Bray 950 Series User manual

SERIES 950

UNIDIRECTIONAL KNIFE GATE VALVES

Installation, Operation and Maintenance Manual

BRAY.COM THE HIGH PERFORMANCE COMPANY

SERIES 950 UNIDIRECTIONAL KNIFE GATE VALVE

Installation, Operation and Maintenance Manual

© 2020 BRAY INTERNATIONAL. ALL RIGHTS RESERVED. BRAY.COM The Information contained

herein shall not be copied, transferred, conveyed, or displayed in any manner that would violate its

proprietary nature without the express written permission of Bray International, Inc.

2 of 22

TABLE OF CONTENTS

1.0 Definition of Terms 3

2.0 Hazard Free Use 3

3.0 Introduction 4

4.0 Parts Identification 5

5.0 Valve Identification 6

6.0 Lifting The Valve 7

7.0 Storage 8

8.0 Installation 11

9.0 Lockout 14

10.0 Maintenance 15

11.0 Packing Replacement | Manual Valves 15

12.0 Packing Replacement | Cylinder Operated Valves 16

13.0 Seat Replacement 18

14.0 Retro Fitting Cylinder Actuator 19

15.0 Troubleshooting 20

16.0 Return Merchandise Authorization 21

SERIES 950 UNIDIRECTIONAL KNIFE GATE VALVE

Installation, Operation and Maintenance Manual

© 2020 BRAY INTERNATIONAL. ALL RIGHTS RESERVED. BRAY.COM The Information contained

herein shall not be copied, transferred, conveyed, or displayed in any manner that would violate its

proprietary nature without the express written permission of Bray International, Inc.

3 of 22

0.00 Identifies and explains sequential procedure to be performed.

NOTE: Provides important information related to a procedure.

CAUTION

Indicates a potentially hazardous situation which, if not avoided, may

result in injury.

NOTICE

Used without the safety alert symbol, indicates a potential situation

which, if not avoided, may result in an undesirable result or state,

including property damage.

WARNING

Indicates a potentially hazardous situation which, if not avoided, could

result in death or injury.

1.0 DEFINITION OF TERMS

READ AND FOLLOW THESE INSTRUCTIONS CAREFULLY.

SAVE THIS MANUAL FOR LATER USE.

2.0 HAZARD-FREE USE

2.1 This device left the factory in proper condition to be safely

installed and operated in a hazard-free manner. The notes and

warnings in this document must be observed by the user if this

safe condition is to be maintained and hazard-free operation of the

device assured.

2.2 Take all necessary precautions to prevent damage to the valve

due to rough handling, impact, or improper storage. Do not use

abrasive compounds to clean the valve, or scrape metal surfaces

with any objects

2.3 The control systems in which the valve is installed must have

proper safeguards to prevent injury to personnel, or damage to

equipment, should failure of system components occur.

SERIES 950 UNIDIRECTIONAL KNIFE GATE VALVE

Installation, Operation and Maintenance Manual

© 2020 BRAY INTERNATIONAL. ALL RIGHTS RESERVED. BRAY.COM The Information contained

herein shall not be copied, transferred, conveyed, or displayed in any manner that would violate its

proprietary nature without the express written permission of Bray International, Inc.

4 of 22

2.4 QUALIFIED PERSONNEL

2.4.1 A qualified person in terms of this document is one who is familiar

with the installation, commissioning, and operation of the device

and who has appropriate qualifications, such as:

2.4.1.1 Is trained in the operation and maintenance of electrical equipment

and systems in accordance with established safety practices.

2.4.1.2 Is trained or authorized to energize, de-energize, ground, tag, and

lock electrical circuits and equipment in accordance with established

safety practices.

2.4.1.3 Is trained in the proper use and care of personal protective

equipment (PPE) in accordance with established safety practices.

2.4.1.4 In cases where the device is installed in a potentially explosive

(hazardous) location – is trained in the commissioning, operation,

and maintenance of equipment in hazardous locations.

2.5 Additional information about Series 950 Unidirectional Knife Gate

Valve — including application data, engineering specifications, and

actuator selection — is available from your local Bray distributor or

sales representative.

3.0 INTRODUCTION

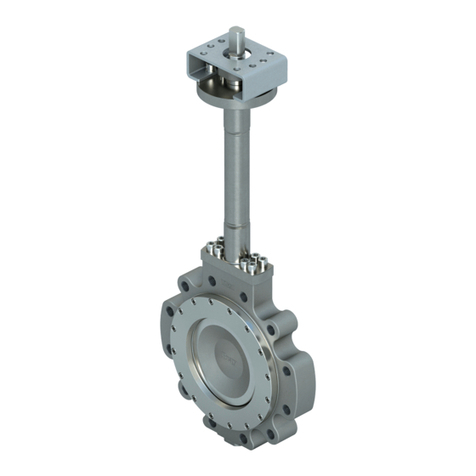

3.1 The Bray Series 950’s single piece, cast body design offers

rugged performance in applications ranging from general

purpose to severe media handling in an economical semi-lug

body. Available with integral metal or replaceable soft seat, the

Bray Series 950 knife gate valve is easily automated for on/off

applications.

SERIES 950 UNIDIRECTIONAL KNIFE GATE VALVE

Installation, Operation and Maintenance Manual

© 2020 BRAY INTERNATIONAL. ALL RIGHTS RESERVED. BRAY.COM The Information contained

herein shall not be copied, transferred, conveyed, or displayed in any manner that would violate its

proprietary nature without the express written permission of Bray International, Inc.

