SPINEA DRIVESPIN Series User manual

OPERATION MANUAL FOR

ELECTRIC ACTUATORS DRIVESPIN®

2

Table of contents

1

General Instructions................................................................................................................................4

1.1

Documentation use.........................................................................................................................4

1.2

Structure of safety symbols.............................................................................................................4

1.2.1 Interpretation of graphical symbols and marks in the document......................................................4

1.2.2 Safety symbols....................................................................................................................................5

1.2.3 Structure of inserted safety instructions............................................................................................5

1.3

Claims resulting from defects and warranty...................................................................................6

1.4

Exclusion of liability for damage......................................................................................................6

1.5

Copyrights........................................................................................................................................6

2

Safety instructions...................................................................................................................................7

2.1

Introductory notes...........................................................................................................................7

2.1.1 Burning hazard ...................................................................................................................................7

2.1.2 Electric shock hazard..........................................................................................................................7

2.1.3 Danger of being pulled in ...................................................................................................................8

2.1.4 Environmental contamination hazard................................................................................................8

2.1.5 Mechanical damage hazard................................................................................................................8

2.1.6 Threatening injury by fall or movement at vertical or horizontal load..............................................8

2.1.7 Health damage hazard for persons with built-in cardio stimulator...................................................9

2.2

Transport and principles of correct and safe storage .....................................................................9

2.2.1 Packing specification ........................................................................................................................10

2.3

Handling ........................................................................................................................................10

2.4

Storage ..........................................................................................................................................10

2.5

Compliance with legislation requirements ...................................................................................11

2.6

Installation and assembly..............................................................................................................11

2.7

Commissioning ..............................................................................................................................11

3

Product characteristics..........................................................................................................................12

3.1

Production label ............................................................................................................................14

3.2

Identification label of electric actuator DS, DSH, DSM, DSF for size 050......................................14

3.3

Identification label of other electric actuators DriveSpin®...........................................................14

4

Electric actuators dimensions ...............................................................................................................15

5

Installation and Operation.....................................................................................................................16

5.1

Mechanical installation .................................................................................................................16

5.1.1 Before you begin ..............................................................................................................................16

5.1.2 Centering of electric actuator DriveSpin®........................................................................................16

5.1.3 Output flange face and circumferential jerking values....................................................................16

5.1.4 Installation of components on electric actuator output flange.......................................................17

5.2

Electric wiring................................................................................................................................17

5.2.1 Instructions for connection..............................................................................................................18

3

5.2.2 Protection against overloading ........................................................................................................19

5.2.3 Commissioning .................................................................................................................................19

6

Maintenance and disposal ....................................................................................................................21

6.1

Maintenance .................................................................................................................................22

6.1.1 Visual check......................................................................................................................................22

6.1.2 Cleaning............................................................................................................................................22

6.1.3 Maintenance schedule .....................................................................................................................22

6.1.4 Lubricant exchange ..........................................................................................................................22

6.1.5 Disposal ............................................................................................................................................23

7

Malfunction during operation...............................................................................................................24

8

Technical parameters of electric actuators DriveSpin® ........................................................................26

Surface treatment, corrosion resistance...................................................................................................26

8.1

Specification of sensors for electric actuators DriveSpin®............................................................26

8.2

Type of connection and wiring diagram of electric actuator........................................................26

8.3

Moments of inertia and weight of electric actuator.....................................................................26

8.4

Performance characteristics..........................................................................................................26

8.5

Technical specification of temperature sensors ...........................................................................27

8.5.1 Temperature sensor PTC 111-K13....................................................................................................27

8.5.2 Temperature sensor PT 1000 ...........................................................................................................28

9

Certificates, regulations and directives.................................................................................................30

4

1

General Instructions

▪Information and instructions contained in this document apply to DriveSpin® electric actuators. The

user of the electric actuator is fully responsible for their correct use. Any other information,

recommendations and procedures not listed in this manual must be consulted and confirmed in

advance by the equipment manufacturer SPINEA, s.r.o. (in the following SPINEA), otherwise company

SPINEA bears any liability for the consequences of their application. SPINEA is notlegallyliable for errors

and modification of the documentation taken over from the manufacturers of electric actuator

components.

▪SPINEA reserves the right to modify this document without notice.

