entegris InVue GV148 User manual

InVue®GV148

Liquid Chemical

Concentration Monitor

User Guide

ADVANCED MATERIALS HANDLING |MANUAL

2

INVUE GV148 LIQUID CHEMICAL CONCENTRATION MONITOR

User Guide | Entegris, Inc.

TABLE OF CONTENTS

—

Introduction ........................................................................ 3

Liability Ownership............................................................ 3

General Manual Notes...................................................... 3

Changes to the Manual.................................................. 3

Intended Audience.......................................................... 3

Intended Use/Scope ....................................................... 3

Principle of Operation ...................................................... 3

Safety .................................................................................... 4

Contacting Supplier with

Emergency Health Issues .............................................. 4

Handling............................................................................... 4

Chemical Leaks ...................................................................5

Specifications...................................................................... 6

Dimensions...........................................................................7

Hardware Installation........................................................ 8

Facility Requirements...................................................... 8

Mounting Requirements ................................................ 8

Mechanical Installation................................................... 8

Electrical Connections ................................................... 9

Software Operation..........................................................11

Installing the HMI Software..........................................11

Connect Tab ....................................................................11

Menu Features............................................................... 12

HMI Top Menu ............................................................... 13

System Tab ...................................................................... 14

Alarms Tab ....................................................................... 15

Info Tab............................................................................. 16

Self Tests Tab................................................................... 16

Total Internal Reflection (TIR) Tab ............................ 19

Concentration Tab.........................................................20

Temperature Compensation Coefficient

(TCC) Tab ......................................................................... 22

Analog/Digital IO Tab ................................................. 24

Communication Command Set ................................... 25

Maintenance ..................................................................... 25

Manual Window Cleaning Method ........................... 25

Automated In Situ Window Cleaning Method ....... 25

Diagnostic Guide .............................................................30

Ordering Information...................................................... 32

Technical Support............................................................ 32

Warranty Service .............................................................. 32

Limited Warranty.............................................................. 32

For More Information ..................................................... 32

Terms and Conditions of Sale....................................... 32

INVUE GV148 LIQUID CHEMICAL CONCENTRATION MONITOR

3User Guide | Entegris, Inc.

INTRODUCTION

—

Entegris, Inc. provides the enclosed product manual

for the user’s information.

Prior to using this manual, the user should verify with

the product manufacturer that the user has the most

recent copy of the product manual.

This manual is owned by Entegris, Inc., an aliated

company, or its suppliers and title shall not pass to

the user with use of the manual.

LIABILITY OWNERSHIP

—

Read the following carefully before continuing:

In no event shall Entegris or its suppliers be liable for

any damages whatsoever (including, without limitation,

damages for loss of business profits, business interrup-

tion, loss of business information or any pecuniary loss)

arising out of the use or inability to use this manual,

even if Entegris has been advised of the possibility of

such damages.

GENERAL MANUAL NOTES

—

CHANGES TO THE MANUAL

The manufacturer reserves the right to make changes

to the product covered in this manual to improve

performance, reliability, or manufacturability.

Although every eort has been made to ensure accu-

racy of the information contained in this manual, the

manufacturer assumes no responsibility for inadvertent

errors. Contents of the manual are subject to change

without notice.

INTENDED AUDIENCE

This manual is intended for technicians familiar with

the proper handling of chemical and other potentially

hazardous materials. Users must also be familiar with

installing and using software on a computer running

the Windows®operating system.

INTENDED USE/SCOPE

This manual is intended to be used by experienced

technicians for the planning, installation, and operation

of the described InVue®GV148 liquid concentration

monitor.

This manual contains basic safety information for

the installation and use of the InVue GV148 liquid

concentration monitor.

WARNING: Mishandling products exposed to a

hazardous substance may result in death or serious

injury. Always follow the recommendations and

guidelines provided by the chemical suppliers and

manufacturers. Always wear appropriate personal

protection equipment as required for the chemicals

in use. Refer to the Material Safety Data Sheet

(MSDS) for each chemical.

PRINCIPLE OF OPERATION

—

Light from an LED is directed toward the optical window

in contact with the liquid chemical. The light is reflected

o the liquid based on its refractive index and directed

towards the light detector. The intensity of the light

detection determines the refractive index of the fluid.

LED light

source

PDA light

detector

LO

W

Light intensity

HIGH

Optical

window

Liquid

chemical

4

INVUE GV148 LIQUID CHEMICAL CONCENTRATION MONITOR

User Guide | Entegris, Inc.

SAFETY

—

DANGER: Failure to follow these safety instructions

may lead to fire, electric shock, chemical exposure,

or other injuries, or damage to property. Read all

safety information before usage.

CONTACTING SUPPLIER WITH EMERGENCY HEALTH ISSUES

Please contact the manufacturer with any emergency

safety and health concerns.

WARNING: Safety is designed into every product.

When followed, these minimum guidelines provide

an acceptable level of safety for operating and

maintaining the system but are not a substitute

for determining internal safety procedures.

FAILURE to comply with the safety precautions or

warnings indicated in this manual violates the safety

standards that form a part of the intended use of

this equipment. The manufacturer assumes no

liability for the user’s failure to comply with

these requirements.

WARNING: Use of controls, adjustments or pro-

cedures other than those specified in this manual

without consulting a competent safety professional

may result in exposure to potential hazards. Always

follow established industrial safety practices when

operating the equipment.

CAUTION: End of life statement. Decommissioning

of the system, or any part of the system shall be

in a manner that is consistent with appropriate

regulations and guidelines.

