enviromental express AutoBlock Fill Administrator Guide

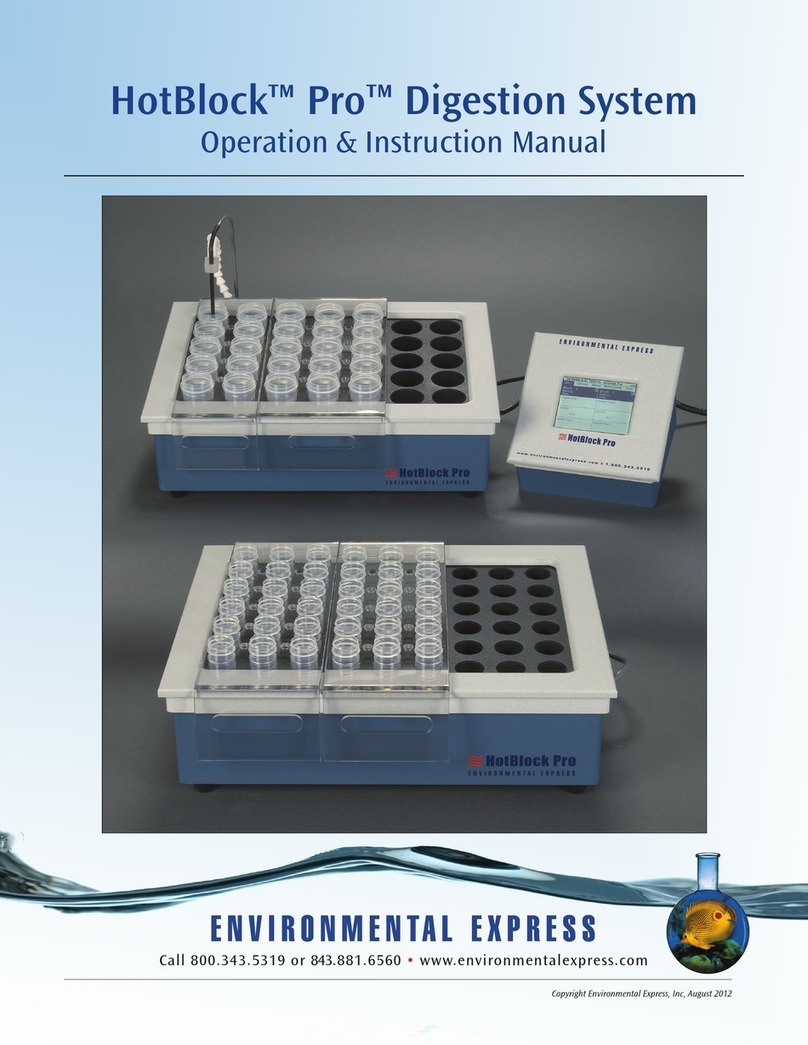

AutoBlock® Fill Filling Station

Operation & Instruction Manual

©2021 Environmental Express. All rights reserved.

July 2021 1065EE26_M Rev 2

+1.800.343.5319 or +1.843.881.6560 envexp.com

+1.800.343.5319 or +1.843.881.6560 envexp.com Environmental Express

AutoBlock® Fill: Operation and Instruction Manual Contents

Contents

General Information

Warranty and Repair Policy 1

Declaration of Conformity 2

About Your AutoBlock®Fill

Part Numbers / Model Information / Specications 3–4

Getting Started

Installation / Safety / Maintenance 4–7

Operation Using the AutoBlock® Fill Software on a PC 8–11

Operation Using Onboard Touch-Screen Controller 11–12

Parts and Supplies

Accessories 13

Adaptation of EPA Methods for Use with Your HotBlock®

Method 200.2, Revision 2.8 14–15

Method 200.7, Revision 4.4 16–17

Method 200.8 18–19

Methods 245.1, 7470, and 7471 for Mercury Digestions 20–21

Method 365.1 for Phosphorus 22

Method 3050B 23–24

NIOSH Method 7303 24–25

Sample Preparation for Lead Analysis using the GhostWipe® Wipes 25–26

Method 3060A for use with the HotBlock®and StirBase™ Systems 27–28

+1.800.343.5319 or +1.843.881.6560 envexp.com Environmental Express • 1

AutoBlock® Fill: Operation and Instruction Manual Warranty and Repair Policy

Loaner AutoBlock® Fill system MAY be available during the repair period. There are only a limited number of these units.

A reasonable charge for “cleanup” will be charged if a loaner is issued. The customer will be responsible for all shipping

charges associated with a loaner unit.

Limited Warranty

The Environmental Express AutoBlock® Fill is warranted against defects in materials and workmanship when used in

accordance with applicable instructions, for a period of one year from the date of shipment. This warranty extends

to parts, labor, and any approved transportation charges. This warranty applies only to damage or failure caused by

normal laboratory use. The warranty is limited to product repair. If Environmental Express is unable to repair the

AutoBlock® Fill, the customer may, at his or her option, receive a replacement unit or a full refund.

In no event shall Environmental Express have any obligation to make repairs, replacements or corrections required,

in whole or in part, as the result of (i) normal wear and tear, (ii) accident, disaster or event of force majeure, (iii)

abuse, neglect, misuse, fault or negligence of or by customer, (iv) use of the product in a manner for which it was not

designed, (v) causes external to the product such as, but not limited to, power failure or electrical power surges, (vi)

improper storage and handling of the product, (vii) use of the product in combination with equipment or software

not supplied by Environmental Express, (viii) ordinary maintenance, (ix) alterations, repairs or installations that have

not been performed by Environmental Express or its authorized representative or (x) failure to maintain product in

accordance with Environmental Express’ written instructions.

Environmental Express makes no other warranty, expressed or implied for this product with respect to merchantability,

tness for a particular use or any other matter and expressly disclaims all other warranties. Environmental Express

is not liable for any consequential, special, indirect or compensatory damages arising from use of, or in conjunction

with this product. the maximum liability of Environmental Express (whether by reason of breach of contract, tort,

indemnication, or otherwise, but excluding liability of seller for breach of warranty (the sole remedy for which shall

be as otherwise provided herein)) shall be the invoice price of this product.

Repair Policies

Note: This warranty does not apply to any consumable items associated with the AutoBlock® Fill system.

