Envirco MAC 10 MDR16 User manual

MDR16

MAC 10®Remote Mount Fan Controller

INSTALLATION, OPERATION, AND MAINTENANCE MANUAL

ENVIRCO Technical Support: 800-884-0002

2

Installation & Operation Manual

Innovators in Clean Air Technology | www.envirco.com

MDR16

MAC 10® Remote Mount Fan Controller

APPLICATION

The MDR16 MAC10® Remote Mount Fan Filter Controller allows manual adjustment of industry standard 0-10VDC automation

signals to control up to 16 ENVIRCO ECM based FFUs. The MDR16 provides local or remote adjustment of the FFU output from

1% to 100% of the motor’s control range. A signal lamp on the control continuously ashes out the ow index. Therefore, other

instruments are not required to read the ow index (%). The MDR16 can be congured for 0-10VDC, a 2-10VDC or a 4-20mA

automation signals. If desired, the MDR16 also can be used for stand-alone manual control by internal jumper conguration.

Signal Lamp Feedback

The MDR16 green front panel lamp continuously indicates the ow index setting for the entire group of FFUs being controlled. After

a pause, the lamp ashes out the tens digit, then the units digit of a number between 1 and 99. Long ashes represent the tens digit

and short ashes represent the units digit. For example, a ow index of 23 ashes two longs, then three shorts. Two extra-long

ashes indicate a ow index of 0. An extra-long ash and ten short ashes indicate a ow index of 100. The lamp ashes the signal

that was present when the ash sequence started.

Operating Control Modes

The MDR support group control of up to 16 ECM based ENVIRCO FFUs in two different modes, including a pure manual mode and

a mode where the FFUs’ performance is slaved to an external automation control input.

Pure manual mode is a simple control capability that is enabled when internal Jumper #3 named Manual Override is present.

With Jumper #3 present, the front panel adjust screw is the only way to control the FFU performance index. With a small straight

screwdriver to turn the front panel accessible potentiometer, the user can adjust the FFU performance index up or down. The Signal

Lamp will provide real-time feedback of the performance index set-point.

Alternatively, if internal Jumper #3 is not present, automatic mode is selected, and the potentiometer has different functions. In

automatic mode (no Jumper #3 present), the potentiometer will control the FFUs’ performance when the automation signal is not

present. This feature allows adjustment of the FFUs on a new installation until automation is installed. Automation will nally start/

stop the motor ve times, and LSO will be disabled. Turning the potentiometer always overrides any automation signal, manually

controlling the FFU for 15 minutes. Control reverts to any connected automation signal when the 15 minute adjust timer expires.

Cycling the power early will instantly reset to automatic mode if required.

There are two additional cases in automatic mode for the adjust function that are set by jumpers. In automatic, the potentiometer is used

to set the FFU default performance level when the automation signal is absent or the automation signal is outside its normal control range.

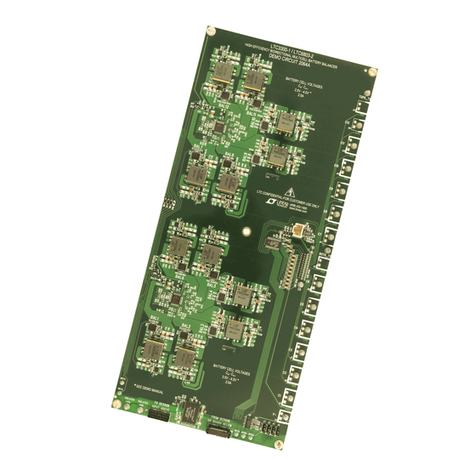

Internal Jumper Options

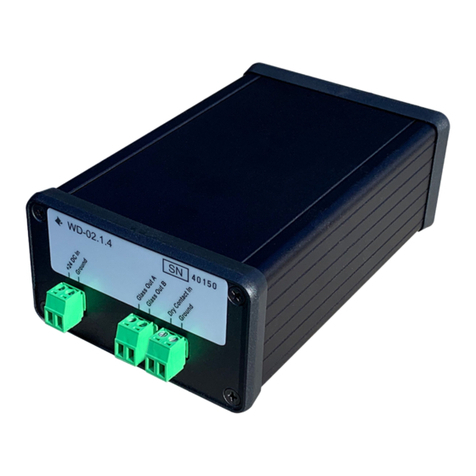

There are ve congurable jumpers inside the MDR16

control box. There is a block of four jumpers: Jumpers

#1, #2, #3 and #4, near the top left corner of the

printed circuit board. Conguration of Jumpers #1-4 is

accomplished by placing the jumper on or removing the

jumper. These jumpers should not be congured while

the MDR is powered on. A white dot on the printed

circuit board denotes Jumper #1.