WARNING: Chemicals are not supplied with this

equipment. Refer to the chemical suppliers’ MSDS

for specific health and safety information.

WARNING: Wear chemical-resistant garments and

eye protection. Use additional personal protective

equipment (PPE) as directed by facility safety per-

sonnel, the MSDS or chemical safety guidelines.

CAUTION: Only technically qualified personnel

should install equipment.

CAUTION: DO NOT use this equipment in any

manner not specified by the manufacturer. If

the equipment is used in a manner other than as

specified in this document, the safety protections

may be impaired.

CAUTION: Fittings and components damage easily;

handle all components with extreme care. DO NOT

scratch or overtighten any component.

CAUTION: EQUIPMENT DAMAGE HAZARD! Turn

o power before connecting or disconnecting any

cable to the device or damage may occur.

CAUTION: Since the monitor uses a light source to

indicate the refractive index, ambient light around

the device should be minimized.

HANDLING

—

The InVue GV148 liquid concentration monitor is

manufactured with strict assembly, test, and inspection

processes to ensure a high-quality product and protec-

tion from unintended chemical release. As with all

chemical handling systems, the monitor has chemical

connection points that must be handled with care.

Do not loosen any screws on the mechanism unless

specifically directed to do so by an Entegris applica-

tions engineer. Use care to prevent any damage to

the unit that could result in chemical leakage.

INVUE GV148 LIQUID CHEMICAL CONCENTRATION MONITOR

5User Guide | Entegris, Inc.

CHEMICAL LEAKS

—

In the event of a suspected or confirmed chemical

leak from the InVue GV148 liquid concentration

monitor, please follow the instructions below:

1. Determine chemical currently in use with monitor.

2. Obtain (material) safety data sheet.

a. Determine if any compatible materials may

come in contact with leaking material.

b. Isolate incompatibles with barriers including

spill containment.

c. Identify appropriate chemical protection

requirements including gloves, face and eye

protection, and chemical protective clothing to

prevent exposure to or contact with chemicals.

d. Determine if the chemical has permissible

exposure limits or short-term exposure limits:

— Identify limits requiring respiratory

protection.

— Ensure appropriate monitoring devices

are available to measure air levels.

3. Only personnel properly trained in the cleanup of

hazardous material spills should conduct cleanup

activities. Consult local authorities or identified

hazardous materials emergency response agencies

or contractors for assistance if the facility does

not have trained personnel for spill cleanup or

containment.

4. Ensure adequate monitoring and protective

equipment is available for cleanup of hazardous

materials.

5. Obtain supplies for cleanup and containment

compatible with the chemical.

6. Obtain compatible containers to collect spilled

material and cleanup materials.

7. Ensure adequate ventilation is provided where

a buildup of vapors could occur. If flammable

material is in use:

a. Monitor area for flammable levels with

appropriate monitoring devices.

b. Isolate all power sources or potential

sources of sparks.

c. Use intrinsically safe tools and monitoring

equipment.

8. Isolate monitor from power sources to prevent

fluids from flowing through unit during cleanup

of leak or spill.

a. When disconnecting nitrogen and/or any

pressurized gas, wear appropriate PPE

including gloves, then close the facility

gas supply to prevent gas release when

disconnecting lines. De-energize/

depressurize before disconnecting/

opening the line.

9. If material is contained in the tubing or the

monitor, provide collection container under

the lines or monitor during removal to collect

chemical and prevent additional spills.

10. Decontaminate surfaces with appropriate

decontamination materials per chemical

manufacturer recommendation.

11. Contain cleanup materials and contaminated

debris and equipment.

12. Dispose of materials in accordance with local,

state, and national regulatory requirements.

13. Provide any required service to the equipment

and verify all spilled material is collected and

cleaned from surfaces.

14. Replace any equipment and secure lines in

accordance with normal maintenance and

service requirements.

15. Confirm air levels are safe.

16. Return equipment to service per standard

procedures.

6

INVUE GV148 LIQUID CHEMICAL CONCENTRATION MONITOR

User Guide | Entegris, Inc.

SPECIFICATIONS

—

Materials of

construction

Flow cell body Polytetrafluoroethylene (PTFE)*

Optical window Single-crystal sapphire*

Cable jacket Polyvinylchloride (PVC)

Bonnet, enclosure Polyvinylidene fluoride (PVDF)

Mounting plate Polypropylene (PP)

Electrical Cable connection 19 pin Turck®male

Current rating 1.0 A at start-up; 0.5 A during operation

Main voltage input 24 VDC ±10%

Digital IO voltage input 12 – 24 VDC

Short protection** Yes

External LEDs 4

Analog outputs 4 – 20 mA concentration, fluid temperature,

refractive index (RI)

Discrete digital inputs 2

Discrete digital outputs 2, 80 mAdc maximum (each)

Re-zero Digital input, serial command, or HMI software

Serial communication RS485 2-wire or 4-wire

RS422 4-wire

Operating system compatibility Windows 7 or 10

Network compatible Yes

Pressure and thermal Maximum pressure 80 psig at 40°C (104°F)

Process fluid temperature range 20° to 40°C (68° to 104°F)

Ambient temperature range 20° to 35°C (68° to 95°F)

Storage temperature range -15° to 40°C (5° to 104°F)

RI Measurement RI range*** 1.32 to 1.40 nD

Accuracy ±2 × 10-4 nD (@ 20°C [68°F] from 1.332987 to 1.4000 nD)

Repeatability 5 × 10-5 nD (in clear fluid @ 20°C [68°F])

Precision 3 × 10-6 nD (in DI water @ 20°C [68°F])

Response time <3 sec unaveraged response to 63% of steady state change

Drift <5 × 10-5 nD/30 days (in DI water @ 20°C [68°F])

Pressure sensitivity (typical) 8 × 10-7 nD/psig in DI water (typical in DI water @ 20°C [68°F])

ROHS compliant Yes

Enclosure IP54

Orientation Any

*Wetted components.