5 of 22

Item Description

1 Body

2Gate

3 Packing Set

4 Gland

5 Gland Bolt

6 Gland Washer

7 Gland Nut

8 Side Plate

9 Mounting Bolt (Top)

10 Mounting Nut (Top)

11 Mounting Nut (Bottom)

12 Spring Washer

13 Clevis

14 Stem

15 Clevis Bolt

16 Clevis Nut

17 Collar

18 Yoke Sleeve

19 Grease Nipple

20 Thrust Washer

21 Hand Wheel

22 Socket Screw

23 Seat1

4.0 PARTS IDENTIFICATION

Figure 1: Series 950 Exploded View

NOTE

1 Optional replaceable resilient seat.

22

21

19

18

14

16

15

2

8

1

5

10

11

12

9

23

4

3

6

7

13

17

SERIES 950 UNIDIRECTIONAL KNIFE GATE VALVE

Installation, Operation and Maintenance Manual

© 2020 BRAY INTERNATIONAL. ALL RIGHTS RESERVED. BRAY.COM The Information contained

herein shall not be copied, transferred, conveyed, or displayed in any manner that would violate its

proprietary nature without the express written permission of Bray International, Inc.

6 of 22

5.0 VALVE IDENTIFICATION

5.1 Valve size and brief material specification of body (markings such

as “SS” or “DI”) are marked on the valve body.

5.2 A stainless steel nameplate (below) affixed to the yoke of the

valve contains most of the relevant information on the valve that

includes a unique serial number of the valve.

NOTE: Please reference the valves serial number when inquiring

for spare parts.

5.3 All Series 950 Knife Gate valves are provided with an identification

tag (Figure 2) printed with the following data:

>SERIAL NUMBER: Unique serial number of valve.

>SIZE: Valve size e.g. 6 in/150 mm.

>MODEL: Series number of the valve.

>FLG. DRILL: Flange Drill e.g. ASME B16.5 CL150.

>BODY: Material grade of body e.g. CF8 (304) etc.

>GATE: Material grade of gate e.g. 304 Stainless Steel.

>SEAT: Material of seat e.g. Buna-N.

>PACKING: Material of packing e.g. PTFE w/EPDM Quad Seal.

>CWP: Maximum permissible pressure in psi/bar(g)

>MAX TEMP: Maximum temperature in °F/°C

SERIAL NUMBER

SEAT PACKING CWP MAX TEMP

MODEL FLG. DRILL BODY GATE

SIZE

Figure 2: Identification tag.

NOTICE

Ensure the box is not damaged externally. Remove the valve from the

packaging and check for any damage to the valve and its components

during transit. Report any damage or discrepancies immediately.

SERIES 950 UNIDIRECTIONAL KNIFE GATE VALVE

Installation, Operation and Maintenance Manual

© 2020 BRAY INTERNATIONAL. ALL RIGHTS RESERVED. BRAY.COM The Information contained

herein shall not be copied, transferred, conveyed, or displayed in any manner that would violate its

proprietary nature without the express written permission of Bray International, Inc.

7 of 22

6.1 The points below are for reference purposes only, use safe and

proper lifting and support techniques. DO NOT lift valves with

any adjoining pipe or other equipment attached. Lift with

properly rated lifting equipment. Follow jurisdictional safety

requirements.

6.2 Suggested lifting points are as shown below to lift valve assemblies

that are in a horizontal orientation. Eye bolts in flange through

holes can be used to lift the valve body or, for 2” through 12”

valves, a sling can be strapped around the top of the valve body.

6.3 KNIFE GATE VALVE WITH BEVEL GEAR ACTUATOR:

For valves with bevel gear actuators, a sling or chain can be

wrapped around the bevel gear actuator body, between the

mounting plate and the input shaft housing. This would be in

conjunction with lifting from the valve body as well. See Figure 3.

Figure 3: Knife Gate Valve with Bevel Gear Actuator,

Horizontal Lifting

6.4 KNIFE GATE VALVE WITH PNEUMATIC CYLINDER ACTUATOR:

For valves with pneumatic cylinder actuators, a sling can be

wrapped around the cylinder, near the cylinder head (piston rod

end). This would be in conjunction with lifting from the valve body.

See Figure 4.

6.4.1 Utilize caution to not bump, dent or damage the cylinder tube.

6.4.2 DO NOT utilize the cylinder tie-rod ends to lift.

Figure 4: Knife Gate Valve with Pneumatic Cylinder Actuator,

Horizontal Lifting

6.0 LIFTING THE VALVE

WARNING

A potential hazard exists with handling valves. Failure to handle valves

properly may cause a valve to shift, slip or fall causing serious injury or

death and/or equipment damage.

SERIES 950 UNIDIRECTIONAL KNIFE GATE VALVE

Installation, Operation and Maintenance Manual

© 2020 BRAY INTERNATIONAL. ALL RIGHTS RESERVED. BRAY.COM The Information contained

herein shall not be copied, transferred, conveyed, or displayed in any manner that would violate its

proprietary nature without the express written permission of Bray International, Inc.

8 of 22

Figure 8: Knife Gate Valve with

Handwheel, Vertical Lifting

Figure 7: Knife Gate Valve with

Pneumatic Cylinder Actuator,

Vertical Lifting

Figure 6: Knife Gate Valve w/Bevel

Gear Actuator, Vertical Lifting

6.5 KNIFE GATE VALVE WITH HANDWHEEL ACTUATOR:

For valves with handwheel actuators, a sling or chain can be

wrapped through the rim of the handwheel. For chainwheel

actuators, a sling can be wrapped in the area between the yoke/

legs and the chainwheel/guide assembly. This would be in

conjunction with lifting from the valve body as well. See Figure 5.

Figure 5: Knife Gate Valve with Handwheel, Horizontal Lifting

6.6 Suggested lifting options are as shown below to lift valve

assemblies that are in a vertical orientation. For valves with bevel

gear actuators, wrap slings or chains around the top of each leg.

NOTE: Use caution not to put any side load on the bevel gear input

shaft or on the valves threaded stem. See Figure 6.

6.7 For valves with pneumatic cylinder actuators, wrap slings around

the top of each leg. Use caution to not bump, dent or damage the

cylinder tube and avoid any side load on the cylinder piston rod.