1.1

Documentation use

▪The documentation is part of the product and contains important information on basic safety rules

and principles for handling, operation, assembly, testing, maintenance, packaging and transport of

DriveSpin® electric actuators.

▪The documentation must be available to a user in a properly legible condition. Make sure that the

persons responsible for the equipment and its operation, and persons working with the equipment

have read and understood the entire documentation. In case of any ambiguity or the need for further

information, please contact SPINEA.

▪The original operating instructions were prepared in the Slovak language; other language versions

represent a translation thereof. In case of any inaccuracies or ambiguities in the translated document,

please contact SPINEA.

1.2

Structure of safety symbols

1.2.1 Interpretation of graphical symbols and marks in the document

▪Be sure to observe the safety instructions and warnings in this manual!

▪The following information illustrates the meaning of safety symbols and instructions to alert you to

personal injury and property damage.

DANGER!

Immediate danger with potential of serious injury or fatality!

WARNING!

Potential occurrence of dangerous situation that could cause serious injury or fatality!

CAUTION!

Information indicating threat of property damage!

5

1.2.2 Safety symbols

General danger

Potential of environmental threat

Dangerously hot surface

Danger of drag-in

Magnetic field effects

Risk electric shock

Risk of mechanical damage

Risk of injury –falling or movement at vertical/ horizontal load

1.2.3 Structure of inserted safety instructions

▪The inserted safety instructions are given directly in the document before the potentially dangerous

action in the following form:

DANGER!

•Type and source of danger!

•Possible consequences in case of ignored danger

- Measure to avoid risk

6

1.3

Claims resulting from defects and warranty

▪Unconditional and complete compliance with the instructions stated herein is a precondition for the

trouble-free equipment operation and a fundamental legal precondition for the assertion of any

potential claims arising from defects or from the warranty. SPINEA shall not be legally liable for the

equipment defects that have occurred, in whole or in part, as a result of a breach or non-compliance

with the instructions given in this manual.

▪Please read the documentation before you start working with the equipment.

1.4

Exclusion of liability for damage

▪Unconditional and complete compliance with the instructions stated herein is a precondition of safe

operation of DriveSpin® electric actuators and for achieving the required properties and performance

parameters of the equipment. SPINEA shall not be legally liable for damages to the health and life of

persons, material and other damages that have occurred, in whole or in part, as a result of a breach or

non-compliance with the instructions given in this manual.

1.5

Copyrights

▪SPINEA an author of this document, reserves all copyrights to this document and its parts. Any

reproduction, publication, modification, alteration, distribution, in whole or in part, or any other

infringement of copyright is prohibited.

7

2

Safety instructions

2.1

Introductory notes

▪This operating manual contains, in particular, the safety instructions, rules, and procedures to prevent

injuries and damages caused by improper handling, handling, use, and transport. Persons responsible

for the equipment and its operation, and persons working with the equipment must observe all safety

instructions stated in this document.

▪Please follow the safety instructions stated in particular document chapters! Take into account the

contents of respective documents and follow the stated instructions bellow:

oRead the operating instructions and diagrams supplied with equipment as accessories,

oobserve the warning and safety labels on the electric actuator,

oobserve the provisions, regulations and requirements specific to the particular equipment.

2.1.1 Burning hazard

WARNING!

•Potential high surface temperature of the electric actuator during its

operation in compliance with intended use.

•Risk of burns upon contact with surface!

- Don´t touch the electric actuator during operation and after switch-off

during cooling stage.

2.1.2 Electric shock hazard

DANGER!

•Incorrect connection method or contact with parts under voltage of the

device can result in damage to the device, serious injury or dead.

- The connection of the electric actuator may only be carried out by a

qualified person.

DANGER!

•Electric shock hazard

- Before removing any connector (power or signal connector), all circuits

must be disconnected from the power supply of the individual circuits.

8

2.1.3 Danger of being pulled in

WARNING!

•Rotating components of electric actuator connected to the device can lead

to the danger of being pulled in.

-Stay in safe distance from the rotating machine parts.

-Secure the machine against unintentional switch-on and movement during

assembly and maintenance.

2.1.4 Environmental contamination hazard

CAUTION!

•Solvents and lubricants can contaminate soil and water!

- Avoid dispersal of spilled material and runoff and contact with soil, water

flows, drains and sewers. Dispose of leaked medium in cooperation with a

professional waste disposal company.

