Eosense eosFD User manual

User Manual

eosFD

eosFD Forced Diffusion

Chamber and Software

User Manual

This guide is distributed by EOSENSE INC (“Eosense'') for users of the eosFD Forced Diffusion

chamber instruments in conjunction with the eosLink-FD software. Eosense is not liable for special,

indirect, incidental, or consequential damages. Eosense's obligation under this warranty is limited to

repairing or replacing (at Eosense's discretion) defective products within one (1) year from date of

delivery to the customer. The customer shall assume all costs of removing, reinstalling, and shipping

defective products to Eosense where applicable. Eosense will return said products by surface carrier

prepaid. This warranty is in lieu of all other warranties, expressed or implied.

This product complies with the following directives for CE Marking:

2011/65/EU (RoHS2)

2015/863/EU (RoHS3)

2004/108/EC (Electromagnetic compatibility)

For more information, contact [email protected]

Version: 3.1

Revised: August 2020

© Eosense Inc.

User Manual

Contents

Contents 2

1 Summary 3

2 Introduction 4

2.1 What is Forced Diffusion? 4

2.2 How is Flux Calculated? 4

2.3 The Measurement Cycle 6

3 Quick Start Guide 7

4 Hardware 9

4.1 eosFD Housing 9

4.2 Main Power and Data Cable 9

4.3 Power Connectors 10

4.4 Data Cables 10

4.5 Analog Data 11

5 Deployment 12

5.1 Setup 12

5.2 Maintenance 13

6 Using eosLink-FD 14

6.1 Overview 14

6.2 Installing and Connecting 14

6.3 Using the eosLink-FD Interface 14

6.3.1 Menus 15

6.3.1 Buttons 20

6.3.1 Status Bar 23

7 Logged Data Files 24

8 Troubleshooting 25

© Eosense Inc.

User Manual

1 Summary

This manual outlines the operation and features of the eosFD-CO2carbon dioxide (CO2) Forced

Diffusion (FD) chamber, as well as the included eosLink-FD software package. Before supplying power

to the eosFD, please ensure that you read the section on Power Connectors (4.3) to avoid any damage

to the sensor. We strongly recommended that all users read the complete manual before use.

This manual is intended for users of the eosFD with version 2.4.4 of the eosLink-FD interface. Please

check the Resources section of the Eosense website for the most up-to-date manuals and software.

If you have any specific questions or require additional guidance or information, please contact

Eosense Technical Support through our website, by phone or by email:

888.352.8313

https://eosense.com/contact-support/

➔Want to jump right into collecting flux measurements? Section 3 (Quick Start Guide) tells you

all you need to know to start out. For best results, we do recommend you read the entire

manual!

➔Want to learn more about customizing your eosFD measurements? Section 6 (Using

eosLink-FD) explains how to change the measurement frequency and collect data, as well as

other important instrument settings

➔Running into problems? Section 8 (Troubleshooting) covers some of the most common issues

and how to address them. And you can always contact us directly at [email protected].

➔Please visit the Resources section of our website at https://eosense.com/resources/ for

additional information and eosFD Application Notes, including:

◆AN0008: Sizing a Solar Power Supply for a Remote eosFD Installation

◆AN0012: eosFD Effects on Soil Moisture and Temperature

◆AN0014: Interfacing the eosFD to a Campbell Scientific CR1000/CR6 Data Logger

© Eosense Inc.

User Manual

2 Introduction

2.1 What is Forced Diffusion?

The eosFD is a stand-alone soil CO2flux sensor, containing a single NDIR sensor, an internal data

logger and small diaphragm pump. The eosFD uses Eosense’s patented Forced Diffusion technology

to measure soil CO2flux directly. Traditionally, gas fluxes from the soil surface are measured using

closed chamber systems, with these “accumulation chambers” trapping gas during the measurement

period. CO2concentrations continue to increase while the chamber is down, and different mathematical

fits (typically linear or exponential) are applied to the data to indirectly estimate the original rate of flux.

Forced Diffusion is a membrane-based steady-state approach for measuring gas flux that establishes

an equilibrium between gas flowing into the chamber and gas flowing out of the chamber through the

membrane, without any external chamber movement. By carefully characterizing the diffusive

properties of the membrane used in the instruments, the eosFD chamber gas concentration can be

correlated directly to the gas flux rate. Essentially, the amount that this membrane limits the flow of gas

out of the chamber is known, and thus by comparing the internal concentration to that outside of the

instrument, the flux rate can be calculated. Unlike other automated chambers that lift and lower onto the

soil surface, the Forced Diffusion approach does not require external moving parts, allowing it to be

deployed in the harshest climates for extended periods without intervention.

2.2 How is Flux Calculated?

Forced diffusion flux is calculated by calibrating the diffusive transport of gas across the eosFD’s

membrane. This flux rate depends on the effective diffusivity of the interface, the concentrations on

either side and the path length between the two points. The relationships between these parameters

are linear, and everything but the soil and atmospheric concentrations are assumed to be constant,

which simplifies to a single calibration slope (G

). The flux is then calculated by multiplying the difference

in soil and atmosphere concentrations by the calibration slope:

The full differential equation showing the (volume/surface area) scaled

rate of change in flux rate equal to the flux from the soil surface (F

S

)

minus the difference in concentration, ∆C (scaled by both the path

length L

and the diffusivity of the interface, D

).

The change in the flux rate is assumed to be zero (steady-state) over

the timespan of the concentration measurements (~60 s). The

steady-state assumption reduces the equation to a linear dependence.

As the path length and interface (membrane) diffusivity are constant,

this can be represented by a single coefficient, G

.

© Eosense Inc.

User Manual

In order to measure the difference in

concentration used to calculate flux,

the eosFD has two internal chambers

where gas is exchanged with the

atmosphere - the Soil Cavity and the

Atmospheric Cavity. Gases emitted

from the soil surface flow into the

bottom of the eosFD and accumulate in

the Soil Cavity. This gas is exchanged

with the atmosphere through two of the

membrane covered windows near the

bottom of the eosFD. The other two

windows lead to the Atmospheric

Cavity, which encircles the inner Soil

Cavity, but is isolated from direct

exposure to soil gas.

When the measurement cycle occurs,

samples from these two cavities are

drawn (via internal pump) to the NDIR

CO2sensor for analysis, before being

returned to the original cavity. These

measurements are used to calculate

the difference in concentration, ∆C.

For more information: Risk, D., Nickerson, N., Creelman, C., McArthur, G., Owens, J., 2011. Forced diffusion

soil flux: a new technique for continuous monitoring of soil gas efflux. Agric. For. Meteorol. 151, 1622–1631.

© Eosense Inc.

