entegris NT 6300 User manual

NT™Proportional

Control Valve,

Model 6300

User Guide

P/N 1365 | REV. C 09/20

1Entegris, Inc. | User Guide

Table of Contents

Introduction ................................... 2

Principle of Operation .............. 2

Factory Configured ................... 2

General Considerations .............. 2

Line Pressure .............................. 2

Dimensions ................................. 3

Installation ..................................... 7

Provided Equipment ................. 7

Mounting Requirements .......... 7

Mechanical Installation ............... 8

Power Supply Requirements ... 8

Electrical Connections ............. 9

Wiring Diagram ........................ 11

Unit Operation ............................ 12

Performance ............................. 12

Operating Environment ......... 13

Operation and Use

Recommendations .................. 14

Performance ............................. 15

Operational Reliability ............ 15

Diagnostic Guide ........................ 16

Maintenance ................................ 17

Normal Operation ................... 17

Valve Homing Function ......... 17

Reference ..................................... 18

Physical Specifications ........... 18

Electrical Specifications ......... 18

Ordering Information ................ 19

Certifications ............................... 20

CE Certification ....................... 20

Repair and Warranty Service .... 20

Technical Support ...................... 20

Warranty ....................................... 21

Terms and Conditions ............... 21

For More Information ................ 21

NT PROPORTIONAL CONTROL VALVE, MODEL 6300

NT PROPORTIONAL CONTROL VALVE, MODEL 6300

2User Guide | Entegris, Inc.

Introduction

This manual is for use with a standard

NT™Proportional Control Valve,

Model 6300. These instruments have

been designed for use in high-purity

fluid applications within industries

that need tightly controlled chemical

processes such as the semiconduc-

tor, biomedical and solar cell

industries. The wetted parts are

constructed with PTFE, PFA or other

similar high-purity inert materials.

WARNING! Attempting to install or

operate standard NT Proportional

Control Valves without reviewing

the instructions contained in this

manual could result in personal

injury or equipment damage.

PRINCIPLE OF OPERATION

—

The user provides a setpoint signal

that corresponds to the desired valve

position. The range code of the

product specifies the maximum CV

of the unit. The setpoint signal will

proportionally control the unit’s CV

from 0 to maximum CV. The CVcurve

is linear.

For example, 6300-CV3-F04-B06-M

has a CVof 1.0 and has a setpoint of

0–5 VDC. A 2.5 VDC setpoint signal

will adjust the valve to a 0.5 CV. A 3.75

VDC setpoint signal will adjust the

valve to a 0.75 CV.

FACTORY CONFIGURED

—

The standard NT Proportional Control

Valve is pre-configured from the

factory for the CVrange chosen by

the user. The specified CVrange is

found on the label of the unit.

NOTE: The NT Proportional Control

Valve has been factory sealed. DO NOT

attempt to remove the cover of the unit.

Any attempt at removal of the unit cover

will void the warranty.

General

Considerations

LINE PRESSURE

—

The system line pressure (measured

at the inlet of the unit) can be

-100 to 415 kPa (-14.5 to 60 psig)

for CV1 – CV4 range. For CV7 – CV 8,

the system line pressure can be

-100 to 550 kPa (-14.5 to 80 psig).

NT PROPORTIONAL CONTROL VALVE, MODEL 6300

3Entegris, Inc. | User Guide

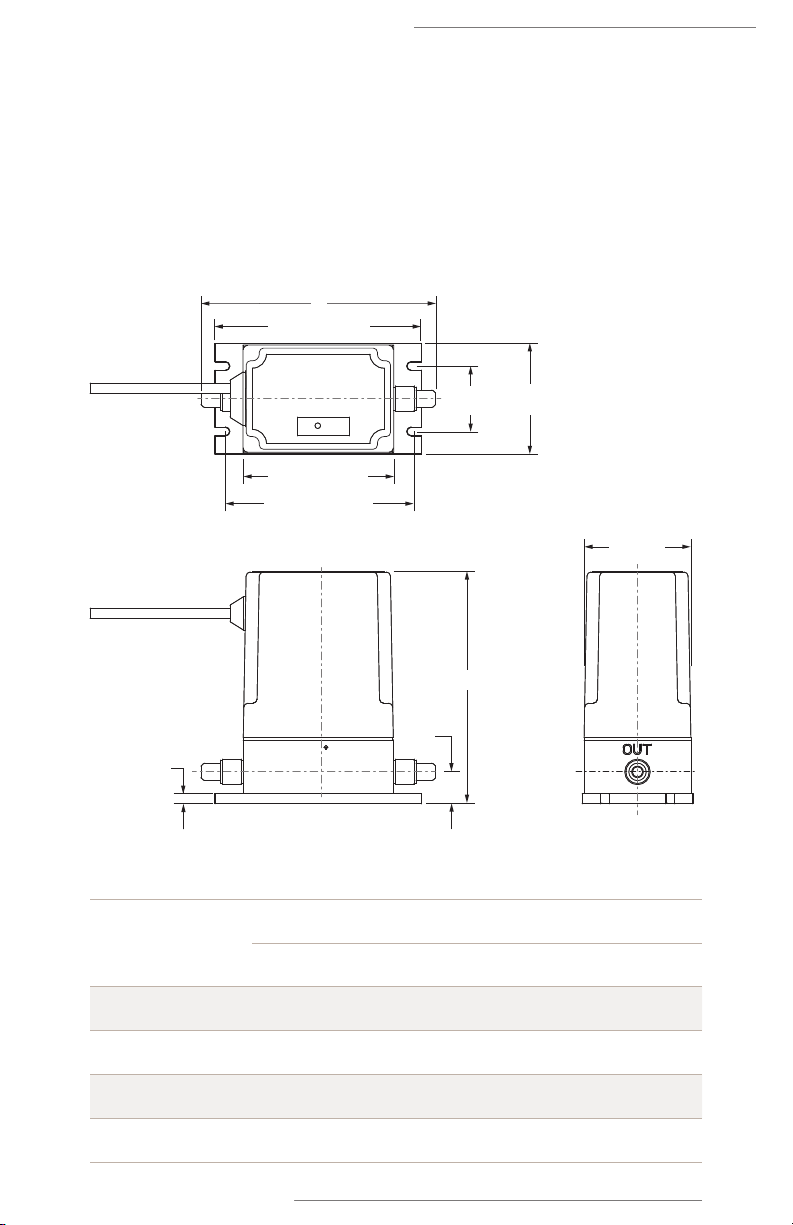

DIMENSIONS

—

The following fitting size and flow

range combinations are available:

Please consult the factory for

custom fitting size and flow range

combinations.

