Envent 330S-Ex User manual

Envent Engineering Ltd.

Hydrogen Sulfide Analyzer

Model 330S-Ex

Model 330SDS-Ex

User's Manual

Revision 1

21 Jan 2022

Table of Contents

INTRODUCTION ................................................................................................................................... 1

Contacting Envent Engineering Ltd .................................................................................................... 1

Canada Office: (Main)..................................................................................................................... 1

USA Office:..................................................................................................................................... 1

China Office:................................................................................................................................... 1

Warranty & Liability Statements ......................................................................................................... 2

Limitation of Warranty..................................................................................................................... 2

Disclaimer .......................................................................................................................................... 2

Key Symbols ...................................................................................................................................... 3

Warnings & Cautions.......................................................................................................................... 3

Warning & Cautions for 330S-Ex & 330SDS-Ex H2S Analyzers ...................................................... 3

Analyzer Specifications ...................................................................................................................... 6

PRINCIPLE OF OPERATION................................................................................................................ 7

Physical Reaction............................................................................................................................... 7

Analysis Cycles .................................................................................................................................. 8

Dual Sensor Analysis cycle (SDS): ............................................................................................... 10

INSTALLATION .................................................................................................................................. 11

Receiving the Analyzer..................................................................................................................... 11

Unpacking the Analyzer................................................................................................................ 11

Standard spare parts for 330S-Ex H2S analyzers: ........................................................................ 11

Installation procedure & Start-up ...................................................................................................... 12

Installation Requirements................................................................................................................. 13

Electrical Requirements ................................................................................................................ 13

Location for the System ................................................................................................................ 13

Earth Connections, Entry Specifications & Space Requirements .................................................. 14

Sample Point Selection................................................................................................................. 21

Sample inlet & sample sweep ....................................................................................................... 21

Vent line ....................................................................................................................................... 21

Sample Volume & Flow Rate ........................................................................................................ 22

Installation of Analyzer Components ................................................................................................ 23

Analog Outputs............................................................................................................................. 23

Sample Chamber.......................................................................................................................... 24

Humidifier Unit .............................................................................................................................. 26

Eductor Block ............................................................................................................................... 28

OPERATION & CONFIGURATION ..................................................................................................... 30

Analyzer Display Interface................................................................................................................ 30

CALIBRATION PROCEDURES .......................................................................................................... 32

H2S Gas Calibration ......................................................................................................................... 32

Re-zero Sensor Procedure............................................................................................................... 33

MAINTENANCE .................................................................................................................................. 35

H2S Sensing Tape Change Procedure ............................................................................................. 35

Sample Conditioning System Cleaning Procedure ........................................................................... 36

Material List .................................................................................................................................. 36

Procedure..................................................................................................................................... 36

TROUBLESHOOTING ........................................................................................................................ 38

APPENDICES ..................................................................................................................................... 48

Recommended Spare Parts List....................................................................................................... 48

Sealing Compound: For sealing fittings in Hazardous Locations ...................................................... 49

Safety Data Sheet for H2S Sensing Tape ......................................................................................... 61

List of Figures

Figure 1. H2S Analyzer Principle of Operation Diagram ......................................................................... 8

Figure 2. H2S Analysis Cycle ................................................................................................................. 9

Figure 3. Enclosure Entries & Earth Connections ................................................................................ 14

Figure 4. Space Requirements & Entry Specifications for Model 330S-Ex (No Backpan) .................... 15

Figure 5. Space Requirements & Entry Specifications for Model 330SDS-Ex (No Backpan) ............... 16

Figure 6. Space Requirements for 330S-Ex with Standard Backpan (Size may vary) .......................... 17

Figure 7. Space Requirements for 330SDS-Ex with Standard Backpan (Size may vary) ..................... 18

Figure 8. Space Requirements for 330S-Ex with Total Sulfur Option (Backpan size may vary)............ 19

Figure 9. Space Requirements for 330SDS-Ex with Total Sulfur Option (Backpan size may vary)....... 20

Figure 10. Recommended Venting for 330S-Ex (Same as the 330SDS-Ex H2S Analyzer)................... 22

Figure 11. AO 4-20 mA Output Wiring Options .................................................................................... 24

Figure 12. Sample Chamber (Exploded View) ..................................................................................... 25

Figure 13. Envent's Humidifier Unit for 330S-Ex & 330SDS................................................................. 27

