enlighted Universal Mounting Case User manual

Page 5 Page 6 93-01651-01 Rev01 Page 1

Copyright © 2016 Enlighted Inc. All rights reserved.

All other brand or product names are trademarks of

their respective companies or organizations.

TechnicalSupport

For questions regardingtheinstallation or operation of

this product,contact Enlighted

TechnicalSupport: support@enlightedinc.com

Company Contact Information

Location: 930 Benecia Ave, Sunnyvale, CA 94085

Phone: +1.650.964.1094

Web: enlightedinc.com

Universal Mounting Case

Installation Instructions

Model: CASE-FS-D22

Universal Mounting Case

Shipped Components

•Enlighted Universal Mounting Case

•Enlighted Mounting Bracket

•½inch Chase Nipple and Locknut

•2 nos. #8 Anchor Screws (Drywall®mount)

•2 nos. #8 Metal Self-tapping Screws (Fixture mount)

Items you may Need

•400BAC Wiremold®Conduit

•18” AWG wire

Tools you may Need

•½” knockout set

•Hand drill

•Wire stripper

•Pliers

•Phillips screwdriver

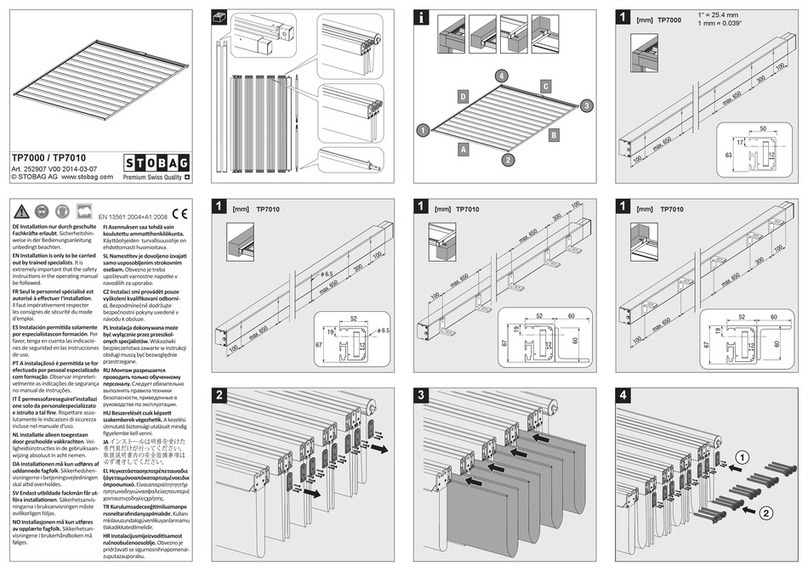

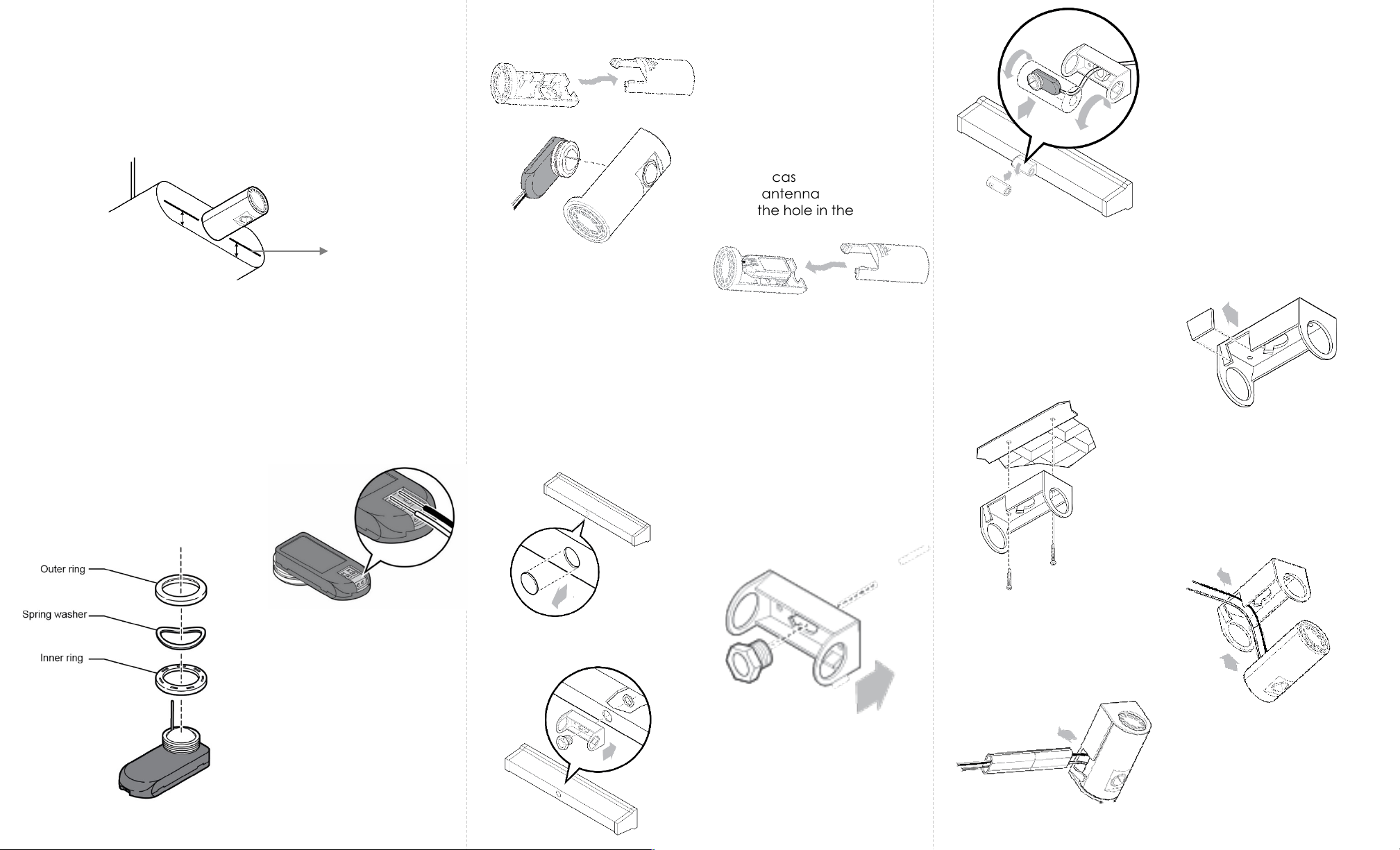

Section 3: Mounting without Bracket

Step 2: Using your thumb or

pliers, push and remove the

knockout of the UMC’s front

case.

Step 3: Insert the ½” Chase

Nipple through the knockout

hole of the UMC’s front case.

Step 4: Insert the sensor into

the UMC case pulling the

cables through the Chase

Nipple. Make sure the lens and

antenna are visible through

the hole in the front.

Step 5: Slide to close the

UMC back cover.

Refer to the design guideline to ensure that the condition is

met. Complete Steps 1, 2, and 3 of Section 1: UMC

Installation before following the procedure below.

Step 6: Mount the UMC to

the fixture by tightening the

Chase Nipple with the

locknut.

Section 4: Wiring the Cables to the LED Driver

To

lamps

From Mains

To Enlighted

Sensors

Step 1: Wire the other end of

the sensor cable to the LED

driver’s XSR connections.

After mounting, rotate the UMC to the required direction and

turn the power on.

Section 5: Rotating the UMC

Step 1: Remove ½” fixture

knockout.

Page 2 Page 3 Page 4

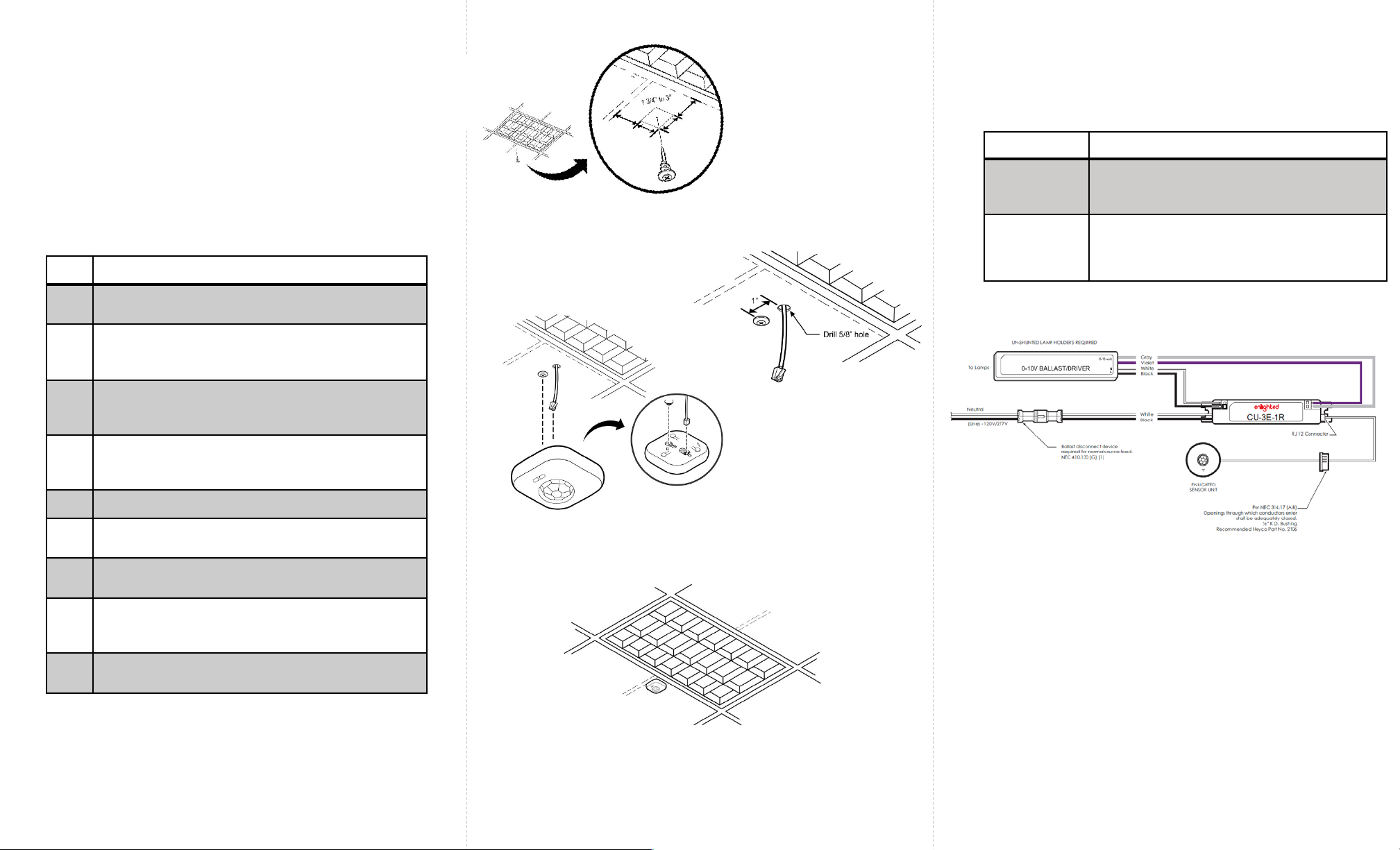

Section 1: Universal Mounting Case (UMC)

Installation

Section 2: Mounting with Bracket

Caution

•Installation and maintenance must be performed by a qualified

electrician in accordance with local, state, and national electrical

codes (NEC) and requirements.

