2

Contents

1 Preliminary note���������������������������������������������������������������������������������������������������4

1�1 Symbols used ������������������������������������������������������������������������������������������������4

2 Safety instructions �����������������������������������������������������������������������������������������������4

3 Functions and features ����������������������������������������������������������������������������������������5

3�1 Applications ���������������������������������������������������������������������������������������������������5

4 Function���������������������������������������������������������������������������������������������������������������5

4�1 Operating modes �������������������������������������������������������������������������������������������6

4�1�1 2-wire operation������������������������������������������������������������������������������������6

4�1�2 3-wire operation������������������������������������������������������������������������������������6

4�2 Switching function (only for 3-wire operation)������������������������������������������������6

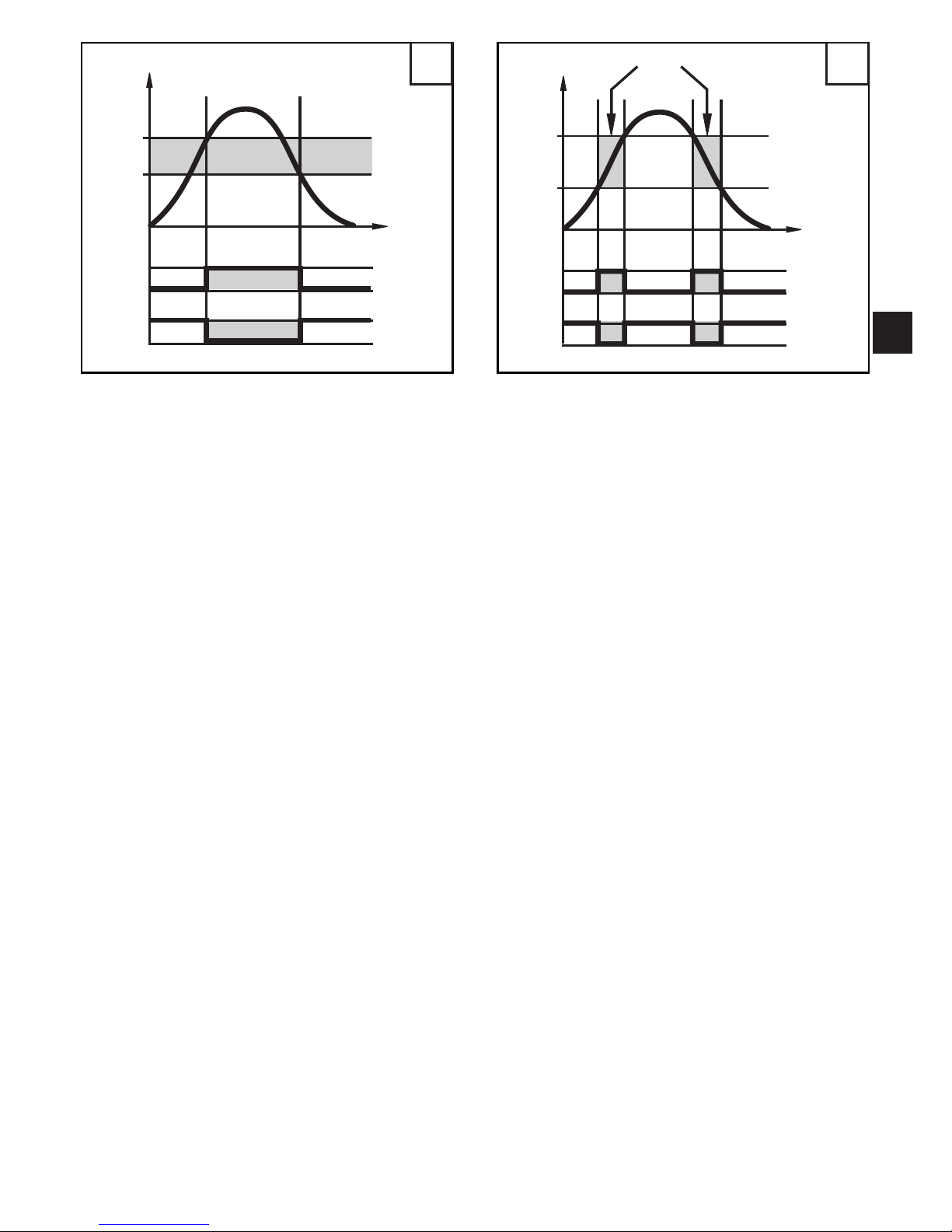

4�3 Analogue function ������������������������������������������������������������������������������������������7