Under Warranty Repair:

If the AutoBlock® Fill should fail to operate as warranted

within the warranty period (one year from date of

shipment), Environmental Express will repair it and

ship it back to the customer at Environmental Express’

expense. The remainder of the warranty period will be

honored from the original ship date. Environmental

Express will bear the cost of ground transportation both

to and from the customer’s location, and bear the cost of

any parts, labor and cleanup required.

However, if it is determined that the damage to the

AutoBlock® Fill was caused by negligence or improper

use or by another excluded cause as set forth above,

this warranty will not apply. The warranty is also void

if the system is used beyond its intended purpose or

in the event of any unauthorized repair. In such cases,

reasonable and customary repair charges will apply.

Repair charges will be quoted prior to work being done.

Out of Warranty Repair:

If the AutoBlock® Fill fails after the warranty period has

lapsed, the repair procedure is as follows:

First, notify an Environmental Express Technical

Service Representative of product’s failure and place

an order for repair. Whenever possible, our customer

service technician will walk you through possible

troubleshooting scenarios which may enable you to

repair your block on-site.

If on-site repair is not possible, the customer may return

the non-working unit to Environmental Express using

appropriate shipping containers and insurance. Repair

charges will be assessed and estimated prior to work

being done. Repair charges will include all freight costs

as well as reasonable and customary charges for parts

and labor.

+1.800.343.5319 or +1.843.881.6560 envexp.com Environmental Express • 2

AutoBlock® Fill: Operation and Instruction Manual Declaration of Conformity

The manufacturer, Environmental Express, 2345A Charleston Regional Parkway, Charleston, SC 29492 declares

that the following product, AutoBlock® Fill Item Number ABF5000, is in conformity with:

4000040

Product Information:

Item # Date of Purchase

AutoBlock® Fill Serial #

Please record the serial # of your AutoBlock® Fill here for easy reference. Your serial # is located on the back of your AutoBlock® Fill.

Standard for Safety Electrical Equipment for Measurement, Control, and Laboratory Use;

Part 1 General Requirements, UL 61010-1, CAN/CSA-C22.2 No. 61010-1, 2nd Edition,

Issued 12 July, 2004 with revisions through and including 28 October, 2008; Equipment

for Measurement, Control, and Laboratory Use Part 2-010: Particular Requirements for

Laboratory Equipment for the Heating of Materials, IEY 61010-2-010, 2nd Edition, Issued

1 June, 2003, Safety Requirements for Electrical Equipment for Measurement, Control, and

Laboratory Use - Part 2-010:Particular Requirements for Laboratory Equipment for the

Heating of Materials, CSA C22.2.61010.2.01

Environmental Express declares that the AutoBlock Fill conforms with the essential

requirements of the applicable EC directives.

Call +1.800.343.5319 or +1.843.881.6560 envexp.com

2345 A Charleston Regional Pkwy • Charleston, SC 29492

AutoBlock® Fill: Operation and Instruction Manual Part Numbers / Model Information / Specications

+1.800.343.5319 or +1.843.881.6560 envexp.com Environmental Express • 3

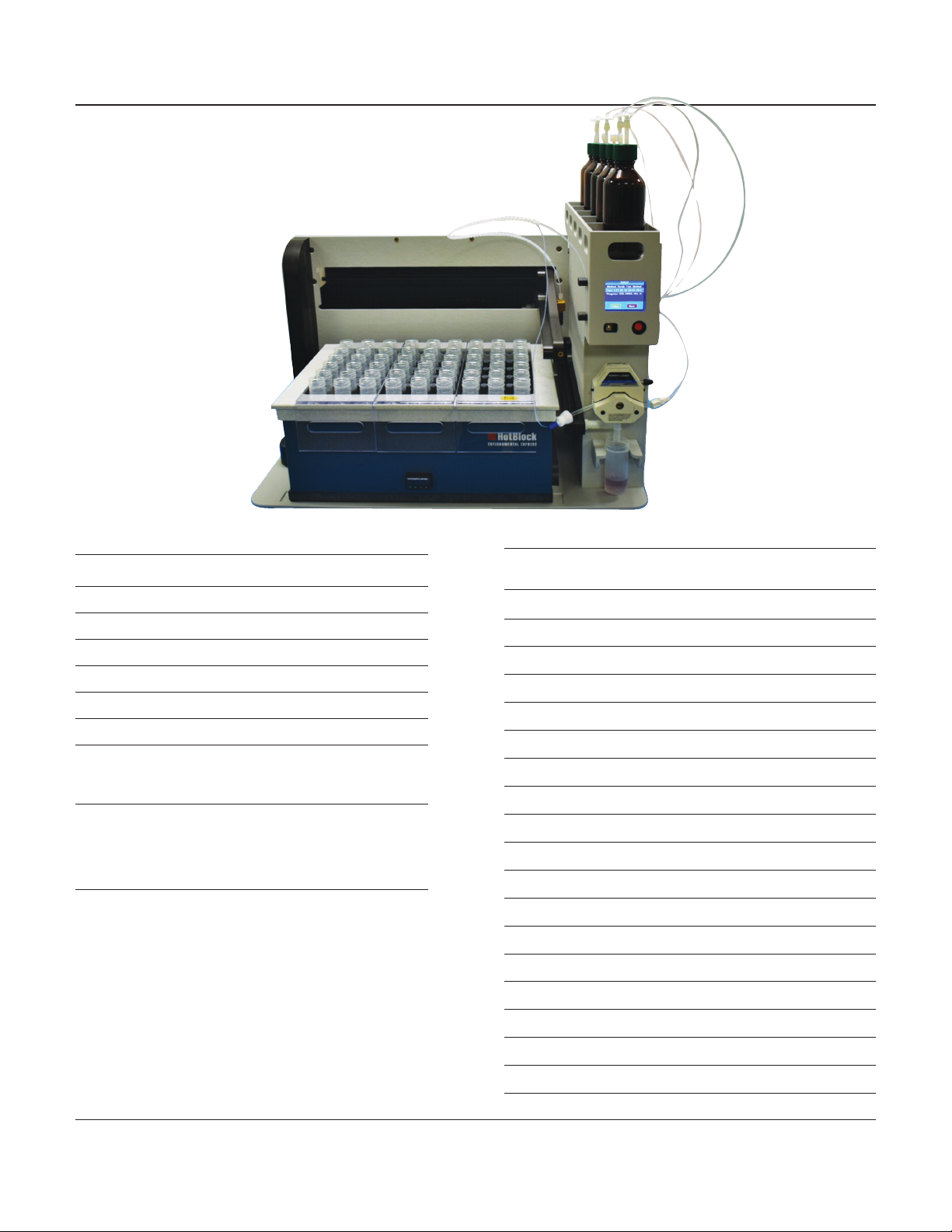

AutoBlock® Fill Station Specications:

Sample Capacity: 12 to 96 wells

Nominal Sample Size: 15 to 100 mL

Volume Resolution: 0.1 mL

Operating Temperature of Block: Ambient to 300°C

Pump Accuracy: ±2% volume

Dimensions: 31”W x 27”H x 22”D

Electrical: 120/240 VAC, 10 A

Description Item #

AutoBlock® Fill lling station with software, ABF5000

integrated pump, PTFE tubing, ve 1-L glass

reagent bottles, 100-mL waste vessel, and

installation hardware

Compatible HotBlock®Models

Volume No. of

per Well Samples Item #

HotBlock systems

15 mL 96 SC196, SC196-240

50 mL 36 SC100, SC100-240

50 mL 54 SC154, SC154-240

100 mL 25 SC150, SC150-240

100 mL 35 SC151, SC151-240

HotBlock Pro systems

15 mL 96 SC189, SC189-240

50 mL 36 SC191, SC191-240

50 mL 54 SC181, SC181-240

100 mL 25 SC192, SC192-240

100 mL 35 SC182, SC182-240

HotBlock 200 systems

15 mL 96 SC2015-96, SC2015-96V240

50 mL 36 SC2050-36, SC2050-36V240

50 mL 54 SC2050-54, SC2050-54V240

100 mL 25 SC2100-25, SC2100-25V240

100 mL 35 SC2100-35. SC2100-35V240

AutoBlock® Fill: Operation and Instruction Manual Installation, Safety & Maintenance

+1.800.343.5319 or +1.843.881.6560 envexp.com Environmental Express • 4

About Your Environmental Express AutoBlock®Fill Station

AutoBlock® Fill provides a safe, efcient method of adding digestion reagents to water, wastewater, soil, and sludge samples

for metals analysis. The station works with any size of HotBlock®, HotBlock® Pro, and HotBlock® 200 metals digestion systems

to automate the most dangerous step of metals digestion—the reagent addition.

The station dispenses independently from up to ve reagent bottles. No need to swap out reagent bottles when switching

digestion methods—a ve-way valve setup provides easy switching between reagents. The reagents are dispensed by an

integrated Masterex® peristaltic pump accurate to ±2% volume (calibratable to any dispensing volume).

The AutoBlock® Fill can be programmed and controlled via the onboard touch screen or use the included software to connect

directly to a computer. The station features preprogrammed EPA methods or the user can create customized programs.

Users should be aware of potential dangers from heating certain types of compounds. Such hazards may include explosion or

the release of toxic or ammable gases. The AutoBlock® Fill is designed to t in a fume hood.

Denitions/Markings

Each AutoBlock® Fill and/or HotBlock® product displays certain markings and symbols. All personnel working with the

AutoBlock® Fill and/or HotBlock® should have an understanding of the following symbols and denitions:

• V = voltage

• ~ = alternating current

• Hz = frequency

• A = amperes

This symbol means Caution

Hot Surface. The surface of the

HotBlock® may be too hot to

safely touch with bare hands.

This symbol means

Read and become familiar

with instructions before

operation of instrument.

Installation of your AutoBlock® Fill Station

1. The AutoBlock® Fill requires some assembly prior to operation. A video showing how to perform the assembly is located

on the AutoBlock® Fill product page.

2. The top section of foam packaging contains the horizontal brace, the HotBlock® rails, and the vertical brace. The

bottom section of foam packaging contains the tower, base plate, XY arm assembly, and power cord and tubing. A bag

of hardware to connect all the pieces together is also included.

3. Attach the tower to the base plate. Set the base plate on a secure at surface with the cam lock lever on the left side.

This will orient the base with the attached brace rail to the right, the wider track slot in the front, and the narrower

track slot towards the back. The far-right side will have an outline of the tower with six screw holes. The tower should

be oriented with the peristaltic pump to the front, the drain trench on the left, and the ve-way valve on the right. Use

six (6) #0.25-20 x 0.75 Phillips head screws. This step and the next one are best accomplished by laying the tower on its

back and having the bottom panel facing you.

4. Attach the vertical brace to the bottom panel at the left rear corner. The rounded end will be up in the air and the at

end will be attached to the panel. The notched side will be at the bottom facing the rear. Use two (2) #0.25-20 x 0.75

Phillips head screws.

5. Remove the side panel from the right side of the tower. You will need a Phillips head screwdriver to remove the screws.

Be sure to note which screws came from which holes. The shorter screws must go back in their specic holes to assure

proper t. Set the panel aside.

+1.800.343.5319 or +1.843.881.6560 envexp.com Environmental Express • 5

AutoBlock® Fill: Operation and Instruction Manual Installation, Safety & Maintenance

6. Attach the horizontal brace to the bottom panel, vertical brace, and tower. The open end of the horizontal brace will

t in the notch on the bottom of the vertical brace. The closed end of the horizontal brace will t up against the side

of the tower. Use ve (5) #10-25 x 0.375 Phillips head screws to secure the bottom of the horizontal brace. Use three (3)

#10-25 x 0.375 Phillips head screws with nuts to attach the horizontal brace to the tower. Make sure the nut is on the

inside of the tower. Use two (2) #10-25 x 0.375 Phillips head screws to attach the horizontal brace to the vertical brace.

Leave the middle spot empty for one (1) #0.25-20 x 0.75 Phillips head screw when attaching the XY arm assembly.

7. Remove the XY arm assembly from the box and set in place behind the unit.

8. Remove the back cover from the XY arm assembly. There are four (4) #10-24 x 0.375 Phillips head screws holding it in

place; two on each side.