User Manual

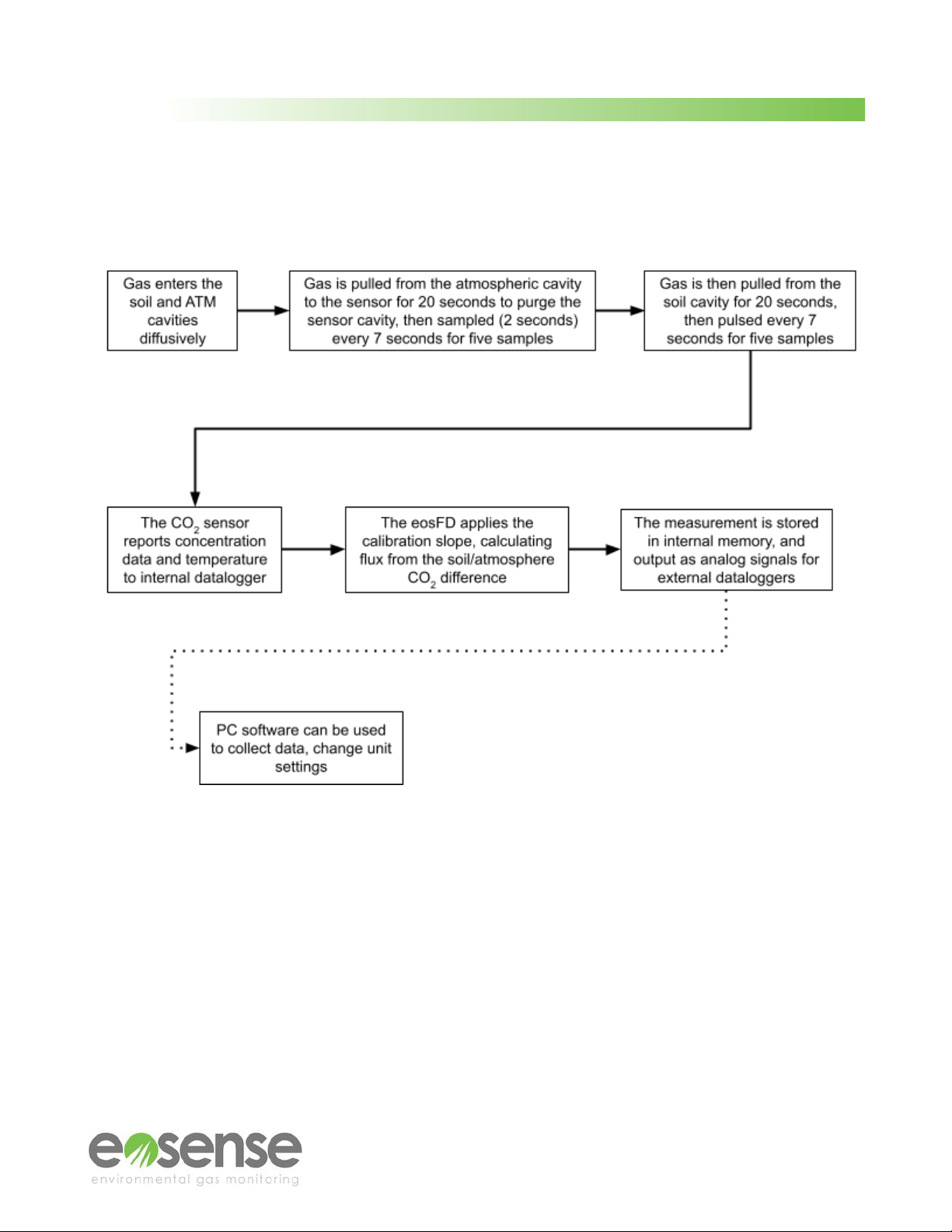

2.3 The Measurement Cycle

The eosFD samples gases from both the atmospheric and soil cavities within the device. The flow

diagram below breaks down the steps that the eosFD goes through to calculate flux.

When gas is being transported to and from the sensor cavity, the eosFD’s pump will be active, creating

a distinct buzzing sound. This sound is also emitted when the unit is turned on (three short pulses) or

when the eosFD accepts a command or data from the eosLink-FD software (one longer pulse).

Please note that how frequently the eosFD pump is active will depend on your measurement frequency.

For the default 10 minute setting, you will hear the eosFD alternate between long (~20 second) pump

activation and shorter (~2 second) pulses. This pattern will repeat twice per eosFD flux measurement,

with the length of silence between measurements depending on the measurement frequency setting.

© Eosense Inc.

User Manual

3 Quick Start Guide

The following steps will guide you through the basic setup and use of an eosFD chamber, with detailed

information available in later sections of the manual.

1.

●First connect the uncapped socket of the eosFD to the single, 12-pin end of the SSC

Power and Data cable.

●Connect the DC+ Power Cable to the 2-pin end of the SSC Power and Data Cable then

to a 12+ VDC power supply, with the red lead going to positive and the black going to

negative / ground (see Section 4.3: Power Connectors). The eosFD should pulse the

pump three times.

●Connect the 3-pin end of the SSC Power and Data Cable to the USB-RS232 Cable.

SSC Power and Data Cable DC+ Power Cable USB-RS232 cable

2. Connect to the device using a Windows based PC, the eosLink-FD software, and the included

data cable.

3. Check that the device’s system time is set appropriately, and choose a measurement frequency

(see Section 6: Using eosLink-FD). Exit the program and then disconnect the USB-R232 cable.

Sampling will begin automatically once disconnected from the eosLink-FD software if the eosFD

remains connected to power (when the first measurement begins will depend on the frequency

settings).

© Eosense Inc.

User Manual

4. Attach the provided Mounting Ring to the top of the eosFD. Clear any vegetation from the soil

surface and gently insert the chamber into the soil surface (depth of approximately 1.5 cm) or a

previously installed collar, making sure that the bottom of the eosFD is flush with the soil surface

(see Section 5: Deployment). Use pegs and line to secure the eosFD to the soil surface via the

Mounting Ring.

