisclear.DONOTOVERCHARGE.

9. Checkevaporatorsuperheat.

AttachanaccuratetemperaturesensortightlytothesuctionlineattheTXbulb.Measurethe

suctionpressureatthecondensingunit.Add2psigtothispressureandconvertittothesaturated

suctiontemperatureusingtheappropriatepressuretemperaturetable.Subtractthesaturated

temperaturefromthetemperaturemeasuredattheTXbulb.Thisisthesuctionsuperheat.

Superheatshouldbebetween8°Fto14°F(5°to8°C)whenthesystemisoperatingatfullloadwith

aclearsight‐glass.

AAF / DCU MANUAL

IOM-52 18 of 23 Apr 13 R2

10. Setupthehotgasbypassvalve(optional).Usingapressure‐temperaturechartfindtherefrigerant

pressurethatcorrespondstoatemperatureof34°F(1°C).

Createalowloadconditionontheevaporatorbyrestrictingtheairflowacrosstheevaporator.

Adjustthehotgasbypassregulatorsothatitwillstarttoopenatthepressurecorrespondingto

34°F(1°C).IfthehotgassystemisequippedwithadesuperheatingTXvalve,measurethe

superheatatthecompressorandensurethevalveisworking.

11. CheckthesettingsoftheCondenserFanCyclingControls(CFC’s),adjustasrequired.

FLUSHINGANDDEGREASINGOFWATERANDGLYCOLCOILS

Coiltubingmaycontainmaterialorresiduefrommanufacturing,transportationorstorage.Toprevent

possibledamagetoothercomponentsinthesystem,thecoilsmustbeflushedanddegreased.Consulta

qualifiedwatertreatmentspecialist.

HEATTRANSFERFLUIDS

Thecoil(s)providedhavebeenselectedforusewithaspecificheattransferfluidasshownonthe

SubmittalRecord.Useofotherfluidswillresultindifferentperformanceandcandamagethecoil(s).

Itisimperativetoproperlyselectandapplyheattransferfluidsusedinheatingandcoolingsystems.

Untreated,improperlytreatedorimproperuseoffluidsoruseoffluidsnotapprovedforusein

commercialheatingandcoolingsystemscandamagecoilsandsystemcomponents.Forselectionand

applicationofheattransferfluids,alwaysfollowthemanufacturers’recommendationsincluding

treatment,mixingandfilling.Warrantywillbevoidifcoildamageresultsfrommisapplicationorimproper

treatmentoftheheattransferfluid.

SHUTDOWNPROCEDURE

Warning:

Electricalshockordeathcanoccurifinstructionsarenotfollowed.Thisequipment

containsmovingpartsthatcanstartunexpectedly.Injuryordeathcouldoccurif

instructionsarenotfollowed.Allworkshouldbeperformedbyaqualifiedtechnician.

Alwaysdisconnectpowerbeforeservicing.DONOTbypassanyinterlockorsafetyswitches

underanycircumstances.

1. Shutdown

Toshuttheunitdownforashorttime(suchasforinspectionorservice).Shutoftheserviceswitch

inthemaincontrolpanelthenturnoffthemaindisconnect.

2. Re‐StartafterShutdown

Turnonmaindisconnectfortheunit.Turnontheserviceswitchinthemainelectricalcontrol

panel.

AAF / DCU MANUAL

IOM-52 19 of 23 Apr 13 R2

MAINTENANCE

Warning: Thisunitisconnectedtohighvoltages.Electricalshockordeathcouldoccurif

instructionsarenotfollowed.Thisequipmentcontainsmovingpartsthatcanstart

unexpectedly.Injuryordeathcouldoccurifinstructionsarenotfollowed.Allwork

shouldbeperformedbyaqualifiedtechnician.Alwaysdisconnectandlockoutpower

beforeservicing.DONOTbypassanyinterlockorsafetyswitchesunderany

circumstances.

Toprovideamaintenancehistory,Itisrecommendedthattheownerhaveamaintenancefileforeach

unit.Thefollowingmaintenanceinstructionsaretobecarriedouteachspringandfallorasotherwise

indicatedbyqualifiedservicepersonnel.

Caution:

Labelallwirespriortoremovalwhenservicingcontrolsorcriticalcomponents.Wiring

errorscancauseimproperanddangerousoperation.

Verifyproperoperationafterservicing.