Figure 1. C

V1 – C

V4 ranges

Inlet/outlet

port connection

CV1 – CV4 ranges

Dimensions

ABC

⁄” Flaretek 142.2 mm (5.60”) 144.0 mm (5.67”) 19.5 mm (0.77”)

⁄” Flaretek 142.2 mm (5.60”) 144.0 mm (5.67”) 19.5 mm (0.77”)

⁄” Flaretek 144.5 mm (5.69”) 150.0 mm (5.91”) 21.6 mm (0.85”)

⁄” Flaretek 153.6 mm (6.05”) 153.7 mm (6.05”) 27.4 mm (1.07”)

127.0 mm (5.0”)

92.2 mm (3.63”)

114.0 mm (4.49”)

Side View

Top View

End View

6.4 mm

(0.25”)

C

A

65.5 mm

(2.58”)

68.1 mm

(2.68”)

40.1 mm

(1.58”)

B

Cv1 – Cv4 Ranges

NT PROPORTIONAL CONTROL VALVE, MODEL 6300

4User Guide | Entegris, Inc.

127.0 mm (5.0”)

92.2 mm (3.63”)

114.0 mm (4.49”)

Side View

Top View

End View

6.4 mm

(0.25”)

C

A

65.5 mm

(2.58”)

68.1 mm

(2.68”)

40.1 mm

(1.58”)

B

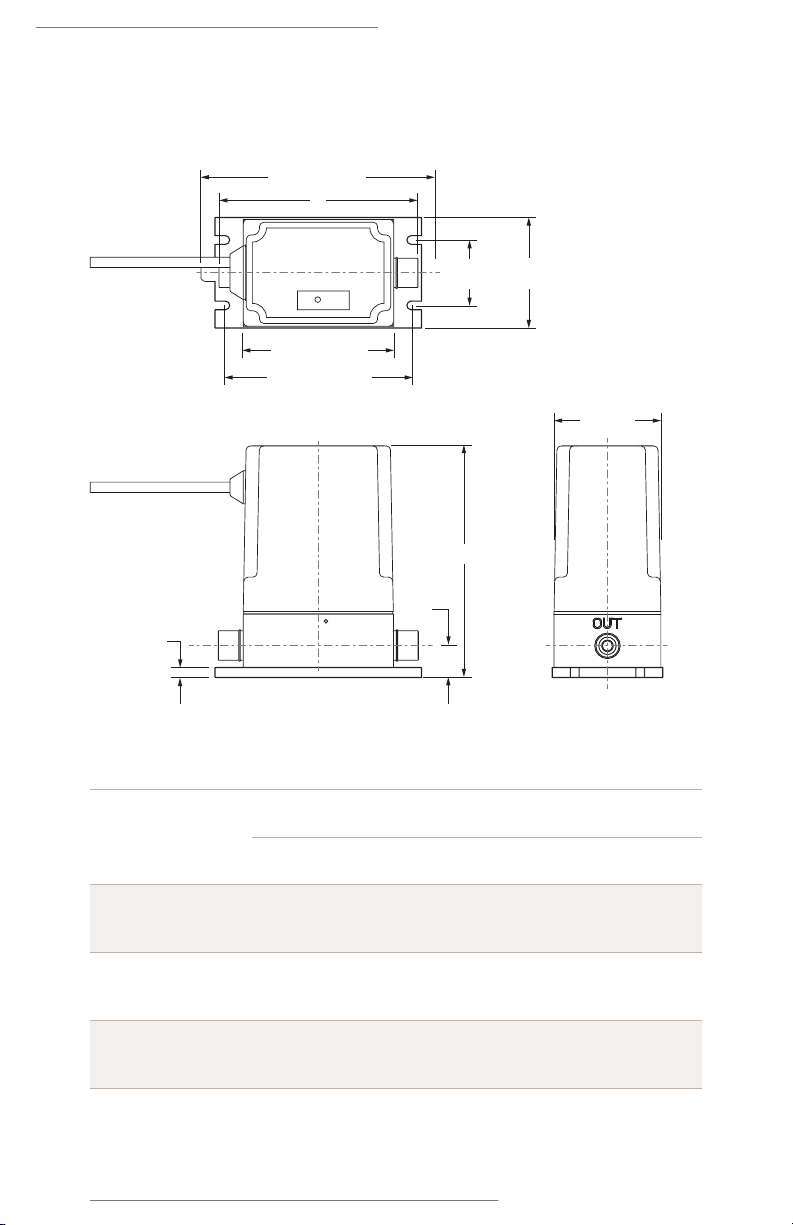

Figure 2. CV1 – CV4 ranges

Cv1 – Cv4 Ranges

Inlet/outlet

port connection

CV1 – CV4 ranges

Dimensions

ABC

⁄” Super 300

Type Pillar 142.2 mm (5.60”) 114.3 mm (4.50”) 19.5 mm (0.77”)

⁄” Super 300

Type Pillar 144.5 mm (5.69”) 127.0 mm (5.00”) 21.6 mm (0.85”)

⁄” Super 300

Type Pillar 153.6 mm (6.05”) 136.1 mm (5.36”) 27.4 mm (1.07”)

