ALF-14020-E-02 All-Flo4

SECTION 2

PRINCIPLES OF OPERATION

The 72000-00 controller is engineered to provide control of the number

of times a solenoid pump fully discharges both liquid chambers, referred

to as a “cycle”, in a batching application. It also controls the speed that

the pump cycles, how many “Batches” are in an operation, and the

interval of time between batches. This allows for greater control and

repeatability of your All-Flo pump. The pump speed can be adjusted

using the buttons on the controller’s keyboard and preset batch

operations can be made to ensure a quick set up.

72000-00 BATCH CONTROLLER

All-Flo’s solenoid pumps use the compressed air to displace fluid in the

same way as a standard Air Operated Double Diaphragm (AODD) pump

while using electric pulses to control the pump speed. The use of a

solenoid pump allows the user to have more control over the operation.

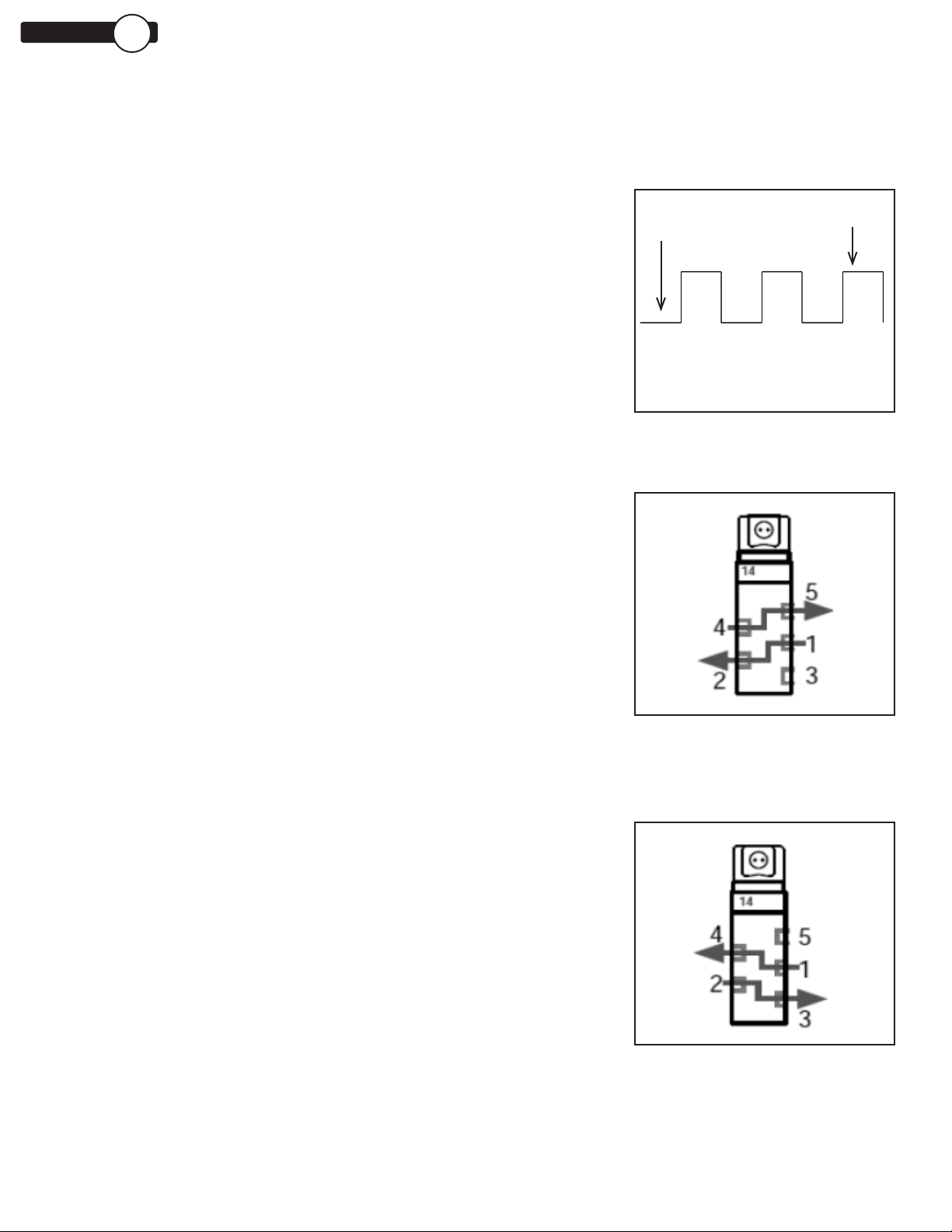

The solenoid pump uses an electrical pulse to energize the solenoid

valve attached to the air end of the pump. These electronic pulses are

sent in the form of a square wave (Figure 1).