2.1.5 Mechanical damage hazard

WARNING!

•Mechanical damage hazard

- Do not use brute force or blows when assembling or disassembling the electric

actuator. There may be irreversible damage to the device and a dangerous

situation or. material damage.

2.1.6 Threatening injury by fall or movement at vertical or horizontal load

WARNING!

DANGER!

•The electromagnetic brakes installed in the electric actuator are not

designed for the emergency stop of electric actuator!

•The use of integrated electromagnetic brake for emergency stopping of

the electric actuator poses a risk of hazardous situation or injury!

-Electromagnetic brake installed in the electric actuator is designed as a

parking brake.

-To achieve an emergency braking torque with a vertical or horizontal load,

an additional external brake with sufficient braking power must be installed.

9

2.1.7 Health damage hazard for persons with built-in cardio stimulator

WARNING!

•Permanent magnets of the rotor emanate strong magnetic field and

related ferromagnetic forces are present even after the electric actuator

switch off. These forces could pose a risk of direct damage of health,

especially for people with built- in cardio stimulator (pacemaker).

- People with built- in cardio stimulator should not perform maintenance, nor

work with and operate the electric actuators.

▪In case of any ambiguities or the need for further information, please contact company SPINEA, s.r.o.

2.2

Transport and principles of correct and safe storage

▪Transport and principles of correct and safe storage are defined in the General Terms of Actuators

Packaging and Storage, available at: https://www.spinea.com/en/downloads

▪General Terms of Actuators Packaging and Storage (hereinafter “VPBSA”) set forth the terms of

packaging, transport and storage of electric actuators DriveSpin®. VPBSA are binding for all electric

actuators´ customers and represent an integral part of every contractual document, the subject of

which is the supply of electric actuators. Failure to comply with the conditions set out in the VPBSA is

a reason for rejecting a claim for defects in the supplied electric actuators.

▪Check the supply immediately upon the receipt. Make sure that the supply has not been damaged

during transport. Notify the carrier company immediately upon identification of eventual damage.

WARNING!

DANGER!

•Damaged shipment must not be put into operation! It poses a risk of

hazardous situation in the terms of injury and material damages!

- Check the supply immediately upon the delivery. In case of identified

damage, immediately notify the carrier!

▪We recommend using the system FIFO (First in –First out) for the warehouse logistics.

▪Except otherwise agreed, the standard packaging is not waterproof sealed. It is intended for transport

by land, not by sea in an enclosed dry and not humid space.

CAUTION!

•When taking over the electric actuator, check the product properties for

compliance with the requirements agreed during the purchasing stage,

and for eventual damages or defects.

- Notify the vendor SPINEA, s.r.o. on eventual defects.

▪Dispose the packaging material in compliance with applicable regulations!

10

2.2.1 Packing specification

▪One-piece electric actuator packing consists of the following parts:

oOuter packing –cardboard box is made of ecological material and is recyclable (size according

to the type size of the electric actuator)

oInner packing (LDPE sack, ductile stretch foil protecting the conserved functional surfaces)

oFixating material –PUR foam/stretch foil/paper

oTest report

oIdentification label (located on the outer packing side).

2.3

Handling

▪When moving the packaged units, follow general OSH principles applicable to handling with loads, as

well as instructions stated on the packing. Since the weight and dimensions don´t always allow manual

handling, use special handling devices to prevent injuries and material damages. Workers assigned

with handling with equipment shall be properly trained and skilled so that they don´t endanger their

own safety or that of others present at work.

▪Workers in charge of relocating equipment must take all necessary measures to ensure their own

safety as well as the safety of other persons involved.

CAUTION!

•Checktheelectricactuatorweightanddimensions.

-Choose a proper method of handling in compliance with the principles of

ergonomics, based on the equipment weight and dimensions.

-Wear all prescribed PPE when handling.

2.4

Storage

Follow the General Terms of Actuators Packaging and Storage.

CAUTION!

•SAFETY MEASURES applicable to electric actuator restoration to original

condition after the storage period!

-Follow instructions stated in the General Terms of Actuators Packaging

and Storage available at: www.spinea.com.

-Perform these operations in an environment where there is no risk of

explosion. The solvent must not come into contact with the sealing rings

in order not to damage the material from which they are made and thus

to impair their functionality! When period of storage exceeds 1 year,

lubricant durability in the bearing units might be shorter than usual.