NT PROPORTIONAL CONTROL VALVE, MODEL 6300

5Entegris, Inc. | User Guide

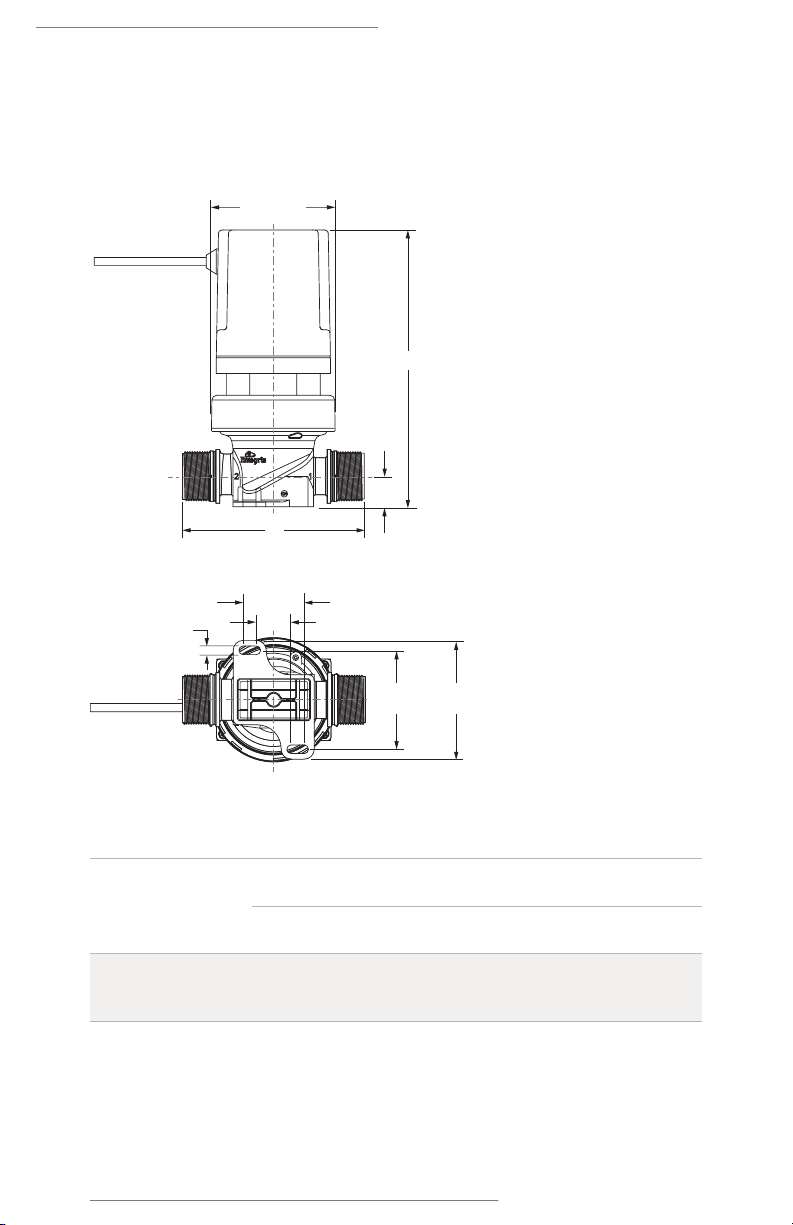

Figure 3. CV7 – CV8 ranges

Cv7 – Cv8 Ranges

(⁄” and 1” Flaretek Inlet/Outlet Type)

Ø99.8 mm

(3.93”)

Side View

Bottom View

A

C

B

49.0 mm

(1.93”)

6.9 mm

(0.27”)

27.9 mm

(1.10”)

79.2 mm

(3.12”)

95.3 mm

(3.75”)

Inlet/outlet

port connection

CV7 – CV8 ranges

Dimensions

ABC

⁄” Flaretek 223.4 mm (8.79”) 129.0 mm (5.08”) 24.4 mm (0.96”)

1” Flaretek 223.4 mm (8.79”) 133.6 mm (5.26”) 24.4 mm (0.96”)

NT PROPORTIONAL CONTROL VALVE, MODEL 6300

6User Guide | Entegris, Inc.

Figure 4. CV8 range

Cv8 Range

(1” Super 300 Type Pillar Inlet/Outlet Type)

Ø99.8 mm

(3.93”)

Side View

Bottom View

49.0 mm

(1.93”)

6.9 mm

(0.27”)

27.9 mm

(1.10”)

79.2 mm

(3.12”)

95.3 mm

(3.75”)

A

B

C

Inlet/outlet

port connection

CV8 range

Dimensions

ABC

1” Super 300

Type Pillar

225.7 mm (8.88”) 146.3 mm (5.76”) 26.7 mm (1.05”)

NT PROPORTIONAL CONTROL VALVE, MODEL 6300

7Entegris, Inc. | User Guide

Installation

PROVIDED EQUIPMENT

—

The product box contains the pro-

portional control valve. For units with

Flaretek connections, two nuts are

included. For units with Pillar connec-

tions, two nuts, two sleeves and two

gauge rings are included.

NOTE: This unit has been assembled

and double-bagged under cleanroom

conditions. To maintain purity, only

open in cleanroom environment.

MOUNTING REQUIREMENTS

—

The proportional control valve may

be mounted in any orientation.

Care should be taken when installing

the proportional control valve to

avoid fluid leaks. Do not use exces-

sive torque or subject the unit to

high heat during installation. The

unit and base bracket assembly must

be mounted to a solid surface to

ensure stability.

Verify the body and the electrical

cable are free from mechanical stress

from the surrounding equipment.

NOTE: The proportional control valve

requires mounting in the direction of

the fluid flow.

#10 (M4)

Pan head

#10 (M4)

Flat washer

Recommended Hardware:

Cv1 – 4

SAE #10 (metric M4)

Cv7 – 8

SAE ¼” (metric M6)

1⁄4”(M6)

Pan head

1⁄4”(M6)

Flat washer

NT PROPORTIONAL CONTROL VALVE, MODEL 6300

8User Guide | Entegris, Inc.

Mechanical

Installation

Prepare and Connect Fluid Lines

The standard NT proportional control

valve must be used with the proper

tubing size and fittings.

CAUTION: Do not tighten the nuts

on the fitting connection without

tubing in place. Tightening the

nuts without the tubing installed

may damage the unit’s

connections.

Flaretek Tube Fitting:

Flare each tube end prior to instal-

lation onto the valve fitting. For

detailed tube flaring instructions,

see “Flaretek tube fitting flare

and assembly procedures” at

www.entegrisfluidhandling.com

Super 300 Type Pillar Tube Fitting:

Prepare tube end prior to instal-

lation onto the valve fitting.

For detailed instructions,

see assembly procedures at

www.nipponpillar.com

CAUTION: Over-tightening of

the nuts with tubing in place will

result in damage to the fitting.