HERESITE®MAINTENANCE

Heresite®isabakedonphenoliccoatingusedtoprotectmetalsfromsomeformsofchemicalcorrosion.

Atthetimeofpurchasenewcoilscan,asanoption,haveHeresite®appliedatthefactory.

IfyouhaveaHeresite®coatedcoil:

Inspectonceperyearormoreoftenasrequired.

Cleanwithlowpressureairandvacuumwithasoftbrush.

Lowpressure,chemicalfreewatermaybeused.

RepairInstructions(usingair‐driedHeresite®touch‐upspray):

1) Ensuresurfacesarecompletelydry.

2) Useanylonbrushtoremoveanyloosescale.

3) Roughenupareastoberepairedwithawirebrush.

4) Vacuumfinsortheaffectedareatoensureanylooseresidueisgone.

5) SprayorbrushS‐440solvent*(oranyequivalentcleaner)todissolveanyoilsorgrease.

6) Again,vacuumtheaffectedarea.

7) Allowonehourforthesolventtodissolvecompletely.

8) Coverareasnotrequiringrepairwithplastic(orequivalent)andmaskingtape.

9) UsingHeresite®VR‐554‐T*coatingsprayallaffectedareasfromdifferentanglestoensure

completecoverage.Apply2‐3fullcoats.Letdry3to4hoursbetweencoats.

10) AllowHeresite®tocure24hoursbeforeputtingequipmentbackintoservice.

*ReviewtheMSDSdocumentationincludedwiththesolventandcoatingspray.

AAF / DCU MANUAL

IOM-52 20 of 23 Apr 13 R2

ELECTRICAL

Checkallwiringforlooseconnections.

Checkvoltageatunit(whileinoperation).

Checkamperagedrawagainstunitratingplate.

Wherepossible,allcontactorsshouldbeinspectedtoensurethatcontactsarecleanandare

makinggoodcontact.Ifcontactsareabnormallypittedorburnedbadly,replacecontactor.Single

phasingandmotorburnoutscanresultfrombadcontacts.

