Engineered air TriMed GH Series User manual

IOM-62 Nov 17 R1

\ P

INSTALLATION, OPERATION

AND MAINTENANCE MANUAL

FOR

GH SERIES

ODOR CONTROL HEADS

UNIT MODEL NO.

UNIT SERIAL NO.

SERVICED BY:

TEL. NO:

CANADIAN

HEAD OFFICE

AND FACTORY

USA

HEAD OFFICE

AND FACTORY

CANADIAN

EASTERN FACTORY

1401 HASTINGS CRES. SE

CALGARY, ALBERTA

T2G 4C8

Ph: (403) 287-2590

Fx: 888-364-2727

32050 W. 83rd STREET

DESOTO, KANSAS

66018

Ph: (913) 583-3181

Fx: (913) 583-1406

1175 TWINNEY DRIVE

NEWMARKET, ONTARIO

L3Y 5V7

Ph: (905) 898-1114

Fx: (905) 898-7244

SALES OFFICES ACROSS CANADA AND USA

Retain instructions with unit and maintain in a legible condition.

Please give model number and serial number when contacting

factory for information and/or parts.

www.engineeredair.com

PGH Manual

IOM-62 2 of 9 Nov 17 R1

TABLE OF CONTENTS

You Have Responsibilities Too .................................................................................................................... 3

Introduction ................................................................................................................................................ 3

Safety Precautions ...................................................................................................................................... 3

Warranty..................................................................................................................................................... 4

Parts ............................................................................................................................................................ 5

Receiving..................................................................................................................................................... 5

Temporary Storage.................................................................................................................................. 5

Installation .................................................................................................................................................. 5

Codes........................................................................................................................................................... 6

In Canada:................................................................................................................................................ 6

In Usa:...................................................................................................................................................... 6

Assembly Drawing....................................................................................................................................... 6

Electrical Connections ............................................................................................................................. 7

Before Starting ..................................................................................................................................... 7

Maintenance............................................................................................................................................... 7

Maintenance Schedule............................................................................................................................ 7

Electrical............................................................................................................................................... 8

Corona Plates ....................................................................................................................................... 8

Corona Plate Inspection: ......................................................................................................................... 8

Troubleshooting Chart................................................................................................................................ 9

© Airtex Manufacturing LLLP. All rights reserved.

PGH Manual

IOM-62 3 of 9 Nov 17 R1

YOU HAVE RESPONSIBILITIES TOO

This installation, operation and maintenance manual cannot cover every possibility, situation or

eventuality. Regular service, cleaning and maintaining the equipment is necessary. If you are not

capable of performing these tasks, hire a qualified service specialist. Failure to perform these duties

can cause property damage and/or harm to the building occupants and will void the manufacturer’s

warranty.

Warning:

Improper installation, adjustment, alteration, service or maintenance can cause

property damage, injury or death. Read the installation, operation and maintenance

manual thoroughly before installing or servicing this equipment.

m

INTRODUCTION

TRI-MED GH oxidizer heads are high quality products designed and manufactured to provide many

years of trouble-free operation. We recommend that this manual be read thoroughly to ensure proper

installation, efficient operation, and proper maintenance of this equipment. The submittal record is

considered to be part of the Installation, Operation and Maintenance Manual.

SAFETY PRECAUTIONS

Read, understand and follow the complete manual before beginning the installation, including all

safety precautions and warnings.

Warning:

This unit contains high voltage circuits. Electrical shock or death could occur if

instructions are not followed. This equipment contains moving parts that can start

unexpectedly. Injury or death could occur if instructions are not followed. All work

should be performed by a qualified technician. Always disconnect and lock out

power before servicing. DO NOT bypass any interlock or safety switches under any

circumstances.

m

c

Caution:

This unit generates high concentrations of ozone. Operate only as directed in this

manual. Never breathe the air directly discharged from the unit. Ozone can be a

respiratory irritant.

m

Warning:

The ETL certification carried by this unit applies for installing the unit in a non-

hazardous location. This unit is approved to the UL 867(US)/CSA C22.2 No. 187

(Canada). It is the owner’s and/or agent’s responsibility to obtain the appropriate

approvals to use this unit in a hazardous environment.