**See Electrical Connections Step 1.

***For fluids with an RI above/below, please consult your local Entegris salesperson.

INVUE GV148 LIQUID CHEMICAL CONCENTRATION MONITOR

7User Guide | Entegris, Inc.

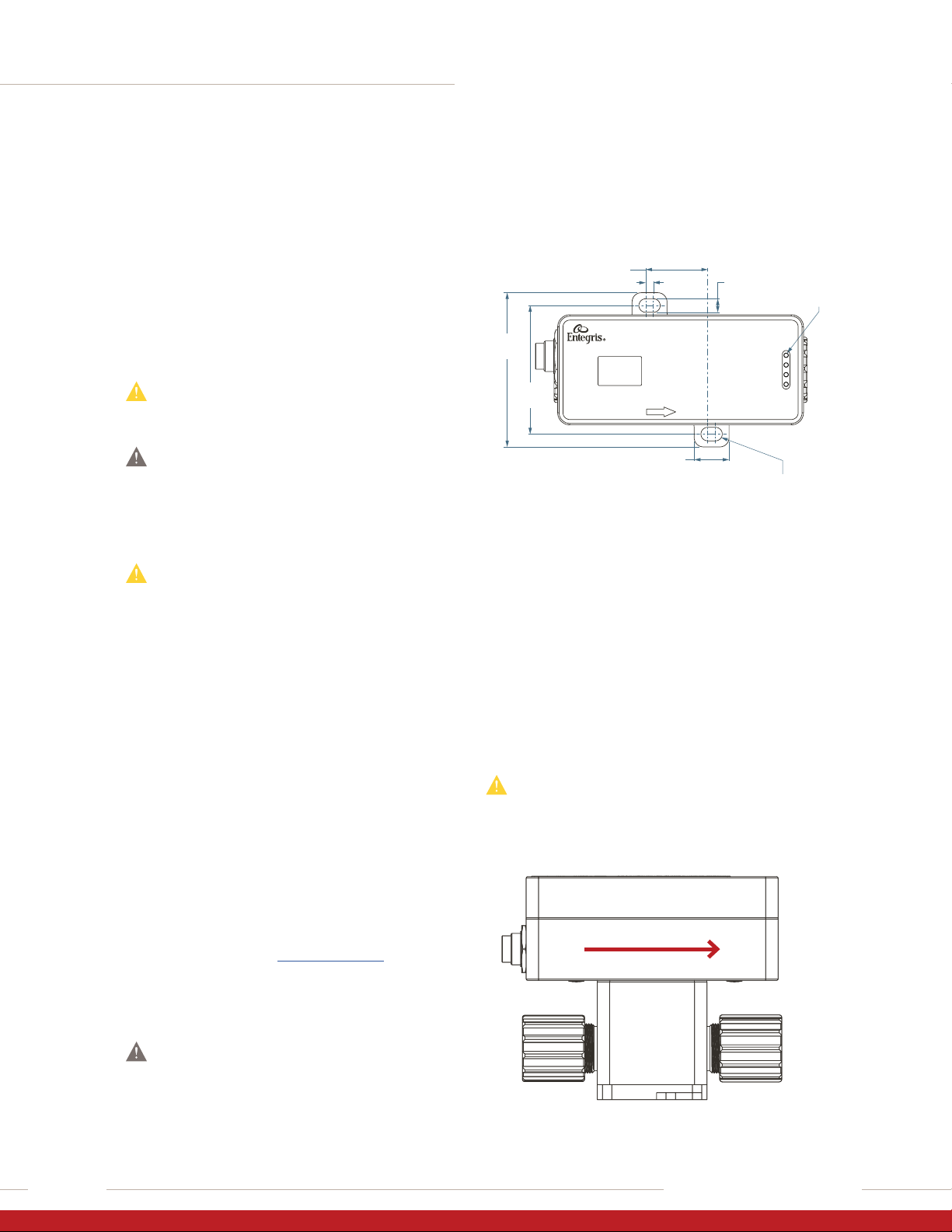

DIMENSIONS

—

LED Status Codes

The monitor has 4 LEDs on the top of the cover

to help indicate visual status of the product.

LED FUNCTION

#1 Processor heartbeat

#2 Communication in process

#3 Reserved

#4 Device error condition

Side View

21.7 mm

(0.86")

57.7 mm

(2.27")

3.6 mm

(0.14")

Front View

B

A

37.0 mm

(1.46")

128.8 mm (5.07")

141.1 mm (5.56")

C

Top View

32.5 mm (1.28")

2 x 4.1 mm (0.16") 2 x 7.1 mm (0.28")

18.3 mm (0.72")

LED #1

Recommended mounting

screws size: ⁄" or M6

67.3 mm

(2.65")

80.8 mm

(3.18")

Inlet /outlet

port connection

DIMENSIONS

ABC

⁄" Flaretek®tube fitting 114.6 mm (4.51") 33.0 mm (1.30") 111.0 mm (4.37")

