ensto LYNX 4400 User manual

NO. NX2010597/ NO. 72983_C

06/04/2021

1 (35)

Ensto Novexia SAS

210 rue Léon Jouhaux

BP 10446

69656 Villefranche-sur-Saône Cedex,

France

Tel. +33 (0)4 74 65 61 61

Fax +33 (0)4 74 62 96 57

4PR-F14-D

LYNX 4400

Installation and operation manual

for current fault detectors and

directional fault detectors

for MV underground grids

NO. NX2010597/ NO. 72983_C

06/04/2021

2 (35)

4PR-F14-D

General

- Before unpacking

> Verify that the product in its packaging has not been damaged during transport.

> Verify that the product is suitable for the intended installation.

- Before installation

> Carefully read the operation guide before installing or using this product.

> Perform the installation carefully, ensuring that the equipment remains clean throughout the operation.

- After installation

> If you are installing this product for someone else, leave the guide for the end user.

> Clean the work area after installation.

Legal notices

-The product may only be installed by a competent person with adequate training in the installation practices

and with adequate knowledge of proper safety and installation practices for electrical equipment. If local

regulations have requirements relating to this training or adequate knowledge in terms of the installation of

electrical equipment, the aforementioned requirements must be complied with by this person.

-Ensto Novexia declines all liability for any property damage or personal injury caused by poor installation,

mishandling, or failure to comply with safety recommendations.

WARNING

For the operation of this system in complete safety, it is essential that the installers, users and technicians

follow the procedures and precautions described in this guide. Non-compliance with these instructions may

cause damage to the products and/or serious or even fatal injury.

This document is the property of Ensto Novexia. It may not be copied or disclosed to third parties without

written permission. Non-contractual documents, drawings and photos. The information and instructions

provided may change without prior notice.

NO. NX2010597/ NO. 72983_C

06/04/2021

3 (35)

4PR-F14-D

Table of contents

1

Presentation................................................................................................................................................ 4

1.1.

Product purpose.................................................................................................................................. 4

1.2.

General characteristics........................................................................................................................ 4

1.3.

List of equipment required for installation (not supplied by Ensto Novexia)..................................... 4

2

Installation................................................................................................................................................ 10

2.1.

Unpacking and handling instructions................................................................................................ 10

2.2.

Installation operations ...................................................................................................................... 10

2.3.

External connections......................................................................................................................... 10

3

Commissioning.......................................................................................................................................... 17

3.1.

Points to be checked before commissioning .................................................................................... 17

3.2.

List of commissioning operations...................................................................................................... 17

3.3.

Operational tests............................................................................................................................... 17

4

Operation.................................................................................................................................................. 24

4.1.

Function by function description ...................................................................................................... 24

4.2.

Commands, tests, configurations - upgrades with new functions.................................................... 24

5

Maintenance............................................................................................................................................. 29

5.1.

Preventive ......................................................................................................................................... 29

5.2.

Corrective.......................................................................................................................................... 29

6

Technical Assistance................................................................................................................................. 32

7

End of Product Life.................................................................................................................................... 33

NO. NX2010597/ NO. 72983_C

06/04/2021

4 (35)

4PR-F14-D

1

Presentation

1.1.

Product purpose

1.2.

General characteristics

1.3.

List of equipment required for

installation (not supplied by Ensto Novexia)

NO. NX2010597/ NO. 72983_C

06/04/2021

5 (35)