NOTE: DO NOT utilize the cylinder tie-rod ends to lift. See Figure 7.

6.8 For valves with handwheel or chainwheel actuators, wrap slings or

chains around the top of the each leg or yoke side.

NOTE: Use caution to not put any side load on the valves threaded

stem. See Figure 8.

7.0 STORAGE

7.1 Short term storage is defined as storage of valves to allow for

project construction and will be installed within a relatively short

amount of time, typically one to three months. During Short-term

storage, the following is required:

7.1.1 The preferred storage location is a clean, dry, protected

warehouse. Do not expose the valve to temperature extremes.

NOTICE

The packaging is designed to protect the valve only during shipping. If

you are not installing the valve immediately after delivery, then you must

store it according to these requirements.

SERIES 950 UNIDIRECTIONAL KNIFE GATE VALVE

Installation, Operation and Maintenance Manual

© 2020 BRAY INTERNATIONAL. ALL RIGHTS RESERVED. BRAY.COM The Information contained

herein shall not be copied, transferred, conveyed, or displayed in any manner that would violate its

proprietary nature without the express written permission of Bray International, Inc.

9 of 22

7.1.2 End protectors shall remain on the valve ends to prevent the

entrance of dirt, debris, or insects/wildlife.

7.1.3 Remain in the original shipping container with the original

packaging materials. This packaging method will not protect

valves that will be stored outside, uncovered, and unprotected.

7.1.4 Storage of valves in an open uncovered area is permissible but

requires provisions for inclement weather including a secure

waterproof tarp and must be elevated from the ground on a pallet,

a shelf or other suitable surface.

7.1.5 Do not stack the valves on top of each other.

7.1.6 Manual actuated valves may be stored in the vertical or horizontal

position. For air or hydraulic actuated valves, the preferred

orientation is with the valve and cylinder in the vertical position.

Access ports should be secured to prevent unauthorized entry and

prevent contamination.

7.2 Long term storage is defined as storage of valves longer than 3

months. During Long-term storage, the following is required:

7.2.1 The storage location shall be a clean, dry, protected warehouse. Do

not expose the valve to temperature extremes.

7.2.2 End protectors shall remain on the valve ends to prevent the

entrance of dirt, debris, or insects/wildlife.

7.2.3 Remain in the original shipping container with the original

packaging materials.

7.2.4 Do not stack the valves on top of each other.

7.2.5 Manual actuated valves may be stored in the vertical or horizontal

position. For air or hydraulic actuated valves, the preferred

orientation is with the valve and cylinder in the vertical position.

Access ports should be secured to prevent unauthorized entry and

prevent contamination.

7.2.6 Valves and equipment containing elastomers, including O-rings,

must be stored in a climate-controlled warehouse according to

SAE-ARP5316D requiring:

- The ambient relative humidity to be less than 75%

- No exposure from direct ultraviolet or sunlight

- Protected from ozone generating equipment or combustible

gases and vapors

- Must be stored at temperatures below 100°F (38°C), away

from direct sources of heat

- Not be exposed to ionizing radiation

SERIES 950 UNIDIRECTIONAL KNIFE GATE VALVE

Installation, Operation and Maintenance Manual

© 2020 BRAY INTERNATIONAL. ALL RIGHTS RESERVED. BRAY.COM The Information contained

herein shall not be copied, transferred, conveyed, or displayed in any manner that would violate its

proprietary nature without the express written permission of Bray International, Inc.

10 of 22

7.2.7 Storage inspection: visual inspection shall be performed on a

semiannual basis and results recorded. Inspection as a minimum

shall include reviewing the following:

- Packaging

- Flange covers

- Dryness

- Cleanliness

7.3 Actuators to be stored with all cable/pneumatic entries plug to

prevent entry of foreign material.

7.4 Do NOT stack the valves on top of each other.

7.5 Leave protective caps and covers on the product.

SERIES 950 UNIDIRECTIONAL KNIFE GATE VALVE

Installation, Operation and Maintenance Manual

© 2020 BRAY INTERNATIONAL. ALL RIGHTS RESERVED. BRAY.COM The Information contained

herein shall not be copied, transferred, conveyed, or displayed in any manner that would violate its

proprietary nature without the express written permission of Bray International, Inc.

11 of 22

8.1 The valve is unidirectional. It should be installed with pressure

exerted against the seat. To enable correct orientation the word

“SEAT” is marked on the valve body to indicate the position of

the valve seat.

8.2 All valves larger than 12"/300mm size with pneumatic cylinder

actuators must be provided with extra support at site.

8.2.1 It is recommended to provide support around areas indicated in

Figures 9 and 10 with an adjustable sling.

Figure 9: Installation support for a Valve installed in Horizontal

orientation (Stem horizontal and Bore horizontal

Figure 10: Installation support for a Valve installed in Horizontal

orientation (Stem horizontal and Bore vertical)

8.2.2 Support from the top as shown or with suitable arrangement from

bottom (such as from an access platform) depending on location

constraints.

8.2.3 After the support is given, please operate the valve a few times to

check free movement and adjust the level (using the sling adjuster

or similar device) if required.

8.2.4 Ensure jerk free movement with the supports in place.

8.0 INSTALLATION

WARNING

The device generates a large mechanical force during normal operation.

WARNING

Observe all applicable safety regulations for valves installed in potentially

explosive (hazardous) locations.

SERIES 950 UNIDIRECTIONAL KNIFE GATE VALVE

Installation, Operation and Maintenance Manual

© 2020 BRAY INTERNATIONAL. ALL RIGHTS RESERVED. BRAY.COM The Information contained

herein shall not be copied, transferred, conveyed, or displayed in any manner that would violate its

proprietary nature without the express written permission of Bray International, Inc.