⁄" Flaretek tube fitting 117.7 mm (4.64") 34.7 mm (1.37") 113.5 mm (4.47")

⁄" Flaretek tube fitting 120.9 mm (4.76") 36.3 mm (1.43") 119.6 mm (4.71")

⁄" Flaretek tube fitting 126.6 mm (4.99") 38.9 mm (1.53") 132.6 mm (5.22")

1" Flaretek tube fitting 126.6 mm (4.99") 38.9 mm (1.53") 154.9 mm (6.10")

⁄" PrimeLock®tube fitting 120.9 mm (4.76") 36.3 mm (1.43") 122.9 mm (4.84")

1" PrimeLock tube fitting 126.6 mm (4.99") 38.9 mm (1.53") 149.6 mm (5.89")

⁄" Pillar tube fitting 114.6 mm (4.51") 33.0 mm (1.30") 100.5 mm (3.96")

⁄" Pillar tube fitting 117.7 mm (4.64") 34.7 mm (1.37") 112.5 mm (4.43")

⁄" Pillar tube fitting 126.6 mm (4.99") 38.9 mm (1.53") 134.5 mm (5.29")

8

INVUE GV148 LIQUID CHEMICAL CONCENTRATION MONITOR

User Guide | Entegris, Inc.

HARDWARE INSTALLATION

—

This section covers site requirements, tools, and

equipment to install the InVue GV148 liquid concen-

tration monitor. Technical support is available for all

installation types.

NOTE: All components are shipped in protective packaging

to prevent damage during transport. If damage is found,

please file a damage claim with the transportation carrier

and contact customer support immediately.

CAUTION: Avoid particulate contamination. Do

not unwrap any cleanroom-packaged item until

immediately before installation.

WARNING: Only technically qualified personnel

should install the system. Wear chemical resistant

garments and eye protection. Chemicals are not

supplied with this equipment. Obtain a chemical

MSDS for each chemical used with the system and

follow all safety requirements.

CAUTION: Fittings and components damage easily;

handle them with extreme care. Do not scratch or

overtighten any part.

FACILITY REQUIREMENTS

• Computer: MS Windows 7 or 10

• Display: Recommended 1024 x 768

• Input power: 24 VDC

• Optional: 4-20 mA analog measurement device

• Basic wiring tools

• Line pressure: 0-60 psig (0 to 4.1 bar)

• Reference chemical: DI water or other

reference chemical used for calibration

• Fluid lines and fittings: Standard ¾” tubing

and ¾” Flaretek connections.

NOTE: For detailed Flaretek and PrimeLock tube fitting

assembly instructions, visit www.entegris.com. For detailed

Super 300 Type Pillar assembly instructions, contact

Nippon Pillar Packaging Company, Ltd.

NOTE: Additional sizes available upon request.

WARNING: Installation location must provide

adequate exhaust ventilation and monitoring. The

installation location should incorporate secondary

containment and spill detection. Facility must have

appropriate alarm and shutdown procedures for

the chemical in use.

MOUNTING REQUIREMENTS

See dimensional details for mounting geometry

below. Use M6 or ¼” threaded fasteners with

appropriate flat washers.