4PR-F14-D

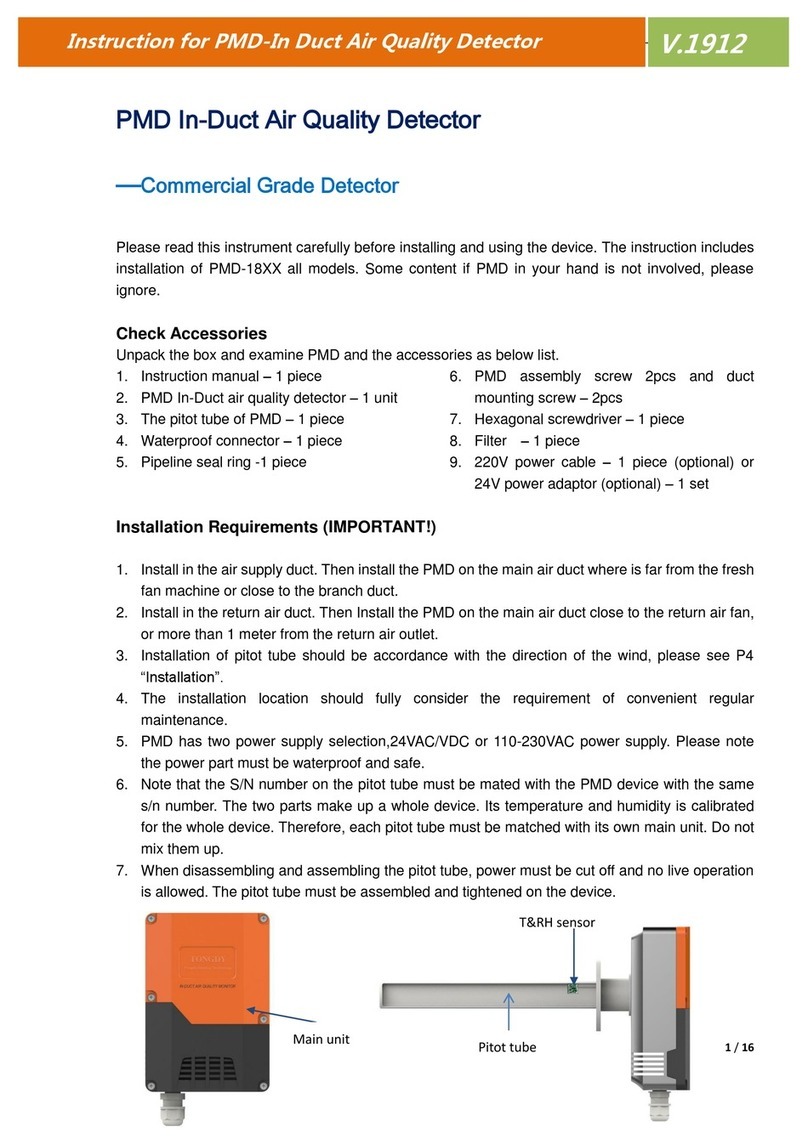

1.1.

Product purpose

LYNX 4400 fault detectors are designed to be installed on the underground sections of MV grids earthed by

means of a limiting resistor or impedance. The detector enables the following aims to be achieved:

•

Improving detection performance

•

Counting faults and changing the operation of auxiliary contacts

•

Standardising cores, PPACS, indicator lights and their connections

•

Standardising and extending the usable lives of batteries and supercapacitors

•

Using plug and coded type connectors for connecting current probes

1.2.

