Enovation Controls Murphy PowerCore MPC-10 User manual

Software Release: [Application Version 2.8.10128; Configuration Version 2.8.10457]

00-02-0939

2016-04-19

Section 40

PowerCore®

MPC-10 Engine Controller &

TEC-10 Panel

Operations Manual

To see this manual in Spanish, German, French or Italian, please go to

www.fwmurphy.com/mpc10

Software Release: [Application 2.8.10128; Configuration 2.8.10457]

In order to consistently bring you the highest quality, full-featured products, we reserve the right to change our

specifications and designs at any time.

Property of American Airlines

Software Release: [Application Version 2.8.10128; Configuration Version 2.8.10457]

Section 40 ii 00-02-0939

2016-04-19

ENOVATION CONTROLS has made efforts to ensure the reliability of the MPC-10 /

TEC-10 and to recommend safe use practices in system applications. Please note

that in any application, operation and controller failures can occur. These failures

might result in full control outputs or other outputs that might cause damage to or

unsafe conditions in the equipment or process connected to the MPC-10 / TEC-10.

Good engineering practices, electrical codes and insurance regulations require that

you use independent external protective devices to prevent potentially dangerous or

unsafe conditions. Assume that the MPC-10 / TEC-10 can fail with outputs full ON;

outputs full OFF; or that other unexpected conditions can occur.

Please read the following information before installing.

BEFORE BEGINNING INSTALLATION OF THIS MURPHY

PRODUCT:

•A visual inspection of this product before installation for any damage during

shipping is recommended.

•Disconnect all electrical power to the machine. Failure to disconnect all electrical

power connections before welding can result in damage to the panel and/or its

components.

•It is your responsibility to have a qualified technician install the unit and make sure

installation confirms with local codes.

•Observe all Warnings and Cautions in each section of these instructions.

•The MPC-10 / TEC-10 is designed for use in industrial environments. There might

be potential difficulties in ensuring electromagnetic compatibility in other

environments due to conducted as well as radiated disturbances.

•Please contact ENOVATION CONTROLS immediately if you have any questions.

IMPORTANT! False or improper use and operation of electronic

products could be dangerous. It is required that point-of-operation

guarding devices be installed and maintained. All such devices must

meet OSHA and ANSI Machine safety standards. The manufacturer shall

not accept any responsibility for installation, application or safety of

systems.

Property of American Airlines

Software Release: [Application Version 2.8.10128; Configuration Version 2.8.10457]

Section 40 iii 00-02-0939

2016-04-19

The MPC-10/TEC-10 can be set as an AutoStart Controller. Please be cognizant at

all times of hands and other objects that are in close proximity to the machine(s)

being controlled as they may commence operation suddenly and without warning.

LENS CLEANING PROCEDURES

The lens on the MPC-10/TEC-10 is composed of Polycarbonate materials. Use

only mild soap and water to clean the lens/display window. Evidence of improper

cleaning techniques or chemicals includes cracks, smear marks, scratches, or

fogged/hazy lenses.

Property of American Airlines

Software Release: [Application Version 2.8.10128; Configuration Version 2.8.10457]

Section 40 iv 00-02-0939

2016-04-19

- THIS PAGE INTENTIONALLY LEFT BLANK -

Property of American Airlines

Software Release: [Application Version 2.8.10128; Configuration Version 2.8.10457]

Section 40 v 00-02-0939

2016-04-19

Table of Contents

Introduction.................................................................................................................................7

Murphy PowerCore 10 (MPC-10 / TEC-10)..................................................................7

User Interface...............................................................................................................9

Accessing the Menu ................................................................................................................10

Main Menu.................................................................................................................................11

Start/Stop Settings...................................................................................................................16

Single Contact Start/Stop...........................................................................................16

Two Contact Maintained Start/Stop (commonly known as Floats) .............................16

Pressure, Temperature Transducer Start/Stop ..........................................................16

Local Start Key Start/Stop:.........................................................................................16

Quick-Start Setup.....................................................................................................................16

Adjusting the Brightness.............................................................................................17

Setting to Mechanical Engine.....................................................................................17

Setting to J1939 Engine (Factory Default)..................................................................17

Setting to Auto Start on a Single Contact Input..........................................................17

Setting to Auto Start on Local Start Key.....................................................................18

Setting to Auto Start on Float Inputs ..........................................................................18

Setting to Auto Start on Pressure...............................................................................18

Setting to Auto Start on Clock ....................................................................................18

Setting to Auto Start on Temperature.........................................................................19

Setting to Run the Engine for a Fixed Period of Time ................................................19

Screen Examples .....................................................................................................................19

Additional Screens .....................................................................................................20

ISO Icons ...................................................................................................................23

Icon Troubleshooting..................................................................................................25

