Ensy AHU-300 HV User manual

User manual and

Installation Guide

AHU-300 HV

AHU-300 HH

393870-2 Rev0: 11.07.2018 BBV

We reserve the right to change technical data without notice. http://www.ensy.no Page 1

393870-2 Rev 0: 11.07.2018 BBV

We reserve the right to change technical data without notice. http://www.ensy.no Page 2

User manual.Page 1 to 13

(Front page and pictures on pages 1-5 shows AHU-300 HV)

To open the front hatch

you will find a key for the

quarter turn latches in

the folder together with

the following documents.

Keep this key in a place so it is out of reach

for children.

To open the locks, turn the key toward the

center of the unit.

Left latch Right latch

To operate this product

people should have

necessary skills, or under the

supervision of a qualified person.

Children should be told to not play

with the appliance.

Before any access into the electrical connections boxes, power must be

disconnected by pulling out the plug from the socket.

It is only allowed for authorized persons to enter into the electrical connection boxes. (Sketch shows

AHU-300 HH)

If any electrical components are damaged, they must be replaced by the manufacturer, dealer or a

qualified person in order to avoid dangerous situations.

393870-2 Rev 0: 11.07.2018 BBV

We reserve the right to change technical data without notice. http://www.ensy.no Page 3

The hatch has three hinger that holds it permanently to the housing. If the unit is placed high under a

ceiling, then is mandatory to get help from another person to take down the hatch. It can be done by

unscrewing 6 pcs of screws from the housing or front hatch.

The safety wire can be removed from inside of the front hatch so that the hatch can be

opened or removed. The safety wire must be reinstalled before the hatch closes.

To close, after putting the hatch back on place, turn the latches the opposite way. You may use some

pressure towards the hatch to close it.

393870-2 Rev 0: 11.07.2018 BBV

We reserve the right to change technical data without notice. http://www.ensy.no Page 4

Adjustment of the unit.

Ahumidity sensor is, from factory, mounted inside the unit. It is set to “0” that

means it is set to not active.

Note!This switch is not used on units produced before february 2015.

After startup, where the unit is placed into a new building with high

humidity, you can let this humidity sensor be turned off for a period

to avoid the full speed of the fan at night. To get the humidity

sensor to operate as intended, you need at one time to put it active.

Than you need to set the switch in position "1".

If the ventilation unit is placed in a house without high humidity,

you should switch to position "1" after you putting ventilation unit

into operation.

This switch will also affect any extra external humidity sensor that is

plugged into the device.

Adjusting the humidity sensor.

If it is necessary to adjust the sensitivity

of the humidity sensor then you just can

remove the black plug and you then can

see the adjusting knob and the RH%

scale.

Note!This black plug is not on

units produced before february

2015.

If bad light condition, it may be easier to

remove the cover so that you easier

seethe RH% scale.

The sensor is set to 80% RH from factory.

If you do adjustments, this only affect

the sensor integated inside the unit.

The sensitivity for the integrated sensor

you can adjusted from 50% (low) to 90%

(high) in accordance to what are the

needs. The arrow points the value

chosen.

If you have a second external sensor that

means you need to adjust that one from

its settings.

Replace the cover and / or plug after

finish adjusting.

393870-2 Rev 0: 11.07.2018 BBV

We reserve the right to change technical data without notice. http://www.ensy.no Page 5

Replacing the filter.

The filters should be replaced every 6. 9. or 12. months.

Before the filters can be removed, you have to unscrew a

little bit two crews for each locking bracket. Push the

bracket away from you to release the filters.

Should than be extracted without use of any tools.

To guarantee optimal properties of the

ventilation unit, use the original filters from

EnSy. The use of spurious filters will limit the

warranty on the product

Ensy art number for filter set is:

011460860-2

FILTERSETT ENSY AHU 300 Himling. F7: 140x240x94.

To insert a new filter you then first have to puch the

bracket away from yourself. Then put the filter in place

and then pull the bracket against yourself and tighten the

skrews on the bracket.

Remember to enter the control panel menu (4.3 Filter) and press Filter OK after the

filters has been replaced.

Cleaning the fans.

This must be done by a qualified person.

Before removing fans the main power must be

disconnected by pulling out the main supply

plug from the socket, or fans to be

programmed to position “AV” or “OFF”

Disconnect the 3-pole and 5-pole plugs.

Before you are able to remove the fans you

first have to unscrew two screws for each fan

that holds the fan in correct position.

The fans can then be pulled out of the

ventilation unit without the need for any tools.

When the fan is placed back into the unit, then

make sure the screws are tightened so that

there is no danger that they loosen during

operation.

Clean with mild soap and water.

393870-2 Rev 0: 11.07.2018 BBV

We reserve the right to change technical data without notice. http://www.ensy.no Page 6

Maintenance and cleaning of rotary heat exchanger

This must be done by a qualified person.

If the unit is placed high under a ceiling, then it might be an advantage to get help from another

person to hold the rotor exchanger in correct position till all four “safety” screws are loosen.

Disconnect the 3-poled plug , and then unscrew those four “safety” screws that holding the rotor

exchanger in place.

(Sketch shows AHU-300 HH, but the

princip is the same for AHU-300 HV)

Can be pulled out of the ventilation

unit without the need for any tools.

Rotor exchanger can easily be removed for

cleaning by unscrewing 12 screws that hold it

together.

Clean parts with mild soap and water.

Do not expose the rotor motor or

connector for moisture.

The exchanger you also can clean

with mild soap and water. Do not use ammonia-

containing detergent, as this will prey on and

discolor aluminum in rotary heat exchanger.

Flushed with hand shower and blow gently clean

with compressed air.

Ensure that all 12 screws are tightened sufficiently so that they do not come loose

during operation.

Preferably use a screwdriver to tight the screws. If use of electrical screwdriver, make

sure that you use low torque to prevent destroying the threads in the sheet metal parts.