Figure 14. Humidifier Unit Installed in a 330S-Ex H2S Analyzer ........................................................... 28

Figure 15. Eductor Block (Venturi Effect) ............................................................................................. 28

Figure 16. 330S-Ex or 330SDS-Ex Display.......................................................................................... 30

Figure 17. 330S-Ex & 33SDS-Ex H2S Sensing Tape Change Procedure............................................. 35

List of Tables

Table 1. 330S-Ex 330SDS-Ex H2S Analyzer Specifications .................................................................. 6

Table 2. Sample Volume and & Flow Rate........................................................................................... 22

Table 3. Aperture Strips & Ranges ...................................................................................................... 26

Table 4. Display Button Description/Function....................................................................................... 30

Table 5. Display LED Description/Function .......................................................................................... 31

Envent Engineering Ltd. Page 1 Revision 1

INTRODUCTION

This manual provides all the necessary information to install, operate and

maintain the 330S-Ex and 330SDS-Ex model H2S Analyzer units. This manual is

intended for all technical level users.

The Envent 330S-Ex and 330SDS-Ex H2S Analyzer is a uniquely rugged and

simple design that utilizes lead acetate-based detection which provides a linear

and interference-free output of H2S concentration. This analyzer can measure a

wide range of hydrogen sulfide concentrations from parts per billion (ppb)

concentrations to parts per million (ppm) concentrations. With the addition of a

dilution sample system, it can read high concentrations in percentage up to

100%. There are other options available such as the sample system for H2S

analysis in liquids or the addition of a hydrogen reaction furnace for total sulfur

measurements.

Throughout this document will be referring to the models 330S-Ex. However, the

information applies equally to the 330SDS-Ex (Dual sensor), unless otherwise

stated. To clarify, the difference between an "S" model and a "SDS" model

analyzer is the second sensor the "SDS" has to measure H2S giving it the

capability to measure H2S from two different samples at the same time.

Contacting Envent Engineering Ltd

This manual covers most of the important information the user is going to need to

install, operate and maintain the 330S-Ex & 330SDS-Ex Analyzers. If more

information is required, you can contact us at:

Canada Office: (Main)

Toll Free: 1 (877) 936 - 8368

Tel: (403) 253 - 4012

Fax: (403) 253 - 4016

Email: info@envent-eng.com

Hours of operation: Monday to Friday – From 8:00 am to 4:30 pm (Mountain

Time Zone). Offices closed on statutory holidays.

USA Office:

Tel: 1 (713) 567 - 4421

China Office:

Tel: (86) 138 - 0119 - 1148

For further information on our products and most updated manuals/product

catalog please visit: www.envent-eng.com

Envent Engineering Ltd. Page 2 Revision 1

Warranty & Liability Statements

Products manufactured and supplied by Envent Engineering Ltd unless

otherwise stated are warranted against defects in materials and workmanship for

up to 18 months from the date of shipment or 12 months from date of start-up,

whichever occurs first. During the warranty period the manufacturer will, as its

option, either repair or replace products, which prove to be defective.

The manufacturer or its representative can provide warranty service at the

buyer's facility only upon prior agreement. In all cases the buyer has the option of

returning the product for warranty service to a facility designated by the

manufacturer or its representatives. The buyer shall prepay shipping charges for

products returned to a service facility, and the manufacturer or its representatives

shall pay for return of the products to the buyer. The buyer may also be required

to pay round-trip travel expenses and labour charges at prevailing labour rates if

warranty is disqualified for reasons listed below.

Limitation of Warranty

The foregoing warranty shall not apply to defects arising from:

•Improper or inadequate maintenance by the user;

•Improper or inadequate unpacking or site preparation/installation;

•Unauthorized modification or misuse;

•Operation of the product in unfavorable environments, especially high

temperature and/or high humidity;

•Corrosive or other damaging atmospheres or otherwise outside

published specifications of analyzer.

Envent Engineering Ltd carries no responsibility for damage cause by

transportation or unpacking, unless otherwise specified in the incoterms.

Extended warranty may be available with certified start-up. Contact Envent

Engineering Ltd for details.

Envent Engineering Ltd reserves the right to change the product design and

specifications at any time without prior notice.

Disclaimer

No other warranty is expressed or implied. The manufacturer specially disclaims

the implied warranties of merchantability and fitness for a particular purpose.