POWER SUPPLY REQUIREMENTS

—

The power supply range for the

proportional control valve is 24 VDC

±10%. The power supply must be

regulated and provide minimum

1.2 ampere (nominal) continuous

service for each proportional control

valve installed. The power supply

requirements must be met at the wire

connections or connector of the

proportional control valve, not only

at the power supply itself.

The power supply to the unit must

provide clean power and must be

used only to power similar measure-

ment-type devices. The power supply

must not be used to power other

inductive loads, such as motors,

relays, or solenoids. These devices

may produce electrical transients

that may aect unit performance.

An induced power spike, creating

an interruption in power greater

than 10 milliseconds in duration,

may cause the unit to reset. Loss of

power will not cause the loss of any

system parameters. Loss of power

may allow the valve to open due to

applied fluid pressure.

In addition to providing clean power,

the instrumentation signals and

power return lines must not be run

within the same conduit or cable

along with heavy current demands

from motors, charging capacitors

or other inductive loads. This may

cause a voltage change within the

instrumentation signal line, causing

erroneous valve operation.

Input Impedance of the

Voltage Setpoint

The input impedance of the voltage

setpoint is 37 kOhm.

Voltage Drop at the 4 – 20 mA

Setpoint Input

The 4–20 mA input will drop

4.6 V at 20 mA. Input impedance

is 230 ohms.

NT PROPORTIONAL CONTROL VALVE, MODEL 6300

9Entegris, Inc. | User Guide

Reverse Polarity Protection

The proportional control valve is

reverse polarity protected; connect-

ing 24 VDC power to any wire will not

harm the unit. To operate properly,

the polarity must be correct.

Over-voltage on any Wire (DC)

In the event of accidental application

of voltage greater than 24 VDC ±10%,

the proportional control valve will

withstand continuous 30 VDC on any

wire without compromising the unit.

Over-voltage on any Wire (AC)

The proportional control valve is not

designed to withstand the accidental

application of ⁄ VAC to any wire.

Application of AC voltage will damage

the unit.

Short Protection

The proportional control valve will

not be damaged or compromised in

any way if any combinations of wires

are shorted together.

Circuit Protection

Entegris recommends fusing

the input power line to the NT

Proportional Control Valve, Model

6300. Use a 2 Amp rated, time-lag

fuse for the proportional control

valve. Place the fusing on the input

power line to the unit at the equip-

ment electrical enclosure to ensure

that both the wiring to the unit and

the unit itself are protected from any

over-current condition. Best practice

is to locate the fuse away from the

typical liquid exposure or harmful

vapor areas. Locating the fuse within

the electrical enclosure shared by the

power supply enables accessibility for

troubleshooting or replacement.

ELECTRICAL CONNECTIONS

—

Pigtail Electrical Cable

Units specified with a pigtail electrical

connection are manufactured with a

permanently attached cable. Table 1

details the wire connections for the

proportional control valve with a

pigtail electrical cable.

Table 1. Wire connections –

pigtail cable

WIRE

COLOR

MARKER

NO. FUNCTION

Red 2+24 VDC

Black 8Ground

(+24 VDC common)

Violet 6Factory use only –

do not connect

White 7Factory use only –

do not connect

Tan 10 Setpoint, current,

4–20 mA

Gray 12 Setpoint, common

Pink 11 Setpoint, voltage,

0–10 or 0–5 VDC

Green 9Valve home input

Pigtail Cable

NT PROPORTIONAL CONTROL VALVE, MODEL 6300

10 User Guide | Entegris, Inc.

G-Series Electrical Connector

Units specified with a G-Series con-

nector use a Turck®brand, versafast

style, BSMK type, constructed of

polyurethane with a nylon coupling

nut. The connector is over-molded

onto an electrically shielded, PVC

jacketed cable. The pin contacts

for the electrical connection are

gold-plated for performance and

corrosion resistance. The connector

is physically “keyed,” making it easy

to connect to a receptacle. Press it

into a receptacle and turn the thread-

ed coupling nut to draw the connec-

tor and receptacle together until

finger tight. G-series connectors to

pigtail mating cables are available.

See the Ordering Information section

of this user guide.

