bentrup TM 100 User manual

TM 100

Operating Instructions

Thermocomputer

TM100

BA

max

-

grad

+

on

off inst

charging

B

A

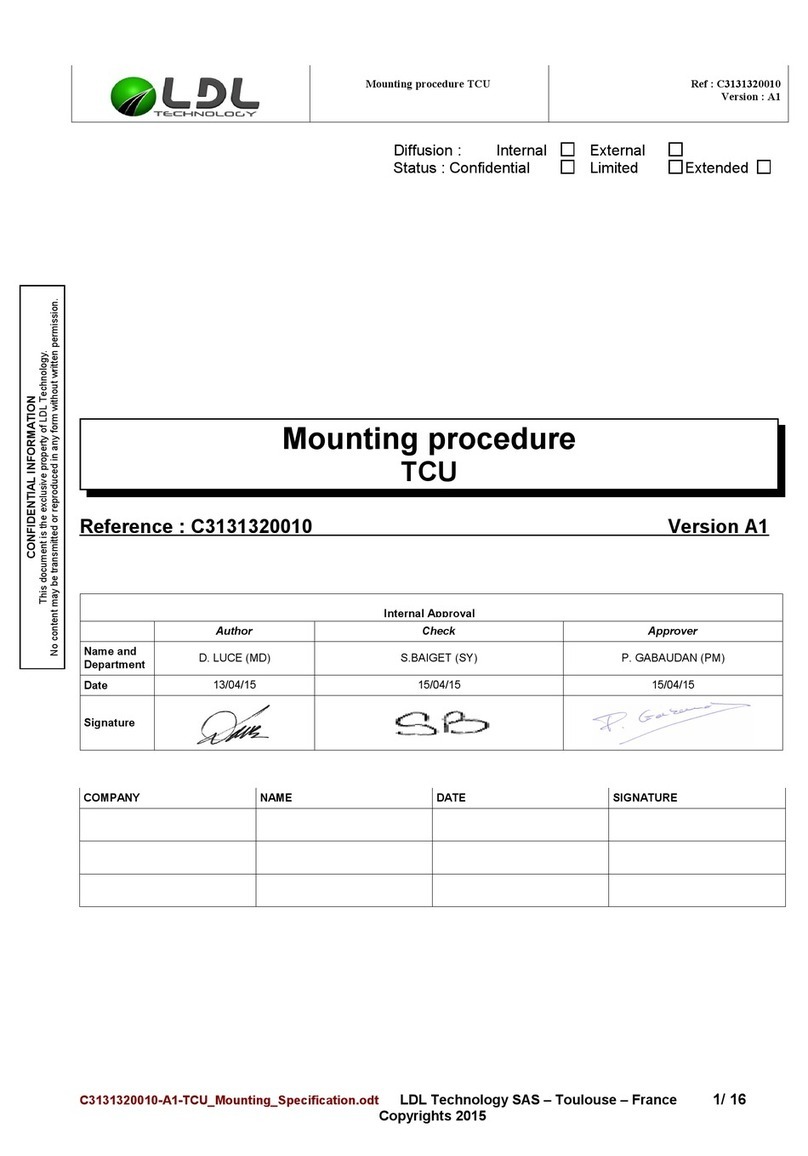

Contents

Front Panel

1Signal Input A

2 Signal Input B (TM100-x2 / -o2 only)

3 Value Display

4 Select Input A key

5 Select Input B key

6 Max Value Key (value “-” on Inst)

7 Gradient key (value “+” on Inst)

8 on / off key

9Entering Configuration Key

10 LED to indicate charging (option, as below)

11 Charging socket (rechargable option only)

Introduction .........................................................1

Safety Notes......................................................1

Setup ................................................................1

Displaying Temperatures ......................................2

Maximum Values..............................................2

Absolute Maximums.........................................2

Temperature Gradient .......................................2

Cold Junction Temp. & Battery Voltage .............3

TM100-O2............................................................3

Changing Combustion Composites ...................4

Charging...............................................................4

Replacing Batteries...............................................4

Opening TM100...............................................4

Messages & Display Codes ...................................5

Error Messages..................................................5

Configuration .......................................................6

Parameterlist .....................................................6

Technical Data......................................................7

3

4

6

8

10

12

5

7

9

11

BBAA

maxmax

--

gradgrad

++

onon

oo instinst

charging

1

Your TM100 is a leading instrument for measuring

temperature and kiln atmosphere in ceramic

applications. The TM100 is a state of the art device

using the latest power saving micro controller

technology allowing highest accuracy combined with

the benefit of mains independent operation.

The basic model of TM100 is designed for

temperature measuring by a thermocouple. The

TM100-x2 allows connecting a 2nd thermocouple as

well as various kind of sensors (pressure, humidity

etc.). Further to displaying the primary value the

TM100 allows checking maximum values, gradient

etc. (very helpful on manually operated gas kilns). For

measuring the atmosphere of a kiln using circone

oxide probes use TM100-o2 (reads lambda, O2, CO

etc.).

Before operating the TM100 please read this booklet

carefully to become familiar with the various features

and options of your new instrument.