11

2.5

Compliance with legislation requirements

▪Electric actuator has been constructed in compliance with the EU Parliament and EU Council

Directive No. 2014/35/EU, dated Feb 26, 2014 on Harmonization of EU Member Countries´ Legal

Regulations on Accessibility on the Market of Electric Equipment Intended for Use Within Certain

Voltage Limits, and requirements of technical standard EN 60204-1:2006/A1:2009/Corr. Feb.:2010 or.

EN 60204-1:2018 respectively.

▪Electric actuator has been constructed in compliance with the EU Parliament and EU Council Directive

No. 2014/30/EU, dated Feb 26, 2014 on Harmonization of EU Member Countries´ Legal Regulations on

Electromagnetic Compatibility, and requirements of technical standard EN 61000-6-

2:2005/Corr.Sept.:2005,EN 61000-6-3:2007/A1:2011/ AC:2012 resp. EN IEC 61000-6-4:2019.

▪Electric actuator has been constructed in compliance with the EU Parliament and EU Council Directive

No. 2006/42/EC, dated May 17, 2006 on Machine Equipment as amended in the Directive No.

95/16/EC, and requirements of technical standard EN ISO 12100.

2.6

Installation and assembly

▪See chapter No. 5.

2.7

Commissioning

▪See clause 5.2.3, chapter No. 5.

12

3

Product characteristics

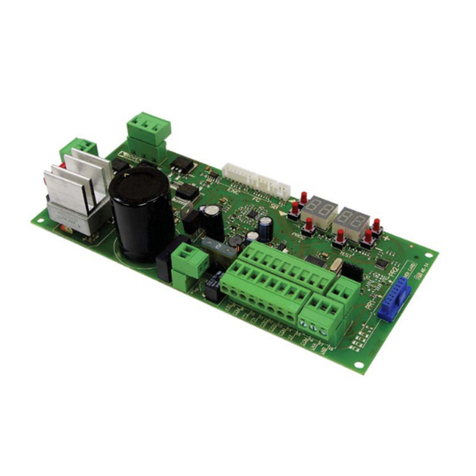

▪Electric actuator DriveSpin® represents a combination of high precision bearing reduction gear

TwinSpin® with implemented axial – radial bearing with high loading ability by tilting momentum at

the output, optimized servomotor (permanent magnet synchronous motor), motor feedback position

sensor, and brake option –see the figure No. 1. High tilting loading ability of the output bearing allows

the electric actuator loading within the bearing limits without the need of additional installation of a

supporting bearing. In order to meet all customer requirements, electric actuators DriveSpin® offer a

broad range of standard combinations of windings, various types of electric connections, and motor

system feedback position sensors, as well as optional integration of the brake and other specific

requirements.

▪Electric actuator DriveSpin® represents a combination of high precision bearing reduction gear

TwinSpin® and a servomotor; i.e., a combination of machinery and electrical equipment.

Figure1 Axial breakdown of electric actuator DriveSpin®

Position sensor

Bearing reduction gear

TwinSpin®

Housing

Brake

Connectors

Servomotor

13

Utilization of electric actuators in the following areas requires risk assessment and

approval by company SPINEA:

oEnvironment with increased explosion risk,

oEquipment specially constructed for the use in nuclear power plants or premises with

increased radiation,

oVacuum,

oHousehold appliances,

oMedical equipment,

oEquipment intended for direct contact with human body,

oEquipment intended for space applications and aviation industry,

oDefense industry,

oEquipment intended for marine applications,

oEquipment intended for food processing industry.

▪Operating manual applicable to electric actuators DriveSpin® contains important information on the

equipment operation, maintenance and servicing. This part of the manual is intended primarily for

persons performing equipment maintenance, commissioning, and servicing.

▪Before starting the work and using the electric actuators DriveSpin® the manufacturer recommends

becoming familiar with the below stated documents (if available):

oThe latest catalogue DriveSpin® available for downloading on the website: www.spinea.com,

oOperating Manual –Electric Actuators DriveSpin® (this manual),

oTesting protocol / test report (an integral part of the electric actuator DriveSpin® supply),

oInstallation and User Manual –Digital Servo- Amplifier,

oUser Manual of digital servo amplifier commissioning and setup SW, supplied by the amplifier

manufacturer,

oInstallation and User Manual for Extension Cards, supplied by the amplifier manufacturer,

oUser and Setup Manual for further accessories.