m

PGH Manual

IOM-62 4 of 9 Nov 17 R1

WARRANTY

LIMITED WARRANTY TRI-MED will furnish without charge, F.O.B. factory, freight collect, replacement

parts for, or repairs to products covered herein which prove defective in material or workmanship

under normal and proper use for a period of twelve (12) months from the date of shipment, provided

the customer gives TRI-MED written notice of such defects within such time periods and provided that

inspection by TRI-MED establishes the validity of the claim and all pertinent invoices have been paid in

full. The repairs or replacements will be made only when the complete product(s) or part(s) claimed to

be defective are returned to TRI-MED or a depot designated by TRI-MED, transportation charges

prepaid. Repairs or replacements as provided for by this paragraph shall constitute fulfillment of all

TRI-MED's obligations with respect to this warranty. Corona plates and filters are considered

consumable items and are to be replaced by the owner/operator as per the maintenance schedule.

Corona plates broken after original shipment will not be considered a manufacturing defect and

replacement will be the responsibility of the owner/operator. This warranty does not apply to any

products or parts thereof that have been subject to accident, misuse or unauthorized alterations, or

where TRI-MED's installation and service requirements have not been met.

The foregoing warranty is in lieu of all other warranties, express or implied. TRI-MED specifically

disclaims any implied warranty of merchantability and/or fitness for purpose. Under no circumstances

shall TRI-MED be liable to, nor be required to indemnify, Buyer or any third parties for any claims,

losses, labour, expenses or damages (including special, indirect, incidental, or consequential damages)

of any kind, resulting from the performance (or lack thereof) of this Agreement or the use of, or

inability to use the goods sold hereunder, including, but not limited to, damages for delay, temporary

heating/cooling costs, loss of goodwill, loss of profits or loss of use. Furthermore, the parties agree

that the Buyer's sole remedy under this Agreement shall be limited to the limited warranty set forth in

the preceding paragraph relating to the repair or replacement of any defective goods. Under no

circumstances shall any claim or award against TRI-MED exceed the original contract price whether

awarded through arbitration, litigation or otherwise.

TRI-MED Warranty is void if:

1. The unit is not installed in accordance with this manual.

2. The start-up and operation of the unit is not performed in accordance with this manual.

3. The unit is operated in an atmosphere containing corrosive substances.

4. The unit is allowed to operate during building construction.

PGH Manual

IOM-62 5 of 9 Nov 17 R1

PARTS

Contact the nearest Engineered Air sales office or factory for replacement parts. Be sure to include

Model Number, Serial Number, date of installation, the nature of the failure and the description of the

part(s) required. Some parts may not be stocked items and must be manufactured or ordered.

RECEIVING

Refer to the back of the packing slip for receiving instructions.

On receipt of the unit, check for damage. Inspect protective covers for punctures or other signs that

there may be internal damage. Remove protective covers and check for internal damage. Replace

covers if the unit is not being installed at this time. Open access doors and check for internal damage.

Close access doors when inspection is complete.

All units are pre-tested at the factory immediately prior to shipping and are ensured to be in good

operating condition at that time. If damage is found, refer to the instructions on the back of packing

slip.

On receipt of the unit, check the electrical characteristics (see rating plate) to make sure that the

electrical supply matches. All parts for field installation are listed on the shipping order form.

TEMPORARY STORAGE

If a unit is to be stored prior to installation the following precautions are required:

Store in a well drained area that will not accumulate surface water.

Store in an area where the unit will not be damaged.

All protective coverings that were provided for shipping must be in place.

Protect indoor mounted equipment from rain and snow.

INSTALLATION

Warning:

This unit is not explosion proof. It is not suitable for hazardous locations as defined

by the National Electrical Code of the Canadian Electrical Code.

m

Warning:

All wiring and piping installation must be completed by qualified technicians in

accordance with all federal, state, provincial and/or local codes.

m

Note: Installation shall be in accordance with this manual and all other associated component and

control Installation, Operation and Maintenance Manuals.

PGH Manual

IOM-62 6 of 9 Nov 17 R1

CODES

In Canada:

1. The installation of this unit shall be in accordance with the latest edition of the Canadian Electrical

Code, Part 1 - C.S.A. Standard C22.1, Provincial and Local Codes, and in accordance with the local

authorities having jurisdiction.

2. This unit shall be electrically grounded in accordance with the latest edition of the Canadian

Electrical Code, Part 1 - C.S.A. Standard C22.1, Provincial and Local Codes, and in accordance with

the local authorities having jurisdiction.

3. The installation of this unit shall be in accordance with all other National, Provincial, and Local

Codes, and in accordance with the local authorities having jurisdiction.