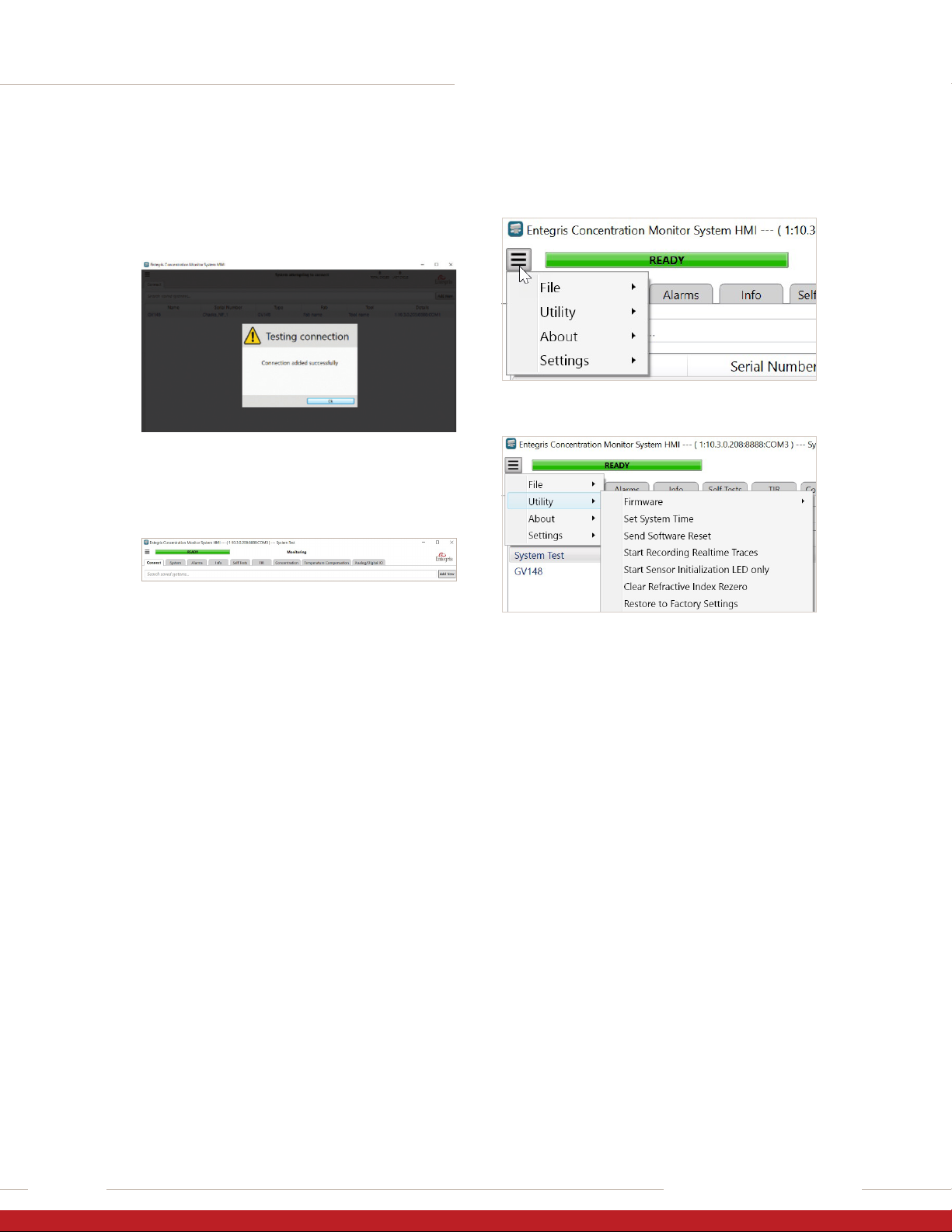

MECHANICAL INSTALLATION

Step 1: Location

Location of the monitor should comprise a steady

process fluid stream from the principal flow to prevent

sediment and bubbles from collecting on the sensor.

Note: Provide minimal flow pulses. Strong pressure

pulses in the flow stream may cause erratic readings.

A pressure regulating device may improve monitor

operation and performance.

Step 2: Installation

CAUTION: The monitor has a directional flow mark.

Verify process flow is passing in the correct direction.

1. Optimum mounting of the in-line fluid monitor is

in this orientation:

32.5 mm (1.28")

2 x 4.1 mm (0.16") 2 x 7.1 mm (0.28")

2 x 18.3 mm (0.72")

LED #1

Recommended mounting

screws size: ⁄" or M6

InVue®GV148 LIQUID CONCENTRATION MONITOR

Electrical Connections – 19 Pin Connector

Pin Color Connection

A. Blu 24 VDC

B. Gry/Pink Power GND

C. Red/Blu TX A

D. Wht/Grn RX A

E. Blk COMMS GND

F. Brn/Grn TX B

G. Pink RX B

H. Wht/Yel IO Power

I. Grn Digi Output 0

Model

S/N

Connections

This product may be covered

by one or more U.S. patents at:

www.entegris.com/patents

Factory Sealed

Assembled in U.S.A. FLOW

Pin Color Connection

K. Yel/Brn Digi Output 1

L. Brn Digi Input 0

M. Orn Digi Input 1

N. Gry/Brn IO GND

O. Vio Ana Output 1

P. Wht AGND

R. Red Ana Output 2

S. Gry AGND

T. Yel Ana Output 3

U. Tan AGND

Heartbeat

Comms

Not Used

Error

Visit the InVue GV148 liquid concentration monitor product page on

www.entegris.com to access the manual and download the software

67.3 mm

(2.65")

80.8 mm

(3.18")

INVUE GV148 LIQUID CHEMICAL CONCENTRATION MONITOR

9User Guide | Entegris, Inc.

2. For improved bubble rejection, mounting should

be in this orientation:

3. For maximum bubble rejection, mounting should

be in this orientation:

NOTE: This orientation is not recommended for

sediment carrying media.

Step 3: Connect Fluid Lines

1. Attach tubing using standard installation procedure

for Flaretek, PrimeLock, and Super Type 300 Pillar

connections.

NOTE: For detailed Flaretek and PrimeLock tube fitting

assembly instructions, visit www.entegris.com. For

detailed Super 300 Type Pillar assembly instructions,

contact Nippon Pillar Packaging Company, Ltd.

ELECTRICAL CONNECTIONS

Connect Wiring

NOTE: The wiring table below references the 19-pin PVDF

male Turck connector on the device (see image below). To

connect to the device, multiple cable options are available

with specific wiring diagrams. Please contact Entegris for

details.

PIN FUNCTION

A24 VDC power input

BPower supply ground

CTX-A

DRX-A

EComms ground

FTX-B

GRX-B

HDigital IO power 12-24 VDC

IDigital output 0, system alarm

KDigital output 1, future use

LDigital input 0, RI re-zero

MDigital input 1, Selection between

primary and secondary temperature

compensation coecients

NDigital IO ground

OAnalog output 1, concentration

PAnalog ground

RAnalog output 2, fluid temperature

SAnalog ground

TAnalog output 3, refractive index

UAnalog ground

A

E

C

G

L

M

N

O

PR

T

U

S

I

H

B

D

F

K

10

INVUE GV148 LIQUID CHEMICAL CONCENTRATION MONITOR

User Guide | Entegris, Inc.

CAUTION: All grounds (power supply ground,

comms ground, digital IO ground, the three

analog grounds) are individually unique. Do

not short grounds together.

CAUTION: If the power supply and serial comms

grounds become common and >+15 VDC is applied

to the serial communication Transmit/Receive (TX/

X) pins, irreversible damage to the unit may occur.

1. Connect the power [A] and ground [B]

2. Connect the digital IO power [H] and digital IO

ground [N]

NOTE: Digital IO usage is optional. Digital IO is used

for re-zero command, temperature compensation

selection, and alarm notification. To reduce signal

noise, ground separately from power supply ground.