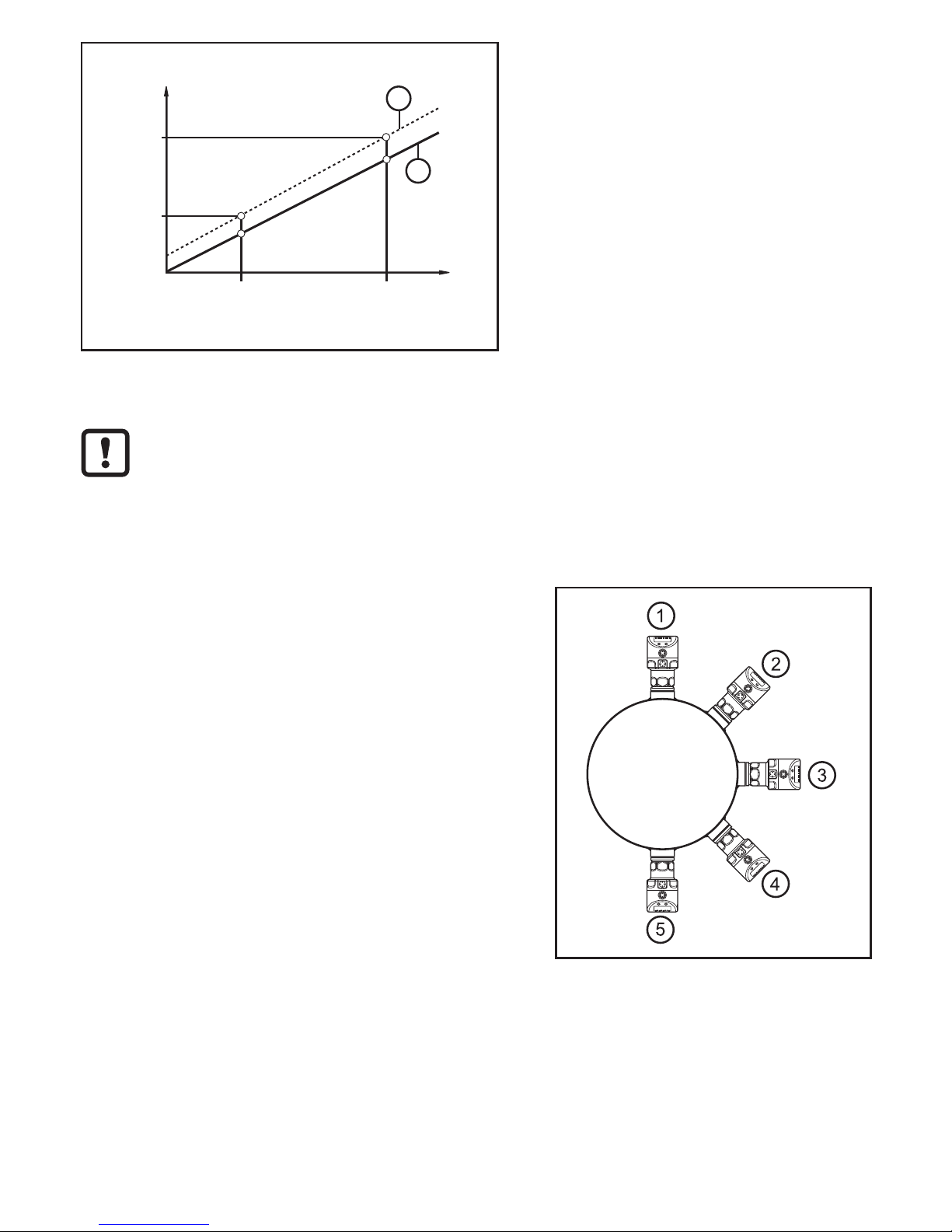

4�4 Customer-specific calibration ������������������������������������������������������������������������9

5 Installation����������������������������������������������������������������������������������������������������������10

6 Electrical connection������������������������������������������������������������������������������������������ 11

6�1 Connection for 2-wire operation ������������������������������������������������������������������ 11

6�2 Connection for IO-Link parameter setting����������������������������������������������������12

6�3 Connection for 3-wire operation ������������������������������������������������������������������12

7 Operating and display elements ������������������������������������������������������������������������13

8 Menu������������������������������������������������������������������������������������������������������������������14

8�1 Menu structure: main menu�������������������������������������������������������������������������14

8�2 Explanation of the main menu ���������������������������������������������������������������������15

8�3 Menu structure: level 2 (extended functions)�����������������������������������������������16

8�4 Explanation of the menu level 2 ������������������������������������������������������������������17