In USA:

1. The installation of this unit shall be in accordance with the latest edition of the National Electrical

Code, (ANSI/NFPA 70), State and Local Codes, and in accordance with the local authorities having

jurisdiction.

2. This unit shall be electrically grounded in accordance with the latest edition of the National

Electrical Code, (ANSI/NFPA 70), State and Local Codes, and in accordance with the local authorities

having jurisdiction.

3. The installation of this unit shall be in accordance with all other National, State, and Local Codes,

and in accordance with the local authorities having jurisdiction.

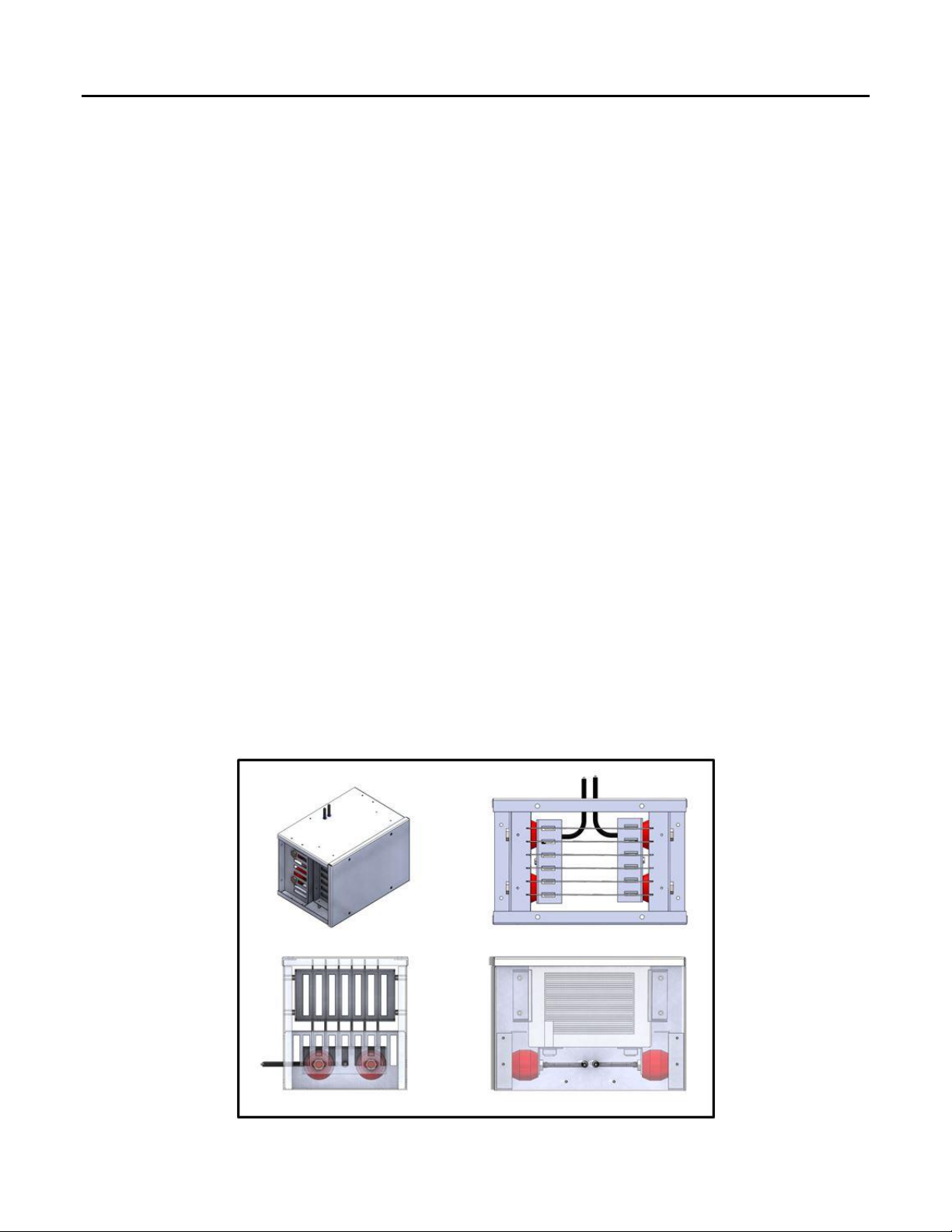

Assembly Drawing

PGH Manual

IOM-62 7 of 9 Nov 17 R1

ELECTRICAL CONNECTIONS

DO NOT install anything that will interfere with equipment access or rating plate.

m

BEFORE STARTING

1. Set all associated electrical switches, controls and disconnect switch to “OFF” position.

2. Tighten all electrical connections.

3. Confirm all shipping materials have been removed. See any supplemental instructions to help

identify possible locations.