3. Connect digital inputs and outputs for re-zero

command [L], temperature compensation selection

[M], and alarm detection [I].

– Digital inputs [L and M] are optically isolated,

sinking inputs (pull signal to digital IO ground to

energize)

– Digital outputs [I and K} are optically isolated,

open collector, 80 mAdc maximum (output pulls

load to digital IO ground when energized)

4. Connect analog outputs and grounds for reading of

concentration [O and P], fluid temperature [R and

S], and refractive index [T and U]

CAUTION: 4 – 20 mAdc analog outputs are self

powered. Analog outputs are always on. Isolate

all unused connections.

NOTE: Analog output usage is optional. Analog out-

puts are used for analog data logging of refractive

indexes, concentration, and sensor fluid temperatures.

To reduce signal noise, ground separately from power

supply ground.

5. Connect serial communications

NOTE: GV148 HMI software is required to fully utilize

the features of the GV148 monitor. Configure the

serial interface for RS422 or RS485 to use the GV148

HMI software.

– RS422 serial communication requires a 4-wire

connection [C, D, F, and G]

– RS485 serial communication requires a 2-wire

connection [C and D together, F and G together]

NOTE: To reduce signal noise, usage of the Comms Ground

[E] is recommended, but not made common to the power

supply ground.

INVUE GV148 LIQUID CHEMICAL CONCENTRATION MONITOR

11User Guide | Entegris, Inc.

SOFTWARE OPERATION

—

The HMI (human machine interface) user software is

used to communicate with the GV148 liquid concen-

tration monitor. Entegris GV148 HMI software files are

available for download from the Entegris website.

INSTALLING THE HMI SOFTWARE

To operate the concentration monitor, communication

must be established using a host computer, laptop, or

similar system using the supplied software. To configure

the software and establish communication:

1. Connect device to serial port or USB to serial port

adapter. Windows will configure hardware for

usage.

2. Using Windows Device Manager, confirm com

port number.

3. Place the HMI software folder in an appropriate

directory.

4. Open the folder and using Windows Notepad or

WordPad, open file {hmiserver.rc}.

5. Edit the com port number determined in Step 2

and save.

6. Confirm the Baud Rate as 57600.

7. Click the icon to start HMI server.

8. The server will open.

9. Click the InVue GV148 icon to start HMI software

and open the “Connect” tab.