12 of 22

Figure 13: L3 Lug Stud

Figure 14: L4 Chest Stud

Table 2: RECOMMENDED FASTENERS - ASME B16.5 Class 150 Flanges

L3 (Figure 13) L4 (Figure 14)

Valve Size Bolt & Nut

Size

Lug Bolt

Length

Lug Bolt

Qty

Chest

Bolt

Length

Chest

Bolt

Qty

Nut

Qty

Washer*

Qty

NPS DN NPS NPS

2 50 5/8-11 5.5 2 2.25 4 8 8

3 80 5/8-11 6.0 2 2.5 4 8 8

4 100 5/8-11 6.0 6 2.5 4 16 16

5 125 3/4-10 6.5 6 2.5 4 16 16

6 150 3/4-10 6.5 6 2.5 4 16 16

8 200 3/4-10 7.5 62.75 4 16 16

10 250 7/8-9 7.5 82.75 824 24

12 300 7/8-9 8.0 83.0 824 24

14 350 1-8 8.5 8 3.5 8 24 24

16 400 1-8 9.0 10 3.5 12 32 32

18 450 1 1/8-7 9.5 10 4.0 12 32 32

20 500 1 1/8-7 11.0 12 4.5 16 40 40

24 600 1 1/4-7 11.0 12 4.5 16 40 40

* Washer Type B Wide

8.3 Observe the following points to prevent distortion of the valve

body and gate when the flange bolts are tightened.

8.3.1 Align the mating pipeline flanges. Select the length of the flange

bolts as seen in Table 1 and Table 2 below. Install the valve

between flanges using fasteners & gaskets.

8.3.2 Refer to GA Drawing/ Technical Bulletin for quantity and size of

blind tapped holes on valve chest area.

Table 1: RECOMMENDED FASTENERS - ASME B16.5 Class 150 Flanges

L1 (Figure 11) L2 (Figure 12)

Valve Size Bolt & Nut

Size

Lug Bolt

Length

Lug Bolt

Qty

Chest

Bolt

Length

Chest

Bolt

Qty

Nut

Qty

Washer*

Qty

NPS DN NPS NPS

2 50 5/8-11 4.5 2 1.25 4 2 8

3 80 5/8-11 5.0 2 1.5 4 2 8

4 100 5/8-11 5.0 6 1.5 4 6 16

5 125 3/4-10 5.5 6 1.5 4 6 16

6 150 3/4-10 5.5 6 1.5 4 6 16

8 200 3/4-10 6.5 6 1.75 4 6 16

10 250 7/8-9 6.5 8 1.75 8 8 24

12 300 7/8-9 7.0 81.75 8 8 24

14 350 1-8 7.5 82.0 8 8 24

16 400 1-8 8.0 10 2.25 12 10 32

18 450 1 1/8-7 8.5 10 2.5 12 10 32

20 500 1 1/8-7 9.5 12 2.75 16 12 40

24 600 1 1/4-7 10.0 12 3.0 16 12 40

* Washer Type B Wide

Figure 11: L1 Lug Bolt

Figure 12: L2 Chest Bolt

SERIES 950 UNIDIRECTIONAL KNIFE GATE VALVE

Installation, Operation and Maintenance Manual

© 2020 BRAY INTERNATIONAL. ALL RIGHTS RESERVED. BRAY.COM The Information contained

herein shall not be copied, transferred, conveyed, or displayed in any manner that would violate its

proprietary nature without the express written permission of Bray International, Inc.

13 of 22

Figure 15: Bolt holes in the chest or

upper flange area are blind tapped

CAUTION

If the gland nuts are pulled too hard, the force needed to operate the

valve will increase, the valve function will be affected and the box packing

lifetime will be shortened.

8.4 Gland packing is tightened to hold the specified pressure and

tested for no leakage before dispatch. However, this may

require some adjustment at site due to loosening in transit etc.

8.4.1 Tighten packing gland in a crisscross pattern until the packing ring

at the top is slightly compressed.

8.4.2 Pressurize the valve gradually and stop when packing leak is visible

or design pressure is reached.

8.4.3 Re-tighten packing gland bolts just enough to stop the leakage.

8.4.4 If maximum design pressure is not reached, continue to pressurize

the valve and repeat steps 8.6.2 and 8.6.3.

CAUTION

Support should be used for valves size 12"and over when installed in

vertical pipe. Failure to do so can result in improper valve orientation

and/or valve failure.

CAUTION

Care must be taken when installing the studs or bolts in the tapped holes

of the flange in the chest area to prevent damage, see Figure 15 and

Figure 16.

Figure 16: Flange Bolting

Note: To determine bolt length for

the blind holes in the upper chest

area of the valve, add thread

depth+ gasket + flange thickness +

any washers (plus deflection cone

and gasket when used)

Figure 15: Bolt holes in the chest or

upper flange area are blind tapped

CAUTION

Incorrect electrical supply to accessories will damage the equipment. Do

not over tighten the gland nuts as this may cause excessive friction and

premature damage to packing.

Figure 17: Cylinder Actuator

8.5 PNEUMATIC CYLINDER OPERATED VALVES

8.5.1 In Figure 17, connect instrument quality air, preferably through an

air filter/regulator of adequate size.

8.5.2 The recommended air pressure is 50-100 psi (3.5-7 bar). Refer to

the appropriate bulletin/drawing for port and cylinder size details.

8.5.3 Make sure the supply air is free from moisture, dirt, and other

foreign particles.

SERIES 950 UNIDIRECTIONAL KNIFE GATE VALVE

Installation, Operation and Maintenance Manual

© 2020 BRAY INTERNATIONAL. ALL RIGHTS RESERVED. BRAY.COM The Information contained

herein shall not be copied, transferred, conveyed, or displayed in any manner that would violate its

proprietary nature without the express written permission of Bray International, Inc.

14 of 22

Figure 19: Lockout pin through

yoke and handwheel.

Figure 18: Manual Valve Stem

8.5.4 Drain the filter regulator before operating the actuator so that pipe

rust and dirt if any in the air line will be removed before actuation.