14

⑪⑩⑨

3.1

Production label

Manufacturer´s product label is attached on a visible place on the DriveSpin® electric actuator

body. Another identification label is located on the outer package side (one- piece packing).

Type designation represents also an ordering code for particular DriveSpin® electric actuator

specification, it is described in detail in the DriveSpin® catalogue or on the websites

http://www.spinea.com.

3.2

Identification label of electric actuator DS, DSH, DSM, DSF for size 050

3.3

Identification label of other electric actuators DriveSpin®

①⑤

②⑥

③⑦

④⑧

where:

1. Type ordering code

2. SN Serial number of electric actuator DriveSpin®

3. Art.No Article number

4. C.No Customer number

5. 11/17 Week /year of electric actuator manufacturing

6. IP Electric actuator coverage

7. IsoKl. Motor isolation class

8. In: Rated motor current

9. Mo Rated stall torque

10. nn Rated motor speed

11. UDC DC bus voltage

15

4

Electric actuators dimensions

▪Dimensions of electric actuators are stated in the DriveSpin® electric actuators catalogue, section

Drawings, or in actual offer documentation.

16

5

Installation and Operation

5.1

Mechanical installation

During installation follow the safety instructions stated in chapter 2.

5.1.1 Before you begin

▪Before beginning with mechanical installation, we recommend checking the following:

oData on the electric actuator identification label, data and parameters stated in the test report

and parameters of digital servo- amplifier (especially output voltage of the servo- amplifier

and its DC bus should correspond to the parameters of electric actuator).

oElectric actuator mustn’t be damaged (apparent damage caused by transport, storage or

handling).

oAmbient temperature should fall within -10°C and +40°C (if these limits are exceeded, consult

it with the manufacturer).

oThe altitude of the installation should reach max. 1,000 m a.s.l., otherwise the drive should be

adjusted to fit the surrounding conditions. In such case contact the electric actuator

manufacturer.

oClean the reduction gear output flange and body from the conservation substances and

eventual contamination with a non-molting cloth soaked in a non-aggressive detergent LOS

1100.

oWipe dry all cleaned mounting surfaces in order to ensure required friction values of the

screwed joints.

CAUTION!

•Cleaning with pressurized air can damage the electric actuator sealing

units!

- Don´t use pressurized air for electric actuator cleaning.

5.1.2 Centering of electric actuator DriveSpin®

▪Electric actuator DriveSpin® should be properly centered to ensure that its output flange isn´t loaded

above limits. Follow the permitted axial and radial load stated in the catalogue DriveSpin® on website

www.spinea.com. Avoid strokes and hitting of the electric actuator body.

5.1.3 Output flange face and circumferential jerking values

▪The values of electric actuators DriveSpin® face and circumferential jerking are stated in the catalogue

DriveSpin® on the website www.spinea.com.

17

5.1.4 Installation of components on electric actuator output flange

CAUTION!

•Unreasonable loading of electric actuator during its mounting could

cause its irreversible damage!

-Don´t attempt to connect the components to the electric actuator output

flange with excessive force or hitting.

-Use only suitable mounting tools.

▪Safe transfer of external load applied on the electric actuator DriveSpin® requires the use of

connection screws of grade at least 10K and degreasing of the friction joints contact surfaces before

mounting. Screw tightening torque is stated in the table 1.

Table 1 Screw tightening torque

Screw

Tightening torque [Nm]

Tightening strength

[N]

Screw material grade and

specification

M3

1,9

3100

ISO 898 T1 10.9K or 12.9K

M4

4,3

5300

M5

8,4

8800

M6

14

12400

M8

35

22750

▪Permitted torque transferred by the connection screws on the output flange and bearing body is stated

in the catalogue DriveSpin® on the website www.spinea.com.

5.2

Electric wiring

DANGER!

•Incorrect method of connection or touching the live parts of the device

can result in equipment damage or serious injury or dead.

- Electric actuator shall be connected only by qualified person.

Obligatorily follow the safety instructions stated in chapter No. 2 when commissioning the

equipment.

▪Prior to starting the work with electric actuator, read the applicable manuals and technical

documentation of the equipment (especially of the electric actuator and digital servo- amplifier).