•Turn off all power to the light fixture by switching off the circuit

breaker.

The procedure below shows how to insert the sensor into the

UMC. The UMC can be mounted with bracket (see Section 2)

or without bracket (see Section 3).

Step 4: Insert the sensor into the

UMC front case. Make sure the

lens and antenna are visible

through the hole in the front.

Step 3: Slide to open the UMC

back cover.

Step 5: Slide to close the UMC

back cover until it snaps into

place.

Step 1: Remove the ½” fixture

knockout

You can mount the UMC with bracket to

Option 1: Fixtures with knockout, or

Option 2: Sheetrock and Fixtures without knockout

Option 1: Fixtures with Knockout

Complete Steps 1 through 5 of Section 1: UMC Installation

before following the procedure below.

Step 2: Remove the sensor’s

faceplate comprising the outer,

inner rings and spring washer from

the sensor

Step 2: Insert ½” Chase Nipple

to the inside of the bracket.

Step 3: Connect the bracket to

the fixture by threading the

locknut screw to the Chase

Nipple.

Step 4: Insert the UMC into

the mounting bracket. Pull

the sensor cables through

the Chase Nipple into the

fixture.

Option 2: Sheetrock and Fixtures without Knockout

Design Guidelines

•When the distance from the center of the knockout to the base of

the fixture is greater than 30mm (and lower than 50mm), mount the

UMC without bracket as described in Section 3.

Complete Steps 1 through 5 of Section 1: UMC Installation

before following the procedure below.

Step 1: Locate the tab on

the side of the mounting

bracket and break away

the tab.

Step 2: Mount the bracket to the

fixture or drywall.

Step 3: Insert the UMC into

the bracket. Make sure the

sensor wires exit through the

open slot in the bracket.

The Universal Mounting Case is designed for use with the two-

wire Fixture Mount (FS-D22) sensor.

1. Fixtures: use metal-self

tapping screws

2. Drywall: use anchor screws

Distance from the

base of the fixture

to the center of the

Knock-out

Note: For any reason, if you need

to remove the wires from the

sensor, push down on the tabs with

a pointed device, and remove the

wires while continuing to hold the

tab down.

Step 1: Strip each end of the 18” AWG

two wires leaving 3/8” of exposed wire.

Connect wires to the sensor.

Step 4: only for drywall Insert

the cables through the

Wiremold conduit.

Page 5 Page 6 Page 1

Smart Sensor

Smart Sensor

(SU-4S)

Installation Instructions

Shipped Components

•Smart Sensor

•Anchor Screw

Items you will Need

•Enlighted Sensor Cable: CBL-2-7F

•Enlighted Control Unit

Items you may Need

•Adjustable Mounting Bracket: BRKT-SU-2O-00 F

93-01658-01 Rev04

Model: SU-4S-H/SU-4S-L

FCC ID: AQQ-SU4S

IC: 10138A-SU4S

Copyright © 2016 Enlighted Inc. All rights reserved.

All other brand or product names are trademarks

of their respective companies or organizations.

TechnicalSupport

For questions regardingtheinstallation or operation of this

product,contact Enlighted

TechnicalSupport: support@enlightedinc.com

Company Contact Information

Location: 930 Benecia Ave, Sunnyvale, CA 94085

Phone: +1.650.964.1094

Web: enlightedinc.com

FCC and Industry Canada Compliance Information

This equipment has been tested and found to comply with the limits for a

Class A digital device, pursuant to part 15 of the FCC Rules. These limits

are designed to provide reasonable protection against harmful

interference when the equipment is operated in a commercial

environment. This equipment generates, uses, and can radiate radio

frequency energy and, if not installed and used in accordance with the

instruction manual, may cause harmful interference to radio

communications. Operation of this equipment in a residential area is likely

to cause harmful interference in which case the user will be required to

correct the interference at his own expense.

This device complieswith Part 15 of the FCC Rules and Industry Canada

license-exempt RSS standard(s). Operation is subjectto the following two

conditions:

•this devicemay not cause harmful interference, AND

•this device must accept anyinterference received, including

interference that may cause undesiredoperation.

Changes or modifications not expressly approved by Enlighted Inc.

could void the user's authority to operate the equipment.

Le présent appareil est conforme aux CNR d'Industrie Canada

applicables aux appareils radio exempts de licence.L'exploitationest

autoriséeauxdeux conditions suivantes:

•l'appareil ne doit pas produire de brouillage,ET

•l'utilisateur de l'appareildoitaccepter tout brouillage radioélectrique

subi, même si le brouillage est susceptible d'en compromettre le

fonctionnement.

CE

This device complies with the essential requirements and other relevant

requirements of the R&TTE Directive (1999/5/EC). The equipment is Class 1

radio equipment which can be placed on the market and be put into

service without restrictions in accordance with article 1(3) of Commission

Decision 2000/299/EC (Version July 2014).

LED Status Description/Solution

LED not on Check power and wiring.

Purple solid All LEDs are on during boot time for 5-6

seconds.

Green blinking Sensor commissioned and working

Red blinking Incompatibility between LED driver and sensor

– Replace LED driver and if not resolved,

replace sensor.

Red solid Faulty sensor – replace sensor.

Green solid Sensor installed, initialized, and

uncommissioned –waiting for discovery.

Blue solid Image being upgraded.

LED Description

Step 4:Slide the Smart Sensor onto the head of the

mounting bracket. See Figure 8.

Figure 8

Front Rear

Step 6: Switch on the circuit breaker to turn the power on.

Step 5: Secure the sensor cable to the bracket or fixture

using cable ties, electrical tape, clips, etc., as appropriate

for the installation.

Page 2 Page 3 Page 4

Installation

Figure 1

Caution

Installation and maintenance must be performed by a qualified

electrician in accordance with local, state, and national electrical

codes (NEC) and requirements.

Step 1: Turn off all power to the light fixture by switching off

the circuit breaker.

Step 2: Mount the Control Unit (CU) in a UL approved

enclosure. Refer to the Control Unit Installation Guide for

installation and wiring instructions. The sensor cable,

terminating in an RJ12 connector, from the CU will need to

connect to the Smart Sensor.

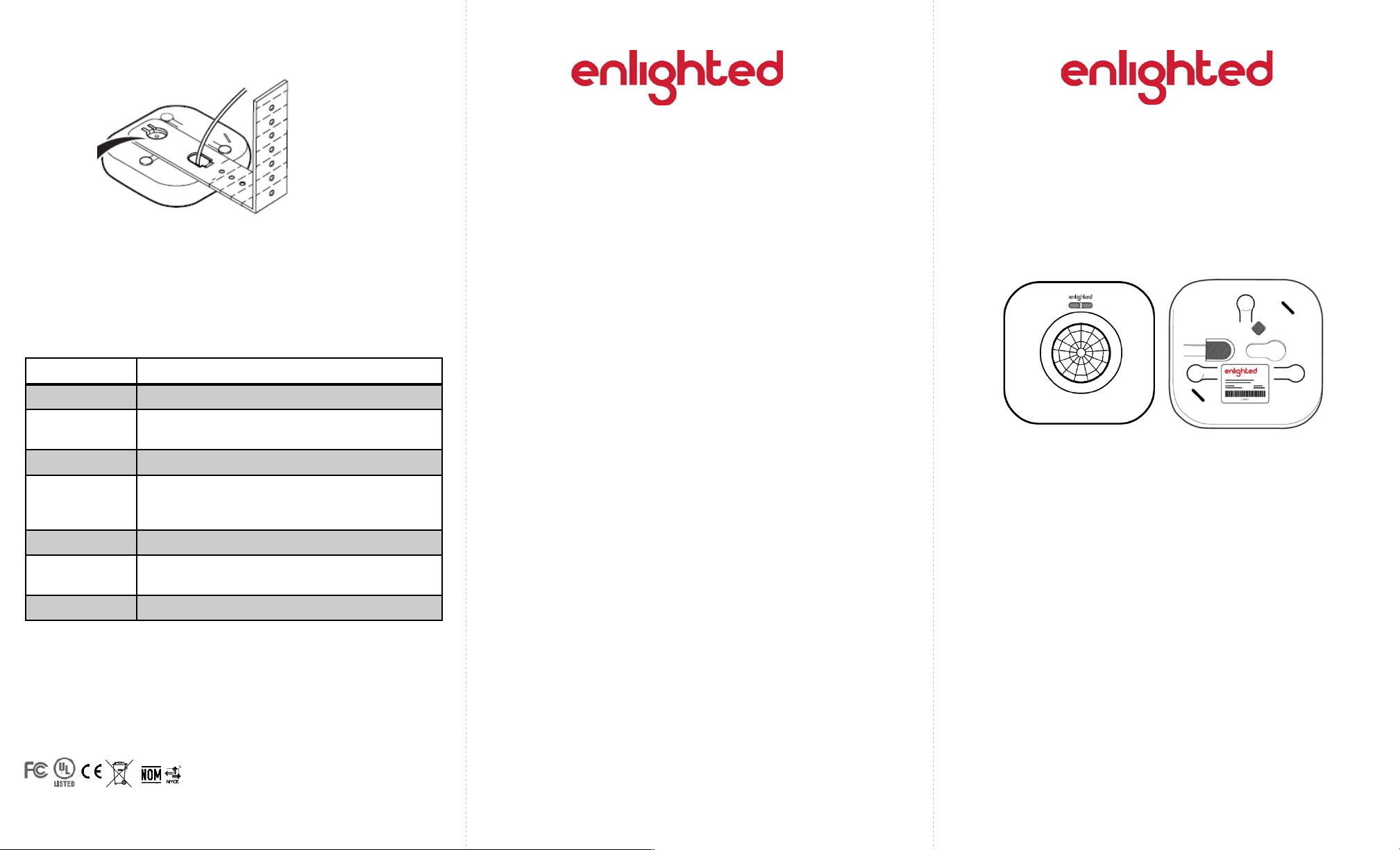

Step 1:Determine the location of

the sensor. Push and rotate the

anchor screw to the tile at that

location.

Step 3: Connect the sensor cable’s RJ12 connector to the

sensor bottom.

Step 4:Align the anchor screw with the slot provided on the

sensor bottom. Slide the Smart Sensor onto the screw head.