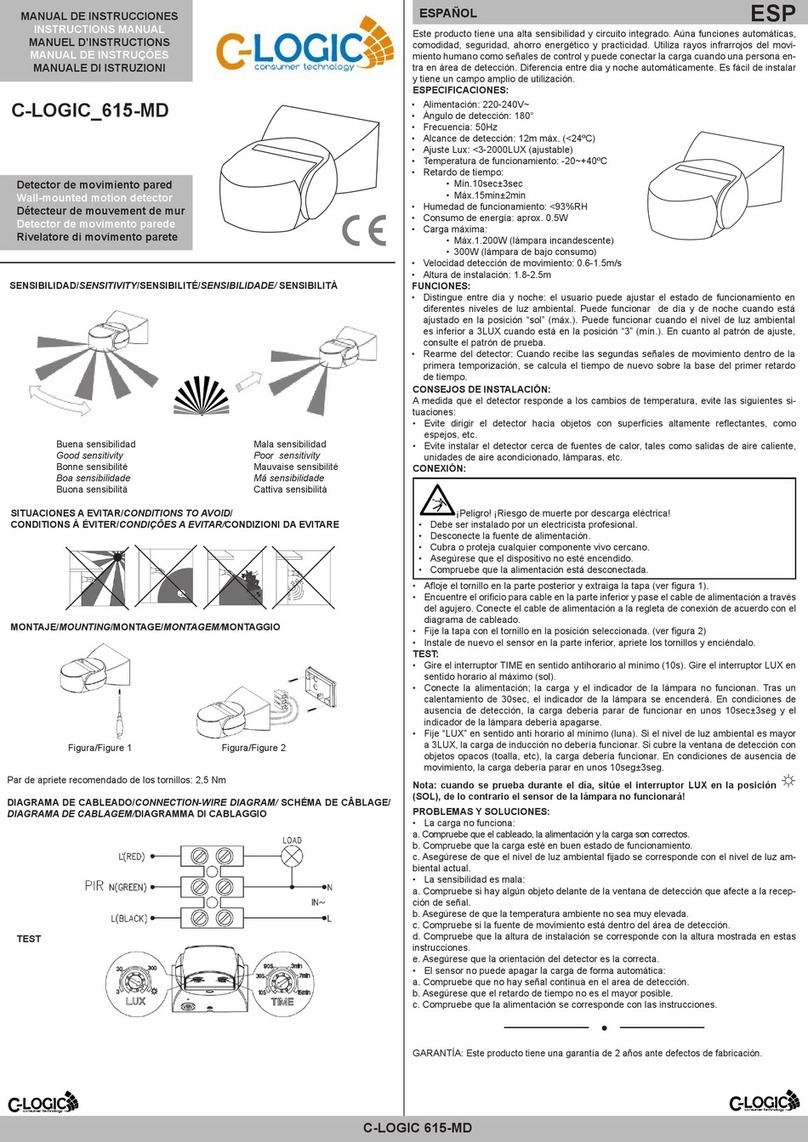

General characteristics

Front panel detail

Error indicator lights Display Calibration indicator light

Test reset and

PPACS calibration button

Display and counter

reset button

Test button

Polycarbonate

case

7 flexible cable

grommets Identification

label

NO. NX2010597/ NO. 72983_C

06/04/2021

6 (35)

4PR-F14-D

Characteristics of LYNX44XX in amperometric configuration

MV grid (in accordance with specification EDF PR-HN-45-S-50 of February 2011)

Voltage Frequency

15 to 20 kV

50 Hz / 60 Hz

Single-phase current thresholds in A

20 - 40 - 80 - 160 - 240

Polyphase current thresholds in A

500, 750, 1200, 1600

Double current thresholds in A

250, 450, 700, 1200

Fault indication duration in Hours

2 hours

Fault response time in ms

100 ms

Fault indication reset after triggering

-Indication locking

-By the return of LV or MV > 5 A

-On expiry of the long-term time delay

-By manual operation

3 s

2 hours

Reset button

Characteristics of LYNX44XX in directional configuration

MV grid (in accordance with specification EDF PR-HN-45-S-51 of February 2011)

Voltage Frequency

15 to 20 kV

50 Hz / 60 Hz

Single-phase phase-earth fault detection

Indication according to the direction of the fault

Red or Green

Thresholds at 20 kV

Preset 1

Preset 2

Residual current

25 A < Ir < 35 A

50 A < Ir < 70 A

Residual voltage

3 kV < Vr < 5 kV

7 kV < Vr < 11 kV

Validation of

detection over 50 ms

1.5 kV < Vr < 2 kV

3 kV < Vr < 4 kV

In 15 kV position, the thresholds are reduced to three quarters of these values

Double phase-earth fault detection

-Trigger threshold

-Fault triggering time delay

-Indication

250 A rms

80 ms

Alternating red-green

Detection of polyphase faults

-Average trigger threshold on balanced fault

-Fault triggering time delay

-Indication

500 A rms

80 ms

Alternating red-green

NO. NX2010597/ NO. 72983_C

06/04/2021

7 (35)

4PR-F14-D

Validation time delay

-From the disappearance of the MV, before triggering of the indicator lamps

(configuration using microswitches)