▪Electric actuator shouldn´t be connected directly to the main power grid! Use the original cabling and

suitable servo –amplifier (or a servo –amplifier recommended by the vendor that is compatible with

the electric actuator) for the proper connection of electric actuator.

▪Prior to the equipment commissioning, ensure the compliance with EU directives applicable to

machines and equipment with built –in electric actuators DriveSpin®.

▪Equipment and machines with servo- amplifier driven motors should meet the protection

▪requirements in accordance with EMC EU directives.

18

5.2.1 Instructions for connection

▪Prior to connection of electric actuator to the servo –amplifier, check for correct connection of power

and signal parts of the electric actuator according to the wiring diagram available in the catalogue

DriveSpin®, on the website www.spinea.com, or in the Test Report of the electric actuator; in order to

avoid injury or eventual damage of the equipment electric parts.

▪Choose the connection cabling and other components routing so as their potential damage during

operation is avoided, especially:

•Mechanical damage caused by moving machine parts,

•Thermal damage,

•Damage caused by other destructive effects of the surrounding environment.

▪In case of longer storage (exceeding 1 year), measure the isolation resistance of the electric actuator

winding.

▪If you use the electric actuator with cable outlet and cabling location in the energy chains, take in

account the cabling installation technical requirements set forth by the cable manufacturer, and

installation instructions of the energy chain manufacturer, especially:

oEnergy chain choice must comply with the requirements of particular used cables. Bending

radius should correspond to the minimum cable bending radius.

oAmbient temperature shouldn´t drop below 5°C during the cable installation.

oThe cables should be installed in the energy chain without any twisting. If cables are twisted

inside the energy chain, premature damage to the cable may occur. The effect can be

accentuated up to potential cable structure damage, which could further cause malfunctions.

oThe cables should be laid freely next to one another inside the energy chain segments.

oIf possible, arrange the cables independently and mutually separated from one another by

spacers, or in separate openings of the energy chain neutral zone.

oFree space of the cables inside the energy chain segments must comprise at least 10% of the

cable diameter.

oThe cables should be installed symmetrically, taking in account their weight and size. The

cables with bigger diameter and weight should be laid on the outer side, while those with

smaller size and diameter should be laid on the inner side. Avoid the cables arrangement one

above another without the use of horizontal spacer.

oIn case of vertical arrangement of the energy chain, create more free space inside the inner

energy chain segment clearance since the operation is associated with certain cable

prolongation. After a short period of operation, it is necessary to check and, if necessary,

correct this cable length setting. Affix the cable on both ends in case of used self-contained

energy chains. Use the recommended affixation by the cable chain manufacturer. In case of

high acceleration values, binding strap solution haslimited durability. Avoid binding the cables

together.

oThe cables shouldn´t be secured or bound within the moving section of the energy chain in

any way. The distance from the end point of the bend to the cable affixation must be as large

as possible. In case of sliding chains, we recommend affixing the cables only on the moving

end. A small cable reserve should be made at the fixed end.

oEnsure location of the cables in the neutral zone of the energy chain, i.e. avoid forced cable

placement along the inner or outer bending and allow for relative cable movement between

one another and towards the energy chain.

oIf uneven movement occursas a result of longitudinal twistingduring operation,it is necessary

to turn the cables on either affixation point so as the cables could be straightened and enable

smooth movement.

oChanges at cable and energy chain length significantly differ in the terms of absolute values.

Natural prolongation of the cables usually occurs within the first few hours of the operation.

19

5.2.2 Protection against overloading

▪There is a temperature sensor integrated in the winding to provide protection of all electric actuator

types against undesirable thermal overloading resulting from excessive effective current. The

temperature sensor integrated in the electric actuator winding doesn´t guarantee complete protection

against overloading.

CAUTION!

•Exceeded maximum permitted temperature on the electric actuator gear

body, stated in the catalogue DriveSpin® on the website www.spinea.com,

can irreversibly damage the electric

actuator!

-Monitor the temperature and the heatingrate of electric actuator reduction

gear surface, depending on the loading.

-Ensure removal of excessive heat in order to avoid exceeded maximum

permitted temperature on the electric actuator reduction gear surface

-Reduce loading.

-Use the electric actuator with higher output power.

CAUTION!