To make sure that the drive belt can adjust itself into correct position you must rotate the exchanger

some few turns. Then insert back into the ventilation unit. Be sure that rotor exchanger is properly

inserted in all the guides inside the unit. If not, this can lead to vibration in the system and internal

air leak in the unit. Make sure that all four “safety” screws are tightened so that there is no danger

that they loosen during operation.

393870-2 Rev 0: 11.07.2018 BBV

We reserve the right to change technical data without notice. http://www.ensy.no Page 7

Main menu

1. Control Button indicator for fan.

2.Control Button indicator set point.

3.Control Button indicator information.

4.Control Button indicator settings.

Overview of control panel

The main screen consists of, from top, left:

Time Indication, hour, minute

Timer, Weekly schedule (if programmed)

Reheating coil (if connected)

Temperature readings, Outdoor / Indoor

Status airflow – fan speed setting

OFF MIN NORM or MAX

Temperature set point, 15 - 21 °C

Reheating coil – (here refers active element)

Rotary exchanger Indicator - (here refers

active rotary wheel)

Indicators in the menu screen:

"Sun" indicates that the rotor has

stopped, the air handling unit is in the

summer operation mode.

"Snowflake" low temperature

indicates that the air handling unit is

in defrosting mode.

"Steaming pot" and blinking fan blades

indicates that the kitchen exhaust is

activated.

"Timer" and the countdown of the fan

symbol indicate that the forced

ventilation is enabled.

From 10 up to 240 minutes

"Away" indicates when the feature is

enabled, this feature will override

timer.

"Clock over the fan symbol" indicates

that the timer is activated.

Co2 over the fan symbol" indicates

that the carbon sensor is activated.

"Exclamation point" indicates that

moisture recorded over the sensor is

higher than the set value.

May also indicate that the motion

sensor is activated if connected on D2

signal output.

Control Button 1.

2.

3.

4.

393870-2 Rev 0: 11.07.2018 BBV

We reserve the right to change technical data without notice. http://www.ensy.no Page 8

1.Fan speed

Ventilation unit has three options for choice of

airflow.

Min, Normal and Max.

For programming of values within each step,

see 4.5.1.3 Using the control button 1, and - /

+ buttons can change between the pre-

programmed selections.

1.1 Fan boost

Forced ventilation, fan speed increases to max

speed. (Means to the speed that is set in

menu 4.5.1.3.) The function is for use if high

humidity in bathrooms and laundry room.

Forced ventilation can be activated with

button

then

Interval adjustable from 10 - 240 min with +

and -

This picture shows 10 min forcing time, but

not activated.

To activate the fan boost use

control button 4.

You can see that the fan are running with Max

speed and the clock will start countdown.

You can easy deactivate the fan boost again

before the countdown automatically stops it.

First control buttom 1 and then 4.

This feature can also be operated with an

external pulse switch. The switch is placed in

the bathroom or adjacent rooms. Connected

to contact D1 in top of the ventilation unit.

(Look at page 19 or 20 in this manual.)

If this option via D1 is intended for use against

wood stove or fireplace then it is

recommended that Max speed under Fan

control in menu 4.5.1.3. is set to Supply 100%

and adjust Extract to be 80 to 85%. (Look at

page 10 in this manual)

2. Temperature

Choose from pre-programmed temperature

settings set point between 15 - 21 °C. Setting

is changed by operating the switch buttons

below - / +symbols.

Heating element can here be set ON or OFF

by operating the switch button 4 in this

screen, but only if heater is connected.

(To see if heating coil is connected or

disconnected, see 4.5.1.1 Heater)

Indicator for activated heating coil.

Small picture show not activated.

393870-2 Rev 0: 11.07.2018 BBV

We reserve the right to change technical data without notice. http://www.ensy.no Page 9

