Your Warranty Rights and Obligations

The U.S. EPA and Engine Distributors, Inc. are pleased to explain the emission

control system warranty on your new 2017 model year emission certified engine (or

brand equipment). New off-road large spark-ignition (LSI) engines must be designed,

built and equipped to meet stringent Federal and State anti-smog standards. Engine

Distributors, Inc. warrants that the emission control system on your engine for the

periods of time listed below provided there has been no abuse, neglect or improper

maintenance of your engine.

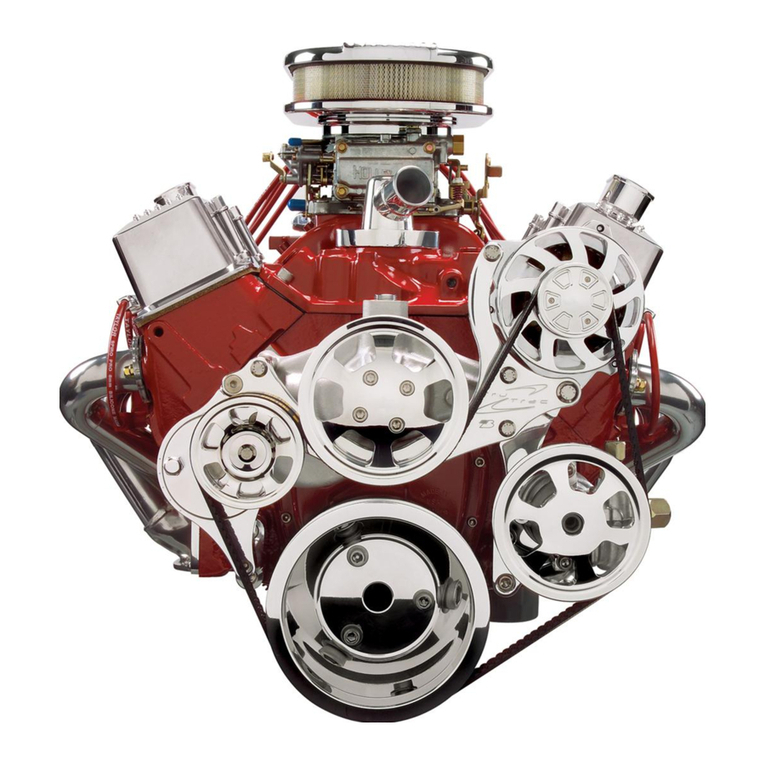

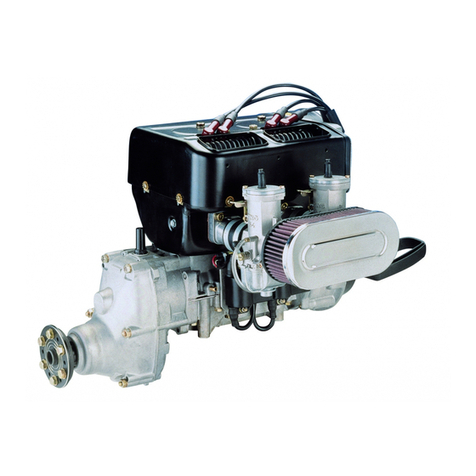

Your emission control system may include parts such as the carburetor, regulator or

fuel-injection system, ignition system, engine computer unit (ECM), catalytic

converter and air induction system. Also included may be sensors, hoses, belts,

connectors and other emission-related assemblies.

Where a warrantable condition exists, Engine Distributors, Inc will repair your LSI

engine at no cost to you including diagnosis, parts, and labor.

Manufacturer’s Warranty Coverage

The new 2017 model year off-road large spark-ignition engines are warranted for

three years or 2500 hours of service, whichever occurs first from the date the

equipment is delivered to the first retail purchaser or when the equipment is first

placed in service. If any emission-related part on the engine is defective, the part will

be repaired or replaced by an authorized Engine Distributors, Inc. dealer. This is

your General Emissions Warranty.

For five years or 3500 hours of service (whichever occurs first) if any emission-

related part specially noted with coverage for five years or 3500 hours is defective,

the part will be repaired or replaced by and authorized Engine Distributors, Inc.

dealer. This is your High Priced Parts Emission Warranty.

Owner’s Warranty Responsibilities

As the off-road LSI engine owner, you are responsible for the performance of the

required maintenance listed in your owner’s manual. Engine Distributors, Inc.

recommends that you retain all records covering maintenance on your off-road

engine, but Engine Distributors, Inc. cannot deny warranty solely for the lack of

receipts or for your failure to ensure the performance of all scheduled maintenance.

As the off-road large spark-ignition engine owner, you should however be aware that

Engine Distributors, Inc. may deny you warranty coverage if your off-road large

spark-ignition engine or a part has failed due to abuse, neglect, improper

maintenance or unapproved modifications.