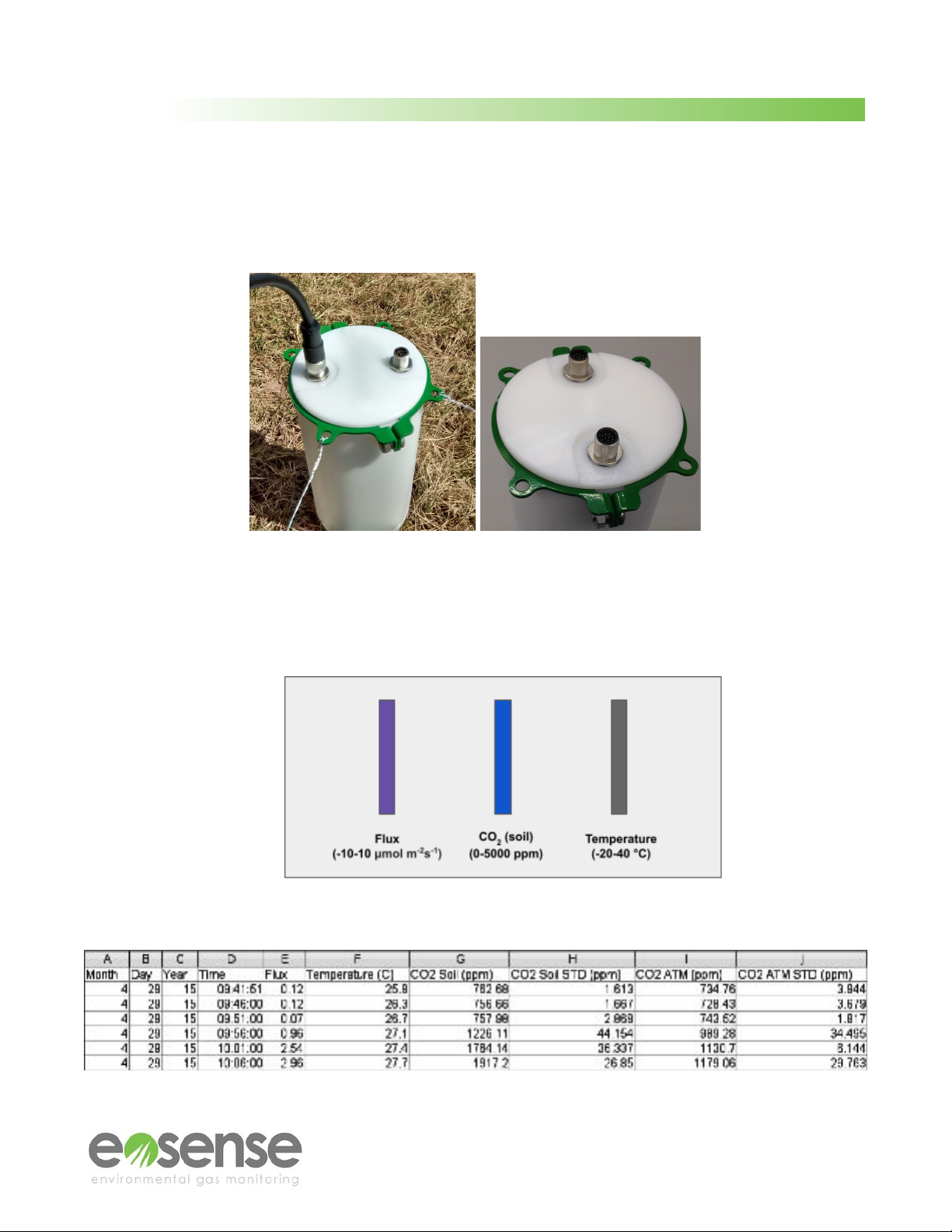

5. If using an external data logger to record FD measurements, connect the purple wire for flux,

the blue wire for soil CO2concentrations, and/or the grey wire for temperature. Each wire

should be connected with one of the black grounding wires as a 0-5 VDC differential voltage

measurement (see Section 4.5: Analog Data).

6. After the desired monitoring time period has elapsed, connect to the device again as described

in Steps 2 and 3 above. Use the Get Data button to transfer the data file to your computer.

© Eosense Inc.

User Manual

4 Hardware

4.1 eosFD Housing

The eosFD housing is machined from acetal plastic, allowing for a durable, water-resistant and

lightweight design. The instrument contains a single CO2sensor, an internal data logger and a small

diaphragm pump. The housing incorporates a diffusive membrane, electrical interface ports and

detachable leg mounting points for a stable field deployment.

The eosFD membrane is critical to proper operation of the device. The membrane should always

appear uniform in colour and free from visible defects. It is important to periodically check the

membrane, as use in field conditions may cause it to tear or otherwise become defective, and the

membrane will degrade naturally over time. Membranes should be replaced annually for best results,

though the membrane life-cycle may be shortened by exposure to harsh conditions. If dirty, membranes

can be cleaned using a gentle tool, such as a soft toothbrush, and a squirt bottle of deionized water.

Use the toothbrush lightly to dislodge any stubborn mud / sediment and then the squirt bottle to wash it

off. Avoid using any solvents such as alcohol, as this can damage the probe's water resistance

New eosFDs have one 12-pin socket. If using an eosFD with

two sockets (one capped and the other uncapped), be mindful

to use the uncapped socket when connecting the eosFD to

power and/or the computer. The capped socket is for

troubleshooting purposes only and should not be used.

4.2 Main Power and Data Cable

The eosFD ships with a standard 5 m power and data cable

(SSC), shown in Figure 1, which plugs directly into the uncapped

12-pin socket on the eosFD housing. Power is supplied to the

eosFD via the two pin connector on the opposite end of the SSC.

This connector also has a tab and notch type system to ensure

that the user connects power with the correct polarity. The eosFD

may be powered by supplying regulated 12 VDC to the sensor via

data logger, battery or other power supply device (see section 4.3:

Power Connectors). A longer 10 m cable (SLC) is also available.

Sensor data is stored on the internal data logger, which can be

accessed using the 3-pin data connector on the SSC, combined

with the USB-R232 cable. The eosLink-FD software is used to

collect stored data, as well as change any of the instruments

settings (see Section 6: Using eosLink-FD). Figure 1 SCC Power and Data cable

© Eosense Inc.

User Manual

4.3 Power Connectors

The DC+ external power cable (Figure 2) included with the eosFD is

used to power the chamber from a DC power supply.

The DC+ cable includes a 2-pin connector for attachment to the

SSC/SLC cables. The opposite end of the cable has bare leads, to

allow for connection to a DC power supply. The black wire should be

attached to the ground terminal of the DC power device, and the red

wire should be attached to the positive terminal. The eosFD operates

on 12 V DC power. Exceeding 12 V may damage the eosFD, please

ensure that the voltage is regulated correctly before connecting the

power supply to the unit. The power consumption will vary slightly

depending upon the supplied voltage. The average draw for a 10

minute cycle is ∼100 mA (1.2 W) with a peak of ∼300 mA (3.6 W).

Figure 2 DC+ Power Cable

4.4 Data Cables

Communication between eosLink-FD and an eosFD uses the RS-232 Serial protocol. The following

components may be used to facilitate this interface:

● SSC Power and Data Cable - (Included) Used to power an eosFD as well as provide an RS-232

interface.

● USB-RS232 Cable- (Included) Connects the SSC data port to a USB port. Used to create a

virtual COM Port, allowing the eosFD to be connected to a computer through a USB port.

●Serial Breakout and Grounding Cable - (Included) Used to connect the eosFD to a data logger

using a serial interface. Also used as the grounding cable for analog connections (see section

4.5 for more information).

Figure 3 SSC Power and Data Cable (left), USB-RS232 Cable (middle), and

Serial Breakout and Grounding Cable (right)

© Eosense Inc.