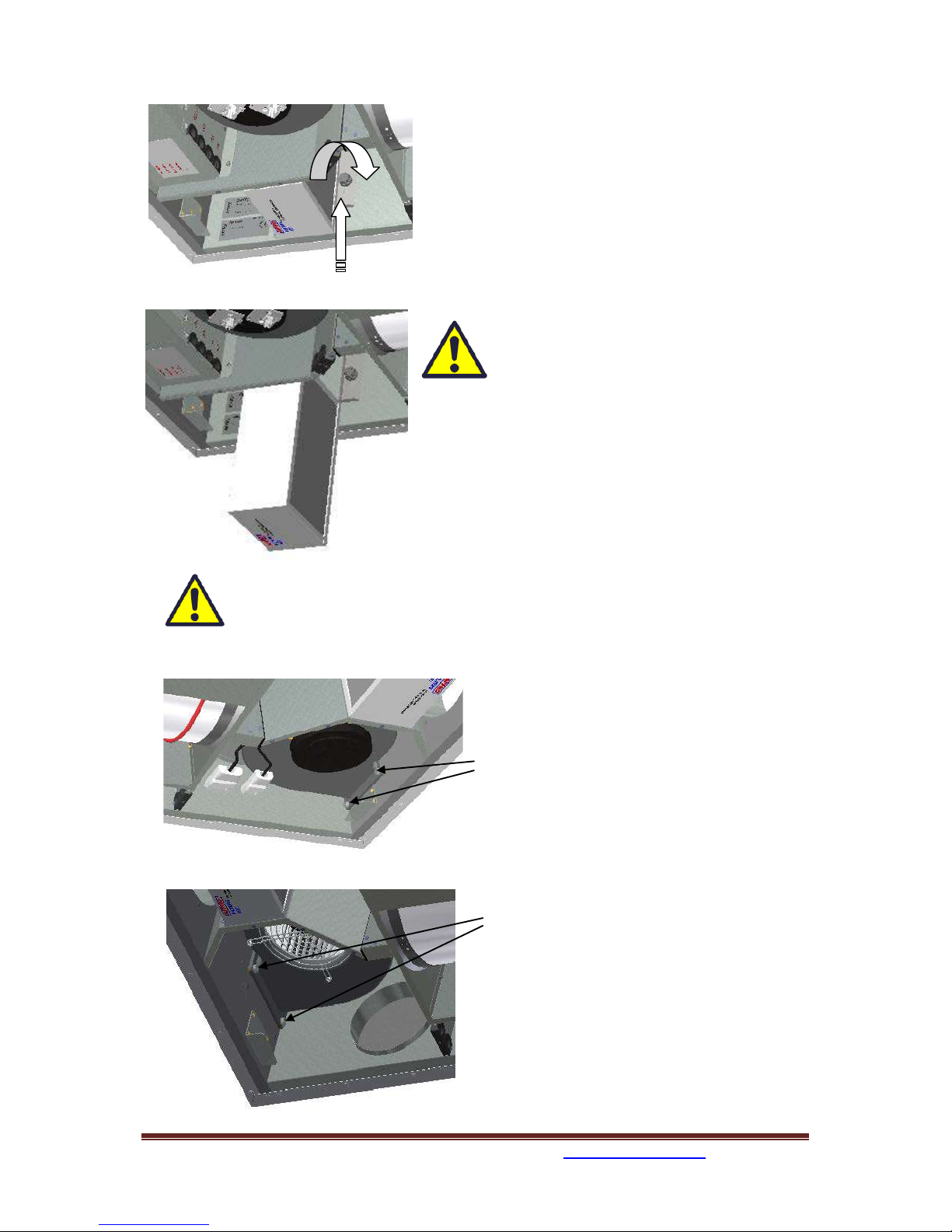

3. Information.

3. Information / 3.1.Alarms

When alarm you can find a source of error

here, as well as info on how the alarm is reset.

(See pages 29 and 30 in this manual)

3. Information / 3.2 Program version

Information about the software

version. This information must be provided to

service personnel at the failure of the unit.

Which display is defined as Display 1 or

Display 2 appears here if the plant has

mounted two displays.

See 4.5.1.10 selection of the displays.

3. Information / 3.3. General info

Here you can see defrost mode that has

been chosen.

(See 4.5.1.9 if you want to change mode.)

4. Preferences

To navigate within the various sub-menus

when using the control buttons below the up /

down cursor key that displays on the display.

4. Preferences / 4.1 Time/date

Setting menu for Time/date. This setting is

important since the information forming the

basis for the weekly schedule function if this is

to be activated. Also for the filter alarm

function it is needed.

393870-2 Rev 0: 11.07.2018 BBV

We reserve the right to change technical data without notice. http://www.ensy.no Page 10

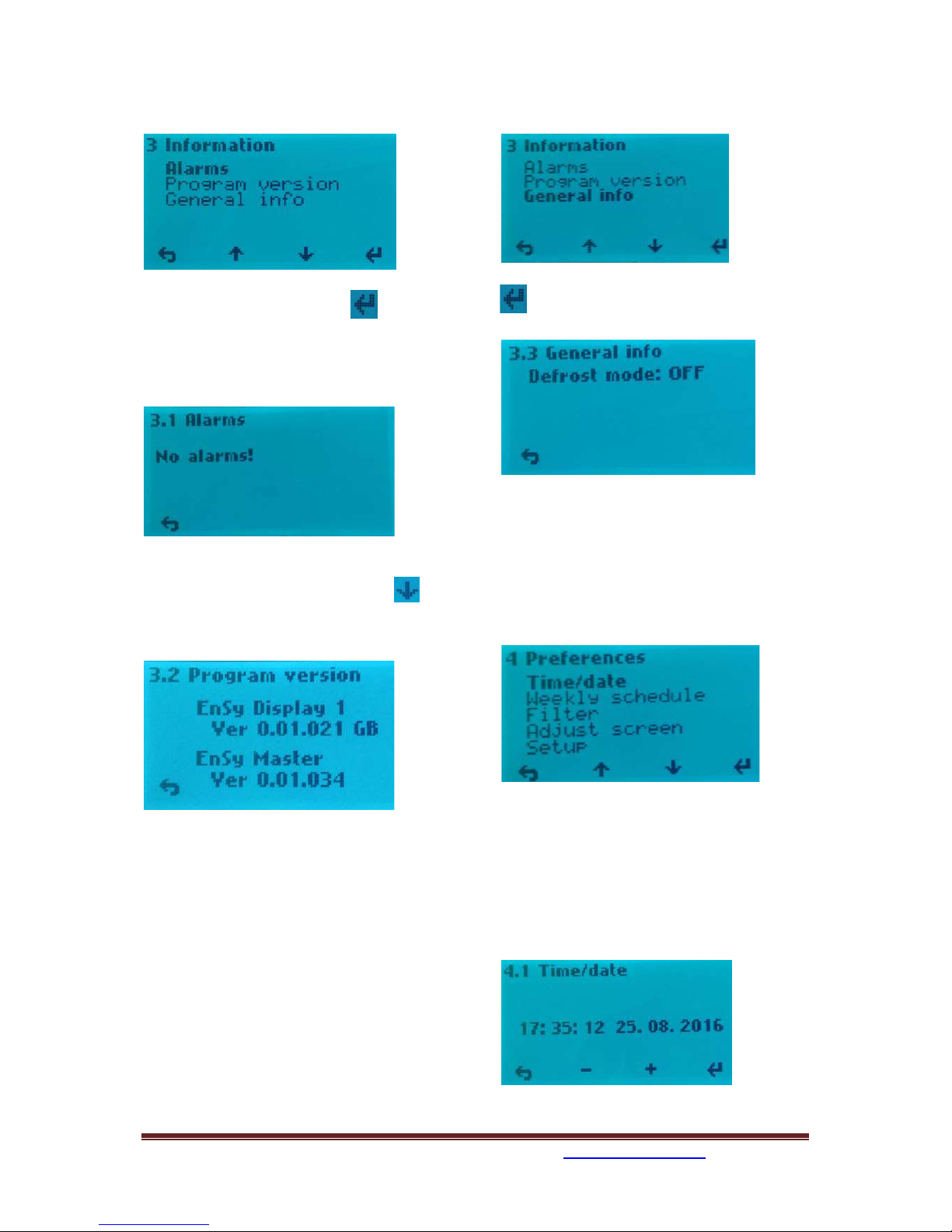

4. Preferences / 4.2 Weekly schedule

Programming of the Weekly schedule, fan

speed and temperature set point. Here it can

be programmed for two periods each day. Ex.

day - night.