4. Confirm voltage is within ± 10% of rating plate. If not, contact the installing electrical contractor

and have the voltage condition corrected before continuing.

MAINTENANCE

Warning:

This unit contains high voltage circuits. Electrical shock or death could occur if

instructions are not followed. This equipment contains moving parts that can start

unexpectedly. Injury or death could occur if instructions are not followed. All work

should be performed by a qualified technician. Always disconnect and lock out

power before servicing. DO NOT bypass any interlock or safety switches under any

circumstances.

m

c

The effectiveness of the GH generator head is a function of its ability to convert oxygen (O2) to ozone

(O3) through high voltage corona plates. It is essential to maintain airflow through clean corona plates.

Dirty filters will not only reduce the oxygen across the corona plates, but also can change the air

balance. To provide a maintenance history, it is recommended that the owner have a maintenance

file.

The following maintenance instructions are to be carried out by qualified service personnel.

MAINTENANCE SCHEDULE

Every installation is different. Therefore, a maintenance schedule needs to be established based on

each installation. An initial two-month or 1400 hour inspection must be performed. If the filters and

plates are found to be dirty, clean and replace and adjust the maintenance schedule accordingly. A

review of the installation should be performed to find the source of the contamination.

Note: Seasonal changes may affect the maintenance requirements. Adjust the schedule accordingly.

The maximum time between maintenance checks should be 6 months.