-From MV presence after MV restoration

10-20-40-70 s

5 s

Fault indication reset after triggering

-By the return of LV or MV > 5 A

-On expiry of the long-term time delay

-By manual operation

3 s or 2 h

Reset button

Common characteristics

Accumulators/Batteries

350-F Lithium supercapacitor

LSH20 batteries

Display

4-digit display

H = 17.8 mm

External indicator light housing

-Number of LEDs

-Total luminous flux

-Flashing frequency

-Standard flashing capacity with lithium batteries

6

7 Ln

1 s

200 h

Environment

-Operating temperature

-Storage temperature

-Humidity level

-Vibration resistance (IEC 68-2-6 & 68-2-29)

-Protection rating

-Overall dimensions

-Device mass (excluding cables)

-15 ° to + 55 °

-25 ° to + 70 °

Up to 100%

2 g (peak value)

IP30 IK07

289 x 200 x 92

1.1 kg

NO. NX2010597/ NO. 72983_C

06/04/2021

8 (35)

4PR-F14-D

Cable routing

External indicator light

Parallel connection

LV power supply Parallel connection of PPACS

LV power supply

Remote indication PPACS voltage

Climatic conditions

Storage

Storage temperature: -25 to +70°C

Relative humidity: 10 to 100%

Operation

Normal operating temperature: -15

to +55°C

200

Cores

289

92.50

NO. NX2010597/ NO. 72983_C

06/04/2021

9 (35)

4PR-F14-D

1.3.

List of equipment required for installation

LADAC detectors:

NAME

Ensto

Novexia no.

DESCRIPTION AND CONTENTS

Lynx 4425

NX2009362

Lynx 3425 low voltage supply+super capa. + cable 7m

Lynx 4425

NX2010140

Lynx 3425 low voltage supply+super capa. 10kV + cable 7m

Composition of a complete unit:

1 Lynx case equipped depending on the version

oWith LV power supply and supercapacitor

oStandalone with two LSH20 batteries

Accessories supplied alone (depending on the option)

1 red and green external indicator light housing connected to the Lynx using a 5, 10, or 15-m

connection cable

1 Lynx connection cable with core connectors 2, 5, 10, or 15-m long

1 Lynx shielded connection cable with PPACS connectors 2, 5, 10, or 15-m long

3 resin-coated cores with 1-metre wired connectors

LSH20 battery

Standard equipment enabling the device to be wall-mounted (screws and wall plugs) is not

supplied by Ensto Novexia.

NO. NX2010597/ NO. 72983_C

06/04/2021

10 (35)

4PR-F14-D

2

Installation

2.1.

Unpacking and handling instructions

2.2.

Installation operations

2.3.

External connections

NO. NX2010597/ NO. 72983_C

06/04/2021

11 (35)

4PR-F14-D

2.1.

Unpacking and handling instructions

Open the box and check in relation to the order.

2.2.

Installation operations

Installing the LYNX 4400 case

The LYNX 4400 case is mounted on a flat wall using the following accessories (not included in the

supply):

4 slotted head screws Ø4.5 X L 35 mm

4 wall plugs Ø6 L 30 mm

To access the 4 case mounting holes, remove the cover.

After inserting the wall plugs in the wall (see

mounting distances opposite), position each of the

four Ø 4.5 screws in its hole.

Installing the external indicator light housing

The indicator light housing is supplied with a 3X1.5² U1000RO2V type cable, 5, 10 or 15 metres long

depending on the order.

Mounting distances for the housing 53 x 38 mm (2 x Ø 4.5 screws).

To connect the indicator light housing to the LYNX case see page 15.

Mounting distances:

215 mm x 175 mm

NO. NX2010597/ NO. 72983_C

06/04/2021

12 (35)

4PR-F14-D

2.3.

External connections

J4 J5 J9 J1 J2

Connecting the CORES (power off)

The current probes used with the LYNX 4400 are split

core current sensors with a lever clasp on a resin-

coated core.

Ratio 1/500.

The assembly uses three identical cores detecting:

-single-phase faults on the earth

-polyphase faults

-double faults

USE OF CORES VERSION 2012

2. Installation

NO. NX2010597/ NO. 72983_C

06/04/2021

13 (35)

4PR-F14-D

Modular MV cell Compact MV cell

Protective shield

Green side

Earth for

cable shields

and the

IP2X connector for the cores cores' S2s

Each core is mounted on a phase of the underground cable, with the green side facing towards the unit's

busbar.