Every day must be programmed individually.

Monday - a period of time, select the start

time. To activate the period, X - over period

number is removed, use the -/ +keys.

Use enter to move between the different

fields.

Choose airflow (fan speed) Speed dialing -

MIN when one fan blade on the indicator is

black. NORM = two black fan blades on the

indicator. MAX speed = three black fan blades

on the indicator.

Select the desired supply air temperature you

want during the period. Settings between 15 -

21°C.

If weekly schedule looks something like

this without any reason then you must

punch in all the data again.

It do not help to update software.

4.Preferences / 4.3 Filter

Setting the time interval for filter change,

current choices are 6, 9 or 12 months. Make

your choices by using the cursor keys +/ -.

Alarm reset elapsed period by pressing the

menu button 4, under "Filter OK"

4. Preferences / 4.4 Adjust Screen

Adjusting the contrast and color on the

display.

You can also adjust how long it should be light

in the display after the operation.

4. Preferences / 4.5 Setup

To proceed, use PIN code 1000

Press +once till it shows 1000 in

display. Then press 4 times on

Then press button 3 for OK 4.5.1

Start time

Stop time

Fan speed

Activation of the period. Here not active

393870-2 Rev 0: 11.07.2018 BBV

We reserve the right to change technical data without notice. http://www.ensy.no Page 11

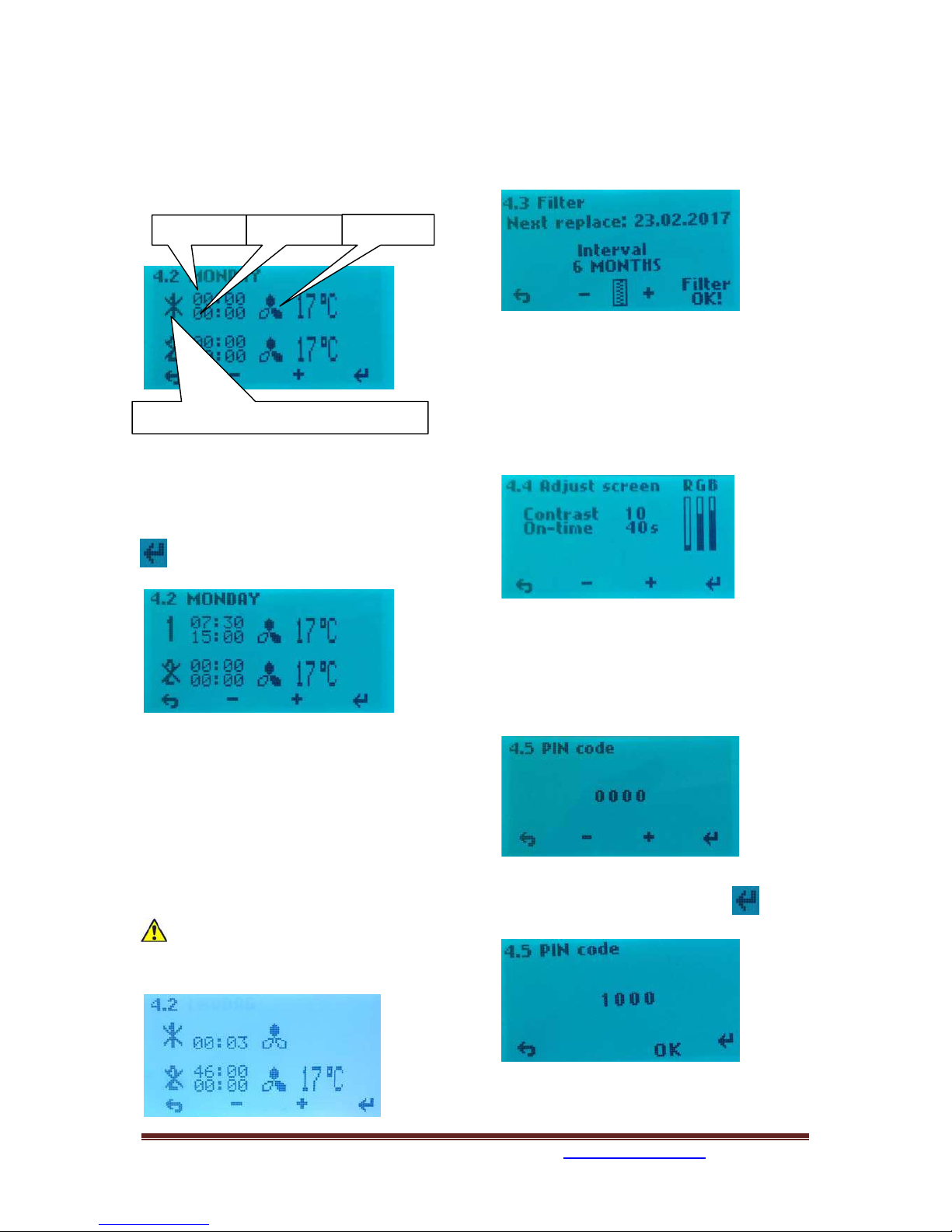

4.5.1 Setup

4.5.1.1 Heater

Turning on/off the reheating coil, use the

minus or plus button to change settings.

4.5.1.2 Cooling recovery

Activation of the cooling recovery:

It is pre-programmed two options for use

when the outside temperature is higher than

the indoor temperature, heat recovery system

will activate the function start and supply air

will be cooled by exhaust air. Engagement

when the outdoor temperature is 2 °C or 3 °C

higher than room temperature. Use button 4

to change setting for Off. Press +to activate

(On). Use button 4 to change setting for 2°C.