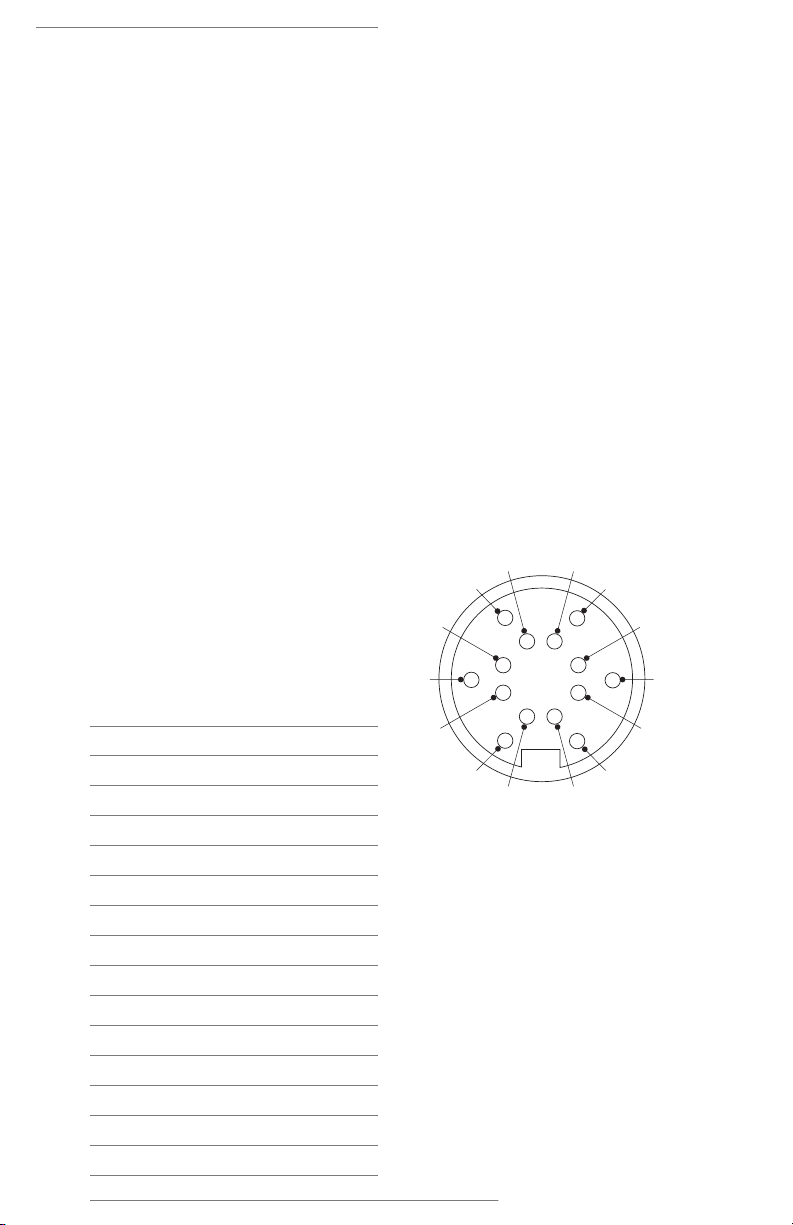

Table 2 and the following pin diagram

detail the wire connections for the

proportional control valve type with

G-series electrical connector.

Table 2. Wire connections –

g-series connector

PIN FUNCTION

R+24 VDC

EGround (+24 VDC common)

JValve home input

USetpoint, current, 4–20 mA

GSetpoint, voltage, 0–10 or 0–5 VDC

SSetpoint, common

OFactory use only – do not connect

PFactory use only – do not connect

MNo connect (NC)

L No connect (NC)

A No connect (NC)

NNo connect (NC)

C No connect (NC)

TNo connect (NC)

Mandatory Connections

Refer to the wire connections in Table

1, Table 2 and the appropriate Wiring

Diagram on page 11.

NOTE: The Valve home input +24 VDC

must be referenced to the same ground

as the main power source ground

2-Black/Pin E connection. See the

Maintenance section of this user guide

for valve homing instructions. Consult

factory with any questions about

electrical installation.

Unused Connections

The 3-Violet/Pin O and 4-White/Pin P

wires are for factory use only. Do not

connect to power supply or ground.

These wires must remain disconnected.

A

E

C

G

J

L

M

N

O

PR

T

U

S

Plug Orientation, Face View

NT PROPORTIONAL CONTROL VALVE, MODEL 6300

11Entegris, Inc. | User Guide

WIRING DIAGRAM

—

For 4–20 mA Setpoint

For Voltage Setpoints

08-Green/Pin J

01-Red/Pin R

(+)

(+)

02-Black/Pin E

06-Gray/Pin S

05-Tan/Pin U

Normally open switch

Power supply

For valve

homing

24 VDC

±10%

Setpoint control signal

4–20 mA

(—)

(—)

Electrical cable

08-Green/Pin J

01-Red/Pin R

02-Black/Pin E

06-Gray/Pin S

07-Pink/Pin G

Electrical cable

Normally open switch

Power supply

For valve

homing

24 VDC

±10%

Setpoint control signal

0–5 VDC

or

0–10 VDC

(+)

(—)

(+)

(—)