The sole remedy of the buyer shall in no case exceed the purchase price of the

analyzer.

The manufacturer shall not be liable for personal injury or property damage

suffered in servicing the product. The product should not be modified or repaired

in a manner at variance with procedures established by the manufacturer.

Envent Engineering Ltd. Page 3 Revision 1

Envent Engineering Ltd is not resposable for the proper disposal of the H2S

sensing tape which contains lead acetate. It is the responsibility of the end user to

properly dispose the tape according to their local or national regulations. Envent

Engineering offers to take back used H2S sensing tape for its proper disposal if

needed, please contact us if this service is required. For more information on the

H2S sensing tape, please refer to "Safety Data Sheet for H2S Sensing Tape" on

page 61.

Key Symbols

The following symbols are used throughout this manual. They are intended to

draw attention to important information.

Description of hazards that could result in major injury or death.

Description of hazards that could result in minor injury or property damage.

Description of important information regarding safety of personal and/or property.

Caution: hot surface.

Description of useful information to help understand a concept.

Warnings & Cautions

This section covers all warnings and cautions for the 330S-Ex and 330SDS-Ex

H2S analyzers. Please read and understand all statements as they are for your

own safety when installing, operating and maintaining the analyzer(s). Some of

these statements are also noted throughout the manual when relevant.

Warning & Cautions for 330S-Ex & 330SDS-Ex H2S Analyzers

Do not disconnect equipment unless power has been switched off or area is

known to be non-hazardous.

Turn off power before servicing. Ensure breakers are off before connecting or

disconnecting power supply.

Envent Engineering Ltd. Page 4 Revision 1

Incorrect configuration of the analyzer may cause incorrect operation. Injury

and/or damage to facilities may occur. Check analyzer's functionality after

configuration changes have been made.

Substitution of components may impair intrinsic safety and suitability for Class I,

zone 1.

Electrostatic Hazard – Backpan and Certification nameplate must be cleaned

only with a damp cloth to prevent static charging hazard.

The analyzer should be mounted in an area in which it is not exposed to

vibration, excessive pressure, temperature and/or environmental variations.

Disassembly of the pressure regulator and solenoids in the field is not advised.

Consult Envent Engineering Ltd if the regulator or solenoid appears

contaminated.

Before resuming line pressure, be sure that all port connections, sample sweep

and sample conditioning system are securely installed.

All connections must be leaktight to ensure the effectiveness of the analyzer as

well as safety. The user is solely responsible for the product selection, safety and

warning requirements for the application. If the equipment is used in a manner

not specified by Envent Engineering Ltd, the protection provided by the

equipment may be impaired.

Do not use solvents, brake cleaners, soaps, detergents or rubbing alcohol to

clean up analyzer or sample system.

This unit may require a disconnect device rated 24 VDC and 5A max. It must be

protected by a circuit breaker rated 24 VDC and 5A max, and it is to be installed

in accordance with local electrical codes.

This unit may require a disconnect device rated 240 VDC and 5A max. It must be

protected by a circuit breaker rated 240 VDC and 5A max, and it is to be installed

in accordance with local electrical codes.

Envent Engineering H2S Sensing Tapes are suitable for use, if stored in the

original sealed package, for 10 years fron date of manufacture. Tapes should be

stored in a coll dry location. If the seal on the package has been broken in

storage, the H2S Sensing Tape should be discarded.

Open circuit before removing cover.

Ensure that the analyzer received is suitable for the electrical classification of the

installation site:

•The 330S-Ex & 330SDS-Ex are designed for:

II 2 G Ex db ib op is IIB+H2 T3 Gb (Check Analyzer Nameplate)

Envent Engineering Ltd. Page 5 Revision 1

Tape enclosure (blue chassis) knob has a capacitance of 119.7 µF, user must

determine suitability in the specific application.

The glass window on the XP enclosure must remain installed in order to maintain

area classification.

Seals not poured. Pour seals before energizing the circuit (See "Sealing

Compound: For sealing fittings in Hazardous Locations"on page 49 for further

details).

Ensure the setscrews provided for the XP motor box and XP electronic enclosure

window are tight and secured. This also applies for total sulfur enclosure caps.

Analyzer may utilize an optional CCS, Model 646 Series pressure switch located

on the side of the XP enclosure:

•Dual seal, MWP 500psi

•Annunciation is visible leakage from the pressure adjustment cover

(flow from this cover can indicate the possibility that a failed primary

seal condition could exist in the pressure switch).