Press +to change to to 3°C, if wanted.

4.5.1.3 Fan control

Factory settings for AHU-300 HV and HH you

can see in next picture.

The installer can adjust these settings so that

it is adequately balanced ventilation.

4.5.1.4 Co2 control

If the unit shall be connected CO² control then

connect it to C0² connector on top of the unit.

(See page 19 or 20 in this manual).

Menu for enabling / disabling of CO² control.

Scroll to Off and press +to activate. On

Here you preprogrammed wanted ppm value

and the boost speed for the fans.

Note: To get balanced ventilation is a

prerequisite that Supply and Extract air fan

has the same value as the MAX value under

4.5.1.3

4.5.1.5 Cooker hood

Menu for programming of fan speeds by

activation of the kitchen hood. KV connector

on the top of the unit (see page 19 or 20 in

this manual) should always get signal from the

kitchen hood when this is activated. This to

prevent rotor alarm.

393870-2 Rev 0: 11.07.2018 BBV

We reserve the right to change technical data without notice. http://www.ensy.no Page 12

Supply and Extract air should have the same

value as the MAX value under 4.5.1.3 (Set to

100% from factory.)

Even if it is installed an "active" kitchen

ventilator with piping not connected towards

the unit, the KV plug must get the signal to

see that kitchen ventilator is activated. This

can be done by using a a pressure switch in

the exhaust tube from the ventilator. Then

Extract set down to around 50% or less to

compensate for the extract air in the hood.

Note! If KV signal plug is not in use for

cooker hood then you can use the signal to get

more supply air when to fire up a fireplace.

Then adjust so that supply air delivers more

air than extract air fan. In this case you must

use a switch and not impulse switch.

4.5.1.6 Extern alarm

If the unit has been connected to an external

humidity sensor or motion sensor. Use the D2

connector on top of the unit. (See page 19 or

20 in this manual). Note! In order for this

feature to work, you need the one-pole switch

marked RH% ON / OFF inside the unit to be set

in position 1. (See page 3 in this manual for

the location of this switch).

Supply and Extract air should have the same

value as the MAX value under 4.5.1.3 (Set to

100% from factory.)

4.5.1.7 Absent

Menu for setting the desired values by

activating away / home function.

Use the D3 connector on top of the unit. (See

page 19 or 20 in this manual) Function is

operated via an external switch.

Set value of the desired temperature will

show in the display after activating the

function.

4.5.1.8 Calibration

Menu reading of embedded temperature

sensors.

These temperature sensors are

delivered calibrated from the

manufacturer and should not be attempted

change in here.

The «Outside air» sensor normally

shows 3-6°C highter temperaature

then the reel outside temperature. This is due

to heating of the air in the duct network from

the intake grille to the intake of the unit

where the sensor are placed.

393870-2 Rev 0: 11.07.2018 BBV

We reserve the right to change technical data without notice. http://www.ensy.no Page 13

4.5.1.9 Defrost

Menu for how to change defrost mode if

temperature is low and humidity is height.

From the start up menu you can see which

defrost mode the unit is set in.

The unit is set in mode OFF from factory.

If it is needed to change the defrost

mode to another mode then press

button 4 and scroll down to Configuration

with button 3.

Press enter button and follow procedure

as in Menu 4.5 Setup to continue.

Press enter button

Defrost mode OFF from factory.

Modus 1: at low humidity.

Defrosting function start at -20°C.

Modus 2: at normal humidity.

Defrosting function start at -15°C.

Modus 3: at high humidity.

Defrosting function start at -10°C.

The function when defrosting starts is that

each hour the supply air fan stops for 6

minutes. The heater EV turns off. Extract air

fan reduces speed to 30% and the rotary

exchanger will run as normal.

To avoid that the rotary exchanger will stop

when the cycle goes back to normal function,

the supply air fan will start up the last minute

of the defrosting mode cycle.

(Supply air fan reacts delayed relative to the

control signals and rotary exchanger so that

the heater will not engage until the speed of

the supply air fan has passed 250 r/min, in

normal operation).

393870-2 Rev 0: 11.07.2018 BBV

We reserve the right to change technical data without notice. http://www.ensy.no Page 14

4.5.1.10 Display number

If two control panels should be used, then

from this menu it has to be specified that one

of the control panels is «Display 1» and the

other one is «Display 2». This to avoid delay in

the signals between the control panels and

main control board inside the unit.

It does not matter which of the control panels

that are called Display 1 or Display 2.

We reserve the right to change technical data without notice. http://www.ensy.no Page 15

393870-2 Rev 0: 11.07.2018 BBV

Mounting instructions. Page 14 to

30.

1.General

2. Mounting of the unit

2.1 Brackets and gaskets to avoid vibration

2.2 Alternative placement on wall

2.3 Placement under concrete ceiling

3. Connections

3.1 Electrical connections

3.2 Duct connections

4.Setting the airflow

5. Alarms

1.General

This guide is made to provide installation and user instructions regarding the correct installation of AHU-

300 HV and HH.

AHU-300 HV and HH is designed for heat recovery with air volumes of up to 220 m³ / h. The energy from

the exhaust air is transferred to supply air through the rotary heat exchanger where the air streams pass

each other without making contact.

The unit has a built in-heater for supplementary heating of supply air.

Humidity sensor for forced ventilation is integrated into ventilation unit.

For AHU-300 HV and HH the control panel is not integrated in the unit. It is delivered separate together

with the unit, are supplied with 10 meters cable, and plug to fit the socket outside the unit.”STYREPANEL”

Option for a second control panel to be connected is also made outside the unit. “STYREPANEL” (See page

19 and 20)

The unit can also connect additional equipment cooker hood over the stove, pulse switch for controlling

the forced ventilation, for example, wet rooms or bathrooms, sensor for carbon management and switch

management away / home function. Control of these options are integrated into AHU-300 HV and HH.

AHU 300 HV and HH is supplied in painted finish, tested and ready for operation.