Only connect the proper type of thermocouple to the

TM100 to avoid damage of kiln and load due to

wrong temperature indication. When receiving TM100

and sensor as a package it is configured properly.

Never put your TM100 on top of a kiln

Carefully insert the thermocouple plug into the socket

(1). TM100-x2 and TM100-o2 only: Connect the

second sensor resp. the oxygen plug to the signal

input B (2). Ensure proper orientation / polarity (wide

and narrow side of the plug). Plug design does not

allow wrong polarization except when exessive force

is applied.

Press key (8) to turn on TM100. Toturn off your

TM100 press and hold key (8) for four seconds until

display confirms “off”.

When no key is pressed for 1 hour and temperature is

below 150°C the TM100 turns off automatically to

save battery power.

Introduction

Setup

Safety Notes

onon

oo

(8)

hold

onon

oo

(8)

Maximum

After turning on the TM100 shows the actual value of

input A.

TM100-x2 and TM100-o2: Press keys (4) and (5)

respectively to show the corresponding value (the

selected input is named for a short moment).

To display the maximum acquired temperature since

last power up press key (6). The display returns to

normal temperature display after 3 seconds.

To reset the maximum temperature without power off

press keys (6) and (7) simultaneously (display reads

“CLr” for a short time).

Pressing key (6) twice displays the absolute maximum

temperature (ie. even after power off). Only

temperatures whichhavebeen read for several

minutes at least will be considered.

This value is also preserved when replacing batteries.

There it is an valuable indication in case of warranty

disputes (damage of kiln bricks etc.).

The current increase of temperature (gradient) is a

value of interest especially when firing gas kilns

manually The value is shown in centigrade Celsius per

hour positive (on increasing temperatures) or negative

when kiln temperature drops. Sudden changes in

temperatures (very large or very small gradient) are

shown as “overrun” or “underrun” (refer to section

“messages and displays)

The example on the left hand side is shown after

pressing key (7). “-87” means that the kiln temperature

will drop 87°C during the next hour assuming that the

current change in temperature continues. Accordingly

the temperature drops by 7°C during the next 5

minutes (87 / 60 * 5).

2

Displaying Temperatures

maxmax

--

(6)

maxmax

--

(6)

gradgrad

++

(7)

+

Absolute Maximum

TemperatureGradient

gradgrad

++

(7)

This values are for technically advanced users:

Presssing keys (4) and (5) simultaneously the TM100

reads the Cold Junction Compensating temperature

(CJC) followed by the current battery voltage (shown

in Volt, “LO BAT” appears continuously (possible

range 2.3 to 3.2V). At anytime the indication “LO

BAT” comes up below 2.4V to warn for replacing

respectively charging the battery.

The battery voltage does not have an impact on the

accuracy. When voltage drops too far the TM100 can

not be turned on any more.

Circone Oxide probes provide a signal depending on

current oxygen concentration and have turned out as

valuable tool when operating gas fired kilns

especially when reduction is required. Formerly the

atmosphere had been estimated by using difficult to

handle diagrams trying to estimate the actual oxygen

or even more difficult the actual grade of reduction.

Your TM100-O2 uses a highly complex combustion

formula to calculate all relevant atmosphere parameters

(oxygen O2,carbon monoxide CO,carbon dioxide CO2,

air/gas ratio lambda). Toenable the TM100 this

calculation some parameters of the combustable need to

be entered in the configuration menue. The temperature

signal of the probe is connected to input A, the O2-signal

is lead to input B. Due to physical laws an oxygen signal

is not available on temperatures below 650°C.

Pressing key (5) shows lambda in a range of (0, 0.001

to 9.99). If lambda can not be calculated (e.g. since

temperature is too low) the display reads “ ---”.

Oxygen concentration is shown after pressing key (6)

(display reads “o2” followed by the value in %).

Carbone monoxide is shown after pressing key (7)

(display reads “co” followed by the value in %).

3

Cold Junction Temp & Battery Voltage

AA

(4)

BB

(5)

+

LO BATLO BAT

after about 1,5 seconds:

TM100-O2 (option)

BB

(5)

maxmax

--

(6)

gradgrad

++

(7)

lambda 1.0 stands for a 1:1 combustion,

lambda >1.0 means “excess air”, lambda <1.0 “excess

gas” (reduction). A lambda of 0.96 stands for a

medium reduction for instance

Displaying percent values is done directly down to

0.001%. Smaller values come up in scientific notation

(example on the left hand side shows a value of

0.000012% as 1.2 E -05).

The composition of the combustable (carbon,

hydrogene, non combustables, details available at

your provider) is required to allow exact calculation.

Enter the values via configuration (refer to page 6).

By default the TM100 is set for liquid gas in bottles

(propane gas, LPG).

The basic model TM100 is available for rechargable

batteries (option; TM100x2 and TM100-o2 by

default). The rechargable model can be identified by

the charging socket (11).

Completely charge your TM100 before using it for the

very first time. Connect the TM100 with the mains

supply using the charging unit. LED indicator (10)

lights up at short breaks. The LED goes off of the

battery is fully charged. New NiMh type rechargable

batteries achieve their maximum capacity (lasts for a

couple of month’soperation) after the 3rd loading

cycle.