Menu Glossary .........................................................................................................................26

System .......................................................................................................................26

Engine Settings ..........................................................................................................27

Advanced Engine Settings .........................................................................................28

Property of American Airlines

Software Release: [Application Version 2.8.10128; Configuration Version 2.8.10457]

Section 40 vi 00-02-0939

2016-04-19

Throttle Menu.............................................................................................................32

Input / Output Menu ...................................................................................................33

Application Configuration...........................................................................................35

Start / Stop Timers..................................................................................................... 39

Communication..........................................................................................................40

Modbus Registers......................................................................................................40

MPC-10 Specifications............................................................................................................ 46

Interface.....................................................................................................................46

Power Supply............................................................................................................. 46

Inputs (9)....................................................................................................................46

Outputs (8).................................................................................................................46

Communications ........................................................................................................46

Connectors ................................................................................................................46

Physical / Environmental............................................................................................46

TEC-10 Specifications............................................................................................................. 47

Interface.....................................................................................................................47

Power Supply............................................................................................................. 47

Inputs (9)....................................................................................................................47

Outputs (8).................................................................................................................47

Communications ........................................................................................................47

Mating Connectors.....................................................................................................47

Physical / Environmental............................................................................................47

Property of American Airlines

Software Release: [Application Version 2.8.10128; Configuration Version 2.8.10457]

Section 40 00-02-0939

2016-04-19 7

Introduction

This document is designed to familiarize a user with the MPC-10 / TEC-10 and how to navigate the

interface and modify the settings when installing and operating the controller. The Quick Set Up

guide assists with establishing the different functions in the MPC-10 / TEC-10 System Controller.

Before attempting to set up the controller, be sure to read and understand this manual in its entirety.

Murphy PowerCore 10 (MPC-10 / TEC-10)

The Murphy PowerCore 10 Controller (MPC-10 / TEC-10) is a general, all-purpose manual/auto start

and manual/auto throttling engine controller designed with rental applications in mind. The controller

is purposed primarily for applications where a wide array of inputs and outputs are not required. This

is a powerful controller that supports J1939 CAN protocols for electronically governed engines as well

as analog sensors on mechanical engines for fault and safety shutdowns.

The MPC-10 / TEC-10 is flexible in many aspects, with the ability to:

•use in most applications where auto start or auto throttling is required or desired;

•use the same controller on electronically governed J1939 and mechanical engines;

•use the same controller on 12VDC or 24VDC systems;

•assign multiple levels of passcode protection to the menu;

•use as auto start or manual start controller;

•use as manual throttle or auto throttle controller;

•change the input sensor type for the analog inputs;

•use analog inputs as digital ground inputs;

•assign functions and actions to digital inputs;

•use digital inputs as battery positive or ground inputs;

•be mounted in all weather environments;

•be customer mounted in panel of choice (MPC-10 only).

Engine Application States

The Controller follows a standard operating sequence. This operating sequence is a set of machine

states that happen in a predetermined order. Machine states can be set to zero if not needed or

adjusted to fit the application. The following states will be executed during the auto sequence, provided

that the corresponding timer has not been set to 00:00:00 or the controller has not been placed in a

manual mode of operation:

•Stabilize: This is a timed state to allow the controller to enable the ECU or any

senders without warnings or errors. This timer can be disabled if set up for mechanical

engine use.

•Stopped: This is a timed state where the engine is ready to be started manually or

automatically.

•Standby:This is a timed state that will shut off the LCD backlight, heater and CAN

transceiver to conserve power while the unit waits for a key press or an automatic start

condition.

•Auto Start Delay: (available in Auto Mode only) The auto start condition is ignored

and must remain active throughout this delay or the delay is reset to zero.

Property of American Airlines

Software Release: [Application Version 2.8.10128; Configuration Version 2.8.10457]

Section 40 8 00-02-0939

2016-04-19

•Check Safe To Start: This is a non-timed state that will check to ensure the engine

can start safely.

•Auto Stop Delay: (available in Auto Mode only) The auto stop condition is ignored

and must remain active throughout this delay or the delay is reset to zero.

•ECU Stabilize Timer: This delay begins timing when the controller is powered up, in

Spindown or when the Standby delays have expired. During this delay, the ECU-

enabled output is turned on. The ECU output turns off when the Standby, ETS or

Spindown delays begin timing.

•Prestart Delay 1: After a start condition has been accepted by the controller, this delay

begins timing, and the prestart output turns on. When this delay expires, the output is

turned off, and the start sequence continues. NOTE: The function selected for

Prestart may only be active in Auto Mode depending on if it is tied to an auto start

function only in the Start sequence.