Jumper #1, if present, congures the MDR16 to provide

a 10 second spin-up delay for the FFUs, in which the

motor or motors will operate at a minimum speed for

the rst 10 seconds after power-up.

Jumper #2, if present, congures the MDR16 for

automated input control.

Jumper #3, Manual Override, permanently enables

Lost Signal Override and allows use in manual mode.

Jumper #4 has two functions. It sets the control input

range/mode and enables stopping the FFUs if the

Jumpers 1-4

Jumper 5

Go Vspd Vcom Signal Com Neu. 24Vac

1

2

3

4

ON

ON

ON

OFF

ECM

Control

Automation

Input

3

Installation & Operation Manual

Innovators in Clean Air Technology | www.envirco.com

control signal is below the operating range. If Jumper #4 is off, then the control input range is 0-10VDC for a 1% to 100% ow index.

In this mode, the FFUs can only be shut off by disconnecting power to the MDR16. Important: If the MDR16 is controlling more than

eight ENVIRCO ECM FFUs, then this jumper must be removed.

If the MDR16 is controlling eight or fewer ENVIRCO ECM FFUs, then Jumper #4 must be on. When Jumper #4 is on, then the

control mode is set to 2-10VDC or 4-20mA, both at 1% to 100% ow index. If Jumper #4 is on and the control input is below 4mA

or below 2V, then the FFUs will be shut off.

Important: If 4-20mA range is desired, then make sure this Jumper #4 is on, and as well, place a 511 ohm ¼ watt resistor across

Signal and Common inputs to properly bias the automated control input for current mode.

Jumper #5 is the nal jumper, and it is a 3-position jumper. The 3-position Jumper #5 is always required to connect the center pin

to the left or center pin to the right pin.

Jumper #5 is used to enable or disable the 3 wire motor control signal “GO” control line. If the MDR is required to control greater

than eight FFUs, then Jumper #5 needs to be connected to the On/On side, which is towards the center of the printed circuit board.

If Jumper #5 is set to On/On, then the only way to turn off the FFU motors is by powering down the entire MDR16.

If Jumper #5 is positioned to the On/Off side or towards the outside of the printed circuit board, then, if using the automated control input

2-10VDC or 4-20MA modes, the FFU motors will be stopped when the control signal drops below the minimum range (<2VDC or <4mA).

Remember, in this mode with Jumper #5 positioned to the On/Off side, only eight ENVIRCO FFUs can be controlled by the MDR16.

MOUNTING & WIRING

The MDR 16 is packaged as a 6”x6”x 2.5” white metal box. To begin, there are three versions of the MDR16 designed to support

120V, 240V, or 277V applications. Be certain that the MDR16 front voltage logo label matches your intended connection voltage.

For mounting the box, it is recommended to disconnect power from the MDR16 or to mount the MDR16 before connecting the AC

power wires. To mount the MDR16, remove the cover of the MDR16 box and nd, on the inside back plate, four corner-located pre-

drilled mounting holes. Use these four holes for your mounting.

In regards to wiring the box into your system, there are two required connections and one optional connection. The main AC power

and EC Motor control outputs are required. Optionally available is the automation control input. The metal box has round knock-outs

available for pass-through of all the wiring for connection to your system. Be sure to only knock-out the minimum holes and thereafter

making the electrical connections completely environmentally re-seal the knock-outs using proper grommets and/or conduit.

Keep high voltage wiring away from the MDR16 circuitry or wiring. Follow electrical code requirements for separation of high and

low voltage wiring and components.

