Enthuze ENT5089 Quick setup guide

1

INSTRUCTIONS FOR ASSEMBLY AND USE OF ITEM: ENT5089

800 LBS UNIVERSAL OVER-CAB ALUMNIUM TRUCK RACK

Enthuze Automotive Products

email: [email protected]

website: www.enthuze.ca

2

Read and understand all warnings, cautions, and assembly, installation and use instructions prior to assembling,

installing or using this product. Failure to follow all warnings, cautions and instructions may result in serious injury.

The warnings, cautions, and instructions in this manual cannot cover all possible conditions or situations that could

occur. Exercise common sense and caution when using this truck rack. Always be aware of the environment and

ensure that the rack is used in a safe and responsible manner.

NEVER allow other persons to assemble, install or use this product until they have read this manual and have

developed a thorough understanding of how the product works.

NEVER attempt to modify this product or subject it to an installation or use for which it was not designed. Doing so

may result in damage and/or serious injury.

SAVE THESE INSTRUCTIONS IN A SAFE PLACE FOR FUTURE REFERENCE

ASSEMBLY, INSTALLATION, USE AND PERSONAL SAFETY PRECAUTIONS

•Park your truck on a level, hard surface well away from hazards. Place transmission in park and set the parking

brake with engine off. If working indoors, ensure adequate clearance for installation and exit prior to starting.

•ALWAYS follow all federal and state department of transportation regulations governing installation and use.

•Verify that installation surface has no hidden wires before installing.

•NEVER allow the rack to come into contact with an electrical source. The rack is not insulated and contact will

cause electrical shock.

•ALWAYS wear appropriate safety gear such as ANSI-approved safety goggles and heavy-duty work gloves when

assembling, installing, loading, unloading or removing/storing the rack.

•NEVER attempt to assemble, install, load or unload the rack while you are tired or under the influence of drugs or

alcohol.

•Keep children and bystanders away from the work area while assembling, installing, loading/unloading the rack.

•ALWAYS thoroughly inspect your rack for loose parts and/or signs of damage prior to each use, installation or

removal.

•NEVER use your rack until any loose parts have been properly secured or damaged parts have been properly

replaced.

•Maximum weight capacity rating applies only to an evenly distributed and properly secured load on a properly

installed rack.

•NEVER exceed the evenly distributed maximum weight capacity of this rack.

•NEVER exceed the rated maximum weight capacity of the truck on which this rack is installed. Refer to the truck’s

Gross Vehicle Weight Rating.

•Carrying any load can be hazardous. All loads must be tied down securely to the rack to prevent them from

changing position or coming loose as a result of wind, road hazards or vehicle movement.

•Top heavy loads increase the chance of rollover. High loads must be transported with GREAT CAUTION to avoid

striking objects with low clearance or vehicle tipping during turns, sudden maneuvers or high winds.

•Be aware of dynamic loading! Sudden load movement may briefly create excess load causing product failure.

Technical Specifications

Property

Specification

Length

133in.

Width

70.5in.

Height

36.5in.

Maximum Weight Capacity

800lbs.

3

PARTS LIST

Prior to assembly and installation, make sure all parts are present, intact and undamaged. If you discover missing

and/or damaged parts, please contact our customer service using the information on page 1.

Item#

Description

Picture

Quantity

Item#

Description

Picture

Quantity

1

Crossbar

3

17

M10x55 Button Head Screws

8

2

Support Bar

4

18

M10 Lock Nut

8

3

Driver Side Front/Passenger

Side Rear Leg Rail Mount

2

19

M10 Hex Nut

8

4

Passenger Side Front/Driver

Side Rear Leg Rail Mount

2

20

Spring Washer

48

5

Upper Connecting Plate

4

21

Flat Washer

44

6

Lower Connecting Plate

4

22

Connecting Plate

2

7

C-Clamp

8

23

Thread Glue

1

8

Clamp Bolt Foot

8

24

Splint

2

9

Side Rail

4

25

Washer

4

10

Crossbar End Cap

6

26

Connecting Plate

6

11

Connecting Base

6

27

Plastic Sleeve

2

12

M10 Nut

44

28

Side Rail End Cap

4

13

M10x75 Hex Head Bolt

8

29

Handle

2

14

M10x25 Button Head Screws

36

30

Thread Block

2

15

M10x40 Button Head Screws

16

31

Ring Bolt

8

16

ST4.8×16 Phillips Head

Self-Tapping Screws

6

32

M10x16 Button Head Screws

8

4

Tools Required

Open Wrench (1 pc.) Allen Wrench (1 pc.) Tape Measure (1 pc)