•Prestart Delay 2 (Precrank): After a start condition has been accepted by the controller,

this delay begins timing, and the prestart output turns on. When this delay expires, the

output is turned off, and the start sequence continues. During this delay, the controller

checks for faults, J1939 com, etc. NOTE: The function selected for Prestart may only

be active in Auto Mode depending on if it is tied to an auto start function only in the

Start sequence.

•Prestart Delay 2 (crank through): After a start condition has been accepted by the

controller, this delay begins timing, and the prestart output turns on. When this delay

expires, the output remains on, and the start sequence continues. The output turns off

when the engine starts. During this delay, the controller checks for faults, J1939 com,

etc. NOTE: The function selected for Prestart may only be active in Auto Mode

depending on if it is tied to an auto start function only in the Start sequence.

•Wait to Start: This is a state in which the controller will not allow the engine to crank

until after the engine ECU stops sending the wait to start message.

•Crank: This is a timed state to try and start the engine.

•Crank Rest: This is a timed state to rest the starter between cranks in case the engine

did not start during the crank state.

•False Start Check: This is a non-timed state that will ensure the engine stays above

the crank cut RPM after cranking.

•Warm-up: (available in Auto mode only) This is a timed state that will allow the

engine to change from idle to desired warm-up RPM after starting. Warm-up will only

set as low as the minimum RPM set point.

•Line Fill 1: (available in Auto mode only) This is a timed state that will exit if the

timer times out or the pressure set point for this state is reached.

•Line Fill 2: (available in Auto mode only) This is a timed state that will exit if the

timer times out or the pressure set point for this state is reached.

•Running Loaded: This is a non-timed state that the controller will stay in until a stop

condition occurs.

•Cool-down: (available in Auto mode only) This is a timed state that will allow the

engine to run at a desired speed to cool down before allowing to go into a stopped

state.

•Spindown:The time allotted for the engine to stop all revolutions and be in a stopped

state with no frequency.

•Post Crank Lockout Delay (setup): This delay begins timing when the engine starts.

During this delay, the selected function is ignored. When this delay expires, the

selected function is armed. During the duration of this delay, the selected function can

cycle from active to not active and not reset the delay.

Property of American Airlines

Software Release: [Application Version 2.8.10128; Configuration Version 2.8.10457]

Section 40 9 00-02-0939

2016-04-19

•Post Warm-up Lockout Delay (setup):This delay begins timing when the warm-up

delay expires. During this delay, the selected function is ignored. When this delay

expires, the selected function is armed. During the duration of this delay, the selected

function can cycle from active to not active and not reset the delay.

•Bubble Lockout Delay (setup): This delay begins timing when the selected function is

active. If the selected function is removed during this delay, the delay resets to zero.

If the selected function remains active throughout this delay, the selected action will

occur.