8.5.5 If valves are supplied with electrical accessories like limit switch

and solenoid valve, ensure wiring is done as per local electrical

safety codes and regulations.

8.5.6 Ensure correct electrical supply is given to electrical accessories

for proper functioning and safety of the equipment.

8.5.7 Open the valve by energizing the solenoid valve/giving air supply

to cylinder and operate the valve 2-3 times.

8.6 MANUAL VALVES

8.6.1 For Figure 18, Stroke the valve through the full open and closed

position to make sure it is functioning properly.

9.0 LOCKOUT

9.1 Lockouts, Figure 19, are designed to prevent unauthorized

operation of the valve. The instructions below are intended for

personnel who are responsible for the installation, operation and

maintenance of the lockout device for Bray knife gate valves.

9.2 Any actuated valve (Pneumatic or Hydraulic or Electric) must be

placed in a “De-energized state” by isolating all potential energy

sources including electricity, operator supply air or hydraulic fluids.

9.3 Valves supplied with spring to close or open contain mechanical

springs in the cylinder and hence cannot be placed in a de-

energized state. Take extreme care when inserting and removing

the lockout pin to avoid any injury to operating personnel.

9.4 For mechanical lockout or full force lockout, where the lockouts

are meant to hold the full actuator force, please contact factory for

assistance and more information.

CAUTION

Once the lockout pins are in place in the lockout brackets, any Bray

actuated valve MUST be placed in a “De-energized state” by isolating the

supply air / hydraulic fluid / electricity.

CAUTION

The lockout device could get damaged when actuator thrust is applied

with the Lockout pin engaging the Gate.

SERIES 950 UNIDIRECTIONAL KNIFE GATE VALVE

Installation, Operation and Maintenance Manual

© 2020 BRAY INTERNATIONAL. ALL RIGHTS RESERVED. BRAY.COM The Information contained

herein shall not be copied, transferred, conveyed, or displayed in any manner that would violate its

proprietary nature without the express written permission of Bray International, Inc.

15 of 22

Table 3: Recommended Lubrication

Lubricant Type

Industrial Grease - Medium

C5 - A Compound

XL 47 - F2 - 75

Molytex Grease #2

Table 4: Recommended Spare Parts

Part Qty

Gland Packing Set of 3 Rows

Spare Seat 1

Cylinder Repair Kit 1

Gate 1

10.1 The stem and nut of the knife gate valve are lubricated at the

factory before shipment.

10.2 The manual valve stem should be lubricated at regular intervals for

smooth operation of the valve. A lubrication nipple is provided on

the collar. See Lubrication requirements in Table 3.

10.3 Cylinder operated valves do not require routine lubrication.

10.4 Parts recommended as spares as shown in Table 4, may be

stocked. Provide the valve serial number and work order number

from the nameplate for proper parts.

10.0 MAINTENANCE

NOTICE

Any modification or use of unauthorized parts voids any and all warranty

considerations.

WARNING

When the process fluid is hazardous, thermal (hot or cold), or corrosive,

take extra precautions.

WARNING

Always wear protective clothing and equipment to safeguard the eyes,

face, hands, skin, and lungs from the particular fluid in the line.

CAUTION

Disconnect electrical, pneumatic, and hydraulic power before servicing

actuator or automation components.

NOTICE

If the cylinder actuator is disassembled for repair, the cylinder wall

and seals need to be lubricated with a lithium-based grease prior

to reassembly.

11.0 PACKING REPLACEMENT - Manual Valves

WARNING

Relieve line pressure before loosening gland nuts to avoid injury and/or

equipment damage. Fully close the valve. Ensure the line is empty, and

flush if necessary. Remove the valve from the pipeline.

SERIES 950 UNIDIRECTIONAL KNIFE GATE VALVE

Installation, Operation and Maintenance Manual

© 2020 BRAY INTERNATIONAL. ALL RIGHTS RESERVED. BRAY.COM The Information contained

herein shall not be copied, transferred, conveyed, or displayed in any manner that would violate its

proprietary nature without the express written permission of Bray International, Inc.

16 of 22

4

3

2

5

6

1

Figure 20: Manual Valve Cutaway

11.1 Ensure the valve is fully closed.

11.2 In Figure 20, Disconnect the stem from the GATE (2) by removing

the clevis BOLTS & NUTS (6).

11.3 Rotate the HANDWHEEL (1) counter-clockwise by holding the

stem from rotation, so that the stem retracts fully from the gate.

NOTICE

If valves are supplied with bellows, ensure stem is not rotating, as rotation

will damage the bellows.

11.4 Remove the old PACKING (3) from the packing chamber, one layer

at a time, using a long thin tool to pry it out.

11.5 The lowest layer is a wiper ring (copper, Inconel etc.), clean it with

a common solvent; if damaged, replace with a new one.

11.6 Insert the new packing one at a time ensuring that the GATE (2)

is in full contact with the seat (gate fully down) and not rubbing

the bottom of the packing chamber. Stagger the cut end of the

packing so they do not line up.

11.7 Tap each PACKING (3) ring firmly and evenly into the chamber

before installing the next ring; the ends of each ring should meet

but not overlap.

11.8 Install the PACKING GLAND (4) and GLAND NUTS (5).

11.9 Ensure the gap between the gland and the gate is uniform

all around.

11.10 Tighten the GLAND NUTS (5) finger tight plus one half turn.

11.11 Lower the stem by rotating the handwheel clockwise while holding

the stem and fasten the stem to the gate with nuts and bolts.

12.0 PACKING REPLACEMENT - Cylinder Operated valves

WARNING

Relieve line pressure before loosening gland nuts to avoid injury and/or

equipment damage. Fully close the valve. Ensure the line is empty, and

flush if necessary. Remove the valve from the pipeline.

12.1 In Figure 21, switch off the electrical supply to the solenoid and

limit switches.

12.2 Remove the cylinder tubing and vent the air inside the

CYLINDER (1).