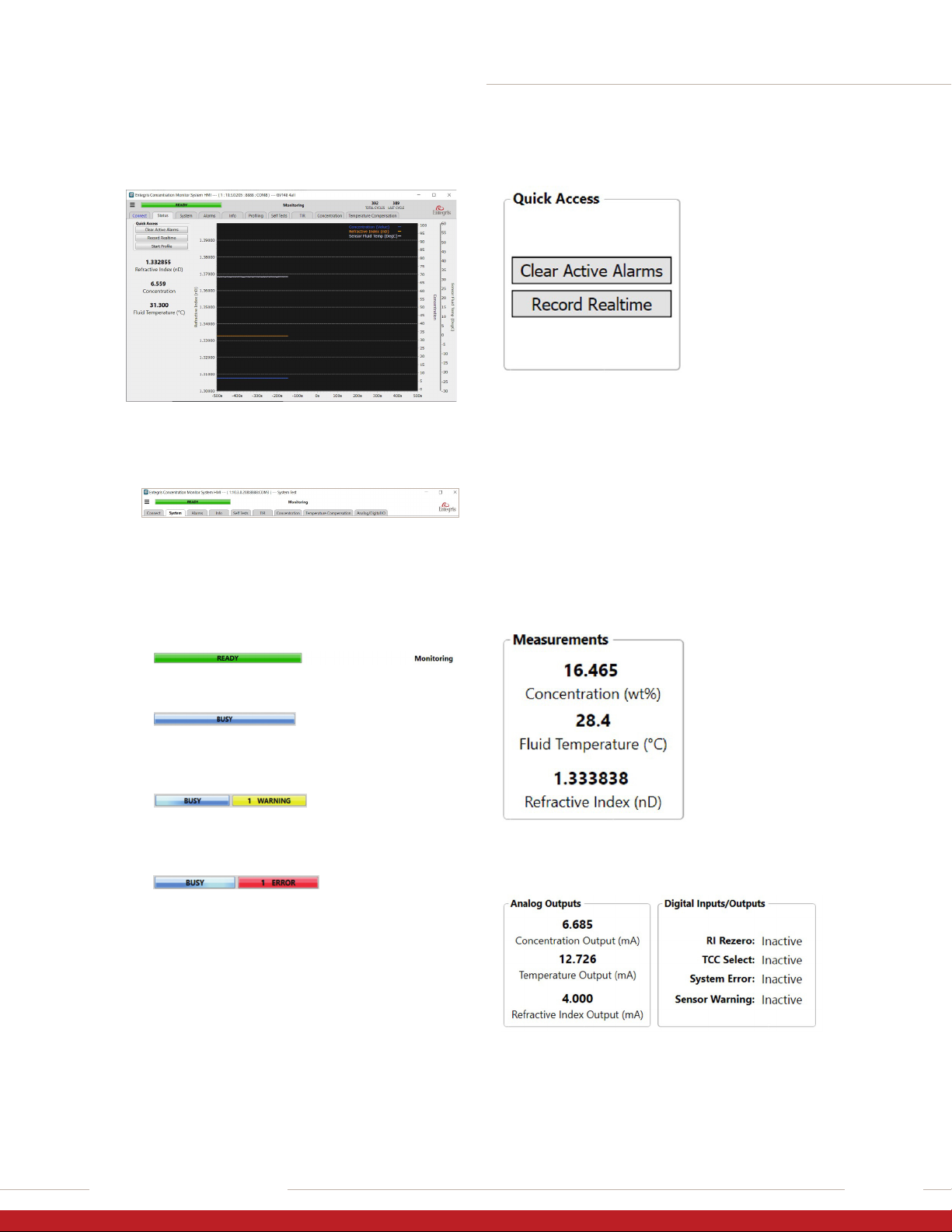

CONNECT TAB

The Connect tab establishes communication between

the concentration monitor and the HMI software.

1. Press “Add New”.

2. The Add New Connection information box opens.

12

INVUE GV148 LIQUID CHEMICAL CONCENTRATION MONITOR

User Guide | Entegris, Inc.

3. Enter “localhost” for server, the COM port number

from the server setup and {1} for the address.

4. Press “Add”.

5. Verify connection.

6. Press “OK”.

7. Double-click on the listed device.

8. Communication established.

9. Once HMI is connected to a specific device, all

connections will be listed in the field below with

the latest connection at the top.

MENU FEATURES

1. Select the menu icon to view the Menu Features

2. Utility has several useful functions

a. Downloading new Firmware to the device

b. Set the devices System Time

c. Recording Realtime Traces (Reference the

Systems Tab section for more information)

d. Start Sensor Initialization LED only

e. Clear the RI re-zero

f. Factory reset

3. The About feature displays the firmware version

4. Settings is used to configure the Realtime

Graph resolution

INVUE GV148 LIQUID CHEMICAL CONCENTRATION MONITOR

13User Guide | Entegris, Inc.

HMI TOP MENU

There are four sections to the HMI top menu:

1. Status Information displayed on every page.

• Monitor name and connection information

• Collapsed menu icon (the three horizontal bars)

• Graphic status

Ready – Monitor is ready and monitoring.

Busy – Monitor is in operation.

Warning – Monitor operation has

triggered a warning.

Error – Monitor operation has

triggered an error.

• Written monitor status

• Individual page tabs

2. Quick Access Group.

• Clear Active Alarms – clears active information,

warning and error postings.

• Record Realtime – starts and ends recording of

refractive index, concentration, and fluid tem-

perature to a {*.csv file}. For recording instruc-

tions, see “Data Logging Using Record Realtime”

on page 14.

3. Realtime Monitoring Data – Data display for

the Concentration, Fluid Temperature, and

Refractive Index.

4. Real-time monitoring data for analog outputs and

digital inputs/outputs.

14

INVUE GV148 LIQUID CHEMICAL CONCENTRATION MONITOR

User Guide | Entegris, Inc.

SYSTEM TAB

The System page allows the user to set and change

variables that aect system operations of the monitor.

This includes concentration outputs, temperature out-

puts, refractive index outputs, and re-zero parameters.

4-20 mA Output Setup

The InVue GV148 liquid concentration monitor can

be used with a 4-20 mA analog device to accurately

interpret signals for concentration, refractive index,

and temperature.

The 4-20 mA analog outputs will allow the end user

to input values beyond the published product specifi-

cations. Inputting such values only aects 4-20 mA

scaling and will not increase or decrease the readable

RI range, temperature, or concentration.

1. Enter the 4 mA and 20 mA value for each output

type.

2. Select “Apply” to send values to monitor.

Re-zero Stability Settings

The GV148 monitor can perform an RI re-zero (see

page 17 for more details). During the re-zero process,

the user can specify the desired RI and temperature

stability values which are measured as 1 standard

deviation of the readings during the re-zero period.

If the RI or temperature deviates more than the user

values, the re-zero result will fail. Recommended

values are 0.00002 nD and 0.01°C.

NOTE: allowing higher and higher instability could indicate

erratic chemical system behavior and could influence the

validity of the final re-zero value.

1. Enter the RI and temperature stability maximum

values

2. Select “Apply” to send values to monitor

Data Logging Using Record Realtime

Record Realtime records concentration, refractive

index, and fluid temperature values to a {*.csv} file.

1. In the Quick Access Menu, select “Record Realtime”

to set the parameters of the data log.

2. Set the duration of the record and sampling

rate to the desired parameters.

3. Assign the file location and file name.

4. Select “Record”.

INVUE GV148 LIQUID CHEMICAL CONCENTRATION MONITOR

15User Guide | Entegris, Inc.

5. The HMI will indicate data is being recorded and if

a timed duration was set, a timer will count down.

NOTE: At any time, the recording can be stopped

by pressing “Stop Recording”. If the duration was

set to “Indefinite”, the HMI will record until it is

manually stopped.

ALARMS TAB

The Alarms page allows the user to see recorded

events and alarms that aect monitor operation.

Alarms are stored in the device memory so that

a history can be kept.

There are four sections to the Alarms page:

1. Active alarm information displays total current

alarms, including warnings, errors, critical errors,

information posts, and log counts.

2. Alarm page commands including:

• 25▼–requests number of alarms to be retrieved

and displayed, up to 5000 maximum.

• Get Alarms – command to retrieve and display

alarms from memory.

• Clear Active – clears all active alarms.

• Write Note – allows the user to add a note into

the alarm log file.