Size=17mm Size=6mm

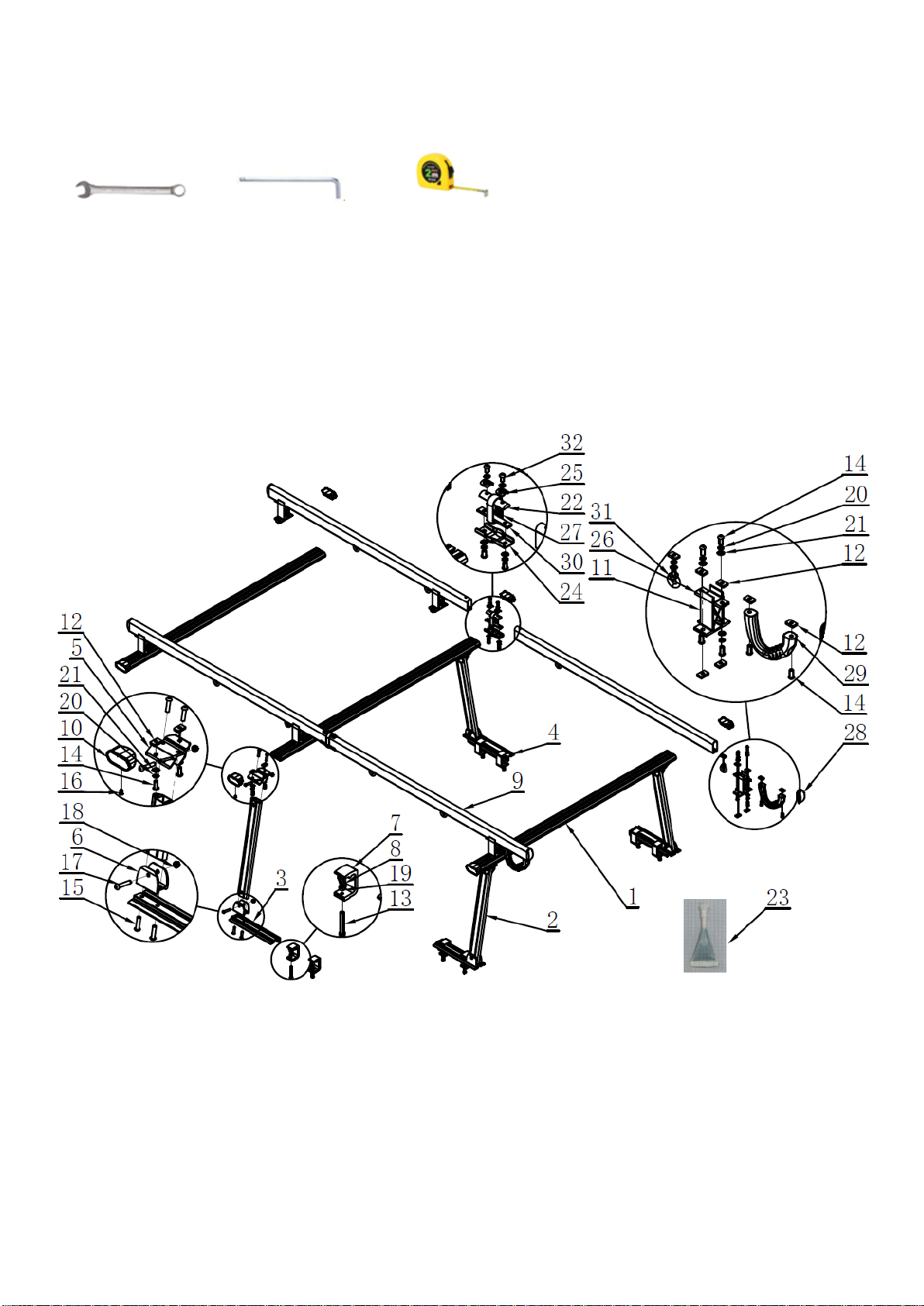

ASSEMBLY/PARTS DIAGRAM

5

ASSEMBLY PROCEDURES

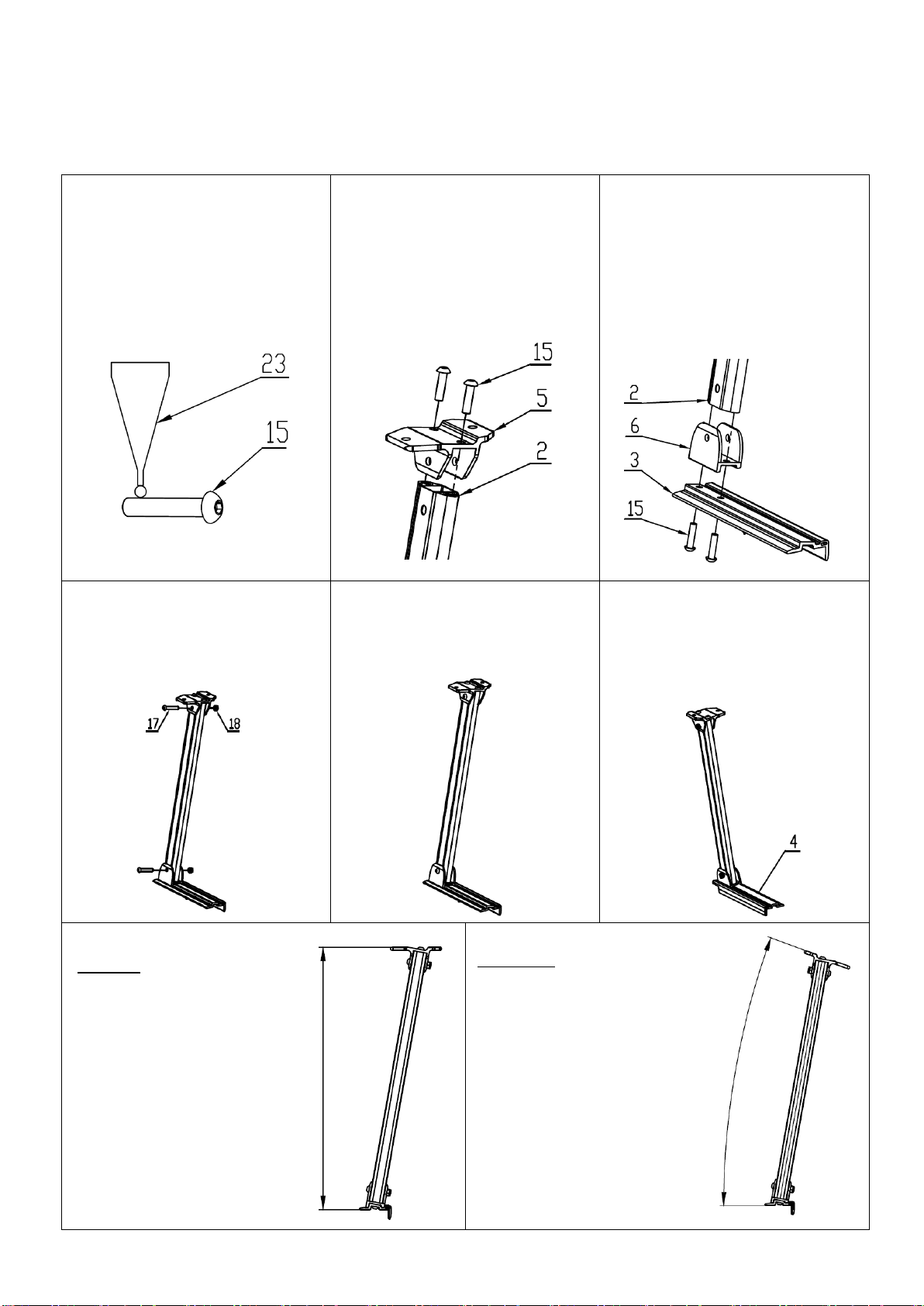

Step 1: Support Arm Assembly

①ATTENTION! All M10x40

Button Head Screws (15), require

a drop of thread glue (23), and

installation/tightening within 2

minutes of glue application.

②Connect Upper Connecting

Plate (5), on Support Bar (2), and

secure with M10x40 Button

Head Screws (15), as shown.

Note: Use Thread Glue (23), on

screws as noted in ①.

③Connect Driver Side Front

Leg Rail (3), & Lower Connecting

Plate (6), to bottom of support

bar (2), using M10x40 Button

Head Screws (15), as shown.

Note: Use Thread Glue (23), on

screws as noted in ①.