9. Attach the XY arm assembly to the frame. Use ten (10) #0.25-20 x 0.75 Phillips head screws to attach the XY arm

assembly from the back. Use one (1) #0.25-20 x 0.25 screw inside the tower at the top.

10. Locate the two loose cable ends on the left side of the XY arm assembly and feed one through each of the two large

access holes in the back of the tower. The X motor cable coming from the far-left side of the assembly should be

inserted in the top hole. The Y motor cable runs inside along the length of the assembly and should be inserted in the

bottom hole.

11. Attach the X and Y motor cables to the top two cables inside the tower; X to the top position and Y to the second

position. The cables screw together and will be secure when you feel a physical click to lock them in place.

12. Attach the valve cables from the tower to the side panel. The cables are numbered near the connectors to match the

correct ones together.

13. Replace the side panel and back cover to the appropriate parts of the unit. Make sure to place the shorter screws on

the side panel in the appropriate positions. Snap the caps in place over the side panel screws.

14. Locate the wire support screws on the front left side of the tower and loosen them several full turns. There is no need

to remove them from the brackets. Insert the long end of the support wire (thicker solid piece) from the spiral-wrapped

assembly into the support brackets. Tighten the screws down to hold the wire in place.

15. Loosen the retaining screw on the side of the moving XY carriage, near the dispensing tip. Insert the other end of the

support wire and tighten the screw to hold the wire securely in place.

16. Loosen the ange nut above the dispensing tip on the XY carriage. Insert the delivery tube into the ange nut and

through the probe until it is ush with the end. Tighten the ange nut but do not clamp it down fully to pinch the

tubing.

17. Lift the locking lever of the peristaltic pump on the front of the tower. Insert the peristaltic pump tubing assembly

in the pump with the blue connector on the left side. Ensure that the pump tubing rests in between the clamps in

the ends of the locking lever prior to securing it in place. The tubing on the right side of the pump tubing assembly

attaches to the center port of the 5-way valve on the right side of the tower.

18. Attach the loose end of the delivery tubing to the left side of the pump tubing assembly. Insert the 100-mL vessel

(# SC490) in the waste container holder underneath the peristaltic pump on the front of the tower.

+1.800.343.5319 or +1.843.881.6560 envexp.com Environmental Express • 6

AutoBlock® Fill: Operation and Instruction Manual Installation, Safety & Maintenance

19. For each digestion reagent bottle, you will need to cut a piece of tubing from the included coil. Use an empty bottle

as a guide in determining the correct length. Insert one end of the tubing into the bottle cap and attach it to an

empty bottle. Slide the tube far enough into the bottle so that the end of the tubing is near the bottom of the bottle.

Do not put the tubing ush against the bottom of the container as it will not be able to draw liquid in an efcient

manner. Run the tubing in a gradual bend to the 5-way valve. Make sure there are no kinks in the tubing to restrict

ow. Use a ferrule and angeless nut to secure the tubing into one of the numbered ports in the 5-way valve. Repeat

for as many digestion reagents are desired.

Note: The bottle with DI water must always be connected to port #1.

20. Attach the 5-pin connector from the power block to the back-right corner of the AutoBlock® Fill.

Installation of a HotBlock® in the AutoBlock® Fill Station

1. If using a new HotBlock®, remove the metal screws from the bottom plate of the unit. Attach the appropriate size

rails to the bottom of the HotBlock® using the hex head screws included with the unit. An appropriate hex head

driver is also included with the AutoBlock® Fill. The rails should run from side to side on the HotBlock®. If using a

previously purchased HotBlock®, remove the PVC screws and rubber feet from the bottom of the unit. Attach the rails

as described above.

2. Adjust the locking cam lever to accommodate the size of the HotBlock® you are using. Slide it to the right for a

square block and to the left for a rectangular block. Tighten it down after adjustment.

3. Place the HotBlock® on the bottom plate of the AutoBlock® Fill with the controller facing front. Insert the power cord

through the slot in the back panel of the AutoBlock® Fill.

4. Slide the HotBlock® towards the back panel of the unit until the rails slide in place in the appropriate slots on the

base plate.

5. Slide the HotBlock® towards the tower until it is ush against the brace beside the tower.

6. Lock the cam lever in place against the side of the HotBlock®. It should be held securely in place and not move in

any direction. The HotBlock® is now ready for positional calibration.

Note: See the “Using the AutoBlock® Fill Software on a PC” section for instructions on how to perform this calibration.

Installation Requirements

If digestions are to be performed on a HotBlock® installed in the AutoBlock® Fill station, make sure to locate the entire

system under a fume hood with a minimum face velocity of 100 fpm, and allow a minimum of 2” of space on all sides. The

following environmental conditions should be observed:

• Ambient temperature range: 5–45°C

• Ambient relative humidity: 0–100%RH

• Altitude: sea level to 2500 meters

HotBlock® units are rated as Pollution Degree 2 and Installation Category 2.

+1.800.343.5319 or +1.843.881.6560 envexp.com Environmental Express • 7

AutoBlock® Fill: Operation and Instruction Manual Installation, Safety & Maintenance

Electrical Requirements

• Required Voltage 120/240 volts, ~50/60 Hz, Current – 10 A.

• Power should not vary greater than ±10%. Connecting to the power supply must be done with the supplied power cord.

• For safety reasons, a separate power receptacle should be provided for any HotBlock® installed in the unit. Do not use

extension cords or outlet adaptors. Make certain that power outlets are earth-grounded at the grounding pin.

Potential Hazards

The AutoBlock®Fill should only be operated by properly trained personnel using standard laboratory safety practices.

• The AutoBlock® Fill has moving parts which can pinch extremities or entangle loose hair or clothing.

• Use extreme caution when operating any attached HotBlock® digestion block. Plastic and graphite surfaces of the blocks may

be too hot to safely touch with bare hands.

• All components contain electrical circuits and devices and compounds operating at dangerous voltages.

Contact with these circuits, devices and components can cause serious injury or painful electric shock.

• Proper grounding is essential to avoid a potentially serious electric shock hazard. Ensure that there is an internal ground

connection between the metal base of the system and the 3-pin earth-grounded receptacle.

• For safety reasons, a separate power outlet receptacle should be provided for the AutoBlock ® Fill and any attached HotBlock®.