NT PROPORTIONAL CONTROL VALVE, MODEL 6300

12 User Guide | Entegris, Inc.

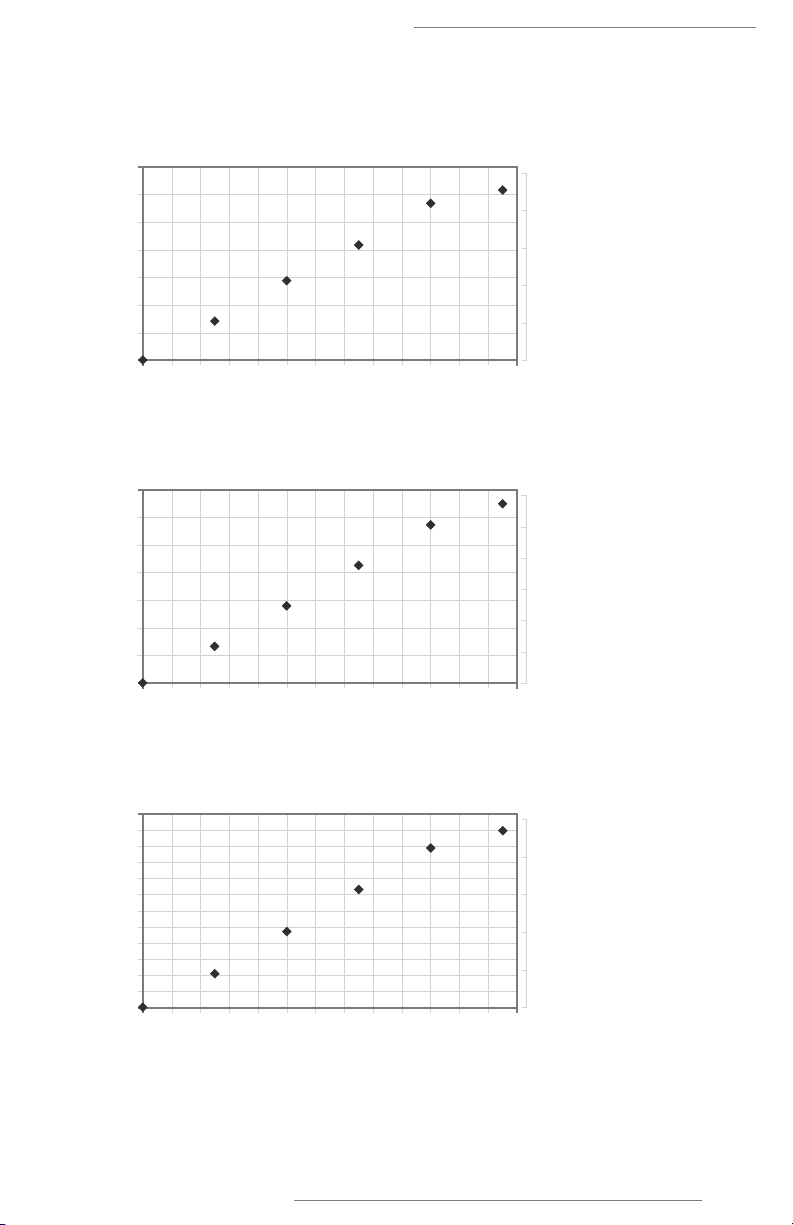

Cv2 F03 (⁄”): Max Cv= 0.68

Cv3 F04/W04 (⁄”): Max Cv= 1.0

Calculated C

v

Cv

Kv

Analog Setpoint Percentage

10 20 30 40 50 60 70 80 90 100 110 120 130

0

0.20

0.18

0.16

0.14

0.12

0.10

0.08

0.06

0.04

0.02

0

0.16

0.14

0.12

0.10

0.08

0.06

0.04

0.02

0

Calculated Cv

Cv

Kv

Analog Setpoint Percentage

10 20 30 40 50 60 70 80 90 100 110 120 130

0

1.2

1.0

0.8

0.6

0.4

0.2

0

1.0

0.8

0.6

0.4

0.2

0

Calculated C

v

Cv

Kv

Analog Setpoint Percentage

10 20 30 40 50 60 70 80 90 100 110 120 130

0

0.9

0.8

0.7

0.6

0.5

0.4

0.3

0.2

0.1

0

0.7

0.6

0.5

0.4

0.3

0.2

0.1

0

Unit Operation

PERFORMANCE*

—

Cv1 F02/ W02 (⁄”): Max Cv= 0.16

NT PROPORTIONAL CONTROL VALVE, MODEL 6300

13Entegris, Inc. | User Guide

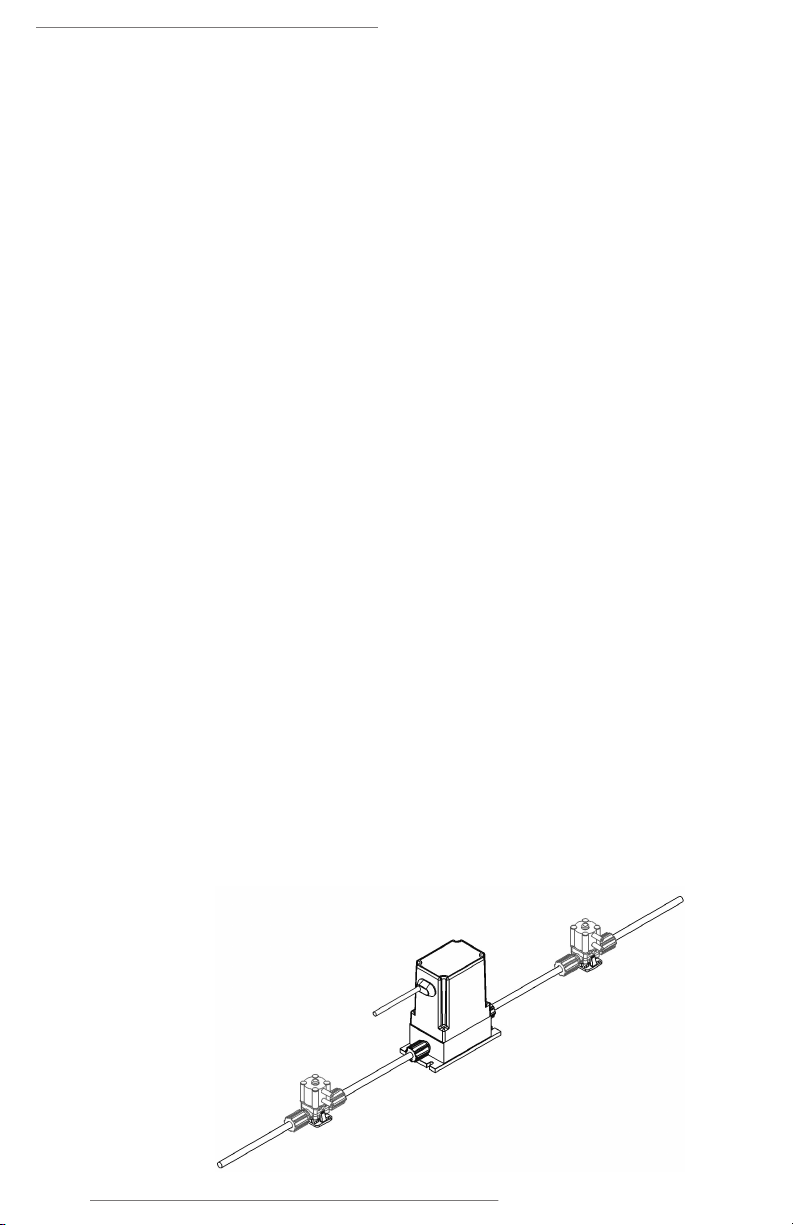

Cv4 F06/W06 (⁄”): Max Cv= 2.8

Cv7 F06 Max Cv= 5.6

Cv8 F08/W08 Max Cv= 10.0

*Graph data is representative and each valve needs to be characterized

with the application to optimize performance.

