Envent Engineering Ltd. 2/2

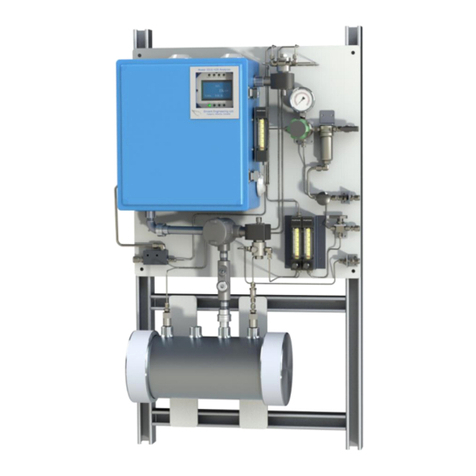

Step 3. Sample conditioning system

CAUTION: Disassembly of the pressure regulator and solenoids in the field is not advised.

Consult the factory if the regulator or solenoid appears contaminated.

a. Remove filter elements from filter housings and discard

b. Remove all sample conditioning system components and soak in cleaning solution

c. Ensure valves are fully open when cleaning

d. Flush sample components with fresh water

e. Rinse with isopropyl alcohol

f. Blow dry with clean compressed air or fuel gas

g. If the any clear (Tygon) tubing appears discolored, replace the tubing

h. Tubing on humidifier should be replaced if it appears contaminated

Step 4. Re-assemble Stainless Steel Tubing to analyzer according to analyzer drawing (refer to back

of manual)

Step 5. Once sample conditioning system has been re-assembled, apply calibration gas to the analyzer,

refer to section E.2.

Step 6. Adjust gain to indicate value from calibration certificate

Step 7. Gains for streams should be ± 2.00 from factory cal sheet or last calibration.

If the reading is not with in range, then the analyzer sample conditioning system may

need further cleaning. Please consult factory.

Envent Engineering Ltd. 7060 Bay E Farrell Road S.E. Calgary, Alberta, Canada,

T2H 0T2, Tel: 403.253.4012 | Fax: 403.253.4016

Email: info@envent-eng.com, Web: www.envent-eng.com

For further information, or a copy of our most recent cleaning manual, please visit us at www.envent- eng.com.

Envent Engineering Ltd. reserves the right to change product design and specifications at any time without prior

notice.

All products carry a one year limited warranty from the date of start-up or 18 months from date of shipment,

whichever occurs first, F.O.B. the factory, against defective parts or workmanship.