Do not use extension cords or outlet adaptors. Make certain each power outlet is earth-grounded at the grounding pin.

• Power requirements for individual blocks may be found on our website.

• Application of the wrong supply voltage can create a re hazard and a potentially serious shock hazard, and could seriously

damage the system. See specications for individual components.

• Users should be aware of potential dangers from heating certain types of compounds. Such dangers may include the

release of toxic or ammable gases or explosion.

Maintenance

• Any service inquiries should be directed to the Environmental Express Technical Service Department at +1.800.745.8218 or

+1.843.881.6560.

• After each use, clean exterior surfaces with a damp sponge to remove acid residue.

• For acid spills, sponge with a diluted solution of sodium bicarbonate followed by distilled water. Acid that is spilled

directly into the digestion wells should be neutralized and removed.

• Before using any cleaning or decontamination methods except those recommended, check with Environmental Express

to conrm the proposed method will not damage your AutoBlock® Fill and/or HotBlock®.

• Avoid excessive spills; as liquid allowed to overow into the AutoBlock® Fill and/or HotBlock® casing can seriously damage

electronic components.

• Monitor the waste receptacle during use to ensure the rinses do not exceed the capacity of the 100-mL waste vessel.

+1.800.343.5319 or +1.843.881.6560 envexp.com Environmental Express • 8

AutoBlock® Fill: Operation and Instruction Manual Operation

Operation Using the AutoBlock® Fill Software and Onboard Touch Screen

The AutoBlock® Fill can be run using either the software on a connected PC (for full control) or via the onboard touch screen

(for routine, daily tasks). After initial calibrations and method development are completed, the only required function for

connection to a PC is for regular pump volume calibration/verication. The software download and a video showing how to

use the AutoBlock® Fill software are available on the AutoBlock® Fill product page.

Using the AutoBlock® Fill Software on a PC

The AutoBlock® Fill software consists of a primary working screen with tabs along the left side of the display. The tabs allow

you to switch between functional screens and alert you to unsaved information or connection issues in the software.

1. Home Screen – The home screen provides an image of the AutoBlock® Fill and a

functional link to the Environmental Express website.

2. Communications Screen – This is where you will set up the serial ports for the

USB connection between the PC and the instrument. The software should connect

automatically once the USB cable is in place, however the rst time connecting may

require manual connection. Select the drop-down menu titled “Serial Port”. It defaults

to “Autodetect” and will need to be changed to whichever port is populated in the

menu. Then click the large button at the top labeled “Open Communications”. The

software will then connect and indicate that communication has been established.

1

2

3

4

5

6

7

8

9

10

+1.800.343.5319 or +1.843.881.6560 envexp.com Environmental Express • 9

AutoBlock® Fill: Operation and Instruction Manual Operation

3. HotBlock® Screen – This screen is used to calibrate the position of the HotBlock® and

check pump volumes. To calibrate the HotBlock® position, you must rst choose the

block type from the drop-down menu. Blocks are listed by the Environmental Express

part number (e.g. SC154) as well as the well conguration (e.g. 9x6). If you are unsure of

the part number, choose any option that has the correct well conguration. Once you

make a selection, a map of the wells will appear onscreen. If you select the “Custom”

option, you will need to specify the number of wells in each row and column. The cups’

positions are labeled in rows by number and columns by letter. You will calibrate on

the front left corner cup (always labeled “A1”) and the back right corner cup.

Click the “Calibrate” button on the row for “Location of Cup A1”. The button will turn

red and the dispensing probe will move to a location close to where the A1 cup should

be. Use the “Jog” arrows to position the arm so that the dispensing tip is centered above

the A1 cup. The magnitude of the motion from the “Jog” arrows can be adjusted to

smaller distances, down to 0.1 mm, by changing the eld value. You can use the

“Dispense” button to verify the position. If you anticipate using the disposable reux

caps, we recommend having one in position over the cup being calibrated.

Click the same “Calibrate” button as before. The button will change color again and the

position will be saved to the unit. Repeat these steps for the location of the cup in the

opposite corner. Once that is completed, click the “Save Block to ABFill” button. If you

have not saved the block calibration to the unit, a red asterisk [*] will appear on the tab

to alert you of unsaved changes.

4. Pump Calibration Screen – This screen allows you to adjust the pump to account for

changes in the pump tubing. The positions of the cups used to check the calibration are

xed but the volume used can be adjusted to something close to the standard amount

of liquid being dispensed. Place a preweighed empty cup in each red shaded well as

indicated on the map of the block. Change the amount listed in Step 1 to the desired

calibration amount; 2 mL is the default value. Click the “Dispense” button to begin the

procedure. The unit will then dispense the indicated amount into each of the cups.

Weigh the cups and determine the amount of water dispensed by the increase in mass.

Average the values and enter in the eld in Step 2. Click the “Update” button and the

software will automatically calculate the Calibration Factor to update in the eld at the

top of the screen. Repeat the calibration steps until the value stabilizes within a margin

of error acceptable for your laboratory.

Note: Environmental Express recommends checking this value at least weekly and

possibly more often depending on the use in your laboratory. We also recommend

changing the peristaltic pump tubing at least monthly.

+1.800.343.5319 or +1.843.881.6560 envexp.com Environmental Express • 10

AutoBlock® Fill: Operation and Instruction Manual Operation

5. Methods Screen – The methods screen allows you to develop programs for dispensing

of digestion reagents as well as conguration of the digestion reagents loaded onto the

unit. Many of the common digestion methods from 40CFR are already preprogrammed

in the software. You may edit an existing method or create a new method from scratch.

The steps available in a method are Dispense, Hold, and Prompt. Dispense allows

you to select a digestion reagent from those that are assigned and specify how much

volume of it you wish to add to each cup. Hold will set a countdown timer for the time

specied (in minutes) and wait until the timer expires before proceeding to the next

step. Prompt will complete the step and then display a custom message that requires

user acknowledgement prior to continuing.

The default reagents available for selection in the assignment screen are water (which

must always be assigned to port #1), HCl, HNO2, H2O2, and H2SO4. If you wish to use a

reagent besides one of these, select “None” for that port, highlight the text, and type in

the reagent name you wish to use. That reagent will then be an option to choose in the

“Dispense” command.