Step 5:Slip the excess sensor cable up into the plenum area

and adjust the ceiling tile to the original position.

Step 6: Switch on the circuit breaker to turn the power on.

Figure 4

Anchor Screw

Sensor Cable

The Smart Sensor (SU-4S) should be mounted to the ceiling

tile within a few inches (between 13/4” to 3”) of the lighting

fixture.

The Smart Sensor can be mounted to ceiling tiles using an

anchor screw or to pendant and industrial fixtures using the

adjustable mounting bracket.

Mounting using an Anchor Screw

Mounting using the Adjustable Mounting Bracket

The Smart Sensor (SU-4S) can be mounted on pendant

and industrial fixtures using the mounting bracket.

Step 1: Determine the mounting location of the sensor on

the fixture. To ensure that the view of the sensor is not

obstructed by the fixture, level the sensor to the bottom of

the fixture and provide enough clearance from the fixture.

See examples below.

Step 2:Bend the adjustable

mounting bracket to the required

shape. Fasten the bracket to the

fixture using two 8” screws.

Figure 5

Figure 6

Figure 7

Step 3:Connect the sensor cable’s RJ12 connector from

the CU to the bottom of the Smart Sensor.

Sensor Cable

Mounting

Bracket Head

Step 2: Select a place near the anchor screw for the RJ12

connector of the sensor cable from the CU to exit. Make a

small cut in the ceiling tile for the cable to exit.

Figure 2

Figure 3

Page 5 Page 6 Page 1

Copyright © 2016 Enlighted Inc. All rights reserved.

All other brand or product names are trademarks of

their respective companies or organizations.

TechnicalSupport

For questions regardingtheinstallation or operation of

this product,contact Enlighted

TechnicalSupport: support@enlightedinc.com

Company Contact Information

Location: 930 Benecia Ave, Sunnyvale, CA 94085

Phone: +1.650.964.1094

Web: enlightedinc.com

FCC and Industry Canada Compliance Information

This equipment has been tested and found to comply with the limits

for a Class A digital device, pursuant to part 15 of the FCC Rules.

These limits are designed to provide reasonable protection against

harmful interference when the equipment is operated in a

commercial environment. This equipment generates, uses, and can

radiate radio frequency energy and, if not installed and used in

accordance with the instruction manual, may cause harmful

interference to radio communications. Operation of this equipment

in a residential area is likely to cause harmful interference in which

case the user will be required to correct the interference at his own

expense.

This device complieswith Part 15 of the FCC Rules and Industry

Canadalicense-exempt RSS standard(s). Operation is subjectto the

following two conditions:

•this devicemay not cause harmful interference, AND

•this device must accept anyinterference received, including

interference that may cause undesiredoperation.

Changes or modifications not expressly approved by Enlighted Inc.

could void the user's authority to operate the equipment.

Le présent appareil est conforme aux CNR d'Industrie Canada

applicables aux appareils radio exempts de licence.L'exploitation

est autoriséeauxdeux conditions suivantes:

•l'appareil ne doit pas produire de brouillage,ET

•l'utilisateur de l'appareildoitaccepter tout brouillage

radioélectriquesubi, même si le brouillage est susceptible d'en

compromettre le fonctionnement.

CE

This device complies with the essential requirements and other

relevant requirements of the R&TTE Directive (1999/5/EC). The

equipment is Class 1 radio equipment which can be placed on the

market and be put into service without restrictions in accordance

with article 1(3) of Commission Decision 2000/299/EC (Version July

2014).

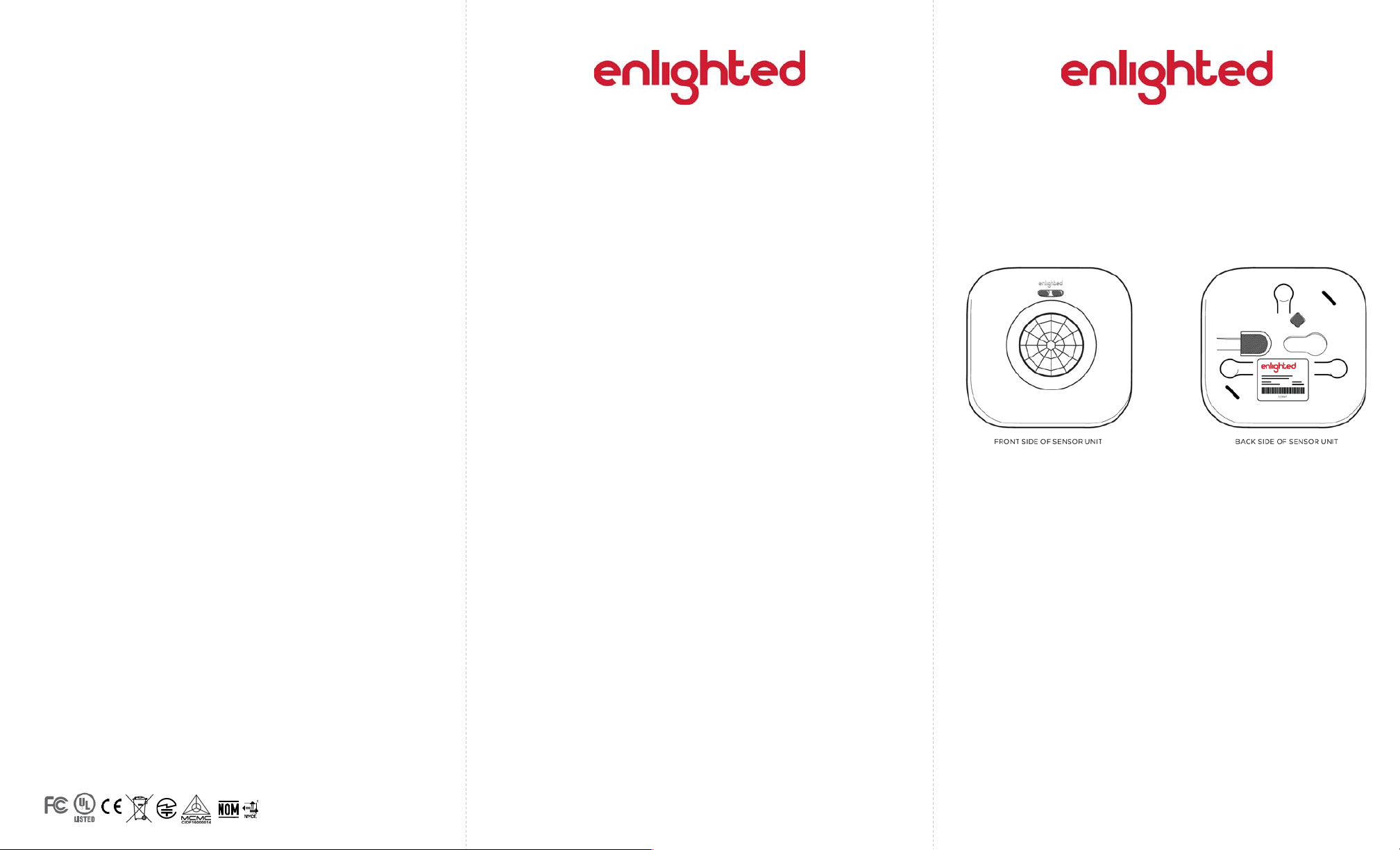

Figure 1: Enlighted Smart Sensor Unit

Smart Sensor Unit

Model SU-2O-00

Installation Instructions

Shipped Components

•Smart Sensor (SU-2O-00) Unit

•Anchor Screw

94-00029-02 Rev05

Model: SU-2O-00

FCC ID: AQQ-SU2

IC: 10138A-SU2

CMIIT ID: 2015DJ5439

Page 2 Page 3 Page 4

Step Description

1 Turn off all power to the light fixture by switching off

the circuit breaker.

2Mount the Control Unit (CU) in a UL approved

enclosure. Refer to the Control Unit Installation

Guide.

3The Smart Sensor (SU-2O) should be mounted to the

ceiling within a few inches of the lighting fixture and

over the service area of the light. See Figure 2.

4 Select a place for the RJ12 data cable from the CU

to exit and make a small cut in the ceiling tile for

the cable to exit. See Figure 3.

5 Install the Smart Sensor anchor screw (as shown).

6 Connect the RJ12 data cable to the Sensor

(bottom entry). See Figure 4.

7 Slide the Smart Sensor onto the screw head as

shown. See Figure 4.

8 Slip the excess RJ12 data cable up into the plenum

area and adjust the ceiling tile to the original

position.

9 For wiring the sensor to the Control Unit, see Figure

6.

Installation

Figure 6: Wiring Drawing

Caution

•Installation and maintenance must be performed by a

qualified electrician in accordance with local, state, and

national electrical codes (NEC) and requirements.

Troubleshooting

Problem Solution

No green

flashing LED

lights

Verify that the RJ12 cable is plugged into the

Control Unit.

Red, flashing

LED

Possible solutions:

•Replace the RJ12 cable

•Replace the Enlighted Control Unit

To install the Enlighted Smart Sensor Unit, perform the following steps: Figure 2: Sensor Distance from the Fixture

Figure 3: RJ12 Cable Exit

Figure 4: Sensor Connected to Anchor screw

Figure 5: Sensor Installed

Page 5 Page 6 93-02026-01 Rev01 Page 1

Ruggedized Sensor

(SU-5S)

Installation Instructions

Models:

SU-5S-HRW: High Bay, White, Ruggedized Sensor

SU-5S-LRW: Standard Bay, White, Ruggedized Sensor

SU-5S-HRB: High Bay, Bronze, Ruggedized Sensor

SU-5S-LRB: Standard Bay, Bronze, Ruggedized Sensor

FCC ID: AQQ-SU5S

IC: 10138A-SU5S

Ruggedized Sensor (Front and Rear)

Shipped Components

•Enlighted Ruggedized Sensor

•½inch Lock Nut

Supplemental Components

•½inch LB Conduit Body

•½inch Chase Nipple

•Enlighted Control Unit

•Enlighted Sensor Cable

•Cable Coupler: CPL-RJ12

Tools you may Need

•½inch Knock out tool

Copyright ©2018 Enlighted Inc. All rights reserved.

All other brand or product names are trademarks of their

respective companies or organizations.

LED Description

LED Status Description/Solution

LED not on Check power and wiring

Green blinking Sensor is commissioned, working, and has

detected motion. If there is no motion in the

sensor’s field of view, the blinking will stop.

Wave your hands below the sensor to restart

LED blinking.

Red blinking Sensor is not commissioned and has detected

a wiring issue. Check wiring to the Control Unit

(CU) and LED driver.