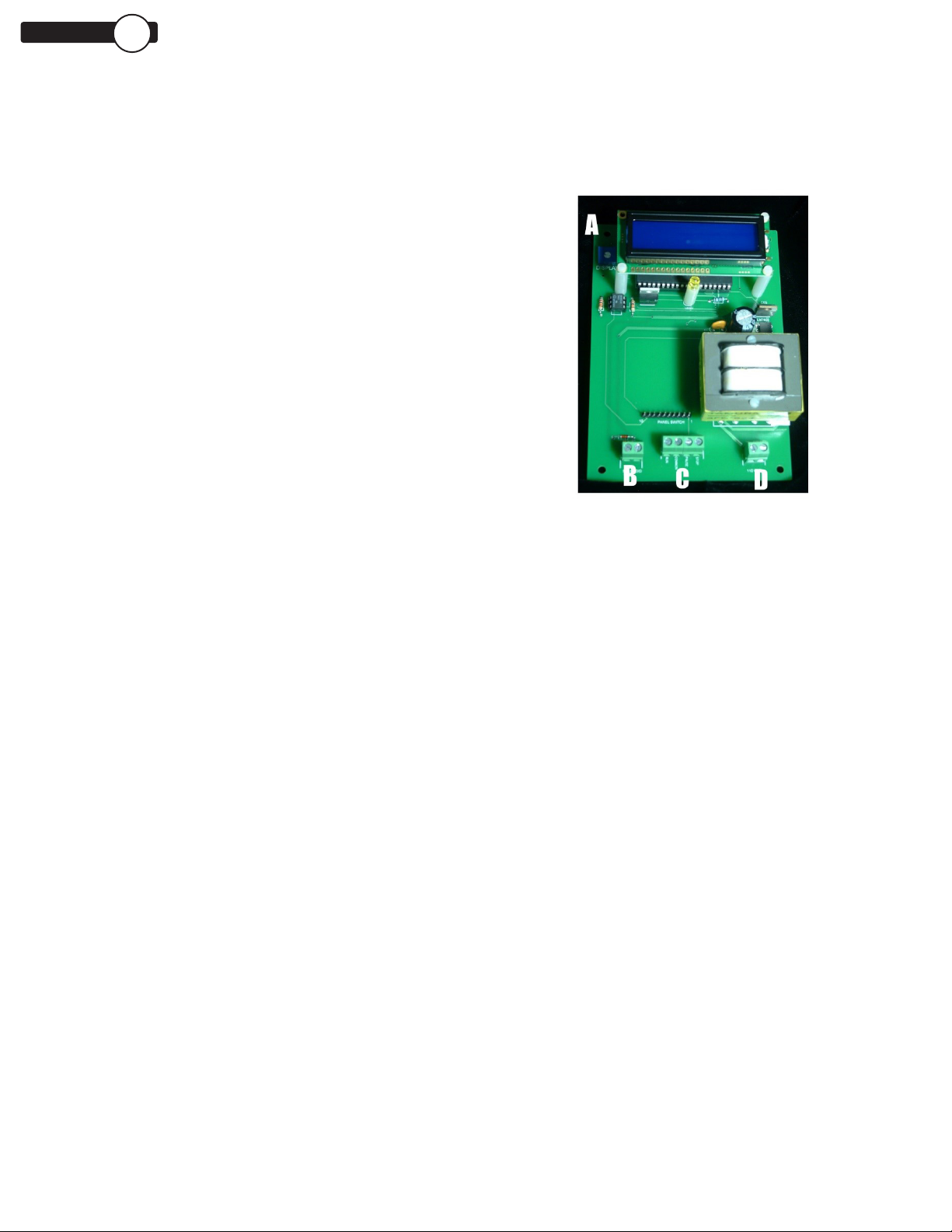

The energized pulses move the solenoid valve connecting the different

ports changing how the air flows. In Figures 2 and 3, port 1 denotes the

connection to the air supply, ports 2 and 4 denote the ports leading the

air chambers, and ports 3 and 5 denote the ports that are open to the

atmosphere.

While the solenoid is de-energized, the valve sits at its standard position,

allowing pressurized air from the air supply (port 1) into one of the

air chambers of the pump (port 2). The other air chamber (port 4) is

connected the exhaust (port 5), discharging any pressurized air in that

chamber.