You must click the button “Save Methods to ABFill” in order to be able to run that

method in a sequence. If you wish to save the method to the PC directory, you must

click “Export Method”. If you have information on the Methods Screen that has not

been saved, it will display a red exclamation mark [!] to alert you.

6. Sequences Screen – This screen will be the day-to-day operations screen. To set a

sequence, you choose a method, choose which cups you wish to use, and give the

sequence a name. If using the PC to control the unit, you can start the sequence by

clicking the “Run Sequence Button”. If the touch-screen controller will be used to run

the sequences, you must click “Save Sequences to ABFill” in order to have them

available.

For routine operation, it is best to create a sequence using your most common

digestion method with no cups selected. Make sure that the “Cup Selection” box is

checked and save the sequence to the unit. This will allow you to ll in the cups needed

for digestion with each batch that you run. You can save multiple sequences to the unit.

When selecting cups, you may choose individual wells by clicking each one, entire rows

by selecting the appropriate letter, entire columns by selecting the appropriate number,

or the entire block by selecting “All” at the bottom left corner of the block map.

The tab will show a red asterisk [*] if there is unsaved information in the sequences

screen.

7. Run Log Screen – If you have checked the “Audit” box on a sequence, the unit will save

basic run information for the sequence including start date/time, operator ID, Batch ID,

sequence name, method used, selected wells, reagents assigned, and end time. The log

must be loaded from the unit and then saved to the PC in order to retain the records.

8. Advanced/Service Screen – This screen should only be used under the direction of

representatives from Environmental Express when troubleshooting the unit.

+1.800.343.5319 or +1.843.881.6560 envexp.com Environmental Express • 11

AutoBlock® Fill: Operation and Instruction Manual Operation

9. Maintenance/Supplies Screen – This screen contains part numbers and ordering

information for common consumable items related to the AutoBlock® Fill.

10. Help Screen – Contains contact information for technical support, links to the

manual, and links to support videos.

Using the Onboard Touch-Screen Controller

The onboard touch screen is intended for use in routine day-to-day operations of the AutoBlock® Fill. It is functional without a PC

being connected to the unit. The touch screen saves a copy of the sequences and methods that have been downloaded to it from

the PC software.

When using the touch screen, the user may cycle through all sequences that have

been saved to the unit. When going through the available sequences the screen

will display the method that has been assigned to that sequence, any cups that are

selected, and the reagents being used.

After selecting the desired sequence, it will display the block size and the volume

needed for each digestion reagent in use for that sequence. The user should verify

that the information is correct and that the appropriate volumes are available before

proceeding.

The next screen shows a map of the block with the selected cups to be lled. The user

will select “OK” or “Adjust Cups” depending on how the sequence is designed.

+1.800.343.5319 or +1.843.881.6560 envexp.com Environmental Express • 12

AutoBlock® Fill: Operation and Instruction Manual Operation

Adjusting the selected cups is done in a similar manner to using the PC software;

individually, in rows, in columns, or the entire block. Press “OK” after the correct cups

have been assigned.

It will then ask if you are ready to start the run. Press “Yes” to begin or “Cancel” to

return to the main menu.

+1.800.343.5319 or +1.843.881.6560 envexp.com Environmental Express • 13

AutoBlock® Fill: Operation and Instruction Manual Parts & Supplies

Polypropylene Disposable Screw-cap Digestion Cups

Eliminate Transfer Steps.

• Certied for low metals background and EPA approved†for digestions

• Volume certied

These carefully engineered digestion vessels provide premium performance in your

HotBlock®systems. Cups are molded of claried homopolymer polypropylene, providing

a higher working temperature (to 130C) and greater chemical resistance than commonly

used co-polymer polypropylene.

Accurate, molded-in graduations allow analysts to easily reproduce volumes to within

0.5%. Vessels serve as graduated cylinders, as well as storage containers. After digestion

is complete, the sample can be brought to volume and capped for storage, eliminating

time-consuming transfer steps. The result is a “one-cup” system that greatly reduces labor

and costs associated with metals preparation.

Screw caps are available with polyethylene-faced foam liners for a leak-proof seal (green

and white caps only) or as a plug-style closure (natural caps only).

Each box of cups comes with a Certicate of volume accuracy and a Certicate of Analysis

for 68 trace metals—only metals-free materials come in contact with your sample. Both

the Ultimate Cup (UC) and the Ultimate Clean Cup (UCC) vessels have been redesigned

for increased durability, stability, and a tighter seal. In addition, the Ultimate Clean Cup

comes in packaging to ensure ready-to-use arrival and is further trace-metal analysis

certied to parts-per-billion and parts-per-trillion levels.

†Environmental Express digestion cups are approved for, but not limited to, EPA Methods 3005, 3010,

3050B, 200.2, 200.7, 200.8, 7470A, 7471A, 245.1, and 245.7.

Total

Description Capacity Graduations Quantity Item #

15mL Cup (clear cap, no liner) 18mL to 15mL 1000 SC415

100mL Cup (white cap, liner) 125mL to 100mL 225 SC490

50mL Ultimate Cup (green cap, liner) 68mL to 50mL 500 UC475-GN

50mL Ultimate Cup (white cap, liner) 68mL to 50mL 500 UC475-W

50mL Ultimate Cup 68mL to 50mL 500 UC475-NL

(natural cap, no liner)

50mL Ultimate Clean Cup 68mL To 50mL 150 UCC000-50

(natural cap, no liner)

Ribbed Watch Glasses allow partial reux during digestion.

Ribbed watch glasses are available to t all Environmental Express digestion vessels.

Polypropylene construction is naturally free of contaminants. Watch glasses have a center

stem to aid in handling and decrease the potential for contamination.

Description For Digestion Cup Quantity Item #

19.5mm Watch Glass 15mL 1000 SC417

44mm Watch Glass 50mL 1000 SC505

52mm Watch Glass 100mL 500 SC610

For a complete list of consumables and

accessories, visit the Metals Digestions

section of our website.

+1.800.343.5319 or +1.843.881.6560 envexp.com Environmental Express • 14

AutoBlock® Fill: Operation and Instruction Manual EPA Method 200.2, Revision 2.8

1.0 Scope and Application

1.1 The following procedures have been written as an aid to EPA digestion

procedure 200.2 for use with the Environmental Express HotBlock. EPA

Method 200.2 is for the determination of total recoverable analytes in

groundwater, surface water, drinking water, wastewater and (with the

exception of silica) in solid samples such as sediment, sludge and soil.