Red solid Faulty sensor – replace sensor

Green solid Sensor installed, initialized, and not

commissioned –waiting for discovery

Blue solid Sensor received a request to identify itself

FCC and Industry Canada Compliance Information

This equipment has been tested and found to comply with the limits for

a Class A digital device, pursuant to part 15 of the FCC Rules. These

limits are designed to provide reasonable protection against harmful

interference when the equipment is operated in a commercial

environment. This equipment generates, uses, and can radiate radio

frequency energy and, if not installed and used in accordance with

the instruction manual, may cause harmful interference to radio

communications. Operation of this equipment in a residential area is

likely to cause harmful interference in which case the user will be

required to correct the interference at his own expense.

This device complieswith Part 15 of the FCC Rules and Industry Canada

license-exempt RSS standard(s). Operation is subjectto the following two

conditions:

•this devicemay not cause harmful interference, AND

•this device must accept anyinterference received, including

interference that may cause undesiredoperation.

Changes or modifications not expressly approved by Enlighted Inc.

could void the user's authority to operate the equipment.

Le présent appareil est conforme aux CNR d'Industrie Canada

applicables aux appareils radio exempts de licence.L'exploitation

est autoriséeauxdeux conditions suivantes:

•l'appareil ne doit pas produire de brouillage,ET

•l'utilisateur de l'appareildoitaccepter tout brouillage radioélectrique

subi, même si le brouillage est susceptible d'en compromettre le

fonctionnement.

CE

This device complies with the essential requirements and other relevant

requirements of the R&TTE Directive (1999/5/EC) and Radio Equipment

Directive (RED) 2014/53/EU. The equipment is Class 1 radio equipment

which can be placed on the market and be put into service without

restrictions in accordance with article 1(3) of Commission Decision

2000/299/EC (Version July 2014).

Wireless protocol: IEEE802.15.4, Radio Freq: 2400 – 2483.5MHz,

RF TX output power (max): 6dBm

Wireless protocol: IEEE802.15.1, Radio Freq: 2400 – 2483.5MHz,

RF TX output power (max): 6dBm

Company Contact Information

Location: 930 Benecia Ave, Sunnyvale, CA 94085

Phone: +1.650.964.1094

Web: enlightedinc.com

Technical Support: support@enlightedinc.com

Page 2 Page 3 Page 4

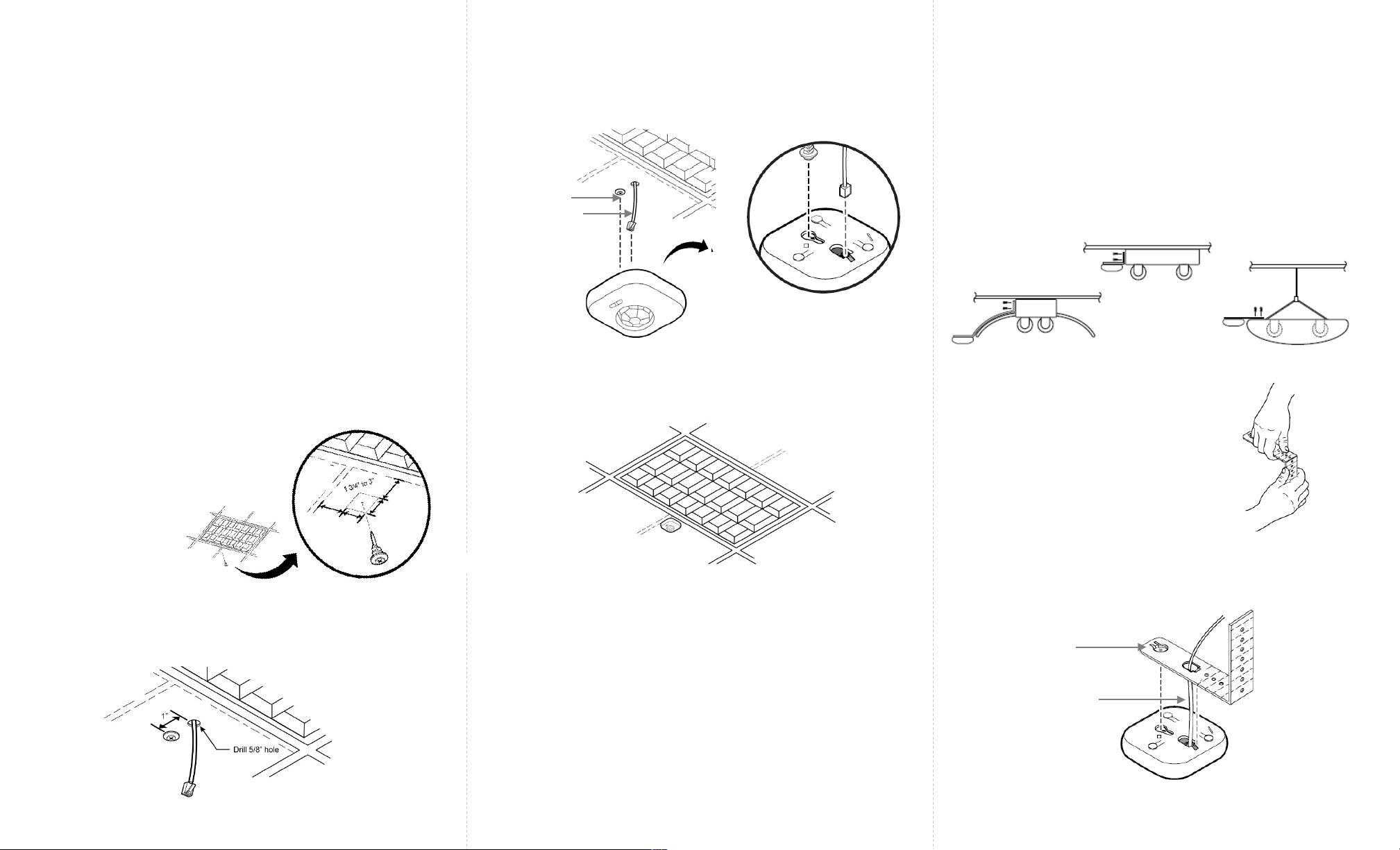

The Ruggedized sensor is shipped with the cable

attached to the sensor. The sensor can be mounted to

the fixture using a conduit body and chase nipple or

locknut.

Step 1: De-energize the luminaire.

Step 1: Remove the cover plate of the ½inch LB

conduit body by removing the two screws.

Step 2:Thread the

Ruggedized sensor onto

the LB conduit body.

Step 3: Replace the cover

and two screws on the LB

conduit body.

Chase Nipple

Enlighted

Control Unit

Step 1: Knock out a ½inch hole on the bottom of the

light fixture.

Step 2: Glide the sensor cable through the knockout of

the fixture.

Step 4: Knock out a ½inch hole on the end of the light

fixture.

Step 6:Thread the chase nipple to securely connect

the LB conduit to the fixture.

Caution

Installation and maintenance must be performed by a qualified

electrician in accordance with local, state, and national

electrical codes (NEC) and requirements.

Installation

Mounting using the Conduit Body and Chase

Nipple

Mounting using the Locknut

Step 3: Thread the locknut tightly to secure the sensor to

the fixture.

Step 2: Energize the luminaire and confirm that the

green LED is on solid. Refer to the LED Descriptions on

page 5.

Step 1: Use an RJ45 coupler with an Enlighted Sensor

cable to connect the RJ45 end of the sensor cable to

the connector of the Control Unit (CU).

For wiring connections from the Control Unit to the

sensor, refer to the Control Unit Installation Guide.

Connecting the Sensor Cable to the Control

Unit

Step 5: Mount the Ruggedized Sensor LB Conduit to

the fixture by guiding the sensor cable through the

knock out and chase nipple into the fixture.

Page 5 Page 6 Page 1

Copyright © 2016 Enlighted Inc. All rights reserved.

All other brand or product names are trademarks of

their respective companies or organizations.

TechnicalSupport

For questions regardingtheinstallation or operation of

this product,contact Enlighted

TechnicalSupport: support@enlightedinc.com

Company Contact Information

Location: 930 Benecia Ave, Sunnyvale, CA 94085

Phone: +1.650.964.1094

Web: enlightedinc.com

FCC and Industry Canada Compliance Information

This equipment has been tested and found to comply with the limits

for a Class A digital device, pursuant to part 15 of the FCC Rules.

These limits are designed to provide reasonable protection against

harmful interference when the equipment is operated in a

commercial environment. This equipment generates, uses, and can

radiate radio frequency energy and, if not installed and used in

accordance with the instruction manual, may cause harmful

interference to radio communications. Operation of this equipment

in a residential area is likely to cause harmful interference in which

case the user will be required to correct the interference at his own

expense.

This device complieswith Part 15 of the FCC Rules and Industry

Canadalicense-exempt RSS standard(s). Operation is subjectto the

following two conditions:

•this devicemay not cause harmful interference, AND

•this device must accept anyinterference received, including

interference that may cause undesiredoperation.

Changes or modifications not expressly approved by Enlighted Inc.

could void the user's authority to operate the equipment.

Le présent appareil est conforme aux CNR d'Industrie Canada

applicables aux appareils radio exempts de licence.L'exploitation

est autoriséeauxdeux conditions suivantes:

•l'appareil ne doit pas produire de brouillage,ET

•l'utilisateur de l'appareildoitaccepter tout brouillage

radioélectriquesubi, même si le brouillage est susceptible d'en

compromettre le fonctionnement.