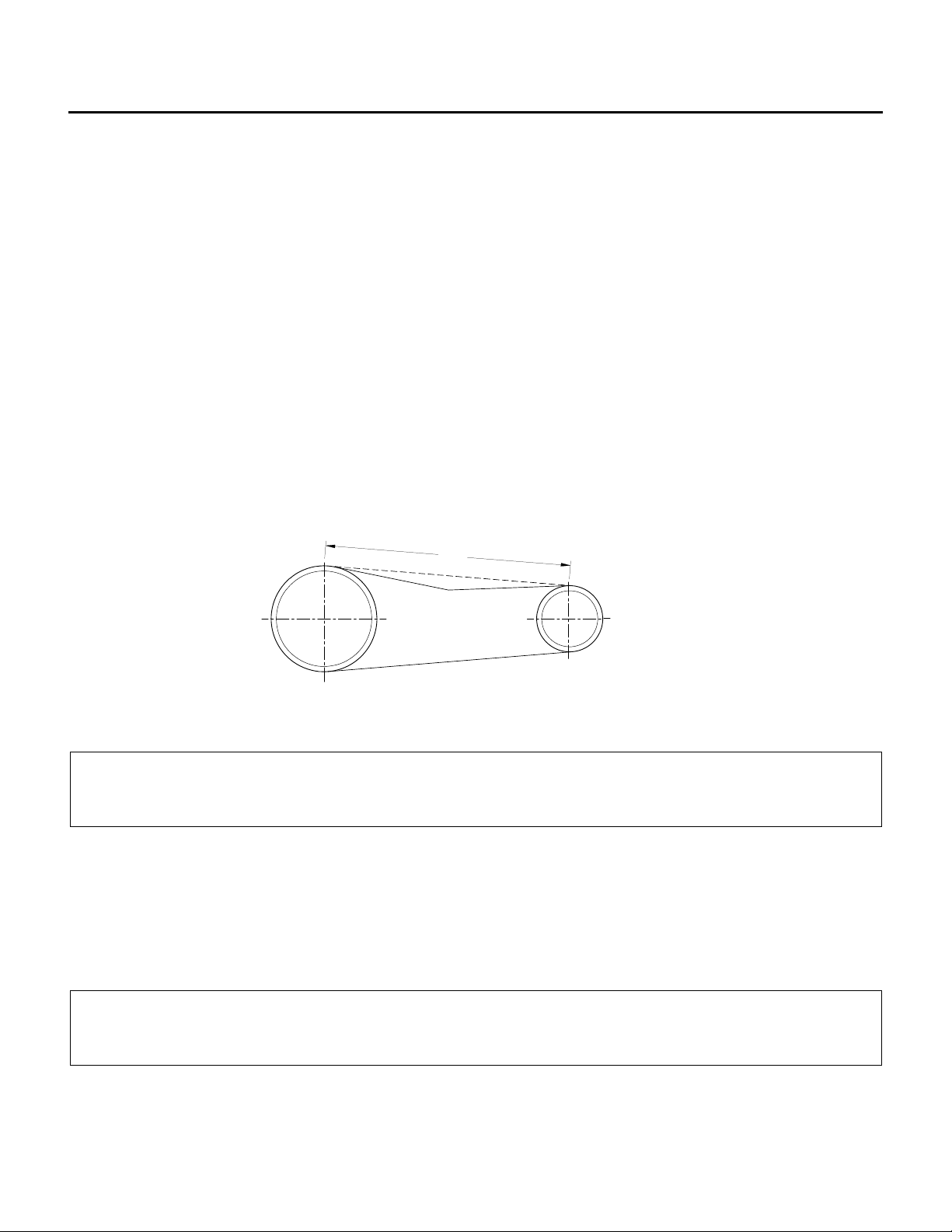

BELTADJUSTMENT

Formaximumbeltandbearinglife,pulleyalignmentandbelttensionmustbeproperlymaintained.Only

replacewithbeltsofthepropertypeandsize.

NOTE:Ifbeltsaretootightorimproperlyaligned,thelifeexpectancyofthemotor(s),fanbearingsand

belt(s)arereduced.

Alignment: Pulleysmustbealignedtowithin1/16”perfoot(1mmper760mm)ofspan.

BeltDeflection: Allow1/64”(0.4mm)ofdeflectionforeach1”(25.4mm)ofspanlength.

CAUTION:

Excessivebelttensionisthemostfrequentcauseofbeltwear,bearingwearandnoise.

SETSCREWS

Checksetscrewsonfanwheel,fanbearings,fanandmotorpulleysforloosenessontheshaft.Tighten

whererequired.Itisimportanttoperformthischeckbeforeinitialstart‐up,afterarun‐inperiodof2

weeksandthenon4monthintervals.

CAUTION:

Overtighteningsetscrewscandamagebearings.

DEFLECTION

SPAN

This manual suits for next models

1

Table of contents

Popular Accessories manuals by other brands

IFM

IFM PI2798 operating instructions

Panamax

Panamax MIW-POWER installation instructions

weinor

weinor Aruba Rund Maintenance instructions and directions for use

Enabling Technologies

Enabling Technologies DYNAMIQUE owner's manual

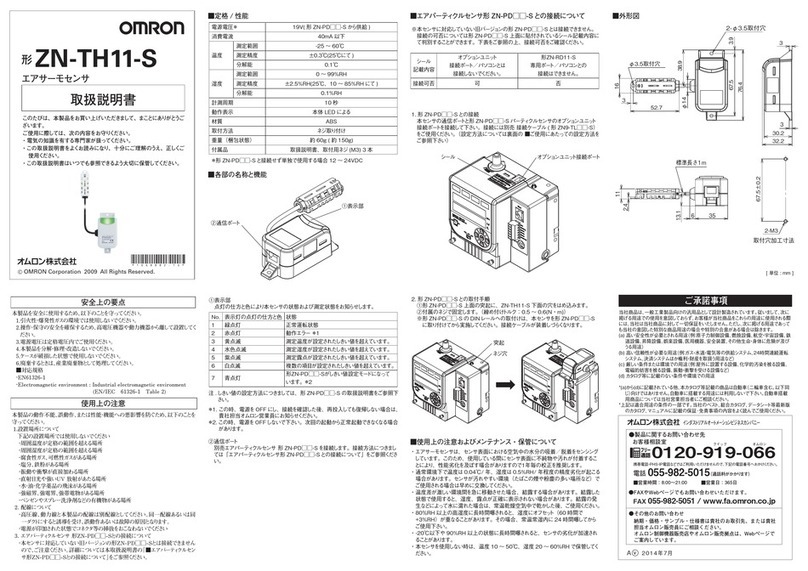

Omron

Omron ZN-TH11-S instruction sheet

Axminster

Axminster Woodturning D-SW Series manual