Use EPA Method 200.2 for reference while following the sample preparation

steps outlined below. A complete list of elements appropriate for analysis is

included in EPA Method 200.2. Analysis can be performed by ame atomic

absorption, GF/AA, ICP and ICP-MS.

2.0 Apparatus and Materials

2.1 HotBlock for Metals Digestions — Item # C6002, SC100, SC150*, SC151*,

SC154, SC196, SC2015, SC2050, or SC2100*

2.2 Polypropylene Digestion Vessels — 50mL, 100mL, or 15mL

2.3 Ribbed Watch Glasses or Reux Caps, appropriately sized for vessel capacity

2.4 FilterMate — Item # SC0401 (or appropriate FilterMate® or FlipMate®) for

sample ltration if necessary

*Note: For all procedures, when using the block with the SC490 digestion vials with

a 100mL sample, double the volume of all reagents and acids added.

3.0 Procedure, Aqueous Sample Preparation

3.1 Mix sample thoroughly to achieve homogeneity. For each digestion

procedure, transfer a 50mL sample (or appropriate volume for your lab)

into the polypropylene digestion vessel. For best results, weigh the sample

directly in the vessel on a tared balance.

3.2 Add 1mL (1:1) HNO3and 0.5mL (1:1) HCl, then swirl. Heat the sample in the

HotBlock at 95°C for 2.5 hours without boiling. Place a ribbed watch glass

(SC505) on top of the digestion vessel.

Note: When using a watch glass, adjust the control point temperature of the HotBlock so

that a 50mL, 5% acid solution is heated to 85°C BEFORE placing the watch glass over the

sample. Laboratory tests have proven that the addition of the ribbed watch glass will add

approximately 10°C to the sample temperature, bringing the sample temperature up to 95°C.

3.3 Using the polycarbonate transfer racks, remove samples from the HotBlock

and allow them to cool.

3.4 After cooling, dilute samples to 50mL with DI Water.

3.5 If necessary, lter with SC0401 (or appropriate FilterMate® or FlipMate®)

to remove insoluble material.

Note: The ltration step should be performed slowly with little pressure placed on the

plunger. If excessive back pressure occurs, stop ltration and allow sediments to “settle out”.

Applying pressure to the plunger may cause sample “blow through” allowing sediment to

pass through the lter into the digestate.

Adaptation for EPA Method 200.2, Revision 2.8 for use with the

Environmental Express HotBlock® Digestion System Revised 12.13

+1.800.343.5319 or +1.843.881.6560 envexp.com Environmental Express • 15

AutoBlock® Fill: Operation and Instruction Manual EPA Method 200.2, Revision 2.8

4.0 Procedure, Solids Sample Preparation

4.1 Sieve a dried sample using a 5-mesh polypropylene sieve and grind in a

mortar and pestle. Weigh a representative sample of 0.5 ±0.01g into a

digestion vessel.

4.2 Add 2mL of (1+1) HNO3and 5mL of (1+4) HCl. Cover with a ribbed watch

glass (SC505) or reux cap (SC506),and place in the HotBlock at 95°C.

4.3 Heat sample for 30 minutes.

4.4 (Optional) Although step 3 is the nal heating step for EPA Method 200.2,

if the sample is suspected of having a high concentration of organic

compounds, it is recommend to complete this step:

Add 2mL of 30% H2O2to the well-cooled sample. Allow the exothermic

reaction to occur (approximately 10 minutes) and place the sample back

in the HotBlock at a temperature of 10° less than the original set point for

an additional 30 minutes. The reaction with the H2O2raises the sample

temperature. Boiling should not occur if the temperature of the HotBlock

is lowered.

Note: H2O2helps aid in the breakdown of high organic compounds in the sample thus

creating a more complete digestion.

4.5 Using the polycarbonate transfer racks, remove samples from the HotBlock

and allow them to cool completely.

4.6 Bring sample volume to 50mL with DI water.

4.7 If necessary, lter with SC0401 (or appropriate FilterMate® or FlipMate®)

to remove insoluble material.

Note: The ltration step should be performed slowly with little pressure placed on the

plunger. If excessive back pressure occurs, stop ltration and allow sediments to

“settle out”. Applying pressure to the plunger may cause sample “blow through” allowing

sediment to pass through the lter into the digestate.

All QC samples, concentration limitations, elemental lists and reagent specications

are addressed in depth in EPA Method 200.2. Safety concerns are also part of the full

method. Follow the instructions listed in EPA Method 200.2. These steps should only

be used as a guide to help improve the performance of your HotBlock.

+1.800.343.5319 or +1.843.881.6560 envexp.com Environmental Express • 16

AutoBlock® Fill: Operation and Instruction Manual EPA Method 200.7, Revision 4.4

1.0 Scope and Application

1.1 The following procedures have been written as an aid to EPA digestion

procedure 200.7 for use with the Environmental Express HotBlock. EPA

Method 200.7 is for the determination of total recoverable analytes in

groundwater, surface water, drinking water, wastewater, and (with the

exception of silica) in solid samples such as sediment, sludge and soil.

Use EPA Method 200.7 for reference while following the sample preparation

steps outlined below. A complete list of elements appropriate for analysis is

included in EPA Method 200.7. Analysis can be performed by ICP.

2.0 Apparatus and Materials

2.1 HotBlock for Metals Digestions — Item # C6002, SC100, SC150*, SC151*,

SC154, SC196, SC2015, SC2050, or SC2100*

2.2 Polypropylene Digestion Vessels — 50mL, 100mL, or 15mL

2.3 Ribbed Watch Glasses or Reux Caps, appropriately sized for vessel capacity

2.4 FilterMate — Item # SC0401 (or appropriate FilterMate® or FlipMate®) for

sample ltration if necessary

*Note: For all procedures, when using the block with the SC490 digestion vials with

a 100mL sample, double the volume of all reagents and acids added.