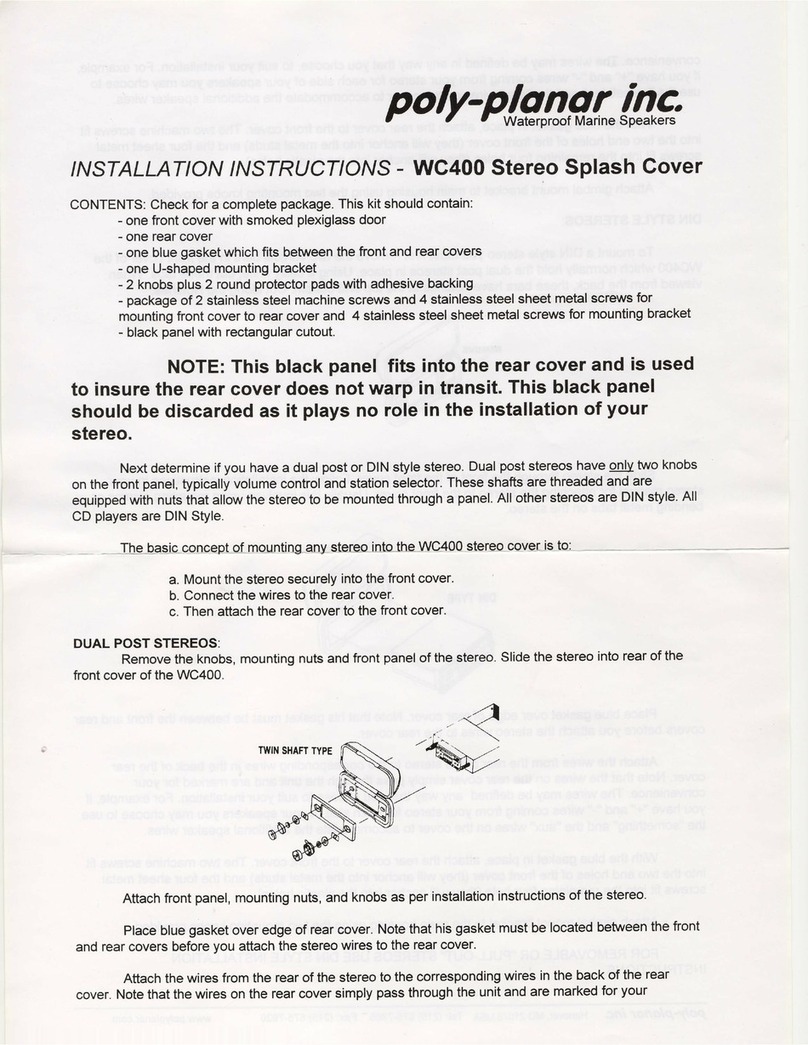

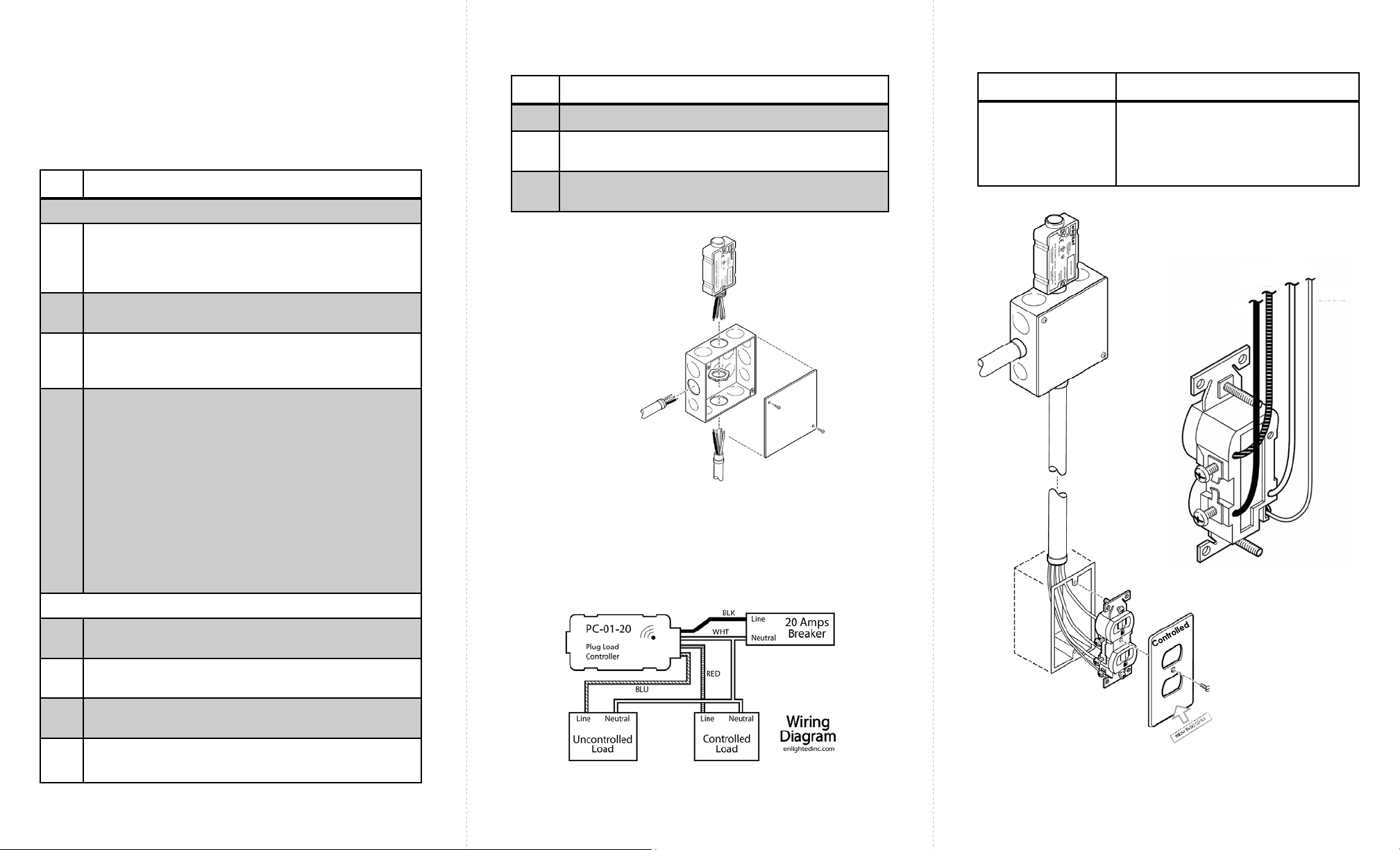

Figure 1: Plug Load Controller, Locknut, and Sticker

Plug Load Controller

Model PC-01-20

Installation Instructions

Shipped Components

•Plug load controller (and ½inch locknut)

•MAC address sticker

Tools You May Need

•Wire stripper

Supplies You May Need

•Wire nuts (or connectors)

•Junction box (j-box)

•Two Conductor plus ground 12 AWG solid wire cable

•Three Conductor plus ground 12 AWG solid wire cable

•Clamps

93-01142-01 Rev05

Model: PC-01-20

FCC ID: AQQ-PC-01-20

IC: 10138A-PC0120

Troubleshooting

Page 2 Page 3 Page 4

Caution

•Installation and maintenance must be performed by a

qualified electrician in accordance with local, state, and

national electrical codes (NEC) and requirements.

Problem Solution

LED is not on when

the device is

powered

1) Check to see that power is present

from the circuit panel.

2) Check the wiring, if LED does not

come on, then replace the

device.

Step Description

J-box Install (see Figure 2)

1Punch out a ½inch knock out from the j-box and

insert the threaded end of the plug load controller.

Secure the plug load controller to the j-box with the

supplied locknut.

2(Main Feed) Feed the j-box with (3) 12 AWG

conductors. (Hot, Neutral, and Ground)

3Connect the j-box with (4) 12 AWG conductors that

run from the j-box to the receptacle wall box.

(Hot, Switched Hot, Neutral, and Ground)

4Using wire nuts (or wire connectors):

a) Connect the hot wire from the main feed to the

black wire of the plug load controller.

b) Connect the neutral wire from the main feed to

the white wire of the plug load controller and the

neutral wire that feeds through to the receptacle.

c) Connect the red wire of the plug load controller

to the switched hot wire that feeds through to the

receptacle.

d) Connect the blue wire of the plug load controller

to the hot wire that feeds through to the

receptacle.

e) Connect all ground wires to the j-box.

Receptacle Install (see Figure 4)

5Break the connection on the “hot side” of the

receptacle between the two outlets.

6 Connect the neutral wire to the neutral connection

on the receptacle.

7Connect the switched hot wire to the hot side of the

“controlled outlet”.

8Connect the hot wire to the hot connection of the

“uncontrolled outlet” (always powered).

Installation Steps

Installation Steps (Continued)

Step Description

9 Install the receptacle in the wall box

10 Attach a receptacle faceplate that distinguishes the

controlled outlet.

11 Attach the included MAC address sticker on the

faceplate.

Figure 2: J-box with plug load controller, showing main

feed and wiring to receptacle.

Figure 3: Wiring Diagram

Figure 4: Receptacle wiring

Main feed:

•Hot

•Neutral

•Ground

Receptacle feed:

•Hot

•Switched Hot

•Neutral

•Ground

Hot

Neutral

Switched

Hot

Ground

Page 5 Page 6 Page 1

Copyright © 2016 Enlighted Inc. All rights reserved.

All other brand or product names are trademarks of

their respective companies or organizations.

TechnicalSupport

For questions regardingtheinstallation or operation of

this product,contact Enlighted

TechnicalSupport: support@enlightedinc.com

Company Contact Information

Location: 930 Benecia Ave, Sunnyvale, CA 94085

Phone: +1.650.964.1094

Web: enlightedinc.com

FCC and Canada Compliance Information

This device complies with Part 15 of the FCC Rules and with Industry

Canada license-exempt RSS standards. Operation is subject to the

following two conditions: (1) this device may not cause harmful

interference, and (2) this device must accept any interference received,

including interference that may cause undesired operation. Changes or

modifications not expressly approved by Enlighted Inc. could void the user's

authority to operate the equipment. This equipment generates, uses, and

can radiate radio frequency energy and, if not installed and used in

accordance with the instruction manual, may cause harmful interference

to radio communications. Operation of this equipment in a residential area

is likely to cause harmful interference in which case the user will be required

to correct the interference at his own expense.

Le présent appareil est conforme aux CNR d'Industrie Canada applicables

aux appareils radio exempts de licence. L'exploitation est autorisée aux

deux conditions suivantes : (1) l'appareil ne doit pas produire de brouillage,

et (2) l'utilisateur de l'appareil doit accepter tout brouillage radioélectrique

subi, même si le brouillage est susceptible d'en compromettre le

fonctionnement.

Under Industry Canada regulations, this radio transmitter may only operate

using an antenna of a type and maximum (or lesser) gain approved for the

transmitter by Industry Canada. To reduce potential radio interference to

other users, the antenna type and its gain should be so chosen that the

equivalent isotropically radiated power (e.i.r.p.) is not more than that

necessary for successful communication.

Conformément à la réglementation d'Industrie Canada, le présent émetteur radio

peut fonctionner avec une antenne d'un type et d'un gain maximal (ou inférieur)

approuvé pour l'émetteur par Industrie Canada. Dans le but de réduire les risques de

brouillage radioélectrique à l'intention des autres utilisateurs, il faut choisir le type

d'antenne et son gain de sorte que la puissance isotrope rayonnée équivalente

(p.i.r.e.) ne dépasse pas l'intensité nécessaire à l'établissement d'une communication

satisfaisante.

This radio transmitter IC: 10138A-GW2 has been approved by Industry

Canada to operate with the antenna types listed below with the maximum

permissible gain and required antenna impedance for each antenna type

indicated. Antenna types not included in this list, having a gain greater

than the maximum gain indicated for that type, are strictly prohibited for

use with this device.

Le présent émetteur radio IC: 10138A-GW2 a été approuvé par Industrie Canada pour

fonctionner avec les types d'antenne énumérés ci-dessous et ayant un gain admissible

maximal et l'impédance requise pour chaque type d'antenne. Les types d'antenne

non inclus dans cette liste, ou dont le gain est supérieur au gain maximal indiqué, sont

strictement interdits pour l'exploitation de l'émetteur.

CE

This device complies with the essential requirements and other relevant

requirements of the R&TTE Directive (1999/5/EC). The product is compliant

with the following standards and/or other normative documents - EN 62479,

ETSI EN 301 489-1-17, EN 300 328 and EN 60950-1

•The equipment is Class 1 radio equipment which can be placed on the

market and be put into service without restrictions in accordance with

article 1(3) of Commission Decision 2000/299/EC (Version July 2014).