If the 330S-Ex or the 330SDS-Ex has a total sulfur enclosure, ensure its caps are

engaged to a minimum of 12 threads.

No modifications to the flamepaths are permitted without consultation with the

controlled documentation.

Cables used in the equipment must be rated to a minimum ambient of 70 °C

Only suitably approved Ex db IIB+H2 Gb cable glands, blanking elements or

thread adapters with a service temperature rating of 0 °C to 50 °C to be used.

Maximum inlet pressure (after sample conditioning system) of 30 psig.

Repair of the flamepaths are not intended.

For IS system installation drawing (H2S-Ex-57), contact Envent Engineering.

Total Sulfur Furnace reaches a temperature of up to 900 °C internally after 1 hour

on. Do not touch external surface as it can reach up to 150 °C. Allow enclosure 1

hour after powering down the analyzer to cool down before servicing.

Envent Engineering Ltd. Page 6 Revision 1

Analyzer Specifications

Analyzer Specification

Measurement

Method

ASTM D4084 - 07: Standard Test Method for Analysis of Hydrogen Sulfide

in Gaseous Fuels (Lead Acetate Reaction Rate Method)

Ambient

Temperature

0-50 °C (standard) consult factory for other requirements, 0 to 90% humidity

(non-condensing)

Power

12-24 VDC @ less than 3W

Or, 100-240 VAC 50/60 Hz, 5W,

(300W when total sulfur option is included)

Electrical

Certification

II 2 G Ex db ib op is IIB+H2 T3 Gb

ATEX CERTIFICATE NUMBER; ITS17ATEX108436X

IECEx CERTIFICATE NUMBER; IECEx ITS 17.0032X

Output Ranges

Standard ranges are between 10-100 ppb and 0-100 ppm

Response Time

20 seconds to 90% of step change

Accuracy

±1.5% of full range on channel 1 (for SDS Models, channel 2 has an

accuracy of ± 2.0%).

For dilution (option): ±2.5%

For Total Sulfur (Option): ±2.0%

For PPB (Option): Based on "base noise average"

Display

Graphic Liquid Crystal Display; menu is scrolled by internal button or

magnetic wand (330S)

Outputs

Two 4-20mA outputs (loop power required), optional 4-20mA powered

output boards are available

Serial Communication:

(1) RS-232 Modbus protocol

(3) RS-485 Modbus protocol (One RS-485 for remote display option)

Ethernet port as an optional feature

4 SPDT relays (120 VAC 5A maximum)

4 solid state solenoid drivers

Optional Features

Total Sulfur

Utilized when all sulfur compounds need to be measured. A Total sulfur

reaction furnace is added which allows the analyzer to measure total sulfur

Dilution Sample

System

Utilized when the analyzer needs to measure ranges above 100 ppm. A

permeable membrane dilution system

Parts Per Billion

Utilized when analyzer requires to read in parts per billion (<1 ppm)

Low Tape Sensor

Utilized when an alarms is required when the H

2

S sensing tape needs to be

changed

Low Pressure

Switch

Utilized for alarming when sample pressure drops below 10 PSI

AO Powered

Boards

Utilized for loop-powered analog outputs

Expander AO

Board

Utilized when more than two analog outputs are required

Ethernet Port

Utilized for TCP/IP communication capabilities

Auto Calibration

Utilized to initiate a calibration based on time of day or manually

Table 1. 330S-Ex 330SDS-Ex H2S Analyzer Specifications

Envent Engineering Ltd. Page 7 Revision 1

PRINCIPLE OF OPERATION

Physical Reaction

Envent's models 330S-Ex and 330SDS-Ex H2S analyzers use ASTM D4084 –

07: Standard Test Method for analysis of hydrogen sulfide in gaseous fuels (Lead

Acetate reaction rate method). This method uses lead acetate impregnated

paper. Throughout this document the term lead acetate tape will be written as

"H2S sensing tape". Refer to "Safety Data Sheet for H2S Sensing Tape" on page

61 for safety information on the H2S sensing tape and "Disclaimer" on page 2.