④Secure Upper (5), and Lower

(6), Connecting Plates using

M10x55 Button Head Screws

(17) and M10 Lock Nuts (18), as

shown.

⑤The front driver side support

arm is now assembled. Confirm it

is correct using the diagrams

below.

⑥Repeat this support arm

assembly procedure using the

Passenger Side Front Leg Rail

Mount (4). Then complete the

rear support arms in the same

manner.

CORRECT assembly example

for front and rear driver side

support arms.

The upper connecting base (5),

is level and parallel to rear leg

rail mount (3).

INCORRECT assembly

example for front and

rear driver side support

arms.

The upper connecting base (5),

is not level and parallel to rear

leg rail mount (3), because it is

facing the wrong direction.

6

STEP 2. Crossbar Installation

①Attach Spring Washers (20),

Flat Washers (21), to M10x25

Button Head Screws (14), and

secure to upper connecting plate

(5), with M10 Nuts (12), as

shown. Do NOT tighten. Repeat

process for all four support arms.

②Support arms are now ready

for crossbar installation.

③Slide the center channel of

the Crossbar (1), onto the M10

Nuts (12), at the top of the

support arms as shown. Only

finger tighten bolts at this stage

to allow for crossbar positioning.

④Place the rack assembly on the truck and center the crossbar on the support arms as shown. Once all

is properly positioned, the M10x25 Button Head Screws (14), can be tightened to lock the crossbar in

place on the support arms. Repeat the same process for the rear rack assembly.

Equal overhang on both sides

Driver

Side

Passenger

Side

7

STEP 3. Installation

①Attach an M10x75 Hex Head

Bolt (13), and M10 Hex Nut (19),

to each of the eight C-Clamps (7),

as shown.

②Position C-Clamp (7), close to

the base of the support arm so

that the tongue on the upper jaw

engages the groove in the Leg

Rail Mount (3), or (4). Place a

Clamp Bolt Foot (8) on the end of

the M10x75 Hex Head Bolt (13),

as shown.

③Tighten the M10x75 Hex

Head Bolt (13), and the M10 Hex

Nut (19), until entire assembly is

firmly affixed to the truck bed

rail. Install a second C-Clamp to

the same Leg Rail Mount at least

4” from the first.

④Continue the above procedure until you have installed two C-Clamps to each of the four Leg Rail

Mounts, securely affixing both crossbar assemblies to the truck bed rails as shown. WARNING! ALL

EIGHT C-CLAMPS MUST BE PROPERLY INSTALLED AS SHOWN FOR SAFE OPERATION OF THIS RACK.