Calculated Cv

C

v

Kv

12.0

11.0

10.0

9.0

8.0

7.0

6.0

5.0

4.0

3.0

2.0

1.0

0

10.0

8.0

6.0

4.0

2.0

0

Analog Setpoint Percentage

10 20 30 40 50 60 70 80 90 100 110 120 130

0

Calculated Cv

C

v

Kv

Analog Setpoint Percentage

10 20 30 40 50 60 70 80 90 100 110 120 130

0

7.0

6.0

5.0

4.0

3.0

2.0

1.0

0

6.0

5.0

4.0

3.0

2.0

1.0

0

Calculated C

v

C

v

Kv

Analog Setpoint Percentage

10 20 30 40 50 60 70 80 90 100 110 120 130

0

3.5

3.0

2.5

2.0

1.5

1.0

0.5

0

2.5

2.0

1.5

1.0

0.5

0

NT PROPORTIONAL CONTROL VALVE, MODEL 6300

14 User Guide | Entegris, Inc.

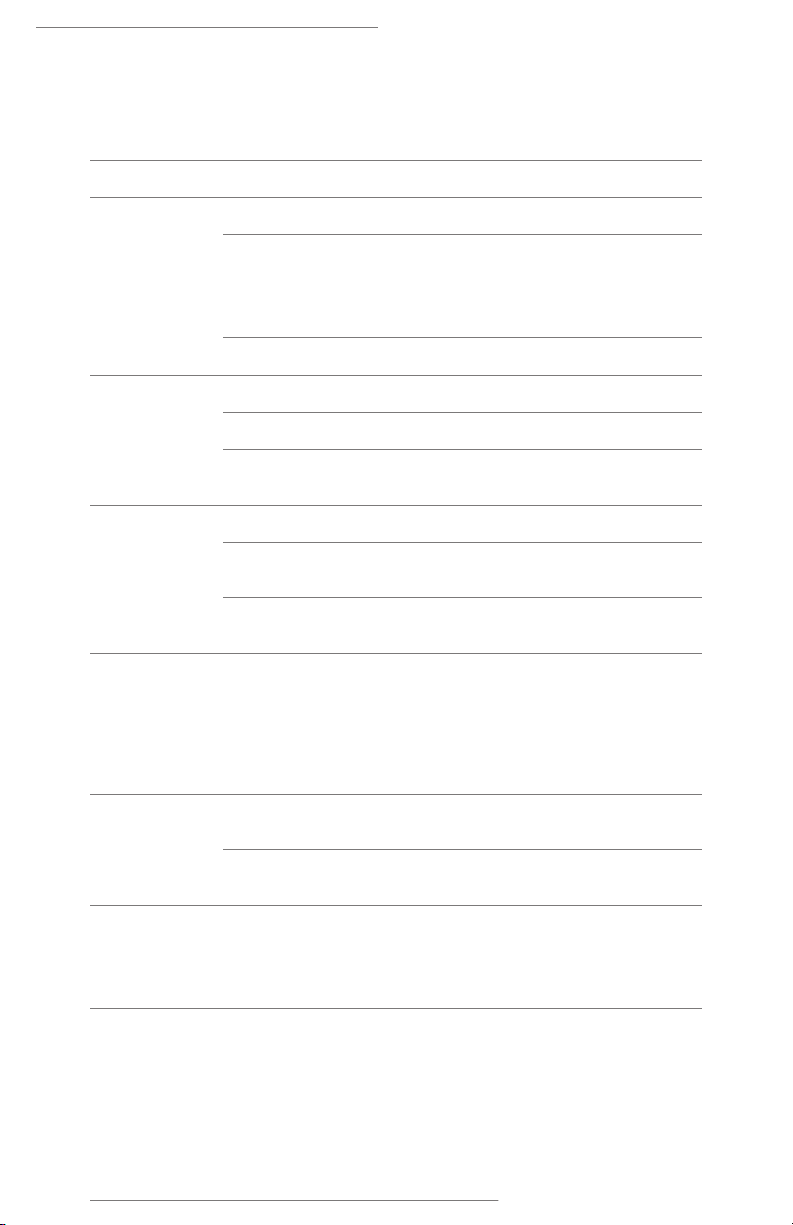

Figure 5. Installation and operation example

with two on/off valves

OPERATING ENVIRONMENT

—

Storage Temperature Range

The proportional control valve can

withstand storage temperatures

between -40° to 65°C (-40° to 149°F)

with no permanent eect on the

performance of the device.

Operating Ambient

Temperature Range

The proportional control valve is

designed to operate in ambient

temperature, cleanroom environ-

ments. Units are specified to oper-

ate at temperatures of 10° to 65°C

(50° to 149°F). For operation above

65°C (149°F), contact the factory.

Operating Process

Temperature Range

Units indicated have a range of

acceptable process temperatures

of 10° to 65°C (50° to 149°F). For

operation above 65°C (149°F),

contact the factory.

Line Pressure

The system line pressure (measured

at the inlet of the unit) can be

-100 to 415 kPa (-14.5 to 60 psig)

for CV1 – CV4 range. For CV7 – CV8

range, the system line pressure can

be -100 to 550 kPa (-14.5 to 80 psig).

Unit Enclosure

The standard NT Proportional Control

Valve cover is factory sealed and

should not be tampered with or

opened. Spray-down or temporary

immersion will not compromise the

performance of the unit.

NOTE: Any attempt to remove, tamper

with or open the proportional control

valve cover will void the warranty.

OPERATION AND USE

RECOMMENDATIONS

—

NOTE: Unit is shipped in an open state.

System Valving Considerations

The NT Proportional Control Valve,

Model 6300 can be installed with

upstream and/or downstream on/o

valves. However, some precautions

should be taken to ensure longevity

and proper operation of the propor-

tional control valve.

The proportional control valve will

close under two conditions:

1. Zero value setpoint

2. Valve Homing signal

command activated

NT PROPORTIONAL CONTROL VALVE, MODEL 6300

15Entegris, Inc. | User Guide

If the proportional control valve closes

while upstream or downstream valves

are closed, this may create a high level

pressure condition in the fluid tubing

due to compressed liquid. This high

pressure condition may lead to

inaccurate homing of the device

(indicated by temporary port-to-port

leaking), a small amount of media

escaping via the weephole, and/or

damage to the device.

To address this issue, one possible

solution is to keep the on/o valves

upstream and downstream of the

proportional control valve open at

all times. If this is not possible, the

proportional control valve should be

closed first, allowing adequate time

before either the upstream or

downstream valves are closed.

Valve Under No-power Condition

The proportional control valve does

not rely on a spring to close. The

motor movement is electrical. Loss

of electrical power will suspend the

valve movement. For example, if the

valve was partially open during loss

of power, the valve will remain par-

tially open. Normal operation will

resume when power is reapplied.

In an unpowered state, the valve

could be forced open with excessive

line pressure.

PERFORMANCE

—

Response Time

Response time is defined as the length

of time required for the proportional

control valve to complete valve move-

ment to match a new setpoint signal.

The maximum response time for

CV1 – 4 is <2 seconds from 5 – 95%

full scale. The maximum response

time for CV7–8, is <4 seconds from

5 – 95% full scale.

The proportional control valve will

accept setpoint changes within 50

milliseconds of receiving the new

setpoint value.

When power is first applied to the

unit (for example, during a startup

sequence), the unit will reach the

correct valve position within ten

seconds.

Temperature Increase at

Unit Enclosure

You may notice a slight temperature

increase of the unit cover while in an

ambient environment after warm-up,

when idling or while controlling flow.

This is normal.

OPERATIONAL RELIABILITY

—

Redundant Process Seals

All internal process wetted seals are

redundant, i.e., there is a secondary

seal that prevents process fluid from

reaching the interior of the device in

the case of a primary seal failure.