Installation, commissioning and tuning must be performed by authorized personnel.

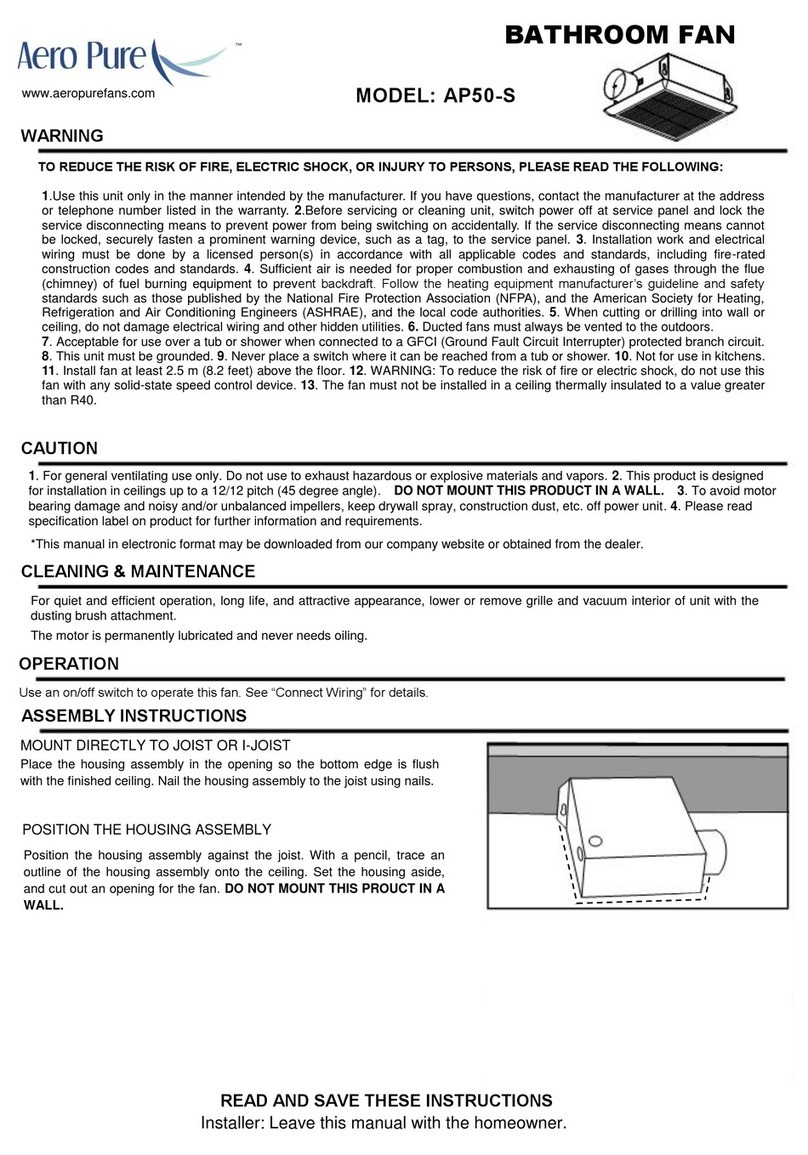

2. Mounting

Together with the unit is delivered the following equipment:

1. Suspension bracket

2. Bracket with vibration dampening gasket for ceiling montage

3. Self-adhesive vibration damping

4. Accessories bag containing the necessary screws

5. 5 pcs. plugs for connecting additional equipment.

6. Key for opening the front hatch.

7. Control panel with 10 meters cable

We reserve the right to change technical data without notice. http://www.ensy.no Page 16

