Envent Engineering Ltd. TSF Installation and Operator’s Manual Last Updated: 26-Nov-21

6

electronics. The spectrometer uses a unique Tunable Fabry-Perot assembly that provides

wavelength scanning with high optical throughput. An advanced spectral processing algorithm

computed in the embedded electronics provides highly accurate and robust quantitative

measurements.

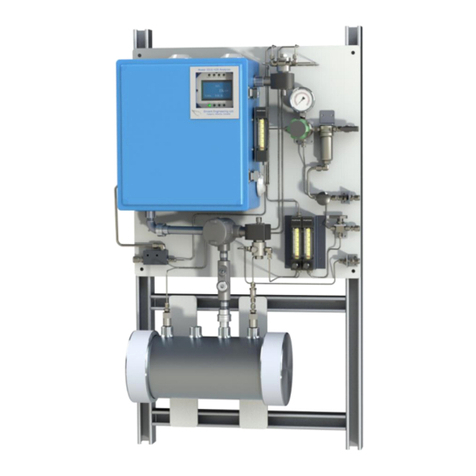

The TFS Gas Analyzer is configured and calibrated for a specific wavelength analysis region(s)

depending on the application for which it is intended. It is designed to be a dedicated on-line

monitoring system that only requires periodic on-site span verification and zeroing every three

months. The specific system configuration and calibration is denoted by a Factory Serial Number

that can be found in the Final Span Calibration Verification Sheet delivered with the analyzer.

Example applications of the TFS Analyzer include:

•Hydrocarbon gas composition monitoring

•Petrochemical process monitoring

•Specialty and chemical gas process and blending monitoring

•Catalysis and combustion process monitoring

Measurement Principle:

When a gas sample is introduced into the gas cell, the light radiation provided by a broadband

light source is partially absorbed by the gas species present. The light absorption occurs at

specific frequencies and magnitudes depending on the gas compound and the concentration of

that compound. The TFS Gas Analyzer spectrometer module scans the wavelength and measures

the true absorption spectra and compares them with the pre-loaded calibration spectra. The on-

board analysis algorithm computes the predicted gas concentrations in real-time.

In principal, the absorption spectrum of each compound is unique which acts as a “fingerprint”

for identification or speciation analysis. In addition, the magnitude of the absorption is a function

of the number of molecules of the gas. With a known path length, pressure, and temperature,

the magnitudes of the absorption spectra are then used to compute volumetric concentrations.

This

first principle

based technique provides accurate and robust measurements with minimal

span and baseline drifts.

The TFS Gas Analyzer employs an internal pressure transducer to measure the sample pressure

in real-time enabling pressure variation corrections. The flow cell is heated to a constant

temperature (default value is 60oC) with a sample preheat module to maintain both sample and

optical sensor temperature at a constant calibrated temperature, thereby ensuring measurement

accuracy and stability despite sample and environmental variations.

Technical Specifications:

+/- 0.2% of full scale per reading

Zero Drift <0.2% of full scale per month

5 – 95% RH non-condensing

(a)

Sample Flow Rate 100 – 1000 cc/min (a)