Position clamps at

least 4” apart

8

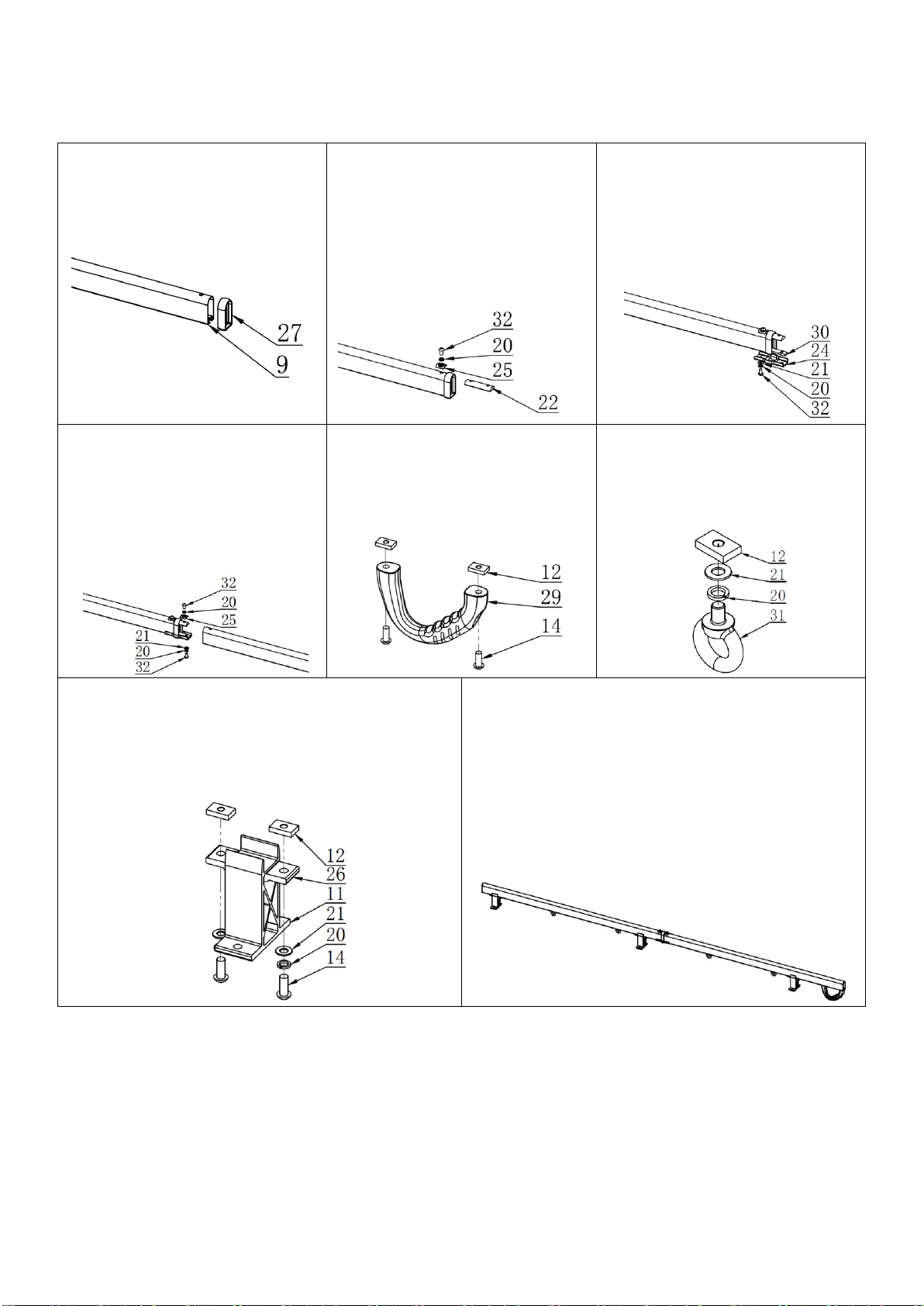

STEP 4. Side Rail Assembly and Installation

①Attach plastic sleeve (27), to

end of Side Rail (9), as shown.

②Attach Connecting Plate (22),

to end of Side Rail (9), using

M10x16 Button Head Screw (32),

Spring Washer (20), and Washer

(25), as shown.

③Attach Splint (24), and

Thread Block (30), to one end of

Side Rail (9), using M10x16

Button Head Screw (32), Spring

Washer (20), and Flat Washer

(21), as shown.

④ Attach a second Side Rail (9)

using the bolts and washers

shown below. Next, alternate

steps ⑤, ⑥ and ⑦ to achieve

side rail assembly configuration

shown in ⑧.

⑤Attach Handles (29), to end

of Side Rails as shown in ⑧

using M10x25 Button Head

Screws (14), and M10 Nuts (12).

⑥Attach Ring Bolts (31), to

bottom of Side Rails (9), using

Spring Washers (20), Flat

Washers (21), and screw M10

Nut (12).

⑦ Install Connecting Plates (26), on Connecting

Bases (11), and attach to bottom of Side Rails (9),

using M10x25 Button Head Screws (14), Spring

Washers (20), Flat Washers (21), and M10 Nuts

(12). Do not tighten until installed on crossbars.

⑧ Repeat steps ① through ⑦ to complete two

side rail assemblies configured as shown below.

Note: Connecting Bases (11), cannot be positioned

under the joints linking the two side rail sections.

9

⑨ Attach side rail assemblies to crossbars using

M10x25 Button Head Screws (14), Spring Washers

(20), Flat Washers (21), and M10 Nuts (12). Do

not tighten until both side rails assemblies are

properly positioned on the crossbars.

⑩Tighten all 16 of the M10x25 Button Head

Screws (14), on the four Connecting Bases (11),

linking the side rails to the two rear crossbars

prior to installing and securing the front-most

crossbar.

STEP 5. Completing your rack.

①Install all six Crossbar End Caps (10), and

secure in place using ST4.8×16 Phillips Head

Self-Tapping Screws (16), as shown.

②Install the four press-fit Side Rail End Caps as

shown.

10

③ Check to make sure all hardware has been securely tightened. Depending on the configuration of

your truck, your installed rack should resemble this diagram. Congratulations, your rack is now ready for

use. Please remember to haul your loads safely.

Table of contents

Other Enthuze Automobile Accessories manuals