Gateway (GW)

Model GW-2-01

Installation Instructions

Figure 1: Gateway Unit (front and back)

Shipped Components

•EnlightedGateway

•Two #6 - 1” screws with standoffs

•Antenna: Nearson S151AH-07826 2.4GHz Swivel

Antenna with 5dBi, 50 Ohm

Tools You May Need

•#2 Philips screwdriver

Supplies You May Need

•Cat-5e or Cat-6 data cable with RJ45 (conforming to

TIA/EIA 568-B) connectors between the gateway

(GW) and PoE Ethernet switch

Model: GW-2-01

FCC ID: AQQ-GW2

IC: 10138A-GW2

CMIIT ID: 2015DJ5440

93-01246-01-01 Rev05

Page 2 Page 3 Page 4

Caution

•Disconnect all power before installation or service.

•Installation and maintenance must be performed by a qualified

electrician in accordance with local, state, and national electrical

codes (NEC) and requirements.

Problem Solution

No LED on the

Gateway (GW) is

on or blinking.

•Verify the Cat-6 cable

betweenthe PoEport on

theEthernet switch and

the Enlighted Gateway

has not been damaged.

•Check that the RJ45

connectors on each end

of the Cat-6 cable are

completely inserted.

•Verify that the PoE

Ethernet switchis powered

and functioning properly.

RedLED on the GW

is on continuously.

Replace the Gateway.

Red LED on the

GW is blinkingat

a slow rate and

thegreen LED is

off.

This is the expected blink

pattern before the

Energy Manager is

connected to the PoE

Ethernet Switch and

made operational.

Red LED on the GW

is off and the green

LED is blinking

rapidly.

This is the expected blink

pattern after the Energy

Manager is connected to

the PoE Ethernet Switch

and made operational,

and before the GW is

commissioned.

Troubleshooting

Figure 2: Attach the unit to the wall on screws

with the antenna pointing up

Figure 4: Wiring Diagram for PoE switch and GW

Step Description

1Determine a location for the GW. The Cat-5e

or Cat-6 data cable from the PoE Ethernet

switch MUST be less than 300 feet. Ideally, the

GW will be at the same elevation as the

sensors it communicates with. It MUST be

visible so that it’s LEDs can be seen for

troubleshooting. Because it uses wireless

communication with sensors, it SHOULD be

placed to maximize the number of sensors

that are near it.

2Select a location for the RJ45 connector

(conforming to TIA/EIA 568-B) of the data

cable to exitthewall or ceiling. Make a small

circular cut(roughly 11/16th of an inch in

diameter) in thewall or ceiling for the RJ45

connector.

3Install the two #6, 1” screws two inches apart.

4Slide the GW onto the screws as shown in

Figures 2 and 3.

5If on the wall, point the antenna straight up.

If on the ceiling, point antenna straight down.

6Insert the RJ45 connector on one end of the

data cable into the GW.

7 Routethedata cable to the PoEEthernet

switch and insert the RJ45 connector into a

powered PoE port (see Figure 4).

8Power on the PoE Ethernet switch and check

for the “PoE Active” LED to be green for the

port connecting the GW.

Installation Steps (both wall & ceiling mounts)

Note: After a Gateway has been commissioned, the red

LED is off and the green LED blinks at a slow rate.

Figure 3: Attach the unit to the ceiling on screws

with the antenna pointing down

PoE Active

LEDs

Page 5 Page 6 Page 1

Copyright © 2016 Enlighted Inc. All rights reserved.

All other brand or product names are trademarks of

their respective companies or organizations.

TechnicalSupport

For questions regardingtheinstallation or operation of

this product,contact Enlighted

TechnicalSupport: support@enlightedinc.com

Company Contact Information

Location: 930 Benecia Ave, Sunnyvale, CA 94085

Phone: +1.650.964.1094

Web: enlightedinc.com

FCC and Industry Canada Compliance Information

This equipment has been tested and found to comply with the limits

for a Class A digital device, pursuant to part 15 of the FCC Rules.

These limits are designed to provide reasonable protection against

harmful interference when the equipment is operated in a

commercial environment. This equipment generates, uses, and can

radiate radio frequency energy and, if not installed and used in

accordance with the instruction manual, may cause harmful

interference to radio communications. Operation of this equipment

in a residential area is likely to cause harmful interference in which

case the user will be required to correct the interference at his own

expense.

This device complieswith Part 15 of the FCC Rules and Industry

Canadalicense-exempt RSS standard(s). Operation is subjectto the

following two conditions:

•this devicemay not cause harmful interference, AND

•this device must accept anyinterference received, including

interference that may cause undesiredoperation.

Changes or modifications not expressly approved by Enlighted Inc.

could void the user's authority to operate the equipment.

Le présent appareil est conforme aux CNR d'Industrie Canada

applicables aux appareils radio exempts de licence.L'exploitation

est autoriséeauxdeux conditions suivantes:

•l'appareil ne doit pas produire de brouillage,ET

•l'utilisateur de l'appareildoitaccepter tout brouillage

radioélectriquesubi, même si le brouillage est susceptible d'en

compromettre le fonctionnement.

CE

This device complies with the essential requirements and other

relevant requirements of the R&TTE Directive (1999/5/EC. The

equipment is Class 1 radio equipment which can be placed on the

market and be put into service without restrictions in accordance

with article 1(3) of Commission Decision 2000/299/EC (Version July

2014).

Two-wire Fixture Mount Sensor (FSD22)

Two-wire Fixture Mount

Sensor (FSD22)

Installation Instructions

Shipped Components

•Enlighted fixture mount sensor

Tools You May Need

•Wire stripper

Supplies You May Need

•18 AWG solid copper wire, rated >= 300V

93-01144-02 Rev08

Model: FS-D22

FCC ID: AQQ-CS-D2

IC: 10138A-CSD2

Page 2 Page 3 Page 4

Installation

LED Description

Figure 4

Note: For any reason, if you need to remove the two wires,

push down on the tabs of the sensor with a pointed device,

and remove the wires while continuing to hold the tab down.

Sensor Antenna

To Enlighted

sensor To

lamps

Figure 1

Figure 2

LED Status Description/Solution

LED not on Check power and wiring

Purple solid All LEDs are on during boot time for 5-6 seconds

Green

blinking

Sensor commissioned and working

Red blinking Incompatibility between LED driver and sensor –

Replace LED driver and if not resolved, replace

sensor.

Red solid Faulty sensor – replace sensor

Green solid Sensor installed, initialized, and

uncommissioned –waiting for discovery.

Blue solid Image being upgraded.

Figure 3 Figure 5

From Mains

The two-wire Fixture Mount sensor is designed to mount in a ½

inch trade size knockout. All parts of the sensor are inside the

lighting fixture except for the outer ring. (See Figure 4). This

sensor is for use with the Philips XSR driver.

Step 1: Switch off the circuit breaker supplying power to the

light fixture.

Step 2: Determine the location for the sensor in the fixture.

Step 3: Remove an existing ½inch knockout or cut a hole in

the fixture.

Step 4: Measure the distance between the sensor’s installation

location and the LED XSR driver.

Caution

Installation and maintenance must be performed by a qualified

electrician in accordance with local, state, and national electrical

codes (NEC) and requirements.

Step 5: Cut two lengths of 18 AWG solid wire that are at least

this measured length plus one inch. Strip each end of the two

wires leaving 3/8 inch of exposed wire.

Step 6: Insert one end of the pair of wires into the LED XSR

driver’s connections wire holes. See Figure 2.

Step 7: Remove the outer ring

from the sensor by unthreading

it. Keep the spring washer and

inner ring on the sensor.

Step 9: Close the light fixture and restore power to the fixture.

Step 8: Insert the sensor assembly into the knockout that was

cut out of the light fixture. Thread the outer ring back on the

sensor. Tighten firmly, but do no over tighten. If you have a

thick fixture, do not use the inner ring.

Note: Make sure that the sensor antenna passes through the

knock out and does not get caught in the rings or assembly.

LED Driver

Sensor Antenna

Page 5 Page 6 Page 1

Copyright © 2016 Enlighted Inc. All rights reserved.

All other brand or product names are trademarks of

their respective companies or organizations.

TechnicalSupport

For questions regardingtheinstallation or operation of

this product,contact Enlighted

TechnicalSupport: support@enlightedinc.com

Company Contact Information

Location: 930 Benecia Ave, Sunnyvale, CA 94085

Phone: +1.650.964.1094

Web: enlightedinc.com

FCC and Industry Canada Compliance Information

This equipment has been tested and found to comply with the limits

for a Class A digital device, pursuant to part 15 of the FCC Rules.

These limits are designed to provide reasonable protection against

harmful interference when the equipment is operated in a

commercial environment. This equipment generates, uses, and can

radiate radio frequency energy and, if not installed and used in

accordance with the instruction manual, may cause harmful

interference to radio communications. Operation of this equipment

in a residential area is likely to cause harmful interference in which

case the user will be required to correct the interference at his own

expense.

This device complieswith Part 15 of the FCC Rules and Industry

Canadalicense-exempt RSS standard(s). Operation is subjectto the

following two conditions:

•this devicemay not cause harmful interference, AND

•this device must accept anyinterference received, including

interference that may cause undesiredoperation.

Changes or modifications not expressly approved by Enlighted Inc.

could void the user's authority to operate the equipment.

Le présent appareil est conforme aux CNR d'Industrie Canada

applicables aux appareils radio exempts de licence.L'exploitation

est autoriséeauxdeux conditions suivantes:

•l'appareil ne doit pas produire de brouillage,ET

•l'utilisateur de l'appareildoitaccepter tout brouillage

radioélectriquesubi, même si le brouillage est susceptible d'en

compromettre le fonctionnement.

CE

This device complies with the essential requirements and other

relevant requirements of the R&TTE Directive (1999/5/EC). The

equipment is Class 1 radio equipment which can be placed on the

market and be put into service without restrictions in accordance

with article 1(3) of Commission Decision 2000/299/EC (Version July

2014).