12.3 Disconnect the piston rod from the gate by removing the CLEVIS

BOLTS & NUTS (6).

SERIES 950 UNIDIRECTIONAL KNIFE GATE VALVE

Installation, Operation and Maintenance Manual

© 2020 BRAY INTERNATIONAL. ALL RIGHTS RESERVED. BRAY.COM The Information contained

herein shall not be copied, transferred, conveyed, or displayed in any manner that would violate its

proprietary nature without the express written permission of Bray International, Inc.

17 of 22

Figure 10: Cylinder Operated

Valve Cutaway

4

3

2

5

6

1

12.4 Apply air slightly to the bottom port of the actuator so that the

piston rod is retracted from the gate.

12.5 Remove the actuator assembly from the valve by removing the

fasteners connecting the yokes to the valve body.

12.6 Remove the GLAND NUTS (5) and the GLAND (4).

12.7 Remove the old PACKING (3) from the packing chamber, one layer

at a time, using a long thin tool to pry it out.

12.8 Insert the new packing one at a time ensuring that the GATE (2)

is in full contact with the seat (gate fully down) and not rubbing

the bottom of the packing chamber. Stagger the cut ends of the

packing so they do not line up.

12.9 Tap each PACKING (3) ring firmly and evenly into the chamber

before installing the next ring; the ends of each ring should meet

but not overlap.

12.10 Install the PACKING GLAND (4) and GLAND NUTS (5).

12.11 Ensure the gap between the GLAND (4) and the GATE (2) is

uniform all around.

12.12 Tighten the GLAND NUTS (5) finger tight plus one half turn.

12.13 Mount the actuator assembly to the valve by attaching the

fasteners connecting the yokes to the valve body.

Table 5: PACKING DETAILS

Valve Size Packing Size Length Quantity

NPS DN mm mm

2 50 Sq. 8 180 3

3 80 Sq. 10 225 3

4 100 Sq. 10 280 3

5 125 Sq. 10 330 3

6 150 Sq. 10 395 3

8 200 Sq. 10 490 3

10 250 Sq. 10 580 3

12 300 Sq. 10 690 3

14 350 Sq. 12.7 765 3

16 400 Sq. 12.7 975 3

18 450 Sq. 16 1005 3

20 500 Sq. 16 1120 4

24 600 Sq. 16 1320 4

28 700 Sq. 19 1520 4

30 750 Sq. 19 1640 4

32 800 Sq. 19 1830 4

34 850 Sq. 19 1950 5

36 900 Sq. 19 2035 5

SERIES 950 UNIDIRECTIONAL KNIFE GATE VALVE

Installation, Operation and Maintenance Manual

© 2020 BRAY INTERNATIONAL. ALL RIGHTS RESERVED. BRAY.COM The Information contained

herein shall not be copied, transferred, conveyed, or displayed in any manner that would violate its

proprietary nature without the express written permission of Bray International, Inc.

18 of 22

Figure 22: Lift clevis after removing

nuts & bolts.

Figure 24: Fully lift out gate and

remove seat.

Figure 23: Tilt super structure.

13.0 SEAT REPLACEMENT

CAUTION

Relieve line pressure before attempting to remove the valve from the line

to avoid personnel injury and/or equipment damage. If the valve has a

pneumatic actuator, solenoid valve, limit switches, or other accessories,

disconnect electrical and pneumatic supply.

13.1 Relieve the line pressure and close the valve. Flushing the line may

be necessary.

13.2 Remove the valve from the line by loosening the flange mounting

bolts, studs, and nuts.

13.3 Clamp the valve in the vertical position to a fixture. Do not block

the valve port when clamping the valve. An overhead hoist may

be needed for larger size valves.

13.4 Disconnect the stem from the gate by removing the clevis, bolts,

and nuts. See Figure 22.

13.5 Remove one set of superstructure bolting and tilt the super

structure to one side as shown in Figure 23.

13.6 Lift the gate up until it fully clears the seat area and remove the

old seat by tilting the top of the seat away from the body.

See Figure 24.

13.7 Insert the new seat with the bottom part first and lower the

gate fully.

13.8 Bolt the super structure to the body again and then fasten the

stem to gate bolts.

NOTICE

If leakage is observed from the packing area after installing the valve in

the pipeline and the valve is pressurized or charged with media, tighten

the gland nuts evenly side to side just enough to stop leakage.

Do not over-tighten the gland nuts.

SERIES 950 UNIDIRECTIONAL KNIFE GATE VALVE

Installation, Operation and Maintenance Manual

© 2020 BRAY INTERNATIONAL. ALL RIGHTS RESERVED. BRAY.COM The Information contained

herein shall not be copied, transferred, conveyed, or displayed in any manner that would violate its

proprietary nature without the express written permission of Bray International, Inc.

19 of 22

14.0 RETRO FITTING CYLINDER ACTUATOR

14.1 Clamp the valve in the vertical position to a fixture. Do not block

the valve port when clamping the valve. An overhead hoist may be

needed for larger size valves.

14.2 Open the Valve by about 10% from the seating position using the

Handwheel.

14.3 Disconnect the stem from the gate by removing the clevis, bolts,

and nuts and loosen the Handwheel mounting bolts and nuts see

Figure 25.

14.4 Remove the Handwheel assembly as shown in Figure 26.

14.5 Keep the Double Acting Actuator in fully retracted position–with

minimal piston rod projection.

14.6 Mount the Actuator on to the yoke/side plate and tighten by hand

as shown in Figure 27.

14.7 Move the piston rod slowly towards close position to align clevis

holes by applying Air pressure (to close) through the cylinder port.

14.8 Fasten the Clevis and Gate as shown in.

14.9 Check the clearance between the seat and gate face using a Feeler

Gauge (A feeler gauge is a tool used to measure gap widths) and

ensure the clearance is between 0.002” to 0.004”.

14.10 If the gap is less than 0.002”, push the Gate away from the seat

face and tighten the Gland.