•Exceeded maximum permitted temperature of the electric actuator motor,

defined by the isolation class and stated in the catalogue DriveSpin® and

on the website www.spinea.com; can irreversibly damage the electric

actuator!

-Monitor the temperature and the rate of motor heating with integrated

temperature sensor.

-Ensure removal of excessive heat in order to avoid exceeding maximum

permitted temperature of the electric actuator motor.

-Reduce loading.

-Use the electric actuator with higher output power.

▪Technical parameters of particular temperature sensors are specified in the chapter 8 of this

document.

5.2.3 Commissioning

▪Commissioning of the electric actuator shall comply with the terms described herein in the chapters 1

and 2.

20

Electric actuator shouldn´t be used as a lifting device!

▪Check the following terms prior to equipment commissioning:

oElectric actuator shouldn’t be damaged or locked.

oMeasure the winding isolation resistance after long time storage.

oAll cable joints must be correctly interconnected and without mechanical damage.

oCheck the rotary seals of the electric actuator which must not be damaged No signs or sources

of eventual danger are permissible.

oEnsure thorough connection of the electric actuator cable shielding (power and signal cables)

to the ground pursuant to servo- amplifier manual.

▪In the following step, set up the limits of following parameters on the servo- amplifier (along with

other necessary parameters): maximum current, torque, and speed of servomotor to equal to or lower

than maximum permitted values of the electric actuator. Particular instructions are contained in the

manual related to particular servo- amplifier. In case of further information required, please contact

the vendor. Ensure that the following requirements are met during the electric actuator operation:

DANGER!