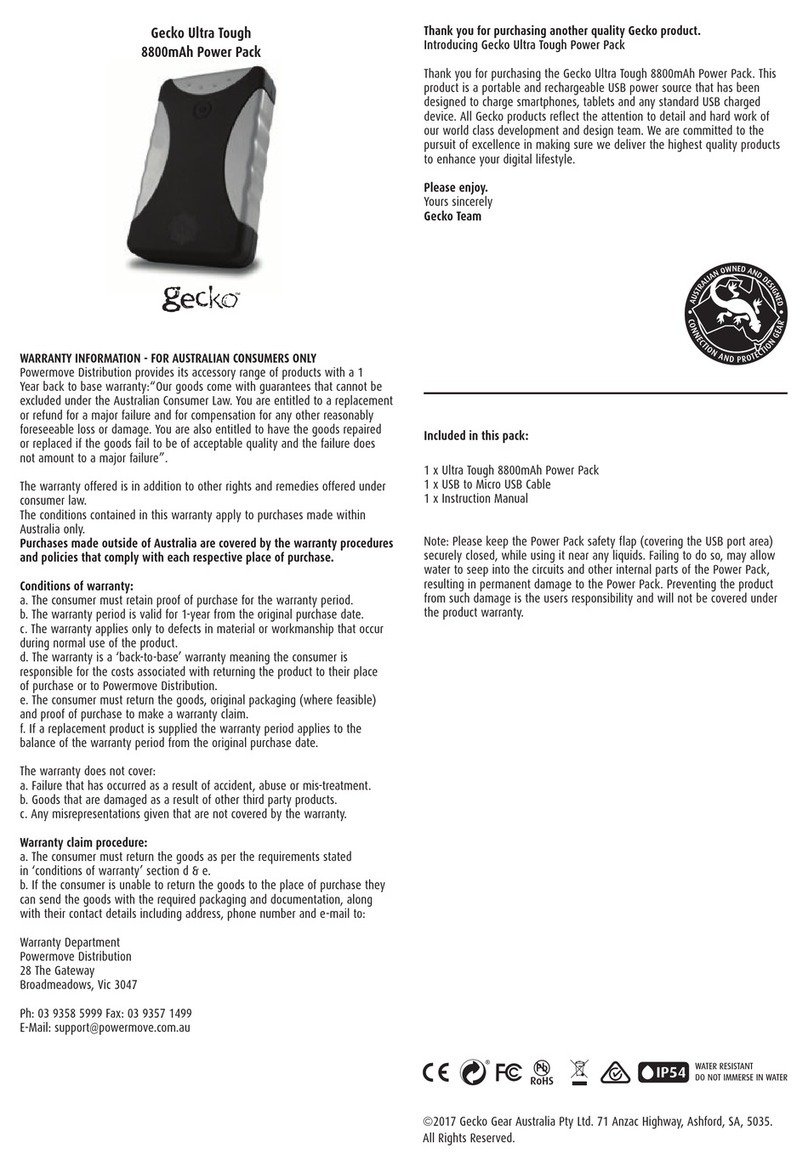

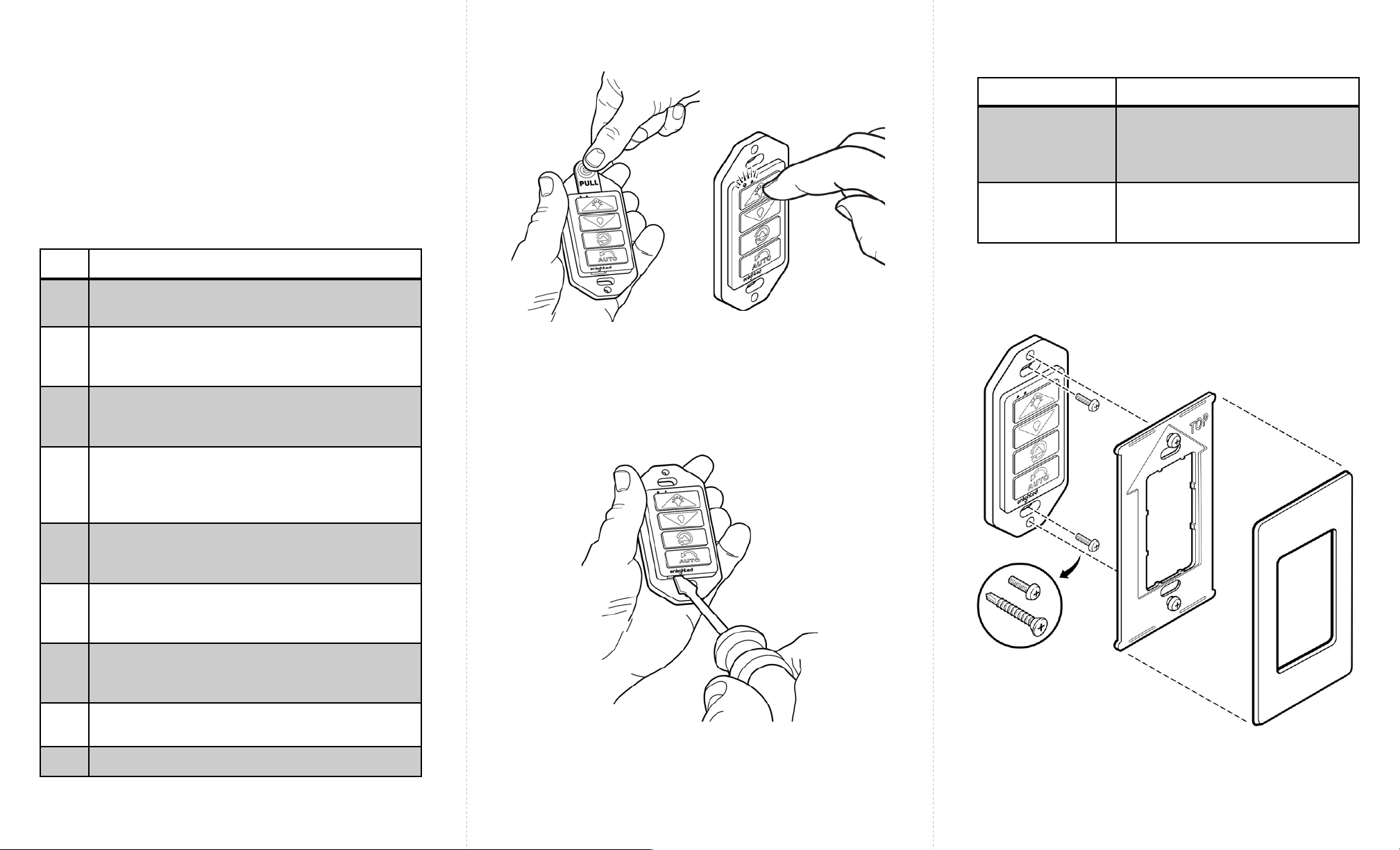

Figure 1: Enlighted Room Control (ERC2)

Room Control (ERC)

Model WS-2-00

Installation Instructions

Shipped Components

•Enlighted Room Control version 2 (ERC2)

•Usage card

•Back plate (with captive screws in place)

•Cover plate

•Two tapping screws

•Two 6-32 machine screws

Tools You May Need

•Phillips screw driver

•Flat head screw driver

93-01140-01 Rev06

Model: WS-2-00

FCC ID: AQQ-WS-2-00

IC: 10138A-WS200

CMIIT ID: 2015DJ5479

Troubleshooting

Page 2 Page 3 Page 4

Caution

Installation and maintenance must be performed by a

qualified electrician in accordance with state, local, and

national electrical codes (NEC) and requirements.

Figure 5: Mounting Sequence

Problem Solution

LEDs do not flash

when a is button

pressed

The energy in the battery may

have drained. Check, and if

needed, replace the battery

(see Figure 4)

Buttons do not

easily move

when pressed

Return unit for replacement

Figure 4: Opening the ERC2’s case to access the battery

Step Description

1 Separate, if needed, the cover and back

plates.

2Remove the plastic pull tab from ERC2 to

allow the battery to come in contact with the

terminals. (See figure 2)

3 Press each button and verify that both the

green and red LEDs flash and that the button

moves smoothly. (See figure 3)

4 If the LEDs do not flash when a button is

pressed, then check, and if needed, replace

the battery. The battery is accessed after

opening the case as shown in figure 4.

5Position the ERC2 on either the wall or on a

junction box with the LEDs on the top and the

Enlighted logo on the bottom. (See Figure 5)

6 Use the provided tapping screws (or machine

screws for a junction box) to attach the ERC2

to the wall.

7Align the back plate (with the arrow pointing

up) to the ERC2. Affix the back plate to the

ERC2 by firmly tightening both captive screws.

8Snap on the cover plate with the arrow (on its

back side) pointing up.

9 Save usage card for room occupants.

Installation Steps

Both Wall and Junction Box Mounting

Figure 2: Remove plastic

tab to allow battery to

power unit

Figure 3: Press each

button to verify operation

and that LEDs flash

Page 5 Page 6 93-01219-02 Rev01 Page 1

Energy Manager

Installation Instructions

Energy Manager

Shipped Components

•Enlighted Energy Manager Server

Items you may Need

•Phillips Screwdriver

FCC and Industry Canada Compliance Information

This equipment has been tested and found to comply with the limits

for a Class A digital device, pursuant to part 15 of the FCC Rules.

These limits are designed to provide reasonable protection against

harmful interference when the equipment is operated in a

commercial environment. This equipment generates, uses, and can

radiate radio frequency energy and, if not installed and used in

accordance with the instruction manual, may cause harmful

interference to radio communications. Operation of this equipment

in a residential area is likely to cause harmful interference in which

case the user will be required to correct the interference at his own

expense.

Copyright © 2016 Enlighted Inc. All rights reserved.

All other brand or product names are trademarks of

their respective companies or organizations.