PGH Manual

IOM-62 8 of 9 Nov 17 R1

ELECTRICAL

1. Check all wiring for loose connections.

2. Check voltage at unit (while in operation).

3. Check amperage draw against unit rating plate.

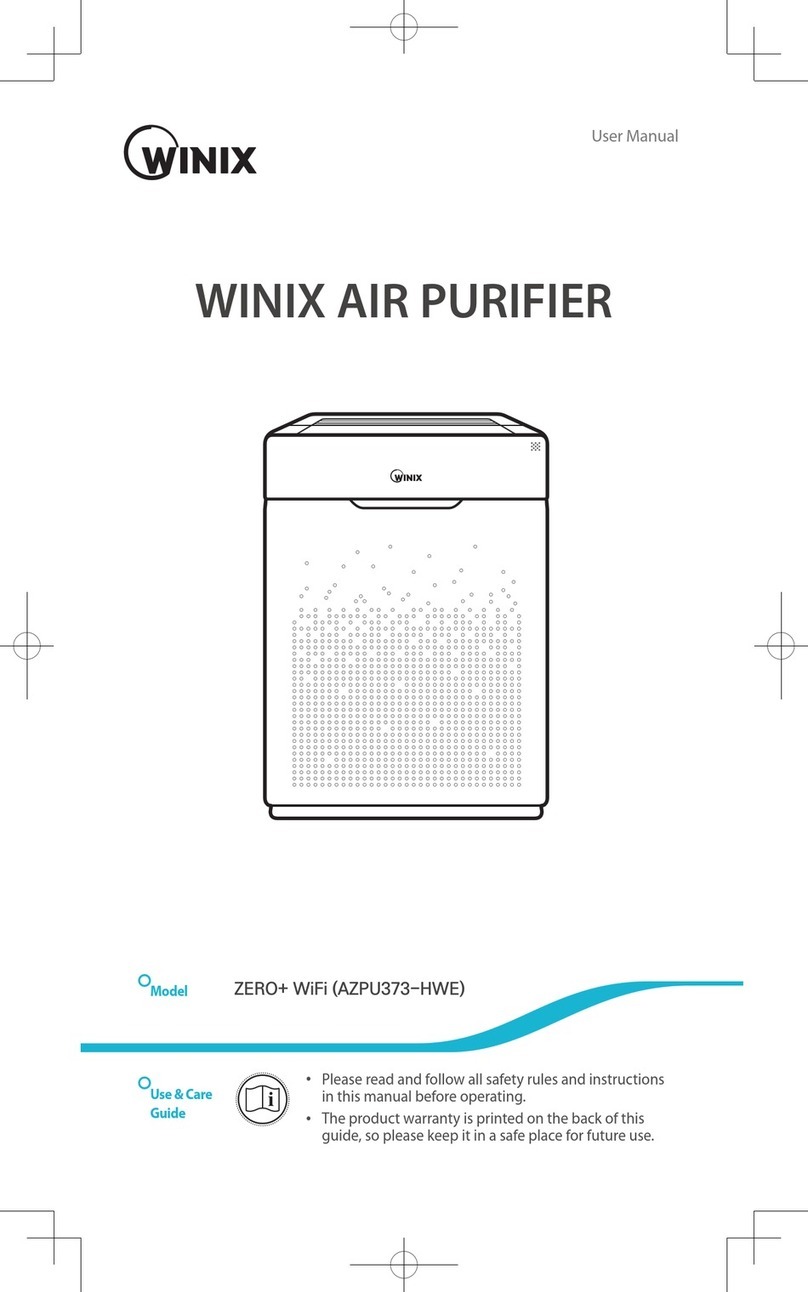

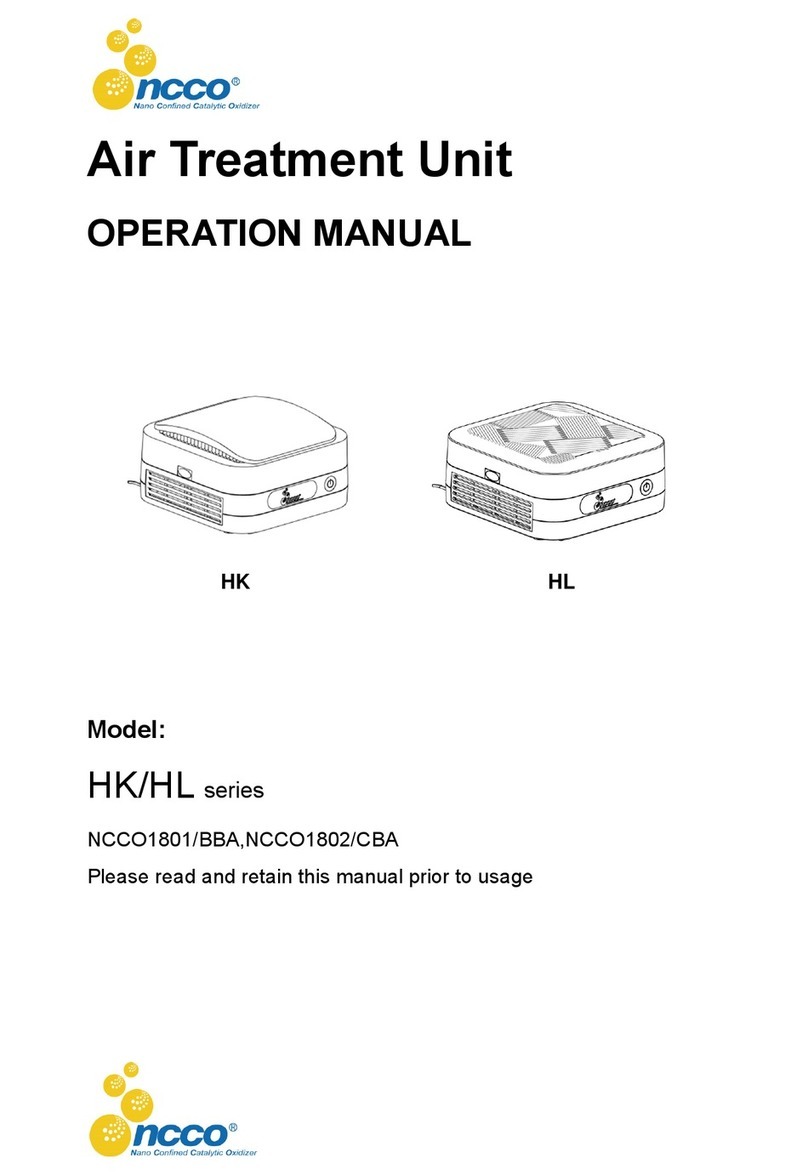

CORONA PLATES

Disconnect the power from the unit. Locate the generator head(s) and remove the cover. Each

generator head has up to 6 corona plates. Locate the corona plates. Slide them out of their locating

grooves and clean. All plates must be cleaned at the same time.