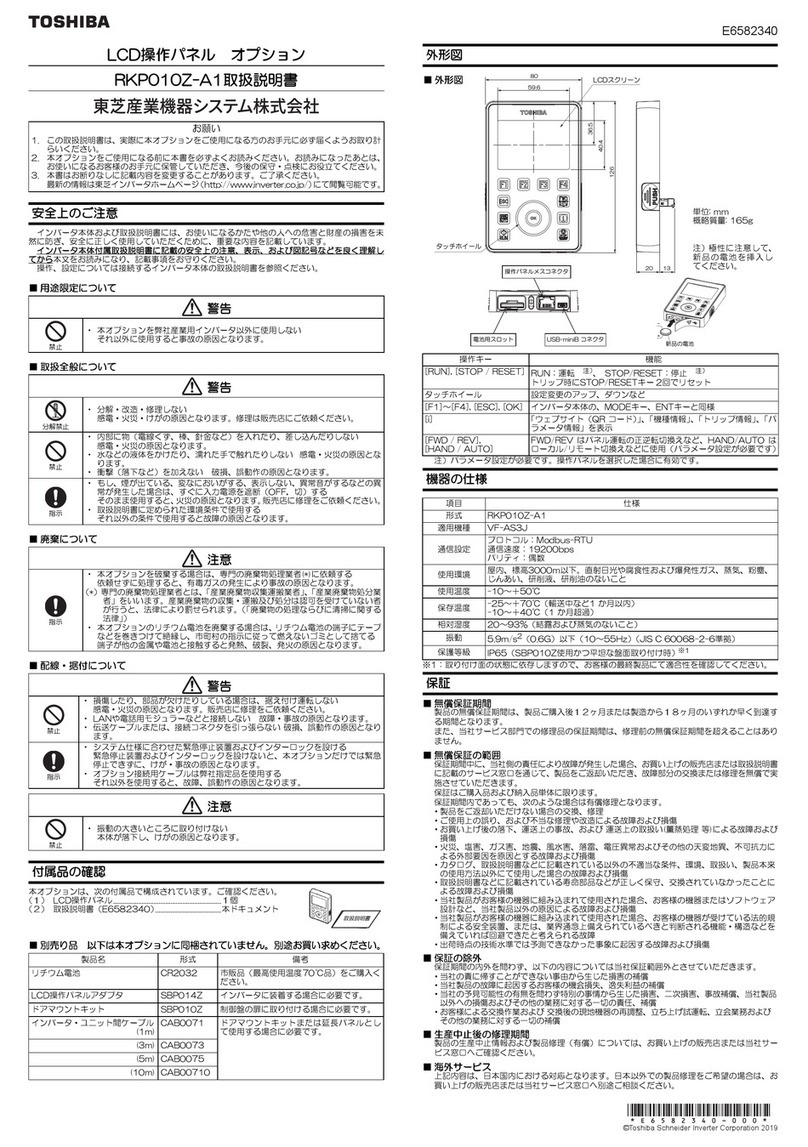

User Interface

The keypads on the MPC-10 / TEC-10 are comprised of 11 tactile buttons. This section describes the

functions of each button.

Figure 1: User Interface

The buttons have the following functions:

•Start Key – Allows the operator to start sequence in Manual Mode or initiate an

auto start sequence when in Auto Mode.

•Stop Key – Allows the operator to initiate the stop sequence in either mode of

operation. As a safety feature, the stop key will skip the cool-down state when it

is pressed twice or held in auto mode. Once shut down, the controller will enter

manual mode to eliminate an auto crank condition if the auto start condition is still

present.

•Auto Key – Allows the operator to change from Auto to Manual or Manual to Auto

Mode by press-hold for 3 seconds.

•Alarm Silence Key – Allows the operator to acknowledge alarms on the controller

when warnings and shutdowns are present.

Property of American Airlines

Software Release: [Application Version 2.8.10128; Configuration Version 2.8.10457]

Section 40 10 00-02-0939

2016-04-19

•Manual Throttle Increase Key – Allows the operator to manually increase the

engine throttle in Manual Mode.

•Manual Throttle Decrease Key – Allows the operator to manually decrease the

engine throttle in Manual Mode.

•Menu Key – Allows the operator to get in and out of the menus.

•Back Key – Allows the operator to move back one step while in the menu.

•Enter Key – Allows the operator to enter a value in the menu when selected and is

used to acknowledge internal and external alarms/shutdowns.

•Up Key – Allows the operator to navigate up through the menu and page forward

on the main pages.

•Down Key – Allows the operator to navigate down through the menu and page

reverse on the main pages.

The TEC-10 Panel offering also has a keyswitch and a stop button:

Figure 3: Panel button and switch

Accessing the Menu

To access the MPC-10 / TEC-10 menu, press the menu button:

The following screen will display to enter the password (3482):

Figure 3: Enter Passcode

Property of American Airlines

Software Release: [Application Version 2.8.10128; Configuration Version 2.8.10457]

Section 40 11 00-02-0939

2016-04-19

The password will be entered left to right. Utilize the up and down arrows, and press the Enter button

after each correct number: Entering this password will allow full access to the menu. If you enter the

wrong password, it will reset the display to 0000, allowing you to restart the entering process.

NOTE: There are three passcodes available in the MPC-10 / TEC-10 controller: Low

Security, Medium Security and High Security. These three passcodes are based on

the level of security needed to access certain parameters within the menu. As a

factory default, all menu items are listed as low security and accessible by any user

with the 3482 passcode. To learn more about passcode security and changing the

security levels, please refer to the Configuration Tool manual for the MPC-10 / TEC-

10.

Main Menu

The MPC-10 / TEC-10 controller is incredibly versatile within the menu structure. The operator is able

to change many parameters and settings from the face without the need of a PC tool, if desired. The

controller must be in its stopped state in order to change a setting in the menu. (The Tier 4

menu is the sole exception). Described below are the main sections of the controller’s menu. Cycling

power to the controller is recommended after making changes to set points and input/output.

Figure 4: Main Menu, page 1

System

The controller System menu provides the operator with the ability to set the:

•Date/Time

•Pressure, Temperature, Flow and Level Units

•Language

•Brightness

•Backlight Control

•Standby Timer

•Service Reminders and several other system settings. Review System under the Menu

Glossary section of this manual for a full list and definition of each setting.

Property of American Airlines

Software Release: [Application Version 2.8.10128; Configuration Version 2.8.10457]

Section 40 12 00-02-0939

2016-04-19

Engine Settings

The Engine Settings menu allows the operator to establish common user-configurable parameters

that would be changed from factory default settings when pairing the controller to an engine. This

menu allows the operator to choose whether the engine is J1939 or mechanical; the engine’s speed

source; the minimum and maximum RPM the operator requires/allows the engine to run; warm-

up/cool-down settings; and other common engine settings. Review Engine Settings under the Menu

Glossary section of this manual for a full list and definition of each setting.