Exhaust air

Fresh air from outside

Supply air to room

Cooker hood

Extract air from room

393870-2 Rev 0: 11.07.2018 BBV

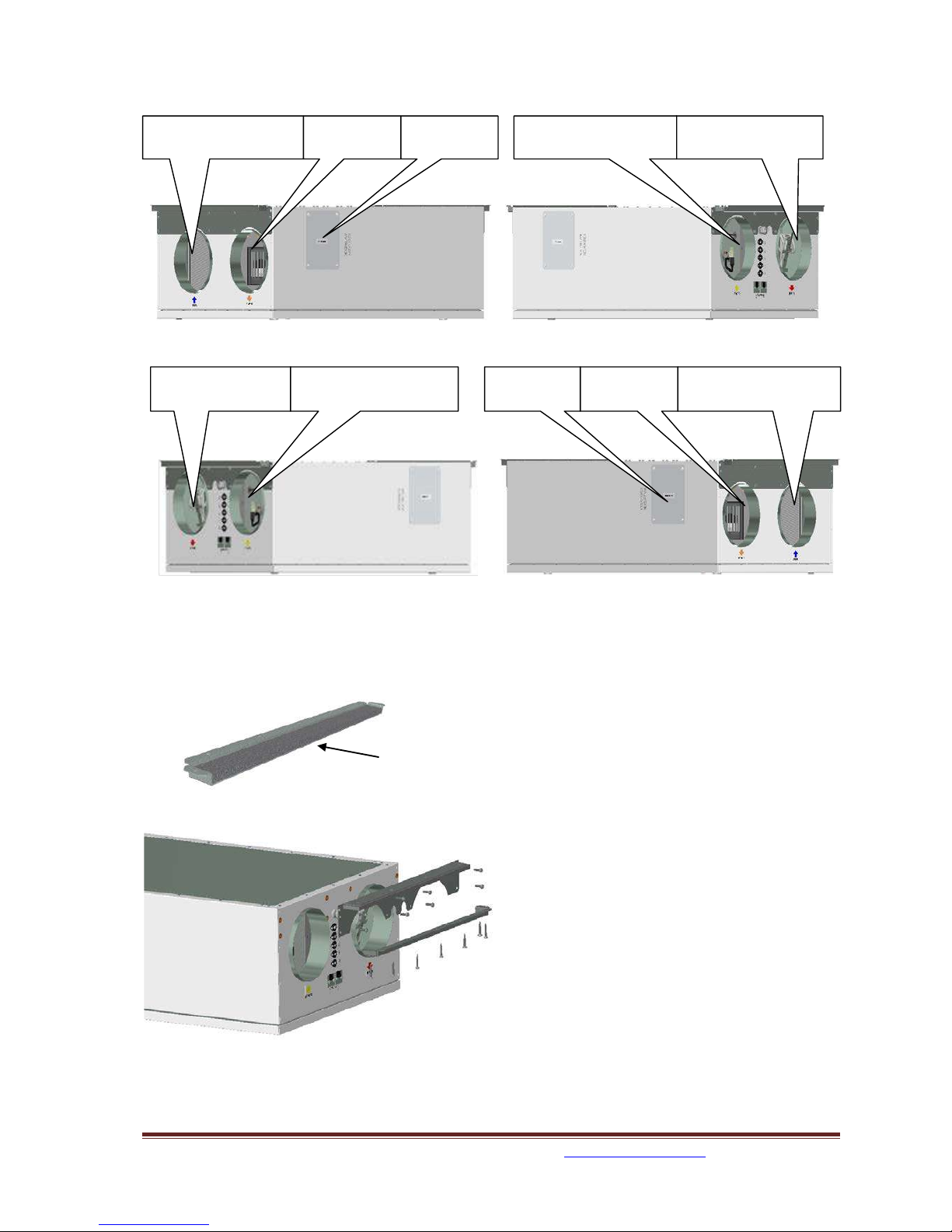

First, select how the unit should bemounted sothat the piping system should beaseasy aspossible

(Sketch shows AHU-300 HH)

(Sketch shows AHU-300 HV)

2.1 Brackets and vibration gasket

Make sure that the gasket is placed on both brackets.

Supply air to room

Exhaust air

Cooker hood

Extract air from room

Fresh air from outside

393870-2 Rev 0: 11.07.2018 BBV

We reserve the right to change technical data without notice. http://www.ensy.no Page 17

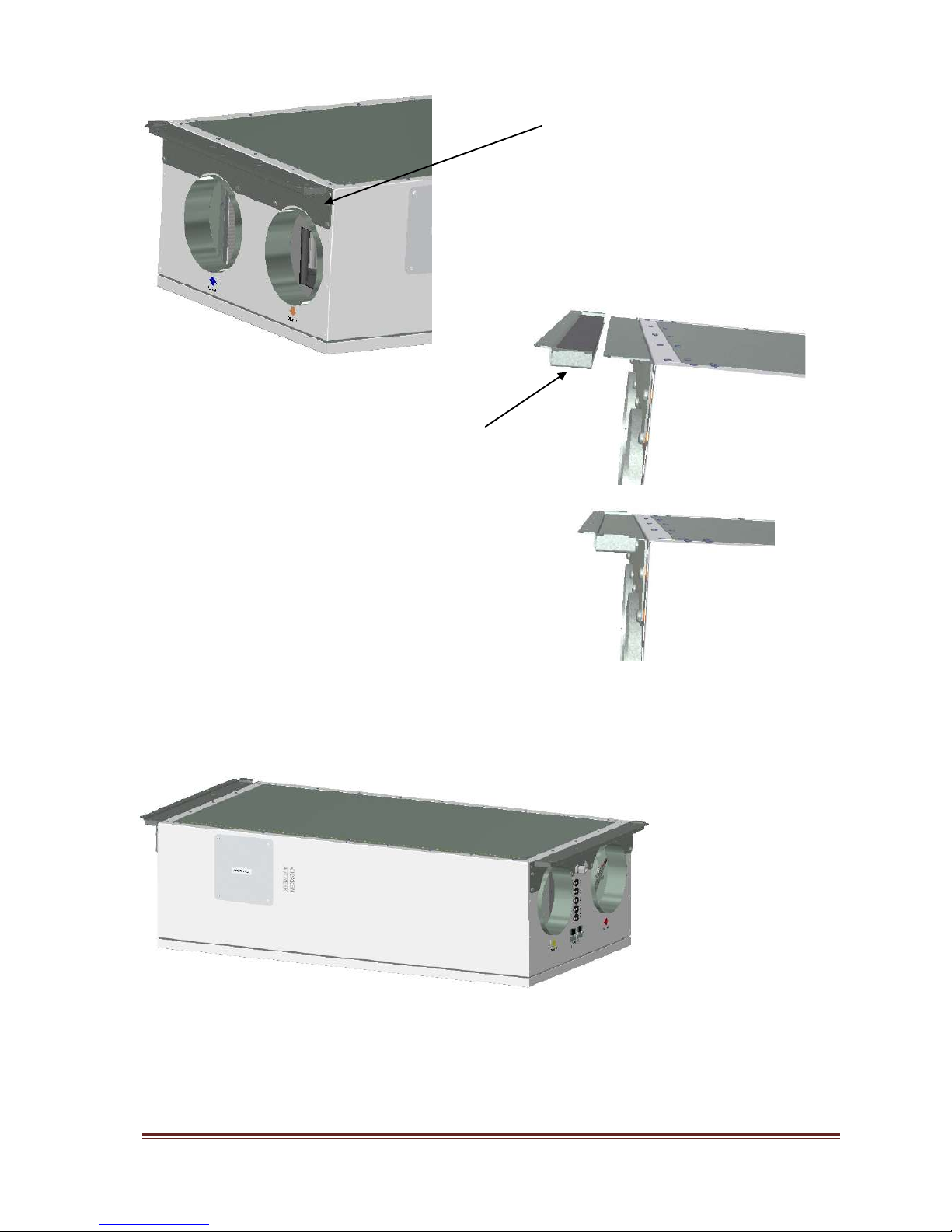

Suspension brackets screwed on the unit as shown on both

ends of the unit.

Use 8 pcs M5 x 16mm, supplied with the unit.

Attach one of the ceiling brackets in correct

position in the roof.