Depending on usage the supplied batteries last up for

years. Use size AA (Mignon) batteries only. Replace

batteries once the experation date is elapsed although

they provide power to avoid chemicals to poor out.

Carefully remove the head covers on upper and lower

side of the TM100 case using a screwdriver (3mm slot

type).

Put the TM100 on its keypad side and lift the bottom

side. Take out the battery holder and replace the

batteries. Assembling the TM100 is done in exactly

reverse sequence.

Never insert standard batteries in a TM100 with

charging option! Unintentional charging could

damage the device! Only use high quality NiMh

rechargable batteries if you have to replace them.

4

Charging

Changing Combustion

Composition

Replacing Batteries

(non rechargable models only)

Open TM100

LO BATLO BAT

INV (invalid):

Acquired value is invalid. Cause could be missing

additional value (CJC or oxygen).

OVR (overrun)

Input signal is out of range. Open input or damaged

signal cable results in “out of range” indication too.

UDR (underrun)

Input signal too small. Usually this points to a bad

thermocouple polarization.

An error messages points clearly to an internal

problem inside the TM100. Contact us for assistance.

Error C1:

internal check failed, no further data acquisition.

Points to an internal problem of the signal converter.

Error C2:

internal check found values to be inaccurate. Might be

caused by exceeding temperature range, when water

entered or electronic damage.

Error D1:

hardware damage. Contact us for repair.

Error D5:

TM100 calibration data invalid, loss of calibration

data. Contact us for recalibration.

Error D6:

Configuration data error, needs to be checked and re-

entered manually.

5

Messages & Displays

Error Messages

The TM100 is configured ex works ie. no adjustments

are neccessary. To adapt for other applications (ie.

different sensor) you can adjust by changing the

configuration.

Press and hold key (9) for 4 seconds to enter

configuration while TM100 is on (display shows

“SET”). Select key (4) or (5) depending which input

you want to configure, applies also to TM100 with

one input only. Now you can modify the 6 input

parameters (+ 3 mode dependant parameters). Please

find parameter details in the table below.

Choose the parameter using keys (4) and (5). The

display changes to parameter-no. (“P x” while x stands

for the parameter number).

Use keys (6) and (7) to adjust the selected parameter.

To choose another parameter use keys (4) or (5) again.

To save changes press and hold key (9) until display

reads “SET”.

To cancel changes press and hold key (8) until display

reads “CAn” (Cancel).

6

Configuration

instinst

(9)

AA

(4)

BB

(5)

or

AA

(4)

BB

(5)

previous / next parameter

maxmax

--

(6)

gradgrad

++

(7)

decrease (-) resp. increase (+) value

onon

oo

(8)

hold = cancel

instinst

(9)

hold = save + quit

Parameter List No. Description Range Default Unit

1input mode 0 - 4 - 0 = input unused

2 value averaging 1 - 5 4 -

3 fullscale trim -10.0 - 10.0 0.0 percent (%)

4zero offset +/-100 0same like value

5 sensitivity J/K thermocouple 1, 2 1 -

6 decimals 0 - 3 0 -

7 to 9 input mode dependant (see following page)

long

7

No. Description Range Default Unit

7type of thermocouple 1 - 5 - (S, R, K, J, B)

8 external CJC 0 - 1 0 1 = CJC input B

9 toto 1 - 3 0 (°C, °F, K)

type 1:

Thermocouple

No. Description Range Default Unit

7 typ of resistor 1 1 1 = Pt100

8 wiring type 2 - 3 2 2/3-wire

9 temperature unit 1 - 3 1 (°C, °F, K)

typ 2: Resistor

No. Description Range Default Unit

7 signal type 1 - 6 - 0-20mV, 0-50mV, 0-5V,

(change internal Jumpers accordingly)

0-10V, 0-20mA, 4-20mA

8 value for zeropoint +/- 1999 0 -

9 value for full scale +/- 1999 0 -

Typ 3: Linear

Input

We reserve the right to make any changes without notice

Operating Instructions TM100 V1.0 (c) 2007 bentrup Industriesteuerungen, D-35463 Fernwald

Accuracy 0.1% refered to full scale

Operating temperature range -15 to 55°C

Storage temperature range -25 to 85°C

Batterie lifetime about 2 years (Alkaline)

Batterie lifetime (rechargable) about 6 months (NiMh)

Loading time about 6 hours

Maximum loading cycles >100

Charging power supply 9V AC, 500mA

Technical Data

No. Description Range Default Unit

7 Carbon 0-9,99 3,01 mol amount * 100

8 Hydrogen 0-19,99 8,02 mol amount * 100

9 non combustables 0-9,99 0,01 percent %

Note: For simple calculation of these 3 values an easy to use EXCEL-worksheet can be

downloaded at www.bentrup.de, service, TM100. This allows to calculate the required

data out of the providers gas specifications (percentage of various combustables).

Typ 4: Circone-

Oxide-Probe

This manual suits for next models

2

Table of contents

Other bentrup Measuring Instrument manuals