MDR16

MAC 10® Remote Mount Fan Controller

4

Installation & Operation Manual

Innovators in Clean Air Technology | www.envirco.com

MDR16

MAC 10® Remote Mount Fan Controller

Power

For the AC connection, connect as follows: Your AC earth ground connects to the green safety wire mounting bolt inside the box.

Use an appropriate size ring terminal (included with MDR16) for connection of your incoming safety ground to the box. Be sure to re-

tighten the earth safety wire nut to the box. For your Hot and Common AC connections, please strip your AC supply wires and attach

the crimp-on ¼” insulated quick connects provided with the MDR16. Then, attach the quick connectors to the respective transformer

terminals labeled Common and either 120V, 240V, or 277V, depending on your MDR16 model number.

MOUNTING HOLE PATTERN

6.50

6.00

4.50

5.50

.75

.50

.178 (4X)

5

Installation & Operation Manual

Innovators in Clean Air Technology | www.envirco.com

MDR16

MAC 10® Remote Mount Fan Controller

Regarding powering off the MDR16 and the ENVIRCO FFUs, there are some factors to consider regarding your AC wiring and entire power

switching design. If the MDR16 is controlling eight or fewer ENVIRCO FFUs, then there is nothing special to consider. If the MDR16 is

controlling greater than eight ENVIRCO FFUs and the system design requires operation with the automated control input, then the only way

to shut down the FFUs is to power down the MDR16 by placing a switch between the AC main connection and the MDR16.

Automation Control Input

The automation input is single-ended, so power neutral and signal common are connected internal to the MDR16. Connect the ¼”

insulated quick connects to your control input wiring. Connect the 0-10VDC control signal to the Signal connection. Wire the control signal

common to the Common connection.

The input presents a 21K ohm load to the signal source. Include the resistance when calculating a dropping resistor for 4-20mA operation.

A 511 ohm series 1% ¼ watt resistor is used to provide 500 ohm dropping resistance.

Motors

Connect all motors in parallel using a bus, star or combination wiring scheme. Use AWG 18 twisted cable. Provided with the MDR is a pack

of 50 self-splice connectors to implement the wiring. See the MDR16 Wiring Connections diagram for details. Important to note: When

connecting larger numbers of FFU’s to the MDR16, please make sure to design and layout the EC Motor control wiring paths to

minimize the total length of wiring accordingly.

Copyright © 2017 ENVIRCO. All Rights Reserved.

Form P/N#: 267913-001 Rev. 02/17

ENVIRCO MAC 10 is a registered trademark of ENVIRCO, USA. Specications subject to modications or changes without notice. US patents 4,560,395 and 5,470,363. Other patents issued and pending in foreign countries.

Industrial

Cleanroom Products

»MAC 10®Original

»MAC 10®IQ™

»MAC 10®IQ™ LAF

»MAC 10®LEAC™

»MAC 10®LEAC2™

»MAC 10®LEDC™

»Ducted Ceiling Module:

DCM & RSR

»AC or DC Control Systems

»MAC-T Ceiling Grid System

Hospital & Healthcare

Hospital & Healthcare

»IsoClean®and IsoClean

with Ultraviolet Light

»AirCeil®

»Hospi-Gard®Room

Pressure Monitor

Enviramedic Products

»HOR Horizontal Flow

Enclosure

»HCF Horizontal Flow

Surgery Room

»VOR Vertical Flow Surgery

Isolator

Pharmaceutical

Pharmaceutical &

Medical Device

»Unimodule M2 Vertical

Laminar Flow Workstation

»METD 100% Exhausted

Vertical Flow Workstation

»Laminar Downow Module

Laboratory & Research

Laboratory & Research

»100-Plus Horizontal or

Vertical Flow Clean Bench

»Unidirectional Flow

Horizontal Flow Bench (LF)

»TT Table Top Horizontal

Flow Clean Bench

»EnviraLab Sterility Module:

ESM

Clean air solutions built for you.

MORE INFORMATION AVAILABLE AT WWW.ENVIRCO.COM

ENVIRCO®

101 McNeill Road | Sanford, NC 27330, USA

tel: 919.775.2201 | toll free: 800.884.0002 | fax: 800.458.2379

This manual suits for next models

1

Table of contents