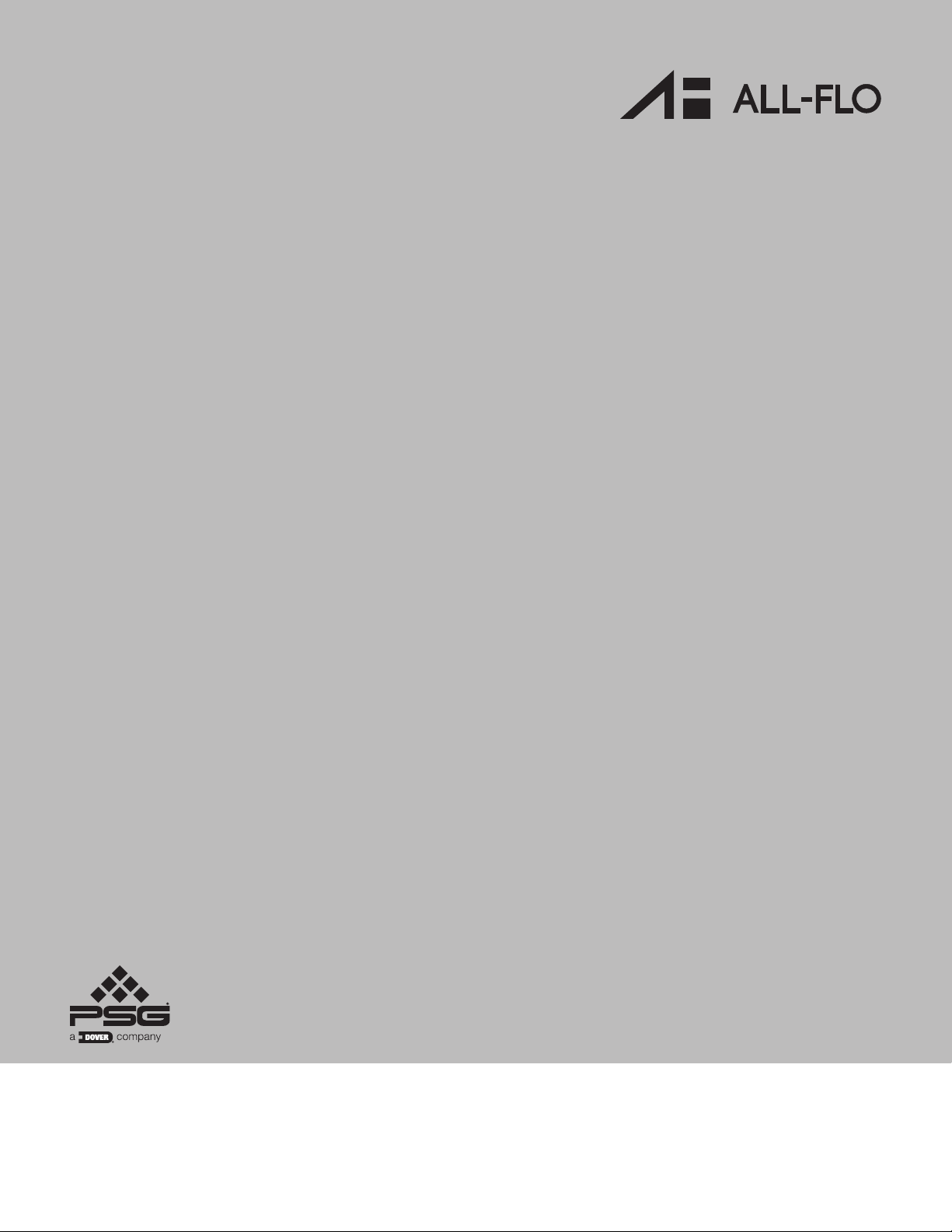

When the pulse is received, the solenoid energizes and moves the valve

to its energized position (Figure 3).

While the solenoid is energized, the pressurized air from the air supply

(port 1) flows into the air chamber of the pump (port 4). The other air

chamber (port 2) is connected the exhaust (port 3), discharging any

pressurized air in that chamber.

This pulsating energized and de-energized states mimics the air flow

cycle cause by the pilot sleeve in the standard pump. The faster these

pulses are applied, the quicker the pump operates.

ALL-FLO’S SOLENOID CONTROLLED PUMPS

FIGURE 3

ENERGIZED

SOLENOID POSITION

FIGURE 2

DE-ENERGIZED

SOLENOID POSITION

FIGURE 1

SQUARE WAVE

Energized

De-energized