It is centred and attached to the cable using 3 self-centring rubber bosses.

THE SCREENED BRAID FOR EACH PHASE MUST BE CREATED BY AN INSULATED CONDUCTOR AND

PASSED INSIDE THE CORRESPONDING CORE.

The wires for each core are connected using a coded 2-contact MATE-N-LOCK connector.

A 4x1.5mm² U1000RO2V type cable equipped with female MATE-N-LOCK connectors is supplied for

connecting cores to the LYNX 4400's J2 terminal block.

Insert the stripped end with end sleeves into the LYNX's cable grommet.

Connect the J2 terminal block as follows:

l1 l2 l3 C NC

Terminal I1: Brown wire

Terminal I2: Black wire

Terminal I3: Grey wire

Terminal C: Blue wire (common)

NC terminal: Not connected

Green side

Earth for cable

shields and the

cores' S2s

Core IP2X connector

NO. NX2010597/ NO. 72983_C

06/04/2021

14 (35)

4PR-F14-D

Connecting the PPACS VOLTAGE SENSORS (in case of directional detector)

The voltage sensors used with the LYNX 4400 are the capacitive dividers of the separable connectors

(plug-in terminals) located:

-Either on the transformers of the MV/LV stations

-Or on the network cells of the disconnection stations.

These capacitive dividers were previously equipped with removable PPACS voltage connection. See the

installation guide of the PPACS supplier.

An earth connection must also be created.

All of the wiring from the PPACS and from the earth connection must be grouped in a standardised

female Harting socket.

To connect the capacitive dividers to the LYNX 4400, a shielded 4X0.5mm² cable is supplied. This cable is

equipped with a standardised male Harting socket on the capacitive divider side.

Connect the J1 terminal block (removable and screwed in) as follows:

Using the Ensto cable

With Cahors cable

Connection of the Lynx cases in parallel (max. 3 per PPACS):

-Route the end of the cable through the cable grommet provided (refer to page 8)

-Connect to terminal J1 by doubling the wires in the terminal block

Important note! The set-up requires cases of the same type (LYNX 4400). You must always

restart the calibration procedure on all cases (refer to page 22).

Terminal U1: wire No. 1

Terminal U2: wire No. 2

Terminal U3: wire No. 3

Terminal C: wire No. 4

Terminal U1: white wire

Terminal U2: green wire

Terminal U3: red wire

Terminal C: three black wires together

NO. NX2010597/ NO. 72983_C

06/04/2021

15 (35)

4PR-F14-D

Connecting the external indicator light housing

The LYNX 4400's indicator light housing has red and green lights. It is supplied with a 3X1.5mm²

U1000RO2V type cable. Position the indicator light with the cable gland facing downwards.

Connect the J9 terminal block as follows:

Terminal +: Brown wire

Terminal V: Black wire

Terminal R: Grey (or blue) wire

+ V R

Connecting to remote indication

The connection is made using a 4X1.5mm² U1000RO2V type cable - not supplied

An equipment fault may be actuated by the detector in response to:

- A need to replace the battery or batteries when the battery becomes flat after 7.5 years of use

- An anomaly affecting the alternative auxiliary power supply

- An anomaly affecting the electronics

Connect the J5 terminal block (removable and screwed-in) as follows:

Power supplies (depending on the option)

LV power supply + supercapacitor option 350 Farad 2.7 V supercapacitor - Usable life 15 years

Standalone option: 2 x D20 LSH 20 type lithium batteries, not supplied - Usable life: ≥ 7.5 years

Note: the two batteries face in the same direction (+ to the left).