Advanced Engine Settings

The Advanced Engine Settings menu allows the operator to set up the less common user-

configurable parameters that are not in the Engine Settings menu and which would be changed from

factory default settings when pairing the controller to an engine. This menu allows the operator to set

items such as the J1939 address claim for the controller, ECU Source Address, ECU hour select,

crank attempts, crank disconnect speed and other user-specific engine settings. Review Advanced

Engine Settings under the Menu Glossary section of this manual for a full list and definition of each

setting.

Figure 5: Main Menu page 2

Throttle

The Throttle menu allows the operator to set up the items for throttling the engine such as throttle

type, rate of RPM increase/decrease, throttle Inc/Dec pulse time and other parameters pertaining to

throttling of the engine. Review Throttle under the Menu Glossary section of this manual for a full list

and definition of each setting.

Input / Output

The Input/Output menu allows the user to establish the I/O needed for the application. This includes

Digital Inputs, Analog Inputs, Relay Outputs and Digital Outputs. This menu is tied to other aspects of

the controller menu such as Auto Start Functions, Analog Inputs for Mechanical Engine setup, Warning

/ Shut-down functions and all outputs needed for starting/controlling the engine and alerting the user.

Property of American Airlines

Software Release: [Application Version 2.8.10128; Configuration Version 2.8.10457]

Section 40 13 00-02-0939

2016-04-19

The Digital Inputs of this menu can be configured from the face of the controller to accept three

types of inputs as the Active state of the input.

•High, B(+)

•Low, B(-)

•Open

The Analog Inputs of this menu can be configured from the face of the controller to accept one of

four types of senders:

•Resistive

•4-20mA

•0-5VDC

•Analog.Digital (B- for additional Digital Inputs)

The Outputs are configurable for the operator to choose which output function to use with the

desired output type as shown below.

•Relay [10A, Form C]

•Digital Out [1A, B(+)]

•Digital Out [1A, B(-)]

NOTE: Although the functionality exists to set all analog and digital inputs to the

same function, Enovation Controls strongly advises against this.

Application Configuration

The Application Configuration menu is where an operator will set up the controller’s Auto Start

Functions and Auto Throttle Methods, if the intended use is as an auto start and/or auto throttling

controller. Depending on which application is chosen in the menu, there are certain auto start

functions and auto throttling methods hidden that are not pertinent to the application chosen. This

automatic hiding feature allows for a simpler, more intuitive controller menu in the MPC-10 / TEC-10.

Review Application Configuration under the Menu Glossary section of this manual for the full list and

definition of each setting.

NOTE: Discharge Pressure is the only pressure type available for Auto

Start/Stop and/or Auto Throttle control by pressure.

Pump All Purpose

The Pump All Purpose application houses auto start functions and auto throttling methods of

the controller for common pumps used in rental applications.

The auto start functions and auto throttle methods are:

Auto Start/Stop Functions

•Single Contact

•Local Start (Green Start key)

•Two Contact Maintained (Dual Floats)

Auto Throttle Methods

•Running Loaded RPM

•Pressure Transducer (will require an analog input setting)

Property of American Airlines

Software Release: [Application Version 2.8.10128; Configuration Version 2.8.10457]

Section 40 14 00-02-0939

2016-04-19

Air Compressor

The Air Compressor application houses the auto start functions and auto throttle methods

meant to be used on all engine-driven air compressor applications. The

MPC-10 / TEC-10 allows for the compressor to start/stop and maintain a desired pressure

during operation.

The auto start functions and auto throttle methods to choose from are:

Auto Start/Stop Functions

•Single Contact (will require a digital input for start and stop)

•Local Start (Green Start key)

•Pressure Transducer (will require an analog input)

Auto Throttle Methods

•Running Loaded RPM

•Pressure Transducer (will require an analog input setting)

Hose Reel Irrigation

The Hose Reel Irrigation application houses the auto start functions and auto throttle

methods meant to be used on hose reel irrigation systems. The MPC-10 / TEC-10 allows for

the hose reel pump to auto start with several methods, including the Local Start key which

may be the most used in this application. The key feature of this application is the auto

throttling method. This feature allows the controller to manage the pump’s throttle in order to

maintain a pressure in the hose during irrigation.

The auto start functions and auto throttle methods to choose from are:

Auto Start/Stop Functions

•Single Contact (will require a digital input for start and stop)

•Local Start

•Two Contact Maintained

Auto Throttle Methods

•Pressure Transducer (will require an analog input)

Frost Protection

The Frost Protection application houses the auto start functions and auto throttle methods

meant to be used on frost protection systems. This application allows for a wind machine,

sprinkler or other forms of frost protection using single contact or a temperature transducer.