User Manual

4.5 Analog Data

In addition to the internal memory of the eosFD, users also have the

option of recording analog data on an external data logger, using the

three wires on the SCC Power and Data Cable (AN0014 provides more

detailed information on interfacing an eosFD to a Campbell Scientific

data logger, including how to record data using the serial interface).

Each wire should be connected along with one of the three black

grounding wires as a 0-5 V DC differential voltage measurement, with

ranges, multipliers and offsets as shown in the table below:

Figure 4 Purple, blue, and grey

wires on the SSC Power and

Data Cable.

*New eosFDs no longer output Soil CO2via analog. CO2values recorded by the eosFD are used

only to calculate the flux, and are not intended to be stand-alone measurements of CO2.

In order to interpret the analog signals, simply apply the appropriate linear transformation to the voltage

data, as determined by the range. For example, to transform a temperature voltage signal, first divide

the voltage by the 0-5 V range, then multiply by the -20-40 °C temperature range. Finally, add the

minimum of the temperature range. The example below shows each step for a reading of 3 V.

(1) 3 V / (5 V - 0 V) = 0.6

(2) 0.6 * (40 °C - -20 °C) = 36 °C

(3) 36 °C + -20 °C = 16 °C

Thus a 3 V analog signal for temperature corresponds to 16 °C.

© Eosense Inc.

Output

Colour

Units

Range

Multiplier

Offset

CO2 Flux

Purple

μmol/m2/s

-10 - 10

0.004

-10

Soil CO2 Signal*

Blue

ppm

0 - 5000

1.0

0

Sensor Temperature

Grey

°C

-20 - 40

0.012

-20

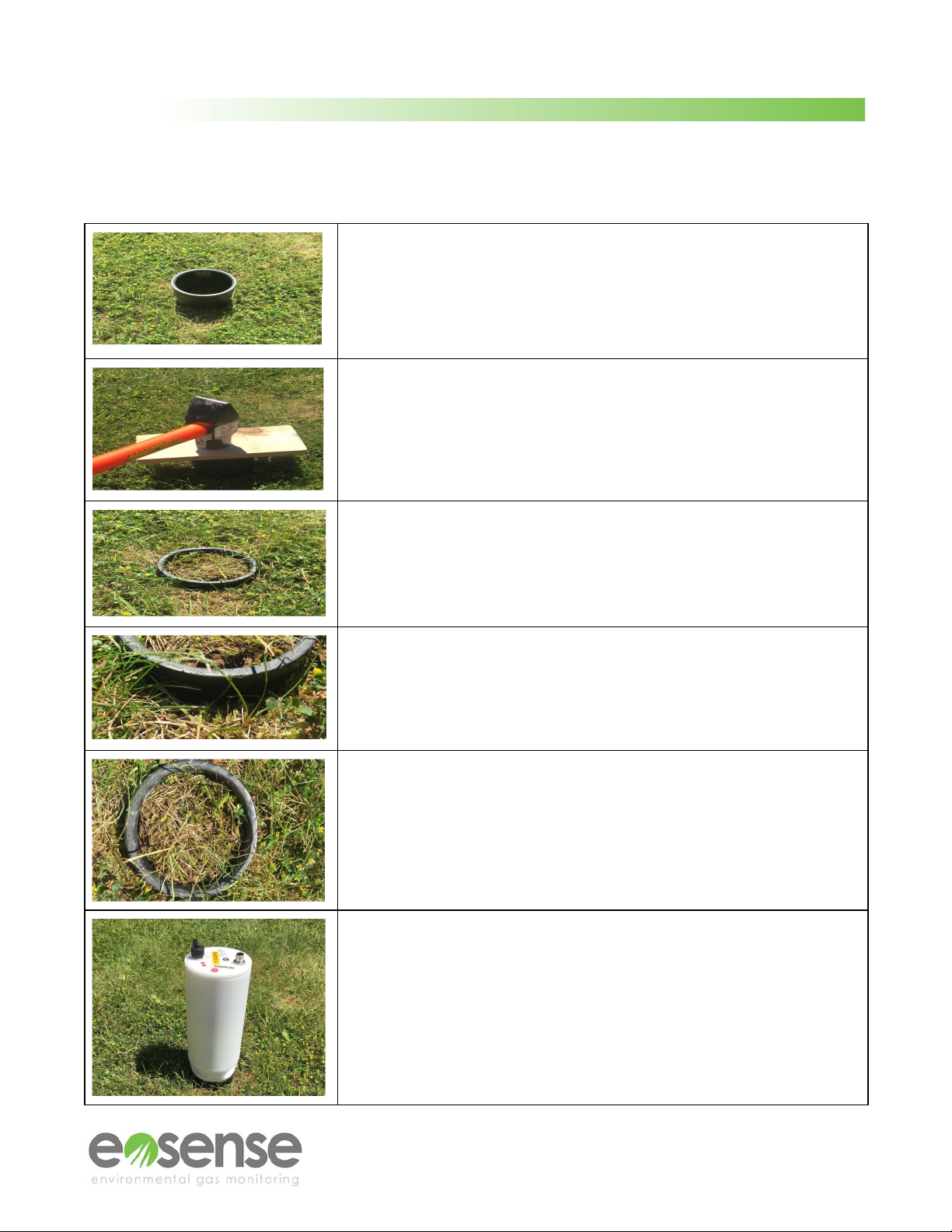

Situate the collar in a flat location, clear of any rocks or debris.

Remove any larger vegetation from the general area. When

possible, deploy the collar at least 24 hours prior to the start of

eosFD measurement collection (or allow for some disturbance

-related fluxes in the early portion of your data).

Gently tap the collar into the ground, ensuring that the force is

distributed evenly across the top of the collar. This can be

accomplished by placing a board or other flat object on top of the

collar, and using a broad-head hammer. Ensure that the top of the

collar remains parallel to the ground by tapping directly above the

collar and not to one side or the other.

Where possible, insert the collar to near full depth, as excessive

distance between the soil surface and the bottom of the eosFD can

increase how long it takes the instrument to respond to changing

flux rates. Ideally, a centimeter of space should be left, to aid in

installation of the eosFD itself as well as collar retrieval.

Inspection of the edges of the collar should show no significant gaps

between the soil and collar, though some near-surface spacing is

unavoidable. Upon subsequent visits to the field site, review these

edges, as the soil should naturally fill in any gaps created during

installation.

Try to minimize disturbance to the soil during collar installation, as

this can increase the equilibration time between the eosFD and the

soil, and potentially cause measurement errors if there is a

particularly bad seal between the soil and collar at depth.

To deploy the eosFD in the installed collar, simply insert one side of

the bottom ring into the collar until flush, then gently push on the

opposite side until the eosFD is securely seated. Inspect all sides to

ensure no gaps exist.