14.11 If the clearance is more than 0.004”, push the Gate towards seat

face and maintain the gap and tighten the Gland

14.12 Apply air pressure and cycle the actuator for 3 open-close cycles

and observe for any scratches/scoring on the Gate surface.

14.13 If the gate surface is not scratched/scored after 3 cycles, tighten

all the fasteners (actuator mounting-side plate bolts and nuts and

clevis to gate bolts and nuts) to the prescribed torque.

14.14 Stroke the valve once to check for smooth operation of the valve.

14.15 Carry out Seat leakage testing with the relevant testing procedure.

Figure 25: Disconnect Stem from

Gate

Figure 26: Remove Handwheel

assembly.

Figure 27: Mount actuator on to

yoke/side plate.

SERIES 950 UNIDIRECTIONAL KNIFE GATE VALVE

Installation, Operation and Maintenance Manual

© 2020 BRAY INTERNATIONAL. ALL RIGHTS RESERVED. BRAY.COM The Information contained

herein shall not be copied, transferred, conveyed, or displayed in any manner that would violate its

proprietary nature without the express written permission of Bray International, Inc.

20 of 22

15.0 TROUBLESHOOTING

TROUBLE POSSIBLE CAUSE SOLUTION

Packing leakage > Incompatible Media

> Packing Deteriorated

> Temperature Variations

> Normal Packing Wear

Replace packing.

Soft Seated Valve:

In fully closed position, seat leakage

Seat is worn or damaged. a) Remove worn or damaged seat.

b) Inspect and clean seat chamber,

install new seat.

Gate is damaged. Gate replacement.

High torque during valve seating

and unseating

Entrapped foreign media in

pipeline prohibiting valve from

seating

Please consult factory for proper

solutions.

Packing not tightened to

recommended torque.

a) Remove valve from service.

b) Review gate to seat interface.

Unable to close or open gate Solidified media between

body and gate.

a) Check for valve orientation, flow

direction and flow indication.

b) Re-orient valve.

c) Replace gate.

d) Clean chest area of valve

Valve jerks during open and close Superstructure fasteners

loosened.

Tighten the superstructure fasteners.

Insufficient air supply. Pneumatic operated valves: Increase

supply pressure.

Solenoid valve dust

accumulation.

Remove and clean solenoid valve.

Piston rod seal damaged. Replace seal.

Packing is too tight. Loosen packing.