Plate Cleaning:

The oxidizer includes a second complete set of corona plates when delivered new. Alternate plate

usage between the two sets. Clean the dirty corona plates by using a dishwasher or hand wash. If

cleaning by hand, begin cleaning the plates by spraying or dipping them in cleaning solution. The

cleaning solution should be a detergent product that is capable of breaking down oils and greases but

leaves no residue when rinsed off. If the plates are rinsed in hard water, then clean compressed air

should be used to dry off of the corona plates to prevent hard water deposits.

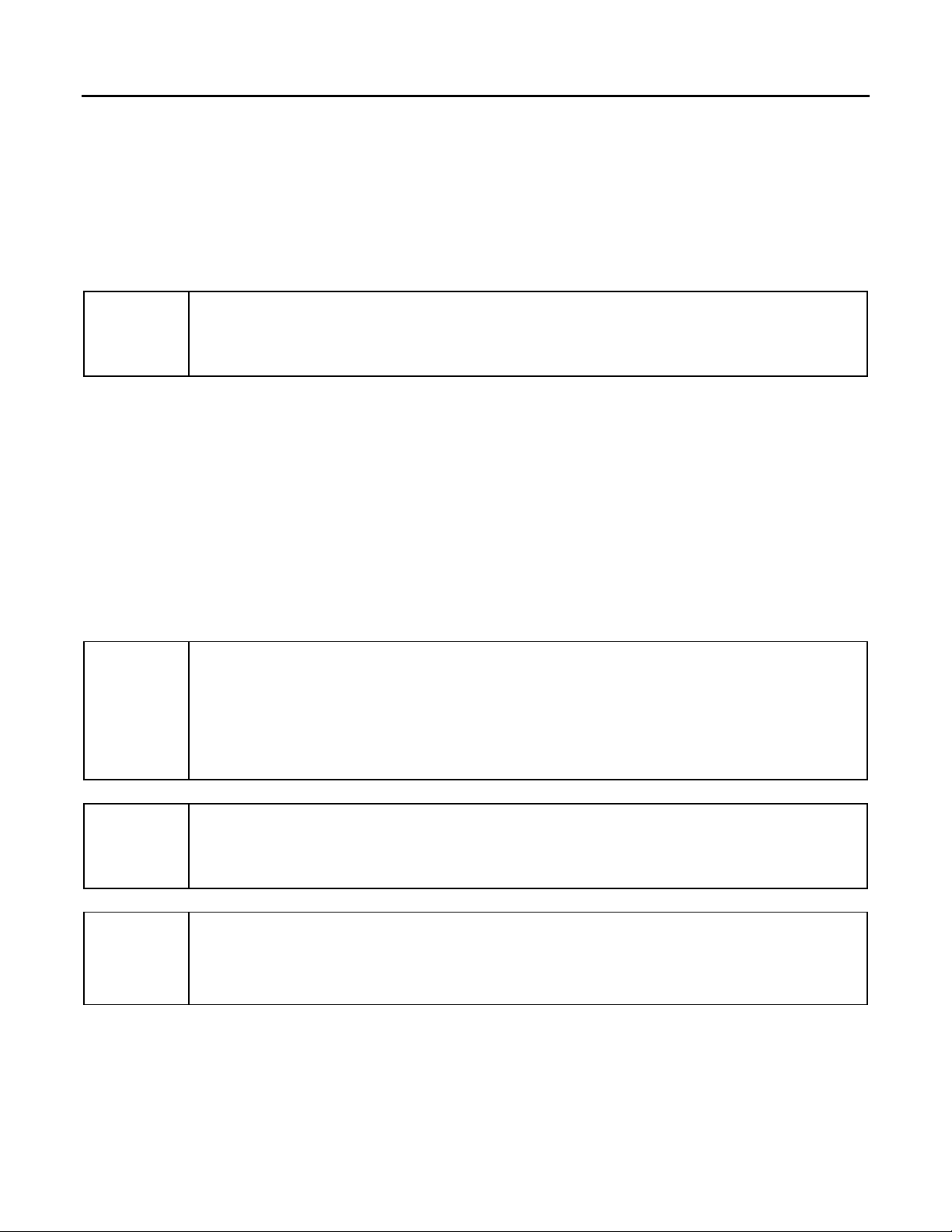

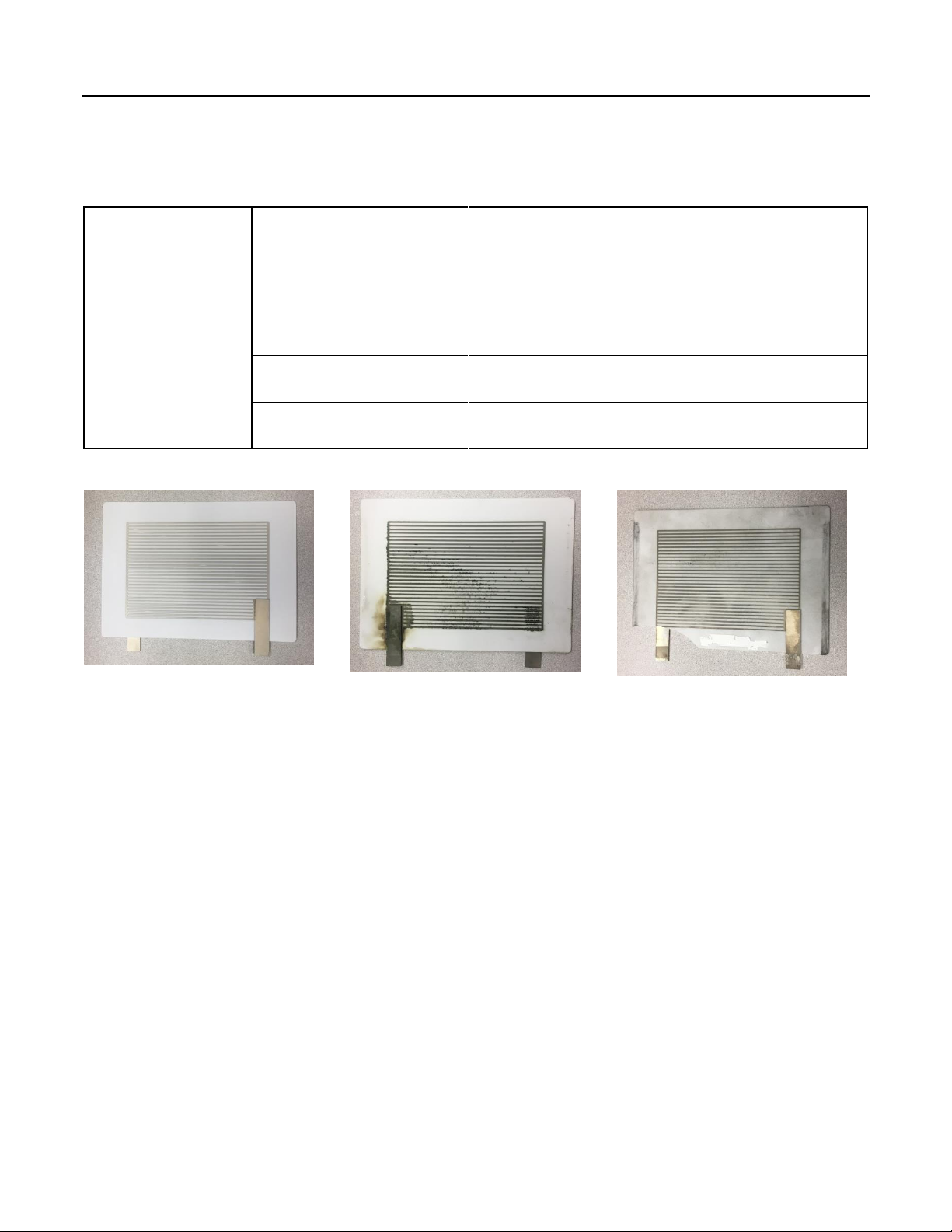

CORONA PLATE INSPECTION:

After cleaning, inspect each corona plate for pin holes or other damage. A pin-hole in the plate will

cause the generator head(s) to operate incorrectly. Holes or cracks should not be visible on the plate.

Replace any corona plates that fail inspection.

After the plates have been checked, reinstall the cover.

PGH Manual

IOM-62 9 of 9 Nov 17 R1

TROUBLESHOOTING CHART

Symptoms

Problem

Cure

Power on - blower

on - no corona buzz

or odor too high

Oxidizer output control not

high enough

Adjust Oxidizer Output control higher.

Energize additional generator heads.

Verify air flow balance across head assembly.

Corona plates dirty

Clean corona plates.

See Plate Cleaning on page 8.

No voltage at plates after

cleaning

Inspect for plate damage and replace damaged

plate.

Defective transformer

Check primary and secondary voltages and replace

if required.

Clean Plate

Dirty Plate

Broken Plate

Table of contents