The H2S sensing tape reacts when in contact with hydrogen sulfide by the

compound relationship shown below. This tape does not react to any other sulfur

compounds in the gas stream. This makes it free from interference when more

than one sulfur compound is present in the sample stream. The H2S reaction is

visibly evident by a brown stain directly on the H2S sensing tape.

COOH

CHPbSCOOCHPbSH

OH

3232

2)( 2+ →+

The electronics built into the models 330S-Ex and 330SDS-Ex have been

programmed to measure the rate of darkening over time which, in turn, gives the

hydrogen sulfide concentration level. When no H2S is in contact with the H2S

sensing tape, the analyzer sensor reads 1000 mV (+/- 100 mV).

The sensor block has a LED and a photodiode detector. The LED emits a red

beam of light which is reflected off of the H2S sensing tape to the photodiode

which detects the light intensity. The darker the H2S sensing tape becomes when

in contact to H2S, the less light the photodiode detector receives reducing the

millivolt value, which in turn, increases the H2S value. The "SDS" models

uniquely measures rate of change on both sides of the H2S sensing tape,

allowing for simultaneous readings of two separate samples.

Envent Engineering Ltd. Page 8 Revision 1

Figure 1. H2S Analyzer Principle of Operation Diagram

Figure 1 above shows a flow and pressure regulated of a filtered sample gas

passing through the humidifier into the sample chamber. An aperture in the

sample chamber, which differs in sizes depending on the application, allows the

gas to come in contact with the H2S sensing tape creating a brown stain.

Flow and pressure are the most important variables when measuring H2S and

must be kept at a constant state for the analyzer to measure H2S properly.

Pressure should be kept at a constant 15 psig. The lowest pressure found to be

tolerable for proper H2S measurement is 0.5 psig. Flow must be kept at a

constant flow of 2 cm (between 100-200 cc/min). A change in flow of +/- 1 cm

affects the reading by 10% of full range.

Analysis Cycles

The analysis of the color rate of change on the H2S sensing tape is measured in

analysis cycles. An analysis Cycle lasts up to a maximum of 720 seconds (12

minutes).

Do not change the Maximum Analysis Time, consult Envent Engineering Ltd.

Once an analysis cycle is complete, the motor moves the H2S sensing tape

giving the sensor block new tape surface area to start the analysis again. In

normal operation, if the analyzer is being exposed to H2S within its range, the

Envent Engineering Ltd. Page 9 Revision 1

analysis cycle should last between 150 to 210 seconds (1.5 to 2.5 min); the cycle

lasts 720 seconds if no H2S is present.

Figure 2. H2S Analysis Cycle

Figure 2 shows a complete analysis cycle from when the motor has advanced

the H2S sensing tape from a previous analysis (1), to the end of the current

analysis (4). Once the H2S sensing tape has finished moving and new tape

surface area is exposed, the reflection of light from the LED to the photodiode

detector is at its maximum and results in a voltage output from the sensor block

of 1000 mV (+/- 100 mV). This voltage is captured by the analyzer and it is

referred to as the "Zero Voltage". The zero voltage will vary for each surface area

of the H2S sensing tape and will represent the starting point for the H2S reading

for that cycle.

From stage (2) to (4) the H2S value starts increasing as the millivolt value drops

from exposure to H2S. This stage is called "RRA Analysis". The RRA stands for

Rapid Response Algorithm and it is the instantaneous H2S readings calculated

every 67 ms. As the H2S sensing tape darkens, the RRA value starts going up

every second. Although the RRA values are calculated almost instantaneously,

they are not as accurate as the final reading obtained at the "Concentration

Calculation" stage (3) to (4). However, RRA values can be used as a trigger

alarms setpoint in case the application requires a rapid response time (less than

the RRA Analysis completion). The first part of the RRA Analysis (2) to (3)

completes when the mV value drops 100 mV. Once it drops 100 mV, stage (3) to

(4) "Concentration Calculation" starts.

On this stage, the H2S slope is optimal for calculating the final H2S value for that

Cycle. Algorithms are used by the controller board to calculate as accurately as

Envent Engineering Ltd. Page 10 Revision 1

possible the H2S final value. Once the final value is obtained, it will stay at that

value (shown in the display and 4-20 mA analog outputs) until the next cycle has

finished and updates the H2S current reading. This stage will always be 1/5 of the

amount of time it takes stage (2) to (3) to complete. Thus, if stage (2) to (3) took

600 seconds, then stage (3) to (4) will take 120 seconds.