NC NC R V DE C

Terminals NC: Not connected

Terminal R: Red fault

Terminal V: Green fault

Terminal DE: Equipment fault

Terminal C: Common

NO. NX2010597/ NO. 72983_C

06/04/2021

16 (35)

4PR-F14-D

NB: During lengthy storage periods, the lithium battery may be passivated, and therefore unable to

supply the current needed for the LYNX 3400 to operate. To depassivate it:

-Short-circuit its terminals with a 47-ohm 3-W resistor

-Wait for a noticeable rise in the resistor's temperature (10 to 30 seconds depending on the

batteries)

-230-V AC external power supply (LV power supply option)

The LYNX 4400's normal power source is low voltage 230 V, which is available on site. The LV is supplied

to the LYNX 4400 by a 2 x 1.5mm² U1000RO2V type cable –not supplied. LYNX 4400s do not need to be

connected to the neutral earth.

Connecting the J4 connector

Insert the cable via the LYNX 4400's cable grommet.

Connect the cable's neutral and phase wires as follows:

-- Neutral, to the left-hand terminal.

-- Phase, to the right-hand terminal.

Check the condition of fuse F1. A 5X20 F type (250 mA)

spare fuse is available on the lower left-hand side

of the detector.

N PH

NO. NX2010597/ NO. 72983_C

06/04/2021

17 (35)

4PR-F14-D

3

Commissioning

3.1.

Points to be checked before commissioning

3.2.

List of commissioning operations

3.3.

Operational tests

NO. NX2010597/ NO. 72983_C

06/04/2021

18 (35)

4PR-F14-D

3.1.

Points to be checked before commissioning

NO. NX2010597/ NO. 72983_C

06/04/2021

19 (35)

4PR-F14-D

3.2.

List of commissioning operations

Selection of the type of detector: Amperometric or directional (configured as directional on leaving the

factory)

Position the selector

On the DDA side for an overcurrent fault detection configuration

On the DFD side for a directional fault detection configuration

LYNX44XX configured in amperometric fault detection mode

1.

Configuration of the homopolar lo detection threshold (phase to earth)

Ex-factory setting: 80 A

2.

Configuration of the indicator light colour for a homopolar fault

Ex-factory setting: Red homopolar fault

3.

Configuration of polyphase Imax detection thresholds (phase to phase)

Ex-factory setting: 500 A

Rm: The polyphase threshold is always higher than the double threshold.

Switch

240 A

160 A

80 A

40 A

20 A

1

OFF

OFF

ON

OFF

ON

2

OFF

OFF

OFF

ON

ON

3

OFF

ON

ON

ON

ON

Switch

Red homopolar fault

Green homopolar fault

4

OFF

ON

Switch

1600 A

1200 A

750 A

500 A

5

OFF

ON

OFF

ON

6

OFF

OFF

ON

ON

NO. NX2010597/ NO. 72983_C

06/04/2021

20 (35)

4PR-F14-D

4.

Configuration of detection thresholds I Double

Ex-factory setting: 450 A

5.

‘Power on’ condition

Ex-factory setting: Power on via LV restoration or I > 5 A

6.

Indication reset condition configuration

Ex-factory setting: Indication reset by LV restoration

LYNX44XX configured in directional fault detection mode

1.

Selection Preset 1 / Preset 2

LYNX 4400 units have two detection levels, called Preset 1 and Preset 2.

Preset 1 corresponds to the greatest earth fault detection sensitivity. This position is used

preferentially.

The Preset 2 position is intended for special cases, such as when most of the detectors used

for the outputs are older-generation detectors (pre-2009).

Switch

1200 A

700 A

450 A

250 A

1

OFF

ON

OFF

ON

2

OFF

OFF

ON

ON

Switch

Power on via LV restoration

Power on via LV restoration or I = 5 A

3

OFF

ON

Switch

Indication reset by restoration of

power

Indication reset by 2-h time delay

4

OFF

ON

Table of contents

Other ensto Security Sensor manuals

Popular Security Sensor manuals by other brands

Honeywell Home

Honeywell Home PROSiXCT installation instructions

PCB

PCB 4115K-08A Installation and operating manual

Ziton

Ziton ZR432-2P installation guide

RLE Technologies

RLE Technologies Falcon WIFI-LD quick start guide

Ingersoll-Rand

Ingersoll-Rand FALCON 1690 Touchbar installation instructions

C-LOGIC

C-LOGIC 615-MD instruction manual