The auto start functions and auto throttle methods to choose from are:

Auto Start/Stop Functions

•Single Contact (will require a digital input for start and stop)

•Temperature Transducer (will require an analog input for start and stop)

Auto Throttle Methods

•Running Loaded RPM

Property of American Airlines

Software Release: [Application Version 2.8.10128; Configuration Version 2.8.10457]

Section 40 15 00-02-0939

2016-04-19

Chipper

The Chipper application houses the auto start functions and engage/disengage methods

meant to be used on Chippers. The operator can also choose between Chipper types, On-

Off-On or Dumping.

The functions available are:

Auto Start/Stop Functions

•Single Contact (will require a digital input for start and stop)

•Local Start Key

Engage RPM

Disengage RPM

Disengage Delay

Chipper Feed System

•On-Off-On

•Dumping

Start / Stop Timers

Figure 6: Main Menu page 3

The Start/Stop Timers menu provides the operator the ability to add a countdown timer and start/stop

times. The countdown timer allows for the operator to set a desired countdown time and walk away

from the engine for a controlled shutdown when the timer expires. There are three Start/Stop Timers

the operator can choose from within this menu that allows for the specific day and hour the controller

will start and stop utilizing the internal clock. Review Start/Stop Timers under Menu Glossary section

of this manual for full list and definition of each setting.

NOTE: Start / Stop timers work in conjunction with other Start / Stop types. If the

engine is already running from another Start / Stop type when a Start / Stop timer

occurs, the Start / Stop timer is ignored. Once the engine is started by the Start /

Stop timer, the timer must expire for a controlled shutdown to occur.

Property of American Airlines

Software Release: [Application Version 2.8.10128; Configuration Version 2.8.10457]

Section 40 16 00-02-0939

2016-04-19

Communication

The Communications menu allows the operator to choose the type of RS485 communications such

as PVA Gauge, Modbus or Local Display. The menu also allows for the operator to choose the RS485

slave address and RS485 Serial setup. Review Communication under the Menu Glossary section of

this manual for a full list and definition of each setting.

Start/Stop Settings

There are five automatic start/stop types in the MPC-10 / TEC-10. Each is detailed below:

Single Contact Start/Stop

The Single Contact Start/Stop is when a remote contact closes and remains closed for auto start and

reopens for auto stop.

Two Contact Maintained Start/Stop (commonly known as Floats)

The Two Contact Maintained Start/Stop is when both contacts close for auto start and both contacts

open for auto stop (not momentarily).

Pressure, Temperature Transducer Start/Stop

A transducer can be used for Auto Start/Stop when needed for the application. There are set points that

allow the operator to enter the appropriate values.

NOTES:

This same transducer can be used for Auto Start/Stop and Auto Throttling if the

application supports transducer control.

Discharge pressure is the only pressure type available for Auto Start/Stop and/or Auto

Throttle control by pressure.

Local Start Key Start/Stop:

The Local Start Key function uses the green and red buttons on the front interface for auto start and

stop.

Quick-Start Setup

The following sections provide a walk-through of the steps necessary for some of the various

configurations and settings available on the MPC-10 / TEC-10 Controller. Cycling power to the

controller is recommended after making changes to set points.

Stepping through the Menu will be depicted as follows:

Menu/System/Contrast directs the operator to go into the Menu first, then look for a parameter titled

System and press [Enter] to go into the System menu. Then look for a parameter titled Contrast and

press [Enter] to go into the Contrast menu, etc.

Property of American Airlines

Software Release: [Application Version 2.8.10128; Configuration Version 2.8.10457]

Section 40 17 00-02-0939

2016-04-19

Adjusting the Brightness

1. Access Menu/System/Brightness and press [Enter].

2. Utilize the Up and Down arrows to adjust the Brightness (values of 0 to 100), and press [Enter]

when the desired number appears.

3. Press the [Menu] key to leave the Menu Setup screens.

NOTE: The brightness of the display will not change until the enter key is pressed.

Setting to Mechanical Engine

1. Access Menu/Engine Settings/Engine Type and press [Enter]. Choose Mechanical and

press [Enter].

2. Down arrow to Speed Source and press [Enter], and select either Alternator or Magnetic

Pickup and press [Enter].

3. Down arrow to Speed Calibration, and press [Enter].

4. Utilize the Up and Down arrows to establish the appropriate number of flywheel teeth or engine

alternator pulses, and press [Enter].

5. Press the [Back]key once.Down arrow to Input/Output, and press [Enter].

6. Access Analog Inputs,and assign one Analog input for Oil Pressure and one for Coolant

Temperature. Press [Enter] to save the settings.