User Manual

While the eosFD is water resistant, avoid situating the probe in areas

of standing water or hollows where flooding is a possibility. For best

results choose a flat, clear soil surface that is free of large rocks to

insert the chamber. Where stability is a concern, use pegs and line to

secure the eosFD to the soil surface via the attached Mounting Ring,

ensuring that the guy-lines remain taut when the pegs are driven into

the soil.

Connect the eosFD to the 12-pin end of the SSC Power and Data

cable. Connect the DC+ Power Cable to the 2-pin end of the SSC

Power and Data Cable then to a 12 VDC power supply. Once

powered, the eosFD will pulse the pump 2-3 times, which indicates

that it is properly connected.

Figure 5 An eosFD deployed in

the field, with uncapped aux port

5.2 Maintenance

The eosFD should be checked-over monthly for best results. Check

the power supply and connection, ensuring that the eosFD pump

sounds when power is cycled. In the event of fouling, the eosFD

membrane can be cleaned by first gently removing any particles

using a dry, non-abrasive cloth. Then, use a damp (no solvents)

cloth to gently remove any remaining dirt or substance.

If the membrane appears to be significantly clogged or punctured

in any way, contact Eosense immediately to determine if the

membrane needs to be replaced. A damaged or fouled membrane

can lead to inaccurate flux measurements by the device. Make

sure to remove any vegetation growing in the collar or directly

around the eosFD that may block the side membrane. Finally,

ensure the collar is still flush with the surface, re-adjusting if

necessary. Figure 6

Top: Mildly fouled membrane.

Bottom: Clean eosFD membrane.

© Eosense Inc.

User Manual

6 Using eosLink-FD

6.1 Overview

eosLink-FD is an application that allows the user to communicate with the eosFD chamber in order to

change various instrument settings, as well as collect and clear logged data. eosLink-FD is compatible

with Windows PCs.

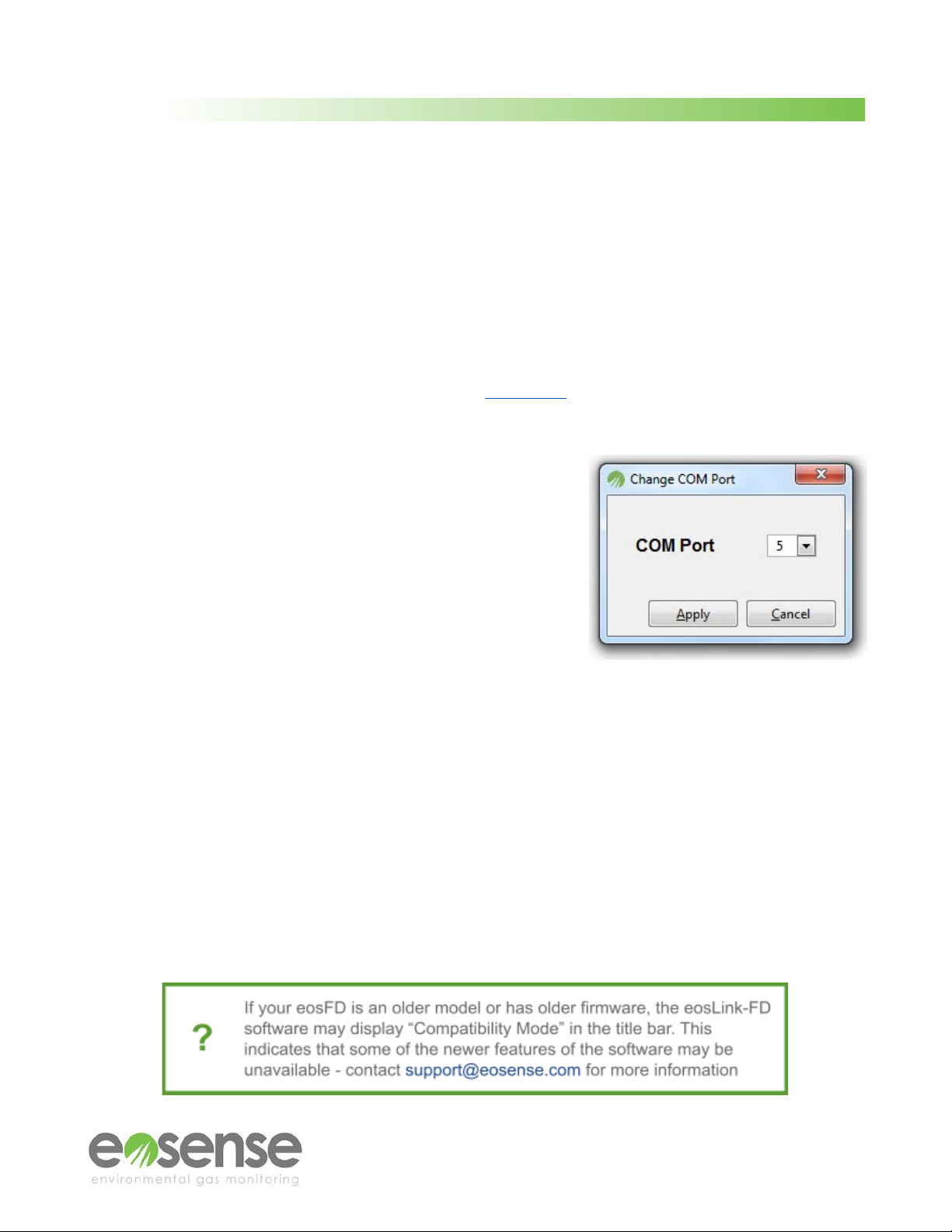

6.2 Installing and Connecting

Simply copy the eosLink-FD.zip file (available on the Resources section of our website, or by contacting

contains the eosLink-FD software folder. None of the files in this

folder should be removed or changed in any way. If this occurs,

simply delete the entire folder from your PC and re-extract from

the zip file to re-create the folder.

We recommended that you connect the data cable to your

computer prior to launching eosLink-FD; however you may also

refresh the program from the Connection menu. You may have

to refer to the Windows Device Manager if several serial port

devices are connected to the computer, and choose the correct

port through (Options⇒Change COM Port).

Figure 7 eosLink-FD Change COM Port

window

Once the port is selected, the eosFD will automatically attempt to connect. When the connection is

successfully established, the grayed out buttons and text will become active, and the eosFD serial

number and storage capacity will be shown at the bottom of the window.

6.3 Using the eosLink-FD Interface

The eosLink-FD window consists of four menus, five buttons and a status section at the bottom, as

detailed in the following subsections. Once the eosFD has been connected, the user can begin

modifying instrument settings. Left idle, the eosFD will automatically disconnect after ten minutes of

inactivity (timeout restarted every time a command is sent).

© Eosense Inc.

User Manual

6.3.1 Menus

There are four menus visible at the top of the eosLink-FD window:

Menu 1 - File: This menu provides the ability to collect both the measurement data file and the error log

file (both commands also have their own dedicated button) as well as a means of exiting the program.