It is important that the analyzer is used for its calibrated H2S range. Do not use

this unit for an application that will require readings outside of its calibrated

range. This will cause the H2S sensing tape to run out faster and may cause less

accurate readings. The range is determined by the aperture strip in the sample

chamber. For more information analyzer ranges, refer to "Aperture Strip" on page

25.

Dual Sensor Analysis cycle (SDS):

Dual sensor analyzers have two sensors that read H2S from two different

samples at the same time, e.g. Sensor 1: 0-20 ppm H2S Sensor 2: 0-200 ppm

H2S. The analysis cycle process is the same per sensor as explained earlier in

this section; however, some extra algorithms have been implementing to help

with the interaction between the two sensors and their analysis cycles' timing.

Both analysis cycles for each sensor will always start at the same time. When the

motor moves and new H2S sensing tape area is exposed, a new analysis cycle

has started for both sensors. However, the analysis cycles from each sensor will

finish at different times. Either sensor 1 or sensor 2 will finish its analysis cycle

first. Regardless of which sensor finishes first, it will wait for the other sensor to

complete its analysis cycle. Once both sensors have completed their analysis

cycles, the motor will move and new H2S sensing tape area is exposed for a new

analysis cycle.

It is important to clarify that when the first sensor has finished its analysis cycle,

even when it is waiting for the second sensor to complete its analysis cycle, it

immediately updates any outputs associated with that sensor (Analog output 4-

20 mA, alarms, display H2S value, etc.).

Envent Engineering Ltd. Page 11 Revision 1

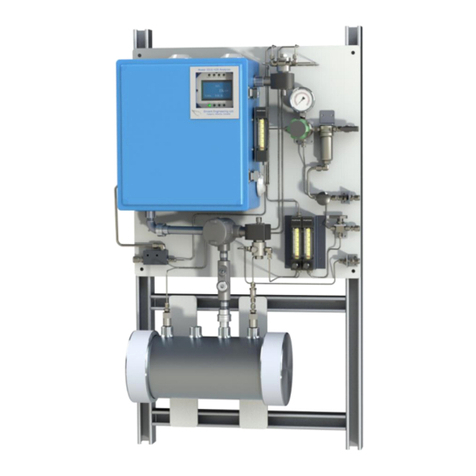

INSTALLATION

Receiving the Analyzer

Inspect the packaging for external damage right after is received. If there is any

physical damage, please contact Envent Engineering Ltd and request that the

carrier's agent be present when the analyzer is unpacked. If a disagreement

arises the incoterms agreed by the seller and the customer will overrule any

dispute.

Unpacking the Analyzer

If damage is found in the shipping container see previous section "Receiving the

Analyzer".

1. Open the shipping container and remove the foam packing or other packing

materials from the shipping box.

2. Take out the analyzer and the start-up kit.

The 330S-Ex and 330SDS-Ex H2S analyzer with a standard Sample

conditioning system weights approximately 105 lb (48 kg). Unpacking and

transporting requires a minimum of two persons.

3. Make sure the start-up kit is complete (refer to list below). For some special

and more complex analyzers, there might be extra parts in the start-up kit.

Standard spare parts for 330S-Ex H2S analyzers:

1. 330S-Ex/330SDS-Ex Customer Binder

•Customer Manual(s) and Addendums

•Factory Calibration Certificate

•Factory Configuration

•Drawing Package

•Cal Gas Certificate(s)

2. USB flash drive (containing all documentation)

3. 300' (91.44 m) H2S Sensing Tape. Part No. 330133XS

4. 1 Liter Analyzer Fluid. Part No. 330129

5. Funnel

6. 330S-Ex Serial Comm. External Cable (USB to Mini USB). Part No. 600002

7. Humidifier (uninstalled). Part No. 330061 (Part No. 330061D for SDS)

8. Bolts For explosion proof enclosure (x22)

9. Resin preparation to pour seals

Envent Engineering Ltd. Page 12 Revision 1

Installation procedure & Start-up

The following steps should be followed for proper installation and start-up of the

analyzer. Refer to sections "Installation Requirements" on page 13 and "Installation of

Analyzer Components" on page 23 for more information.

1. Unpack the analyzer and check for damages.

2. Ensure the analyzer power supply and range are suitable for the installation

location.

3. Check that the hazardous location rating is suitable for the installation location.

4. Ensure that the selected installation site provides adequate room for maintenance

and repair.