3.0 Procedure, Total Recoverable Elements, Aqueous Sample

(EPA Method 200.7, Paragraph 11.2)

3.1 Mix sample thoroughly to achieve homogeneity. For each digestion

procedure, transfer a 50mL sample (or appropriate volume for your lab)

into the polypropylene digestion vessel. For best results, weigh the sample

directly in the vessel on a tared balance.

3.2 Add 1mL 1:1 HNO3and 0.5mL 1:1 HCl and swirl. Heat in the HotBlock at a

sample temperature of 85°C and evaporate to about 10mL taking care that

the cup does not go dry. This will take approximately 2 hours.

3.3 Cover the vessel with a disposable watch glass (Item # SC505) and reux an

additional 30 minutes.

Note: When using a watch glass, adjust the set point temperature of the HotBlock so

that a 50mL, 5% acid solution is heated to 85°C BEFORE placing the watch glass over the

sample. Laboratory tests have proven that the addition of the ribbed watch glass will add

approximately 10°C to the sample temperature, bringing the sample temperature up to 95°C.

3.4 Using the polycarbonate transfer racks, remove samples from the HotBlock

and allow them to cool. Bring samples up to volume with DI water.

3.5 If necessary, lter with SC0401 (or appropriate FilterMate® or FlipMate®) to

remove insoluble material.

Note: The ltration step should be performed slowly with little pressure placed on the

plunger. If excessive back pressure occurs stop ltration and allow sediments to

“settle out”. Applying pressure to the plunger may cause sample “blow through” allowing

sediment to pass through the lter into the digestate.

Adaptation for EPA Method 200.7, Revision 4.4 for use with the

Environmental Express HotBlock® Digestion System Revised 12.13

+1.800.343.5319 or +1.843.881.6560 envexp.com Environmental Express • 17

AutoBlock® Fill: Operation and Instruction Manual EPA Method 200.7, Revision 4.4

4.0 Procedure, Total Recoverable Elements, Solids Sample

(EPA Method 200.7, Paragraph 11.3)

4.1 For each digestion procedure, transfer 0.5g ± 0.01g of a dried sieved

sample into the 50mL polypropylene vessel.

4.2 Add 2.0mL (1:1) HNO3and 5mL (1:4) HCl and swirl. Cover the vessel with

a disposable watch glass (item # SC505) and reux an additional

30 minutes at a sample temperature of 85°C.

Note: When using a watch glass, adjust the set point temperature of the HotBlock so

that a 50mL, 5% acid solution is heated to 85°C BEFORE placing the watch glass over the

sample. Laboratory tests have proven that the addition of the ribbed watch glass will add

approximately 10°C to the sample temperature, bringing the sample temperature up to 95°C.

4.3 Allow to cool and bring to 50mL volume with DI water.

4.4 Filter with SC0401 (or appropriate FilterMate® or FlipMate®) to remove

insoluble material.

All QC samples, concentration limitations, elemental lists and reagent specications

are addressed in depth in EPA Method 200.7. Safety concerns are also part of the full

method. Follow the instructions listed in EPA Method 200.7. These steps should only

be used as a guide to help improve the performance of your HotBlock.

+1.800.343.5319 or +1.843.881.6560 envexp.com Environmental Express • 18

AutoBlock® Fill: Operation and Instruction Manual EPA Method 200.8

1.0 Scope and Application

1.1 The following procedures have been written as an aid to EPA digestion

procedure 200.8 for use with the Environmental Express HotBlock. EPA

Method 200.8 is for the determination of total recoverable analytes in

groundwater, surface water, drinking water, wastewater, and (with the

exception of silica) in solid samples such as sediment, sludge and soil. Use

EPA Method 200.8 for reference while following the sample preparation

steps outlined below. A complete list of elements appropriate for analysis is

included in EPA Method 200.8. Analysis can be performed by ICP-MS.

2.0 Apparatus and Materials

2.1 HotBlock for Metals Digestions — Item # C6002, SC100, SC150*, SC151*,

SC154, SC196, SC2015, SC2050, or SC2100*

2.2 Polypropylene Digestion Vessels — 50mL, 100mL, or 15mL

2.3 Ribbed Watch Glasses or Reux Caps, appropriately sized for vessel capacity

2.4 FilterMate — Item # SC0401 (or appropriate FilterMate® or FlipMate®) for

sample ltration if necessary

*Note: For all procedures, when using the block with the SC490 digestion vials with

a 100mL sample, double the volume of all reagents and acids added.

3.0 Procedure, Aqueous Sample Preparation -- Dissolved Analytes

(EPA Method 200.8, Paragraph 11.1)

3.1 For the determination of dissolved analytes in ground and surface waters,

pipet a 20mL or greater aliquot of ltered, acid-preserved sample into the

polypropylene digestion vessel.

3.2 Add an appropriate volume of (1+1) HNO3to adjust the acid concentration

of the aliquot to approximate a 1% (v/v) nitric acid solution. If the direct

addition procedure is being used, add internal standards, cap and mix.

Note: If a precipitate is formed during acidication, transport or storage the sample aliquot

must be treated using procedures for Total Recoverable Analytes.

4.0 Procedure, Aqueous Sample Preparation — Total Recoverable Analytes

(EPA Method 200.8, Paragraph 11.2)

Note: This section applies to water samples containing turbidity of greater than 1 NTU.

4.1 For each digestion procedure, transfer 50mL of well-mixed, unltered,

acid-preserved sample into the polypropylene digestion vessel.

4.2 Add 1.0mL (1+1) HNO3and 0.5mL of (1+1) HCl and swirl. Heat in the

HotBlock at a sample temperature of 85°C. The HotBlock set temperature

should be approximately 105°C. The temperature of a reference blank

should be tested to ensure correct temperature.

Adaptation for EPA Method 200.8, for use with the

Environmental Express HotBlock® Digestion System Revised 12.13

This manual suits for next models

1

Table of contents

Other enviromental express Laboratory Equipment manuals

Popular Laboratory Equipment manuals by other brands

Belden

Belden HIRSCHMANN RPI-P1-4PoE installation manual

Koehler

Koehler K1223 Series Operation and instruction manual

Globe Scientific

Globe Scientific GCM-12 quick start guide

Getinge

Getinge 86 SERIES Technical manual

CORNING

CORNING Everon 6000 user manual

Biocomp

Biocomp GRADIENT MASTER 108 operating manual