Table of contents

Other Bray Control Unit manuals

Bray

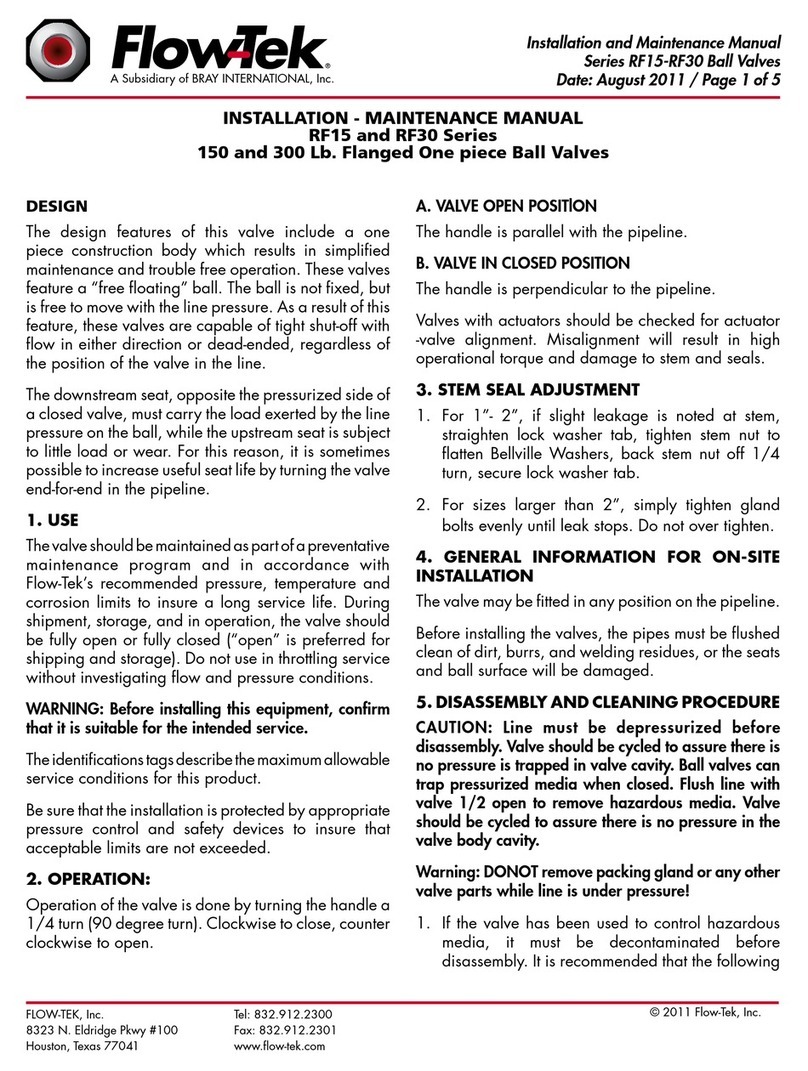

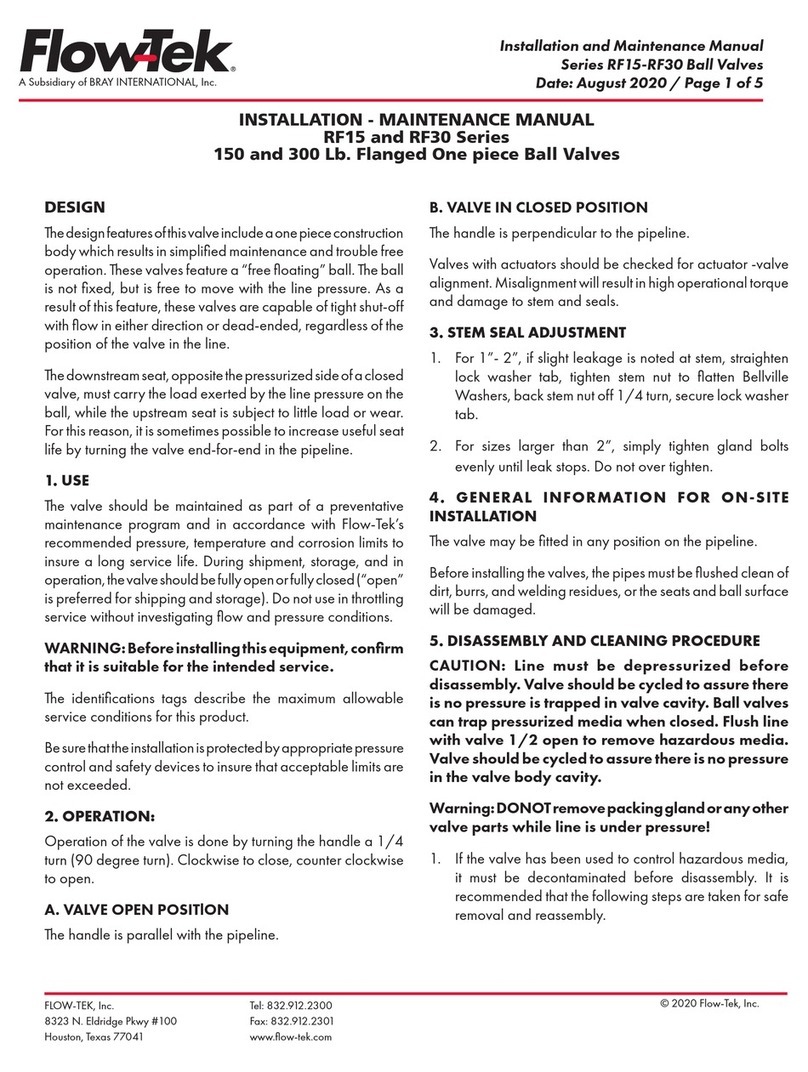

Bray FLOW-TEK Series User manual

Bray

Bray RF15 Manual

Bray

Bray TRI LOK User manual

Bray

Bray FLOW-TEK Series User manual

Bray

Bray FlowTek F15 Series Manual

Bray

Bray TRI LOK User manual

Bray

Bray FLOW-TEK 19 Series User manual

Bray

Bray TRI LOK Class 150 User manual

Bray

Bray McCANNALOK Series User manual

Bray

Bray RF15 Instruction Manual

Bray

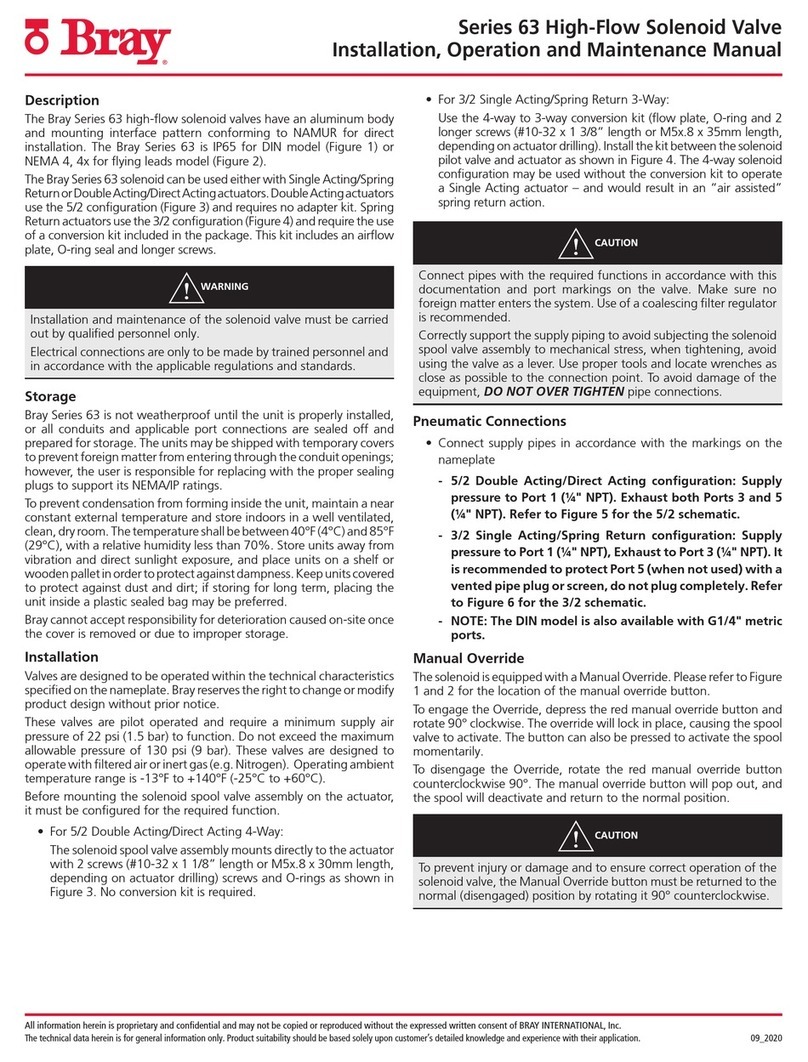

Bray 63 Series User manual

Bray

Bray TRI LOK User manual

Bray

Bray KUGELHAHN MULLER KM20 User manual

Bray

Bray 942 Series User manual

Bray

Bray 752 Series User manual

Bray

Bray Flow-Tek 5000 Series User manual

Bray

Bray 19L Series User manual

Bray

Bray 940 Series User manual

Bray

Bray FlowTek F15 Series User manual

Bray

Bray TRI LOK User manual