5. Select an installation location close to the sample point.

6. Bolt the analyzer to the wall with the H2S sensing tape drive at approximately eye

level.

7. Wire the power, analog outputs and discrete outputs from the analyzer.

8. Tube the Sample inlet, sample sweep, and sample vent lines from the analyzer.

9. Ensure there is enough H2S Sensing tape.

10. Install the Humidifier, if applicable. Ensure there is enough 5% acetic acid or

distilled water in the humidifier.

11. Apply power to the analyzer. The display will illuminate and the H2S sensing tape

will advance for a few seconds.

12. Press the menu button until mV is displayed. Check that the mV reading is 1000

mV (± 100 mV).

There are two mV values shown in the display, the "mV Zero" and the "mV"

Values. Check for the "mV" Values.

For the SDS models, check for "Sensor 1 mV" and "Sensor 2 mV".

13. Make sure the sample inlet valve, sample sweep valve, and pressure regulator are

completely closed. The pressure regulator is completely closed when the knob

handle is counterclockwise.

14. Turn on the sample gas flow to the conditioning sample system and then open the

sample inlet valve.

Envent Engineering Ltd. Page 13 Revision 1

15. Open the sweep valve slightly and adjust pressure regulator to 15 psig and the

flow meter to 2.0.

16. Allow twenty minutes for the analyzer to stabilize. The analyzer calibration can be

verified if calibration gas is available. If no calibration gas is available, the analyzer

may be operated using the factory calibration settings until calibration gas is

available.

Installation Requirements

Electrical Requirements

The 330S-Ex/330SDS-Ex H2S analyzer's controller board can either be 110-

240VAC or 10-32VDC. Consult the analyzer nameplate attached to it or factory

calibration certificate for more information.

Certification nameplate shows the voltage range at which the controller board can

withstand (e.g., 120 – 240 VAC), however, when using external devices which

are powered by the controller board (e.g., solenoids), that voltage range no

longer applies and only the external device’s voltage rating shall be used; e.g.,

120 VAC rated solenoid, the analyzer shall be powered with only 120 VAC and

not 240 VAC.

The power consumption for a VDC analyzer is 3 Watts and for a VAC is 5 Watts.

For the total sulfur option the power consumption 300 Watts.

Ensure the setscrews provided for the XP motor box and XP electronic enclosure

window are tight and secured. This also applies for total sulfur enclosure caps.

Cables implemented in the equipment must be rated to a minimum ambient of 70

°C

Only suitably approved Ex db IIB+H2 Gb cable glands, blanking elements or

thread adapteors with a service temperature rating of 0 °C to 50 °C to be used.

Location for the System

First to be considered is the electrical area classification the analyzer will be

installed in. Make sure the analyzer meets the requirements for the installation

site. These analyzers are to be installed in Zone 1 areas.

The 330S-Ex and 330SDS-Ex H2S analyzer should be mounted in an area in

which it is not exposed to vibration, excessive pressure, temperature and/or

environmental variations. The ambient temperature range for the analyzers is 0

to 50 Degree Celsius.

Envent Engineering Ltd. Page 14 Revision 1

Earth Connections, Entry Specifications & Space Requirements

Figure 3. Enclosure Entries & Earth Connections

Envent Engineering Ltd. Page 15 Revision 1

Figure 4. Space Requirements & Entry Specifications for Model 330S-Ex (No Backpan)

This manual suits for next models

1

Table of contents

Other Envent Measuring Instrument manuals

Envent

Envent 132S User manual

Envent

Envent 330S User manual

Envent

Envent 131S User manual

Envent

Envent TFS1 User manual

Envent

Envent 330 Configuration guide

Envent

Envent 330S User manual

Envent

Envent 131S Mounting instructions

Envent

Envent 331S User manual

Envent

Envent 131S-T4 User manual

Envent

Envent 330S User manual

Popular Measuring Instrument manuals by other brands

SureShot

SureShot PINLOC 6000iPSM user manual

thermastor

thermastor Quest Sentry user guide

Arun Microelectronics LTD

Arun Microelectronics LTD PVU3 User instructions

LineEye

LineEye LE-8600X quick start guide

KEPCO

KEPCO INTELLECT-69 Series Installation & operating instructions

Delta-T Devices

Delta-T Devices WET150 quick start guide