Weep holes are provided from the

secondary containment regions.

Drop and Topple

If the unit topples over from a

45-degree angle onto a bench

top, the performance will not be

compromised and the unit will

not be externally damaged.

Cable Pull

The cable will withstand a static pull

test of 9.1 kg (20 lbs.) straight and

4.5 kg (10 lbs.) at 90 degrees without

being damaged.

NT PROPORTIONAL CONTROL VALVE, MODEL 6300

16 User Guide | Entegris, Inc.

Diagnostic Guide

SYMPTOM POSSIBLE CAUSES SUGGESTIONS

1. Unit is

unresponsive

No power Check power connections or fusing.

No setpoint signal Check setpoint wiring for correct setup.

Verify setpoint code of the proportional

control valve matches your wiring setup

and applied setpoint.

Rezero line active Clear rezero line.

2. Unit is unable

to meter flow

Unit is undersized Use a larger CVunit.

Unit is oversized Use a smaller CVunit.

Unstable setpoint signal Check wiring and setpoint electrical

stability.

3. Unit operation

is unstable

Unit installed backwards Verify inlet/outlet connection.

Unstable pressure Check applied pressure stability and/or

stability of downstream backpressure.

Unstable setpoint signal Check wiring and setpoint

electrical stability.

4. Unit causes

high pressure

when closing

External valving Verify the unit does not close against a

fixed volume, trapped between valves

(the proportional control valve can be

one of the two valves).

Stepper motor valve closes and creates

entrapped fluid.

5. Unit does

not close

External valving —

entrapping a fixed volume

Close unit before closing external valve.

See page 14 for more information.

Foreign object in valve Clear obstruction with back flush/

forward flush procedure.

6. Unit leaks

fluid out of

weep hole

Overpressure on unit Intermittent — single overpressure

event. Monitor for future instances.

Continuous — diaphragm rupture.

Call factory for more information.

NT PROPORTIONAL CONTROL VALVE, MODEL 6300

17Entegris, Inc. | User Guide

Maintenance

NORMAL OPERATION

—

During normal operation, the

standard NT Proportional Control

Valve, Model 6300 requires no

maintenance, other than a periodic

valve homing of the unit. In applica-

tions with greater movement duty

cycle, more frequent valve homing

is recommended.

At the time of unit power-up, and

any subsequent power cycle, the

proportional control valve will

perform a valve homing procedure

before becoming active.

VALVE HOMING FUNCTION

—

NOTE: The following procedure

must be followed precisely to ensure

proportional control valve homing.

1. The proportional control valve

homing function requires the

use of the same 24 VDC ±10%

power source that is used to

power the unit.

2. Apply 24 VDC ±10% to the

8-Green/-Pin J wire to initiate

valve homing routine, for a

mini-mum of 1 second. The

24 VDC for valve homing must

use the same ground as the

ground 2-Black/Pin E wire. Only

apply 24 VDC to this 8-Green/-

Pin J wire, long enough to

re-home the valve. The valve

homing will be complete within

5 seconds.

NOTE: The valve homing function will

remain active and at home position as

long as 24 VDC is applied to the valve

home input wire.

In most applications, the valve

homing procedure may be auto-

mated using switches, a PLC or

other logic proportional control

valve devices.

NT PROPORTIONAL CONTROL VALVE, MODEL 6300

18 User Guide | Entegris, Inc.

Reference

PHYSICAL SPECIFICATIONS

—

Materials of

construction

Wetted parts Body and diaphragms PTFE or PFA

Nonwetted parts Polypropylene, Viton®, PVDF

Response time CV1 – CV4<2 seconds from 5 – 95% full scale

CV7 – CV8<4 seconds from 5 – 95% full scale

Pressure range* -14.5 to 60 psig

(CV1 – CV4)

-14.5 to 80 psig

(CV7 – CV8)

Over pressure limit 100 psig

Process temperature** 10° to 65°C (50° to 149°F)

Setpoint input signal 4–20 mA, 0–10 VDC, 0–5 VDC; separate homing line

also included

Enclosure NEMA 5/IP54

Connection type*** Flaretek tube fitting and Pillar Super 300 tube fitting

Approvals

Note: Preliminary specifications and features subject to change.

* Please consult the factory for pressure ranges from 60 to 80 psig.

** Please consult the factory for temperatures from 65° to 80°C (149° to 176°F).

*** For PrimeLock®connections and other options not listed, please contact Entegris.

ELECTRICAL SPECIFICATIONS

—

Input voltage 24 VDC ±10%, regulated

Input current 1.0 A nominal, 1.2 A peak

Impedance of setpoint input (voltage) 37 kOhm

Voltage drop, current setpoint input <4.6 volts @ 20 mA @ 230 ohm

Electrical connection FEP or PVC-jacketed cable

NT PROPORTIONAL CONTROL VALVE, MODEL 6300

19Entegris, Inc. | User Guide

Ordering Information

The model number can be established using the following chart.

NT Proportional Control Valve

6300 Base model

Cv

CV1 0.16 maximum CV(only F02/W02)

CV2 0.68 maximum CV(only F03)

CV3 1.00 maximum CV(only F04/W04)

CV4 2.80 maximum CV(only F06/W06)

CV75.6 maximum CV(available in F06)

CV810.0 maximum CV(available in F08 or W08)

Inlet/OutletType

F02 ⁄”Flaretektubefitting

F03 ⁄”Flaretektubefitting

F04 ⁄”Flaretektubefitting

F06 ⁄”Flaretektubefitting

F08 1” Flaretek tube fitting

W02 ⁄” Super 300 Type Pillar tube fitting

W04 ⁄”Super 300 Type Pillar tube fitting

W06 ⁄”Super 300 Type Pillar tube fitting

W08 1” Super 300 Type Pillar tube fitting

ElectricalConnectorType

B12 FEP-jacketed12’ pigtailelectricalcable

G01 PVC-jacketed 1’ electrical cable terminated with 14-pin Turck connector*

Setpoint Input Signal

K 4–20mA

L 0–10VDC

M 0–5VDC

*14-pin mating cable required for installation

Example model number: 6300-CV1-F02-B12-K

Table of contents

Other entegris Control Unit manuals