7. Press the [Back] key twice to access Relay and Digital Outputs.

8. Assign relay outputs for Crank and Fuel.

NOTE: DO3 and DO4 are factory set to Throttle Decrease and Throttle Increase for

the AT03069 Throttle Actuator.

9. Press the [Menu] key to leave the Menu Setup screens.

Setting to J1939 Engine (Factory Default)

1. Access Menu/Engine Settings/Engine Type and press [Enter]. Choose J1939, and press

[Enter].

2. Arrow down to Speed Source, and press [Enter]. Select J1939 and press [Enter].

3. Press the [Back] key once. Arrow down to Throttle menu and press the [Enter] key twice.

Select desired throttle type and press [Enter].

4. Ensure the analog inputs are not set to oil pressure or coolant temp (disable or change to

something else). Some ECUs require an external oil pressure sender. Although some ECUs

require an external oil pressure sender, this is an exception but can be done within the

controller.

5. Press the [Menu] key to leave the Setup screens.

Setting to Auto Start on a Single Contact Input

1. Access Menu/Application Configuration/Auto Start_Stop Function/Single Contact

(available in all applications).

2. Press [Back]once, and select Input / Output/Digital Inputs.

3. Assign the Function of Single Contact Start/Stop to one of the Digital Inputs.

4. Press the [Menu] key to leave Setup.

Property of American Airlines

Software Release: [Application Version 2.8.10128; Configuration Version 2.8.10457]

Section 40 18 00-02-0939

2016-04-19

Setting to Auto Start on Local Start Key

1. Access Menu/Application Configuration/Auto Start_Stop Function/Local Start Key and

press [Enter] (not available for Frost Protection).

2. Press the [Menu] key to leave the Menu Setup screens.

Setting to Auto Start on Float Inputs

1. Access Menu/Application Configuration/Auto Start_Stop Function (only available in

Pump All Purpose).

2. Highlight Single Contact or Two Contact Maintained and press [Enter].

3. Press [Back]once and access Input/Output/Digital Inputs. Select a Digital Input to modify.

4. Assign the appropriate input for the selected DI.

NOTE: If Single Contact is chosen, only one digital input needs to be configured. If

Two Contact (Maintained) is chosen, two digital inputs need to be configured - one

for start and one for stop.

5. Ensure the appropriate number of Digital Inputs is configured (as per the Note above), and press

the [Menu] key to leave Setup.

Setting to Auto Start on Pressure

1. Access Menu/Application Configuration/Auto Start_Stop Function/Pressure Transducer,

and press [Enter] (only available in Air Compressor).

2. Complete the parameters that apply (i.e., Maintain Pressure, Start/Stop Pressure, etc.)

3. Press [Back]twice, and access Input_Output/Analog Inputs.

4. Select an Analog Input to modify.

5. Assign the appropriate pressure input for the selected AI.

6. Configure Sensor in the Sensor setup menu.

7. Press the [Menu] key to leave Setup.

Setting to Auto Start on Clock

NOTES:

1) Ensure the correct date and time are established in the System menu prior to

establishing the Auto Start on Clock settings.

2) The MPC-10 / TEC-10 have the ability to establish three different Start/Stop

dates and times. If desired, repeat steps 2-4 for subsequent Timers.

3) The Countdown Timer is separate from the internal clock. This is a run time after

a Key Start is initiated. When this timer expires, an auto stop will occur.

4) The Clock start timer that started the engine is the only timer that stops the

engine.

1. Access Menu/Start_Stop Timers, and select the first Start/Stop Timer.

2. Select Start Day 1 and then select the appropriate day or Daily.

3. Select Start Time 1 and establish the hour, minute and second to start.

4. Establish the Stop Day and Time as in steps 2-3.

Property of American Airlines

Software Release: [Application Version 2.8.10128; Configuration Version 2.8.10457]

Section 40 19 00-02-0939

2016-04-19

Setting to Auto Start on Temperature

1. Access Menu/Application Configuration/Frost Protection/Auto Start_Stop

Function/Temperature Transducer. Press [Enter].

2. Arrow down to Temperature Transducer.

3. Establish a Start and Stop Temperature, and press [Back]twice.

4. Access Input_Output/Analog Inputs, and select an Analog Input.

5. Assign the appropriate temperature input for the selected AI.

6. Press the [Menu] key to leave Setup.

Setting to Run the Engine for a Fixed Period of Time

The operator is able to use the countdown timer to run in auto for a specific amount of time. This

feature is only used when local key is selected in the auto start method. An auto stop will occur when

either the countdown run timer expires or a local key stop occurs.