TechnicalSupport

For questions regardingtheinstallation or operation of

this product,contact Enlighted

TechnicalSupport: support@enlightedinc.com

Company Contact Information

Location: 930 Benecia Ave, Sunnyvale, CA 94085

Phone: +1.650.964.1094

Web: enlightedinc.com

Page 2 Page 3 Page 4

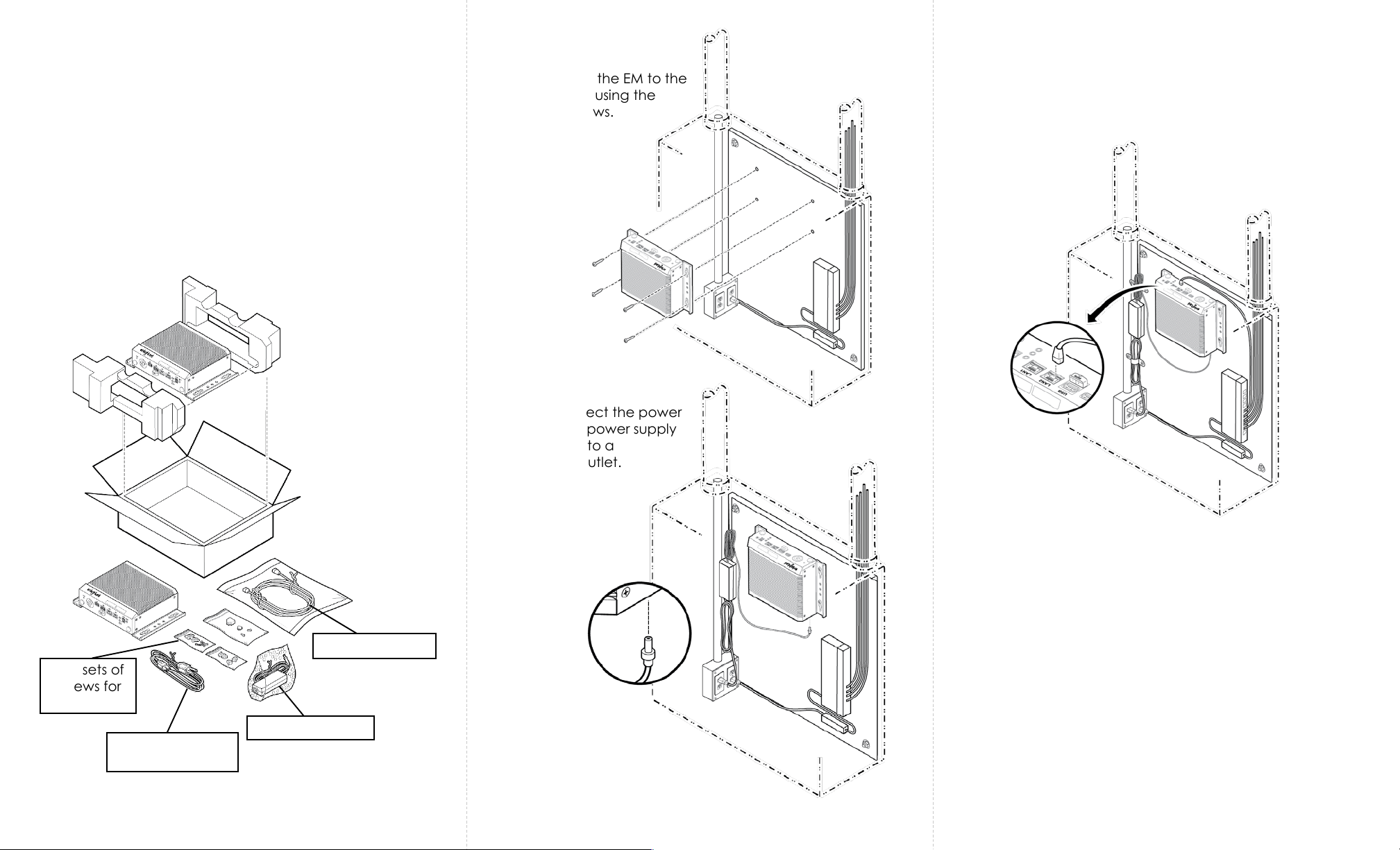

The procedure below shows how to install the Energy Manager.

The Energy Manager (EM) can be installed on a backer board,

which can be inside or outside of an enclosure.

Step 1: Unbox the Energy Manager (EM).

Caution

Installation and maintenance must be performed by a

qualified electrician in accordance with local, state, and

national electrical codes (NEC) and requirements.

Step 2: Attach the EM to the

backer board using the

mounting screws.

Step 3: Connect the power

cable to the power supply

and plug it into a

receptacle outlet.

Step 4: Use an Ethernet cable to connect LAN2 port on the

EM to a standard port on the PoE switch.

Step 5: Tie the extra-length of the cables using tie wraps

and/or hold downs.

Power supply

Power cable for

power supply

Two sets of

screws for

mounting

Ethernet cable

Page 5 Page 6 Page 1

Copyright © 2018 Enlighted,Inc. All rights reserved.

All other brand or product names are trademarks of

their respective companies or organizations.

TechnicalSupport

For questions regardingtheinstallation or operation of

this product,contact Enlighted

TechnicalSupport: support@enlightedinc.com

Company Contact Information

Location: 930 Benecia Ave, Sunnyvale, CA 94085

Phone: +1.650.964.1094

Web: enlightedinc.com

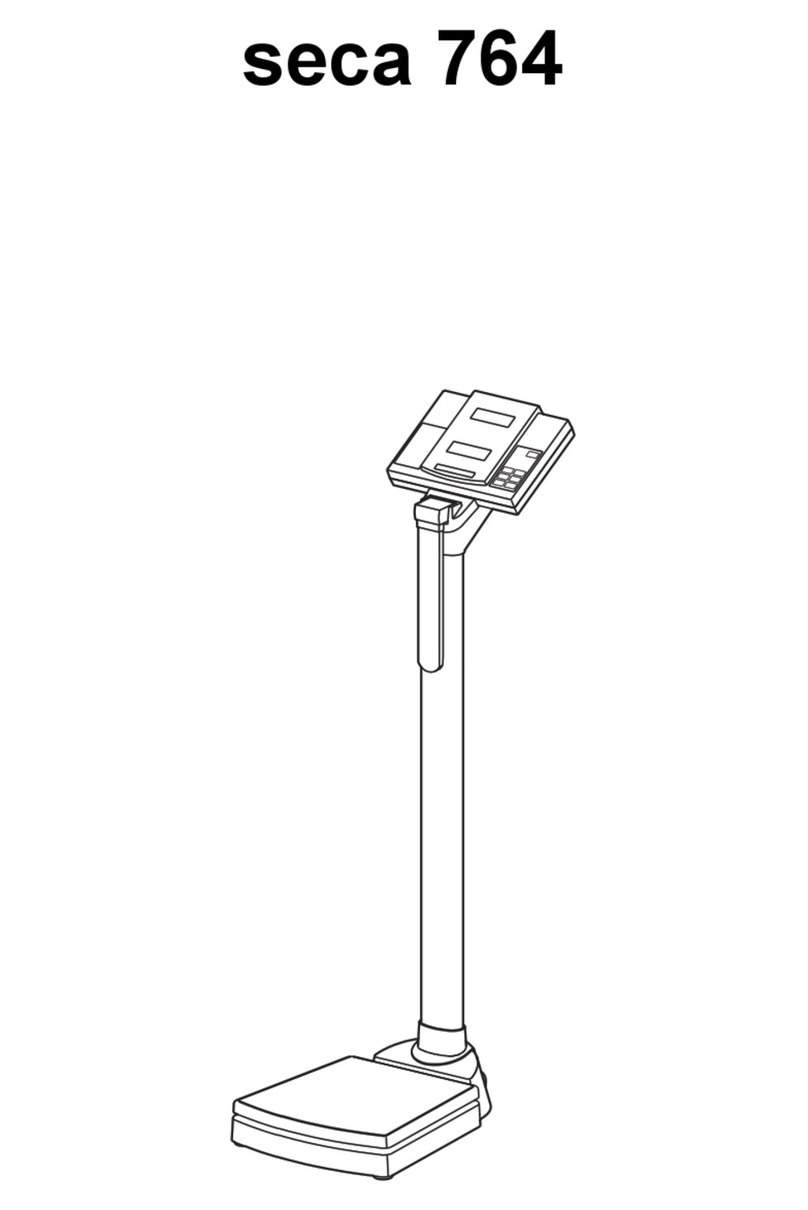

Fixture Mount Control Unit

Model CU-4E

Installation Instructions

Shipped Components

•Enlighted Fixture Mount Control Unit

Items you will Need

•Two mounting screws, as appropriate for mounting

the Control Unit to the inside of the luminaire

93-02297-01 Rev.03

FCC and Industry Canada Compliance Information

This equipment has been tested and found to comply with the limits

for a Class A digital device, pursuant to part 15 of the FCC Rules.

These limits are designed to provide reasonable protection against

harmful interference when the equipment is operated in a

commercial environment. This equipment generates, uses, and can

radiate radio frequency energy and, if not installed and used in

accordance with the instruction manual, may cause harmful

interference to radio communications. Operation of this equipment

in a residential area is likely to cause harmful interference in which

case the user will be required to correct the interference at his own

expense.

CAN ICES-003 (A)/NMB-003 (A)

CE

This device complies with the essential requirements and other

relevant requirements of CISPR 24, CSIPR 32 in the EMC Directive

2004/108/EMC and is compliant with the following standards:

EN61000-6-2, EN61000-6-4. In addition the device is compliant with

the IEC 61347-2-11 safety standard for Lamp Control gear.

Models: CU-4E-FM,

CU-4E-FMH

Open Energy

Mgt. Eqp t.

3WG4

Page 2 Page 3 Page 4

Installation Steps

Step 1: Switch off the circuit breaker supplying power to

the light fixture.

Step 2: Open the fixture cover and remove the cover for

the ballast cavity. The ballast and its wiring should now be

visible.

Step 3:Utilizing a voltmeter, verify that power is off to the

ballast. If power is present, stop work, identify, and switch

off the circuit breaker.

Step 4: Place the Control Unit (CU) in the desired location

and secure it with mounting screws. If desired, the CU

mounting tab can be shortened by snapping off the tab

at the notch on the AC input side of the CU.

Step 5: Disconnect the “Hot” wire (Line) of the ballast

from the power input wire.

Step 6: Connect the power input “Hot” wire (Line) to the

Control Unit black Wago Lin (Line In) connector.

Step 7: Connect the ballast power input “Hot” wire to the

Control Unit red Wago Lout (Line Out) connector.

Step 8: Connect the power input (Neutral) wire to either one

of the two white Wago N(Neutral) connectors on the CU.

Step 9: Connect the ballast (Neutral) wire to either one of

the two white Wago N(Neutral) connectors on the CU.

Step 10: Bend wires into place such that the ballast cover

can easily be reattached.

Step 11: Install the RJ45 sensor cable between the Control Unit

and the Enlighted sensor. Do not use RJ12 cable as it may

damage the sensor port. Refer to the corresponding Sensor

Installation Guide for connecting the cable between the

sensor and the Control Unit (CU).

Completing the Installation

Step 2: Connect the gray wire (-) from the dimming ballast to

channel A gray Wago terminal on the Control Unit. Repeat for

channel B if required.

Step 1: Connect the violet wire (+) from the dimming ballast to

channel A violet Wago terminal on the Control Unit. Repeat for

channel B if required.

Step 1: If the sensor is mounted outside of the luminaire, use

a snap bushing in the knockout hole on the lighting fixture to

route and protect the sensor cable. If the sensor is mounted

within the luminaire, then bushing is not needed.

Step 2: Install the cover for the ballast cavity and apply

power to the newly wired lighting fixture.

Step 3: The lights should turn on to full bright state, and then

may cycle or dim based on the sensor commissioning status

or programming.

The Control Unit (CU-4E) can connect to two dimming

ballasts on two separate channels (channels A and B) for

“Tunable White” applications. If using both dimming

channels, gently break the tab above channel B. For single

channel dimming, use channel A terminals only. For multiple

dimming drivers on the same channel the dimming wires may

be connected in parallel (violet to violet and grey to grey) for

all drivers on that channel.

Installation and maintenance must be performed by a

qualified electrician in accordance with state, local, and

National Electrical Codes (NEC) and requirements.

The Fixture Mount Control Unit must be installed in a UL-

rated fixture or enclosure rated for this application.

Caution

Additional Installation Instructions for Use with a

Dimming Ballast

This manual suits for next models

13

Table of contents