This manual suits for next models

1

Table of contents

Popular Controllers manuals by other brands

Paxton

Paxton Switch2 How to program

Roger Technology

Roger Technology B70/1DC instructions

Pakedge Device & Software

Pakedge Device & Software C36-07 user manual

Real-El

Real-El STAB SLIM-300 Operation manual

FUTABA

FUTABA MC401CR Sport Edition instruction manual

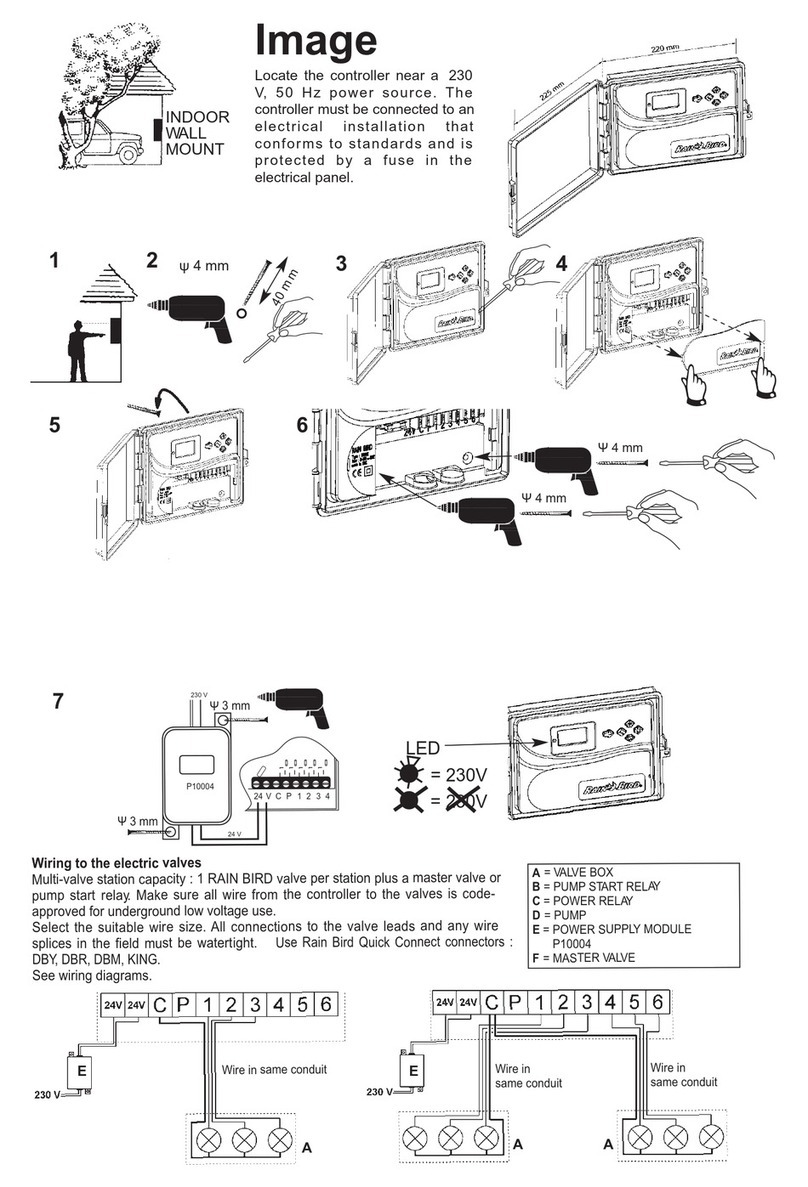

Rain Bird

Rain Bird Image Series quick start guide

rotork

rotork GPSA Series instruction manual

Flowserve

Flowserve Limitorque L120-190 User instructions

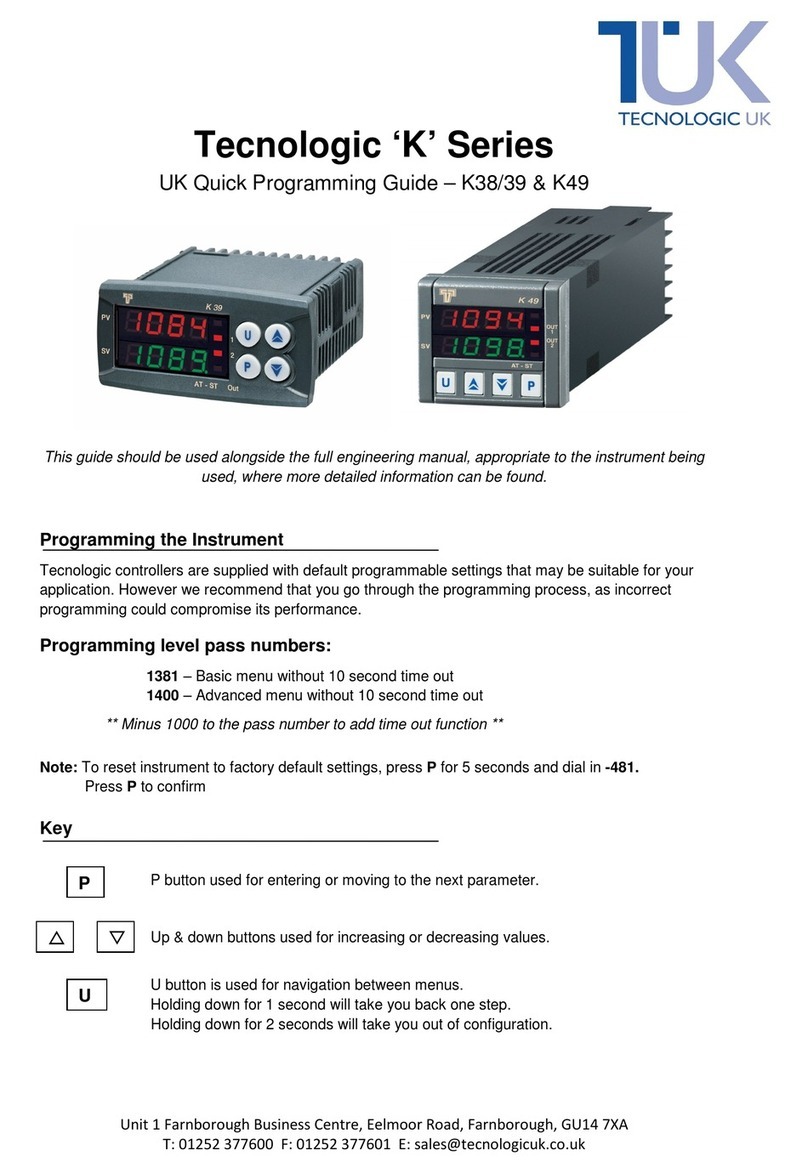

Tecnologic

Tecnologic K series Quick programming guide

Siemens

Siemens SIMOTION D410 Commissioning manual

nVent RAYCHEM

nVent RAYCHEM 465 Installation, operation and maintenance manual

YOKOGAWA

YOKOGAWA YS1700 Tech note