Menu 2 - Connection: The Connection menu has three options, including the ability to refresh the list

of available COM ports and choose a specific port number. If the program was launched prior to the

eosFD being connected, you will need to refresh the connection to allow the correct port to be chosen.

Menu 3 - Options: This contains a number of secondary functions which are described below.

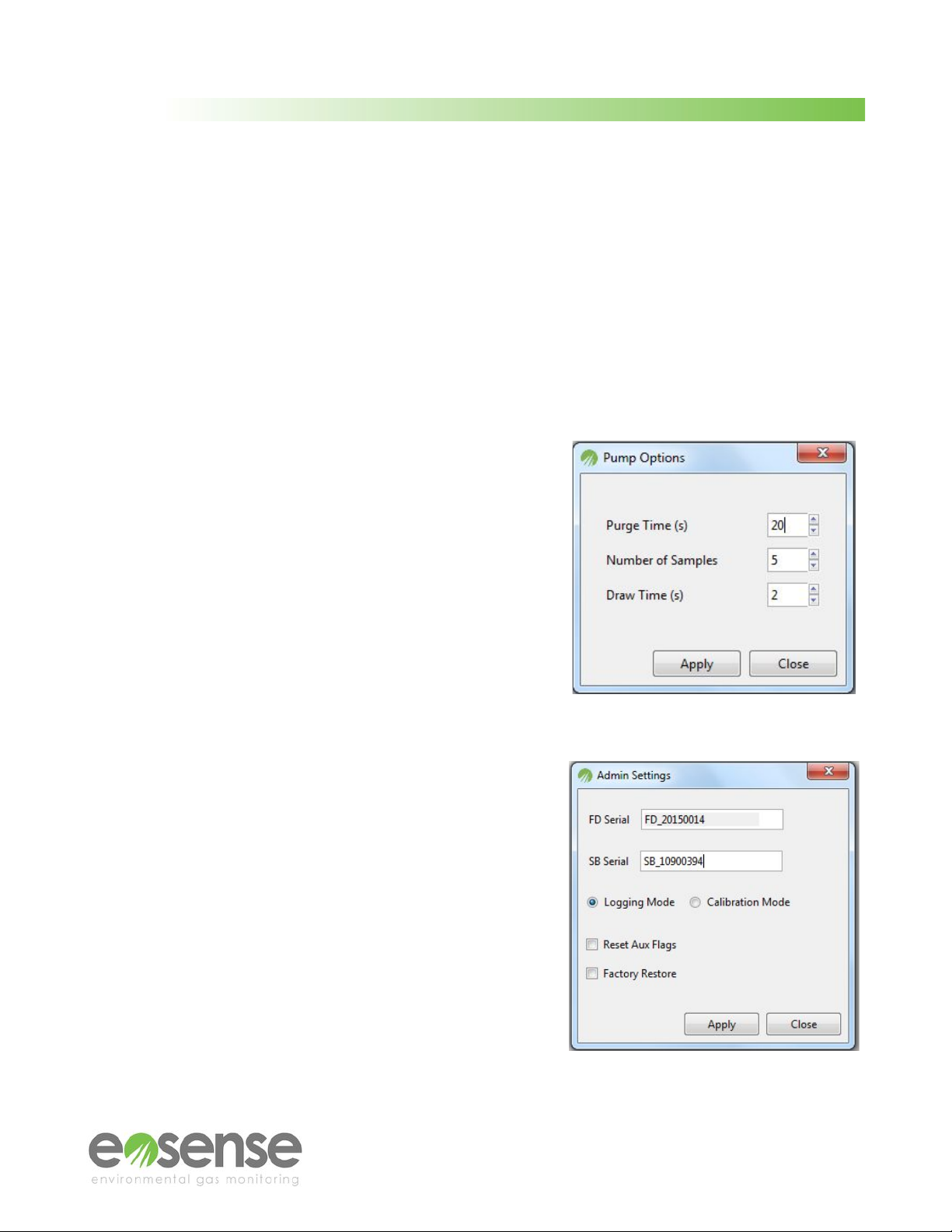

● The Pump Options window allows the user to change

the pump settings used to draw and analyze soil and

atmospheric cavity CO2gas concentrations. Altering

these values may affect the accuracy of measured flux

rates. Purge Time refers to the length of the purge

cycle between atmospheric and cavity samples.

Number of Samples sets the number of concentration

measurements from which the median concentration is

taken. Draw Time controls how long to allow for

pump-transport of gas from a soil or atmospheric cavity

to the sensor for analysis.

Figure 8 The Pump Options window

● The Device Settings window allows the user to

change the eosFD’s operating mode, serial number

and stored calibration. Please contact Eosense for

access to these options if required. Changing these

options may prevent the eosFD from collecting

flux measurements. Logging Mode is the normal

operating mode for the eosFD, while Calibration

Mode allows for recalibration of the internal CO2

sensor. Reset Aux Flags reverts any changes to the

internal diagnostic values, and Factory Restore

reverts any changes made to the eosFD settings,

including calibration parameters and measurement

frequency settings.

Figure 9 The Device Settings window

© Eosense Inc.

User Manual

● The Record Concentrations window has three suboptions; Soil Cavity, Atmospheric Cavity,

and Alternating. These suboptions are convenient for troubleshooting purposes as it allows the

user to directly measure soil, atmosphere or alternating concentrations at a relatively high

frequency. While recording, a pop-up window displays the sampling measurements which

allows the user to monitor the concentrations live. When sampling is complete, the data will

automatically save to the eosLink-FD software folder.

Alternating data will correlate atmosphere and soil concentrations by an identification number

(0 or 1) located in the fourth data column (Figure 10). The Atmospheric Cavity is identified by 0

and Soil Cavity as 1. The four columns of exported data include:

Time Elapsed The time at which the measurement occurred (seconds)

Concentration The soil/atmosphere concentration of CO2 in ppm.

Temperature The approximate internal temperature of the eosFD in °C.

