Contents

1 General information .................................................. 4

1.1 Information .......................................................... 4

1.2 Symbols used ...................................................... 4

1.3 Definition of terms .............................................. 4

1.4 Warning notes ..................................................... 4

2 Safety information .................................................... 5

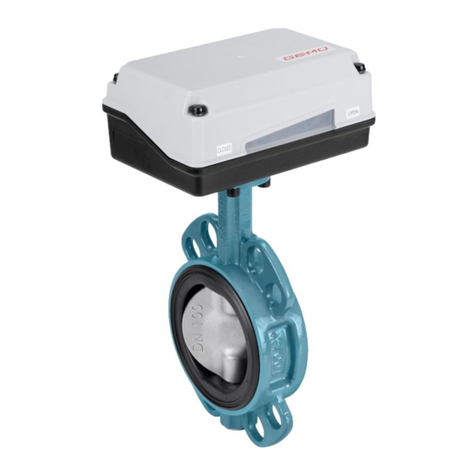

3 Product description ................................................... 5

3.1 Construction ........................................................ 5

3.3 Function ............................................................... 6

4 GEMÜ CONEXO ......................................................... 6

5 Correct use ............................................................... 6

6 Order data ................................................................. 7

7 Technical data .......................................................... 9

8 Dimensions ............................................................... 13

9 Manufacturer's information ....................................... 17

9.1 Delivery ................................................................ 17

9.2 Packaging ............................................................ 17

9.3 Transport ............................................................. 17

9.4 Storage ................................................................. 17

10 Installation in piping .................................................. 17

10.1 Preparing for installation .................................... 17

10.2 Installation for flanged connection .................... 18

11 Electrical connection ................................................. 20

11.1 Connection and wiring diagram – actuator ver-

sion 1015, 2015, 3035 ......................................... 20

11.2 Connection and wiring diagram – actuator ver-

sion 2070, 4100, 4200 ......................................... 22

12 Limit switches ........................................................... 27

12.1 Setting the limit switch for 1015, 2015 and

3035 ..................................................................... 27

12.2 Setting the limit switch for 2070, 4100, 4200 .... 28

13 Commissioning ......................................................... 28

14 Operation .................................................................. 29

14.1 Normal operation ................................................ 29

14.2 Optical position indicator .................................... 29

14.3 Manual override ................................................... 29

15 Troubleshooting ........................................................ 31

16 Inspection/maintenance ............................................ 32

16.1 Spare parts .......................................................... 32

16.2 General information regarding actuator re-

placement ............................................................ 33

16.3 Replacing the actuator ........................................ 33

16.4 Replacing the seals ............................................. 34

17 Removal from piping ................................................. 36

18 Disposal .................................................................... 36

19 Returns ..................................................................... 36

20 Declaration of Incorporation according to 2006/42/

EC (Machinery Directive) ........................................... 37

21 Declaration of conformity according to 2014/30/EU

(EMC Directive) ......................................................... 38

22 EU Declaration of conformity 2-way metal ball valve . 39

GEMÜ 768www.gemu-group.com 3 / 40