• Save Log – saves the alarms log to a {*.csv file}.

3. Search alarm log allows the user to enter a

keyword to search through the log record of

the alarms displayed.

4. Display field shows the alarms. Alarms can be

arranged by double-clicking the header of each

category.

• Alarm – displays the alarm number in numerical

order.

• Type – graphic display of the alarm type

ALARM TYPE ACTION SOLUTION

Critical Error Monitor is disabled. Clear error. If problem persists,

contact Entegris support.

System Error Monitor stops after completing

current function.

Clear error. If problem persists,

contact Entegris support.

System

Warning

Event occurred. Normal

operation continues.

Clear warning. Investigate cause

of warning.

Information Event occurred. Normal

operation continues. No eect. Alarm log only.

• Time – displays the time the alarm occurred.

• Code – displays the code number associated

with the alarm.

• Description – describes the event that occurred.

16

INVUE GV148 LIQUID CHEMICAL CONCENTRATION MONITOR

User Guide | Entegris, Inc.

INFO TAB

The Information page is mostly read-only information

that is assigned during manufacturing regarding PCBs,

sensors, firmware, monitor cycles, volumes, and

resettable cycles and volumes.

NOTE: The user should add monitor identification and

location descriptions like Customer Name, Fab Name,

Tool Name, etc. These identifying markers are used as

references on the Connect page and in saved profiles.

SELF TESTS TAB

The Self Tests page allows the user to perform self-

diagnostic tests to check the functionality of the

system or perform standard routines like re-zero.

Follow the instructions given in the Test Description

for each test.

Refractive Index Re-zero from the HMI

The re-zero function calibrates the refractive index

measurement to a known baseline. The typical base-

line for DI water is [IoR = 1.332987].

CAUTION: Process lines that cannot use DI water

may use another reference chemical of a known

concentration or Index of Refraction.

CAUTION: The monitor and fluid lines must be

free of air bubbles.

CAUTION: In order to accomplish an accurate

Refractive Index Re-zero Self Test, a Primary or

Secondary Chemistry (TCC) value should be

defined via the Coecients Generator located

on the Temperature Compensation tab.

1. Select the “Systems” tab.

a. Enable either “Primary Chemistry (TCC)”

or “Secondary Chemistry (TCC)” to select

a chemistry.

INVUE GV148 LIQUID CHEMICAL CONCENTRATION MONITOR

17User Guide | Entegris, Inc.

b. Ensure the desired value of “RI Rezero Stability

Max” is within the defined Upper Limit and

Lower Limit

– Default value is 0.000020 nD

c. Ensure the desired value of “Temp Rezero

Stability Max” is within the defined Upper

Limit and Lower Limit

– Default value is 2.00 Degrees

2. Select “Self Tests” tab

a. Select “Select a test to run…” drop-down menu

b. Select “Self Test: Refractive Index Rezero”

18

INVUE GV148 LIQUID CHEMICAL CONCENTRATION MONITOR

User Guide | Entegris, Inc.

c. Enter the “Input: RI Value to Rezero”.

(In the case of DI water, enter 1.332987.)

d. Confirm monitor status is Ready before

pressing “Start”.

– The test will run for approximately 40 seconds

and is designed to calculate an oset between

the desired RI and actual measured RI.

e. Upon completion, the test will either show Pass

or Fail. The test field will fill in with statistics.

INVUE GV148 LIQUID CHEMICAL CONCENTRATION MONITOR

19User Guide | Entegris, Inc.

– Results of the Rezero Self Test will also be

posted to the Alarm Log viewable on the

“Alarms” tab

Analog Outputs

This Self Test sets the analog outputs either high or

low so that their output could be checked with an

external measuring device.

1. To test the analog output, set it to low or high and

press “Start”.

2. Measure the output with appropriate device during

this 30 second cycle.

3. At the end of the 30 seconds, the outputs will revert

to represent their normal values.

TOTAL INTERNAL REFLECTION (TIR) TAB

This tab allows you to view 2 TIR curves at a time.

To load new TIR curves, press Load New for both

TIR A and TIR B. Notice that you can now hide

one or both curves.

Press Load File to display a saved or reference

TIR curve for either A or B, or Save File to store

on your PC

20

INVUE GV148 LIQUID CHEMICAL CONCENTRATION MONITOR

User Guide | Entegris, Inc.

CONCENTRATION TAB

The Concentration page allows the user to calibrate

chemical concentration to the refractive index. There

are three methods to creating and saving calibration

tables: manually, directly, or from an existing file.

CAUTION: The GV148 monitor has a maximum

of 30 calibration points. It is recommended that a

minimum of five calibration points is set above and

below the target process concentration range with

the target concentration as mid-point. Concentra-

tion steps should be in increments of 0.1%.

Creating and Saving Manually

This process requires the user to run various chemical

concentrations through the monitor with correspond-

ing refractive index readings to create the interrelation

between concentration and the refractive index.

1. The default table has two rows. To expand the

table, select “Add Entry”. It is recommended that

a minimum of five concentration points be used.

2. Introduce the desired chemical concentration at

the temperature, pressure, and flow characteristics

of the manufacturing process.

3. When the concentration is stable, click on the

Copy/Paste icon in the first edit cell to enter

the value.

4. Type the concentration value into the

Concentration edit field.

5. Repeat the process for the desired number

of entries.

6. As the data is collected, the chart will populate

and create an algorithmic curve.

7. Dierent algorithms can be selected for optimum

design.

Table of contents

Other entegris Measuring Instrument manuals