1. Access Menu/Start_Stop Timers/Countdown Timer.

2. Set the hours, minutes and seconds desired for the running of the engine, and press [Enter].

3. Press the [Menu] key to leave Setup.

NOTE: When the Countdown Timer is set for a countdown, the controller will always

countdown upon an auto start until the timer is set to 0.

Screen Examples

Figure 7: Screen Example

Property of American Airlines

Software Release: [Application Version 2.8.10128; Configuration Version 2.8.10457]

Section 40 20 00-02-0939

2016-04-19

Additional Screens

Figure 8: Main Screen

This is the main screen, and it displays actual and target RPM, Mode of Operation, Timer progress, %

Soot Level, % DEF Level and current State, along with icons and warnings.

Figure 9: 4 Up Screen

This is the first 4 up screen, displaying engine RPM, oil pressure, engine temperature and battery

voltage. If alternate parameters are desired, these may be changed using the free MPC-10 / TEC-10

software configuration tool.

Figure 10: Another 4 Up Screen

This is the second 4 up screen, displaying engine RPM, engine temperature, fuel level and GPH. If

alternate parameters are desired, these may be changed using the free MPC-10 / TEC-10 software

configuration tool.

Property of American Airlines

Other manuals for Murphy PowerCore MPC-10

1

This manual suits for next models

1

Table of contents

Other Enovation Controls Control Panel manuals

Popular Control Panel manuals by other brands

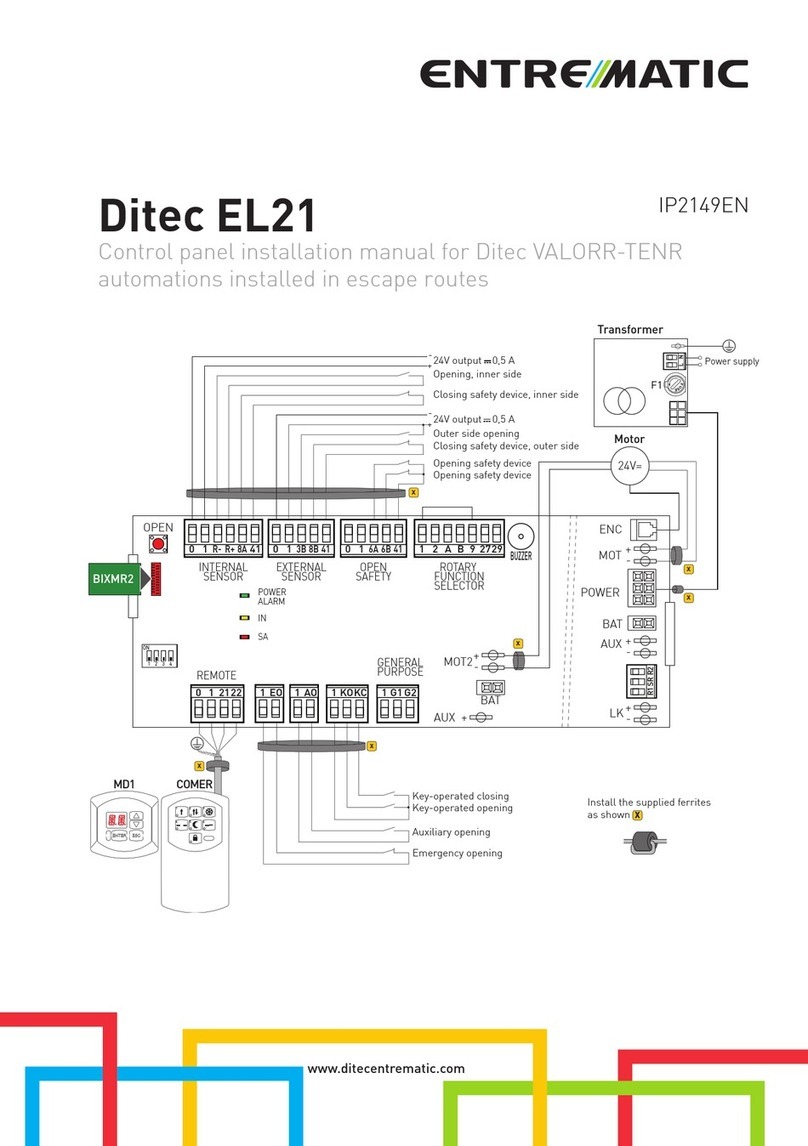

Entrematic

Entrematic Ditec EL21 installation manual

XROCKER

XROCKER 2.1 Wireless manual

ICON

ICON DPC1 Installation and operation manual

WhisperPower

WhisperPower WhisperTouch WP 5.0 inch user manual

Ceasefire

Ceasefire INTELLI-SENSE Installation, commissioning & operating manual

Delta

Delta VTH5422HW user manual