8�5 Menu structure: level 3 (simulation)�������������������������������������������������������������18

8�6 Explanation of the menu level 3 ������������������������������������������������������������������19

9 Parameter setting ����������������������������������������������������������������������������������������������20

9�1 General parameter setting���������������������������������������������������������������������������20

9�2 Configure display (optional)�������������������������������������������������������������������������22

9�3 Set output signals ����������������������������������������������������������������������������������������22

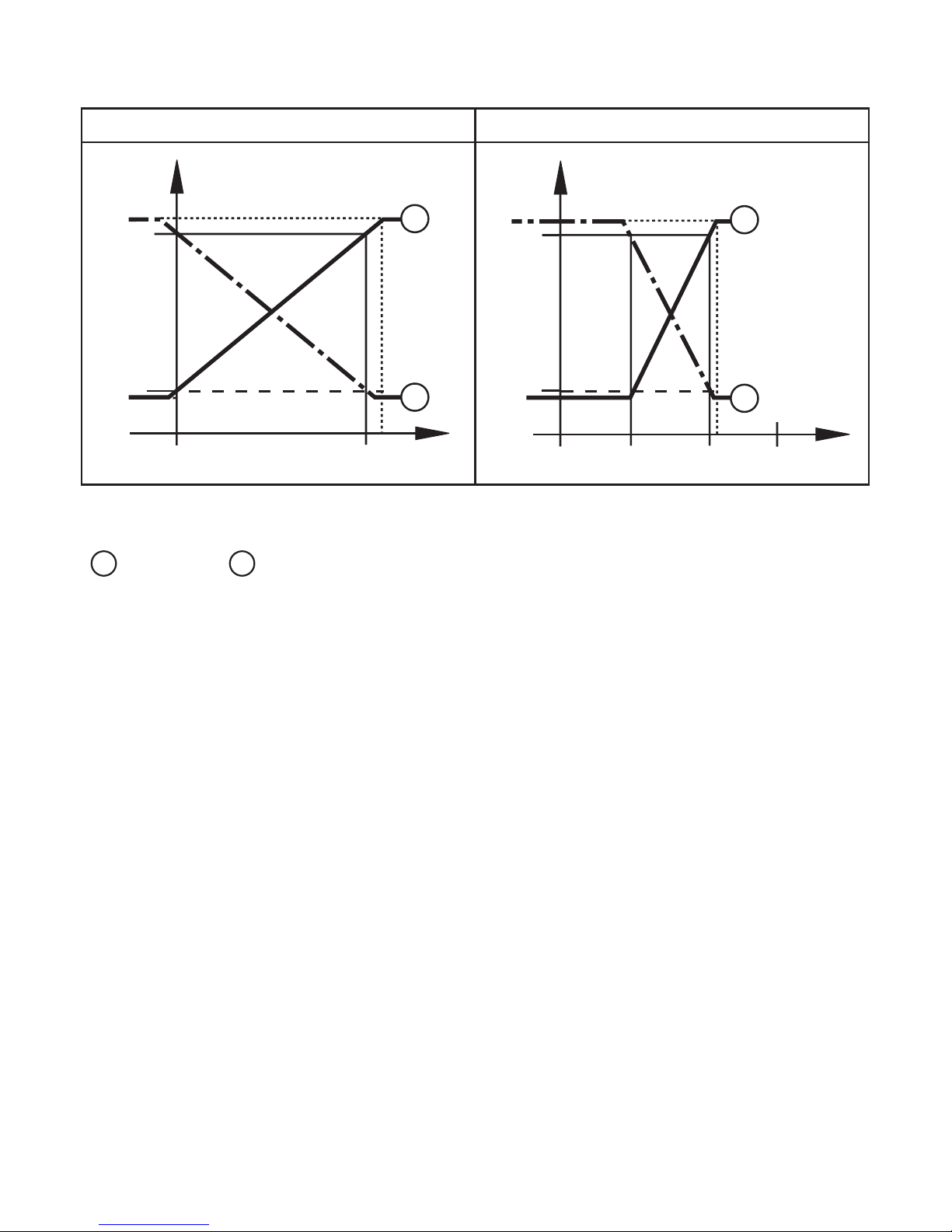

9�3�1 Set output functions����������������������������������������������������������������������������22

9�3�2 Set switching limits ����������������������������������������������������������������������������23

9�3�3 Scale analogue value for OUT2 ���������������������������������������������������������23

9�4 User settings (optional)��������������������������������������������������������������������������������24

9�4�1 Carry out zero point calibration ����������������������������������������������������������24