ATM/Soil Identity Atmosphere Identity (0) Soil Identity (1)

Figure 10 Example of eosFD Alternating Cavity Data, viewed as a spreadsheet

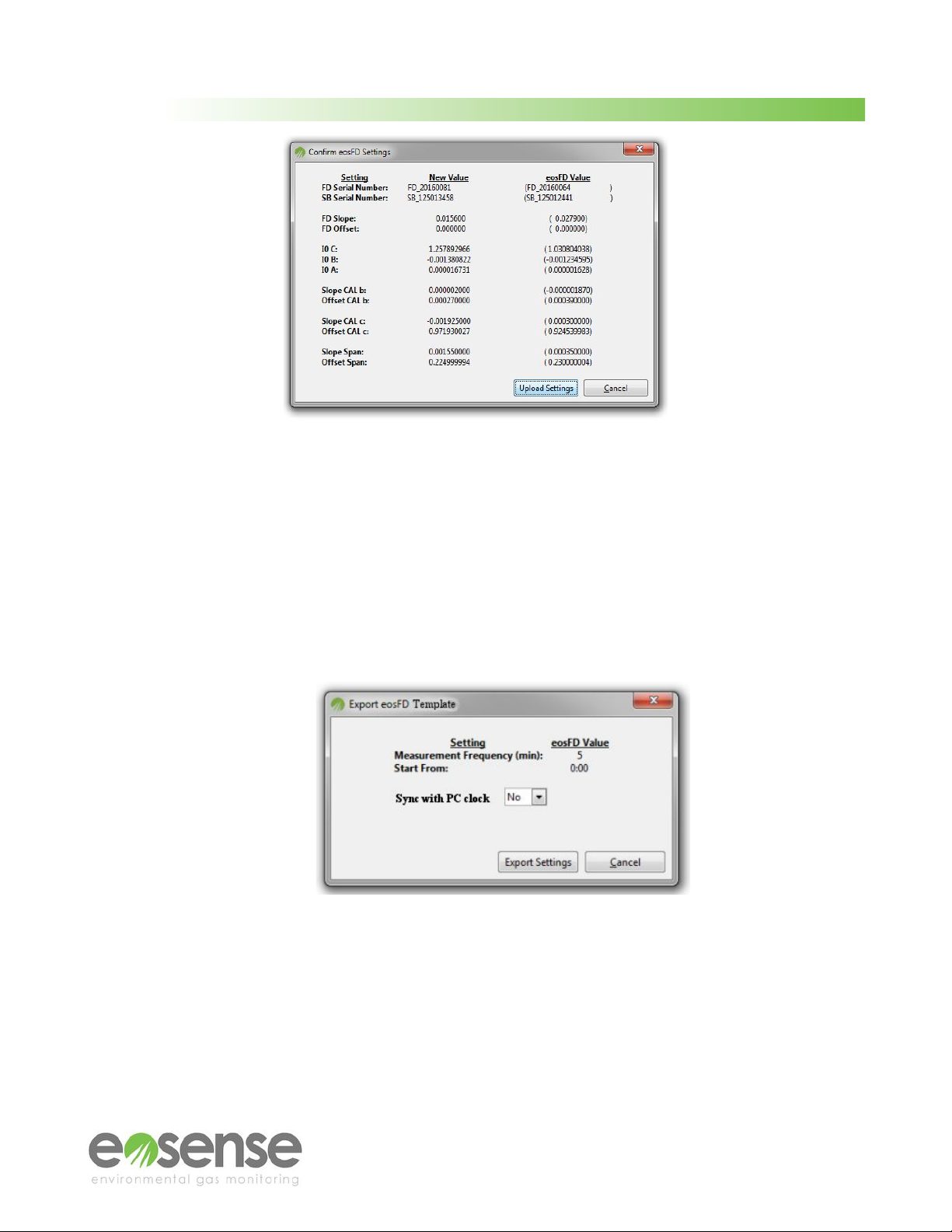

● The eosFD Settings File menu allows a calibration batch file (concentration and flux) to be

uploaded to the eosFD, or exported to a local file. This functionality allows for easy restoration

to factory calibration settings. To export a settings file, choose Export Settings. The eosFD

serial numbers and calibration parameters will be requested from the instrument, and then

displayed in a new window. Clicking the Export Settings will then allow you to choose a location

to save these values for future use.

To upload a settings file, choose Upload File from the menu, and then navigate to a compatible

file (.cal extension). The contained calibration settings will be read in and displayed beside the

current instrument parameters. Click the Upload Settings button to transfer the new coefficients

to the connected eosFD (see Figure 11).

© Eosense Inc.

User Manual

Figure 11 Uploading an eosFD Settings File

●The eosFD Template Files menu allows the user to export eosFD measurement settings as a

local file, which can be used to quickly customize the instrument for different deployment

conditions (e.g. less frequent measurements for off-grid sites) or to standardize settings

amongst multiple eosFDs.

To create a template, choose Export Template from the eosFD Template Files menu, then

choose a save location and filename. The current measurement frequency and start time will be

shown, along with the option to embed a command to synchronize the clock of the eosFD with

the local PC when the template is applied.