Use 7 pcs wood screws 5 x 40mm, supplied with

the unit, for each bracket

Then lift the unit and place the bracket on the

unit between the gasket and roof.

Then lift up the unit in correct position and make sure there are no contact between parts on unit and

building construction.

Then the second bracket

can be placed in the other

end of the unit.

393870-2 Rev 0: 11.07.2018 BBV

We reserve the right to change technical data without notice. http://www.ensy.no Page 18

2.2 Alternative placement on wall

The unit can also be placed on a wall. You then need the use of a separate wall bracket. This do not follow

the unit and has to be ordered separate. (Ensy Art no: 01008045-2)

To avoid vibration from the unit towards building constructions it here is important that there are placed

5 mm vibration damper on the back of the unit.

Two vibration gaskets screws for the extra

bracket follows the extra bracket.

One of the gaskets are placed in top of the

unit.

The other one you place approx. 60 mm

from the button of the unit so that id do not

will come in contact with the wall bracket.

Then first put those two brackets in each end of the unit as

shown on page 16.

Then the wall brackets, with 10 mm gasket, is screwed to the

wall where it is wanted.

Use 8 pcs wood screws 5 x 40mm.

Then you can lift the unit and place it on the wall bracket. Then you use the brackets that follows the unit.

One in each end. Use 7 pcs wood screws 5 x 40mm, supplied with the unit, for each bracket

Wall bracket

393870-2 Rev 0: 11.07.2018 BBV

We reserve the right to change technical data without notice. http://www.ensy.no Page 19

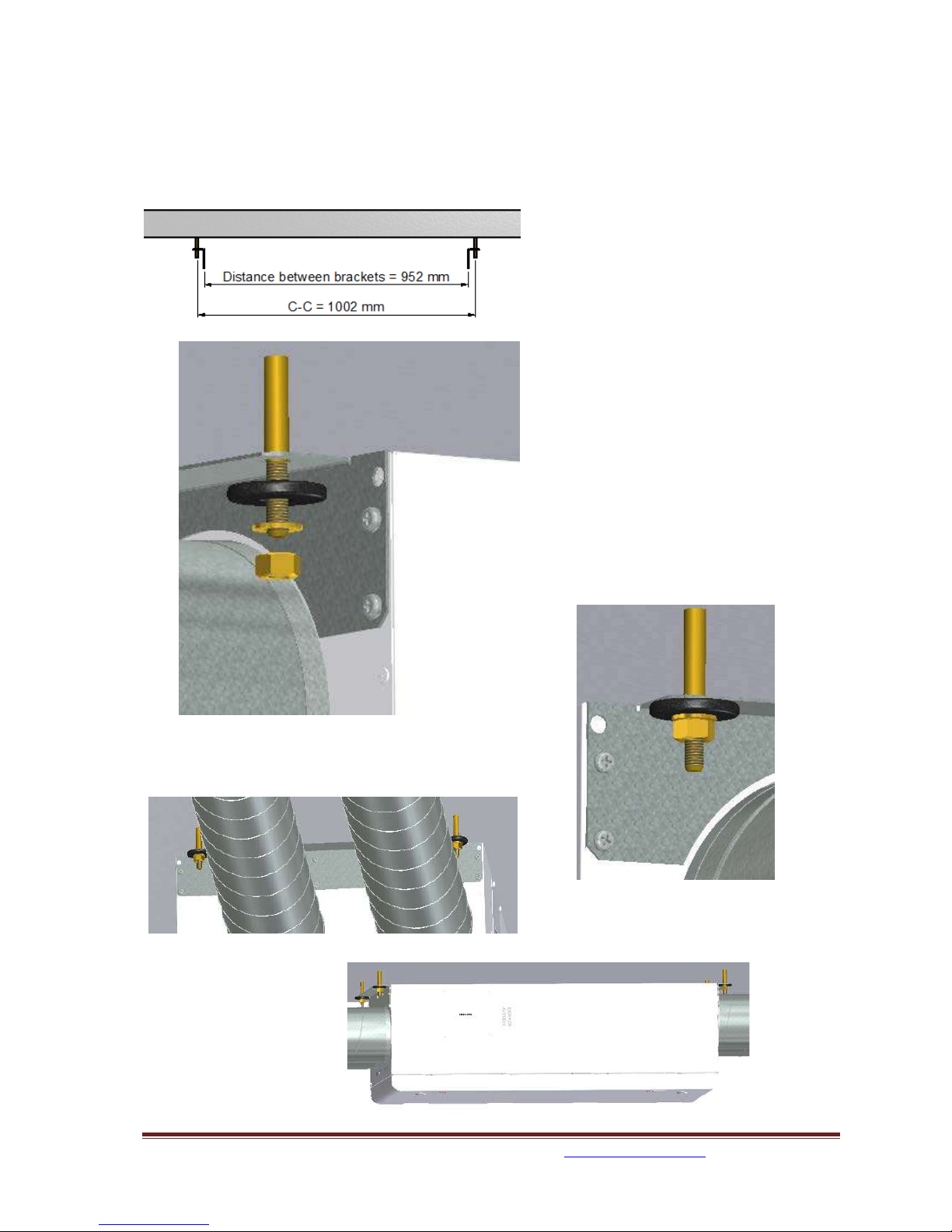

2.3 Placement under concrete ceiling

If the unit is to be mounted directly into concrete ceiling where there may be uneven or not level than it

may be easiest to use expansion bolts fastened into the ceiling. That way, you can adjust with the nuts so

that the unit is in level.

If so, then use the suspension brackets as jigs

for the bolts so that the distance between

brackets will be correct.

Use correct drill for use for the M10 mm

expansion bolts.

Make sure the bolt is turned so hard that it

can not loosen. The bolts are available in

different lengths so select someone suitable

for this purpose. Lift the unit into position.

Use a rubber cushioning, 4-6 mm thick,

between washers and mounting brackets.

Then adjust with the nuts so that the unit is in

level.

This manual suits for next models

1

Table of contents

Other Ensy Fan manuals