Figure 12 Exporting an eosFD Template File

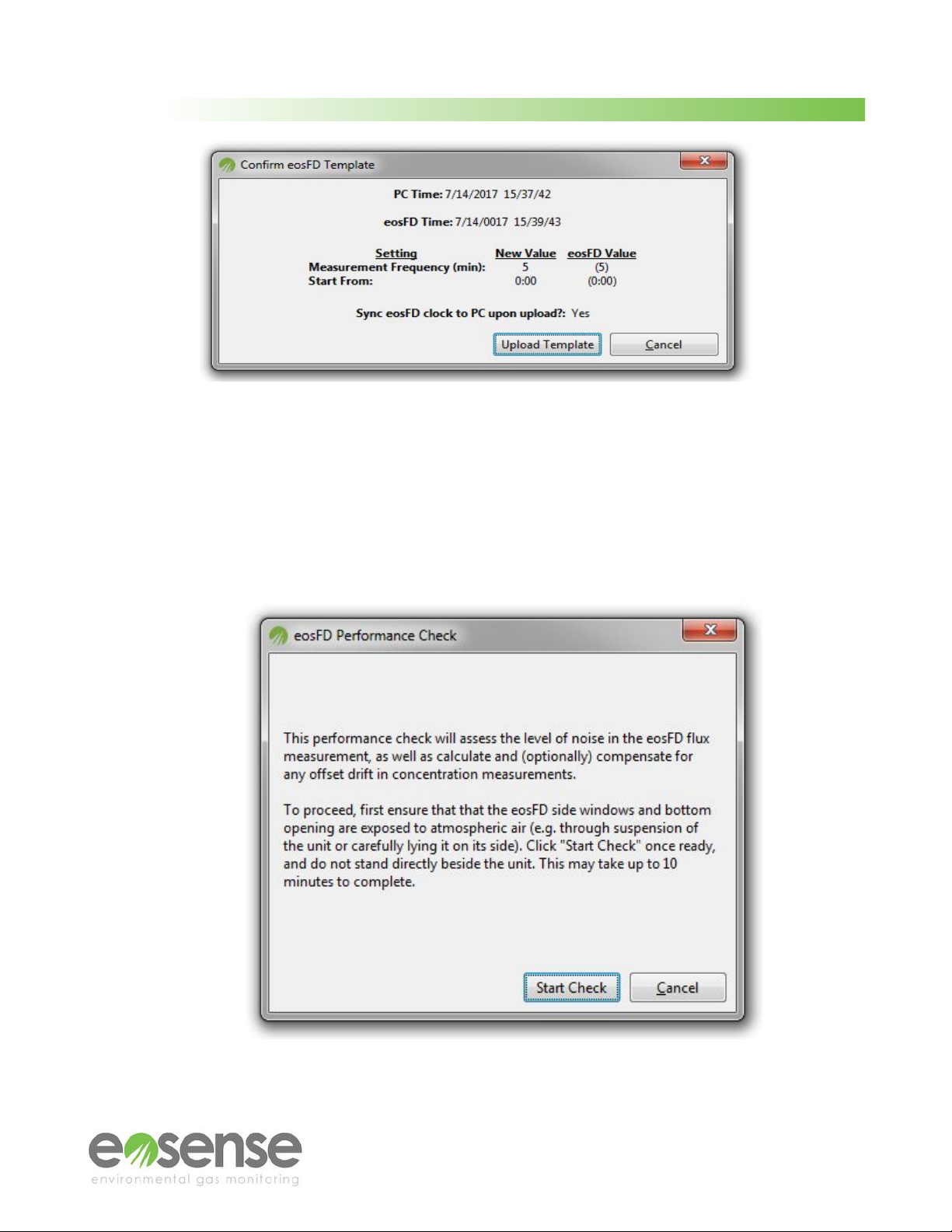

To apply a template file to an eosFD, choose Upload Template from the eosFD Template

Files menu, then navigate to a compatible file (.efd extension). Once the file has been read, the

applicable eosFD measurement settings will be displayed for confirmation. Clicking Upload

Template will apply the frequency and start time settings, and sync the instrument clock with the

local PC (if applicable). See Figure 13 below.

© Eosense Inc.

User Manual

Figure 13 Uploading an eosFD Template File

●The Performance Check option allows the user to assess the atmospheric concentration and

zero flux stability of the eosFD. Choosing this option displays a short explanation of the required

procedure, with the Start Check button used to launch the data collection.

Before proceeding, ensure that the eosFD side windows and bottom opening are exposed to

atmospheric air. For best results, avoid standing directly beside the unit during the Performance

Check.

Figure 14 Starting an eosFD Performance Check test

© Eosense Inc.

User Manual

Once the Performance Check has begun, the eosFD will run through several accelerated

measurement cycles. During this time, the internal pump will operate frequently, as will the

valves. Two progress bars will show the test’s progression.

Figure 15 An eosFD Performance Check in progress

Once the data collection is complete, the results will be presented in two tabs.

Figure 16 Performance Check results for the zero flux

measurements (left) and the atmospheric comparison (right).

The results should show an average flux within 0.2 umol/m2/s of zero under normal conditions,

while the Concentration Results will show an average CO2concentration near 400 ppm.

Differences between the concentration observed by the eosFD (e.g. concentration drift) can be

resolved through the Upload Offset button, though this is not necessary for accurate flux

measurements due to the Forced Diffusion method.

● Admin Mode allows the user to enter a password to enable additional eosFD modifications.

These are not required for normal eosFD operation. Pump Options, Device Settings and

Upload Settings File are restricted to administrator access only. These settings should not

require alteration, however, in special cases where this is necessary please contact

© Eosense Inc.

Table of contents

Popular Industrial Equipment manuals by other brands

Felder

Felder ERM 1050 operating manual

LYSON

LYSON Minima W2092S instruction manual

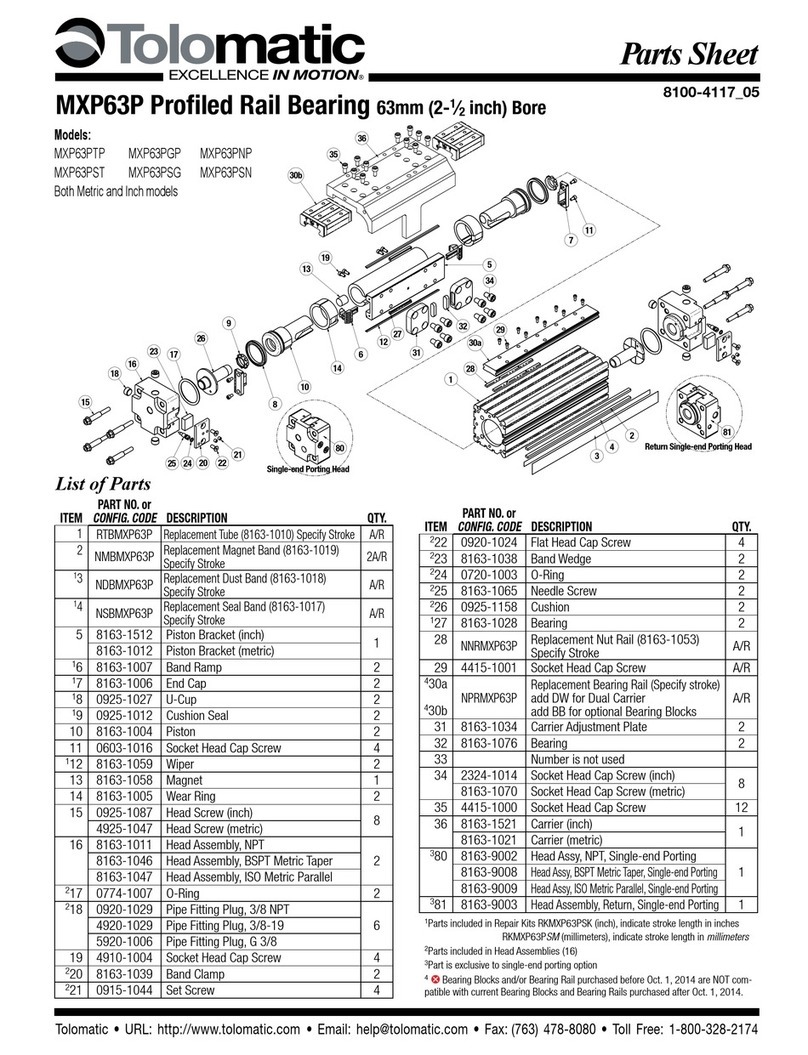

Tolomatic

Tolomatic MXP63PTP quick start guide

HOMEDEPOT

HOMEDEPOT 131-4168 installation instructions

Roadready

Roadready IntelliStage quick start guide

woodmizer

woodmizer Accuset 2 Safety, Operation, Maintenance & Parts Manual

FRONIUS

FRONIUS Energy Package operating instructions

woodmizer

woodmizer LT40HD-R Safety, Setup, Operation & Maintenance Manual

LB Foster

LB Foster PROTECTOR IV TOR Trackside Installation, operation and maintenance manual

Thomas&Betts

Thomas&Betts Elastimold Molded Vacuum Reclosers instruction manual

Alfalaval

Alfalaval Toftejorg MultiJet 25 instruction manual

Sunsystem

Sunsystem P Series Installation and operation manual