Robotis DYNAMIXEL XM430-W210 Guide

Table of contents

Other Robotis Industrial Equipment manuals

Popular Industrial Equipment manuals by other brands

Siemens

Siemens FHA2054-U1 Mounting & installation

Bowcom

Bowcom GMX Instruction manual / spare parts list

Ormandy Group

Ormandy Group Breeze operating & maintenance manual

Fein

Fein Grit GX75 Series manual

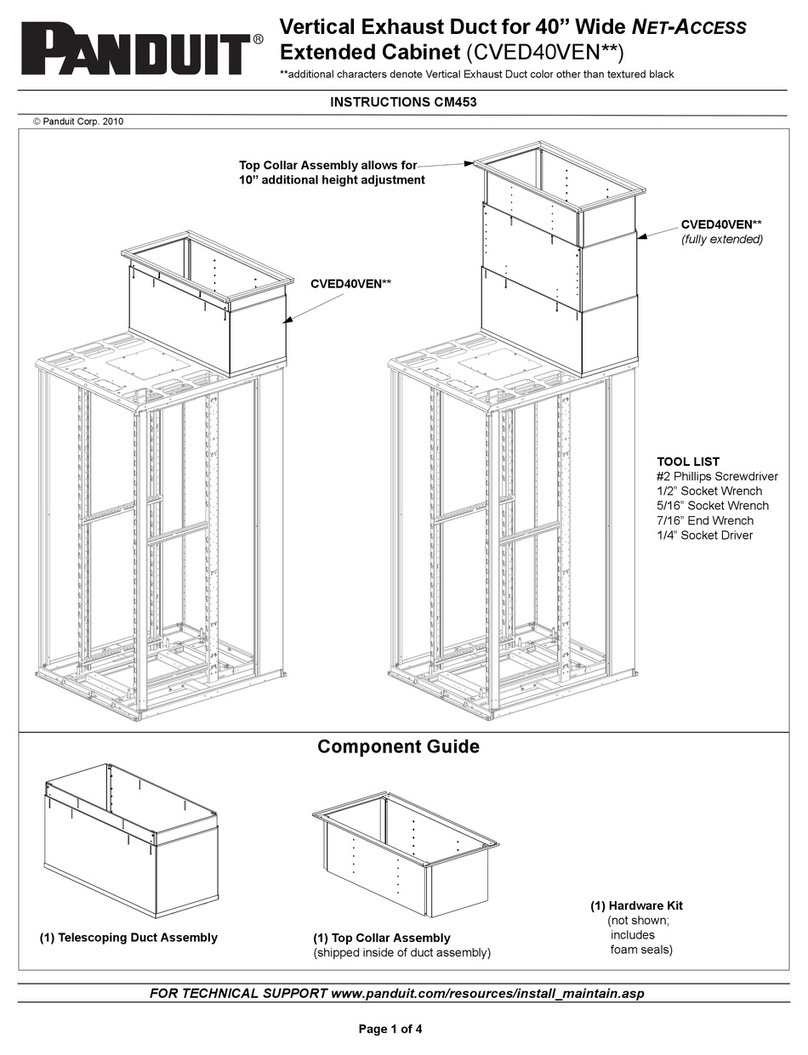

Panduit

Panduit CVED40VEN Series instructions

Imesa

Imesa FLATWORK IRONER Installation and use instructions and warnings

DANA

DANA SPICER Torque-Hub S6B Assembly and Disassembly

Daktronics

Daktronics M Series Operation manual

Siemens

Siemens RM400 C Series operating manual

Nidec

Nidec Leroy-Somer Powerdrive MD Smart Integration guide

AVK

AVK VARI TAP Installation, operation & maintenance manual

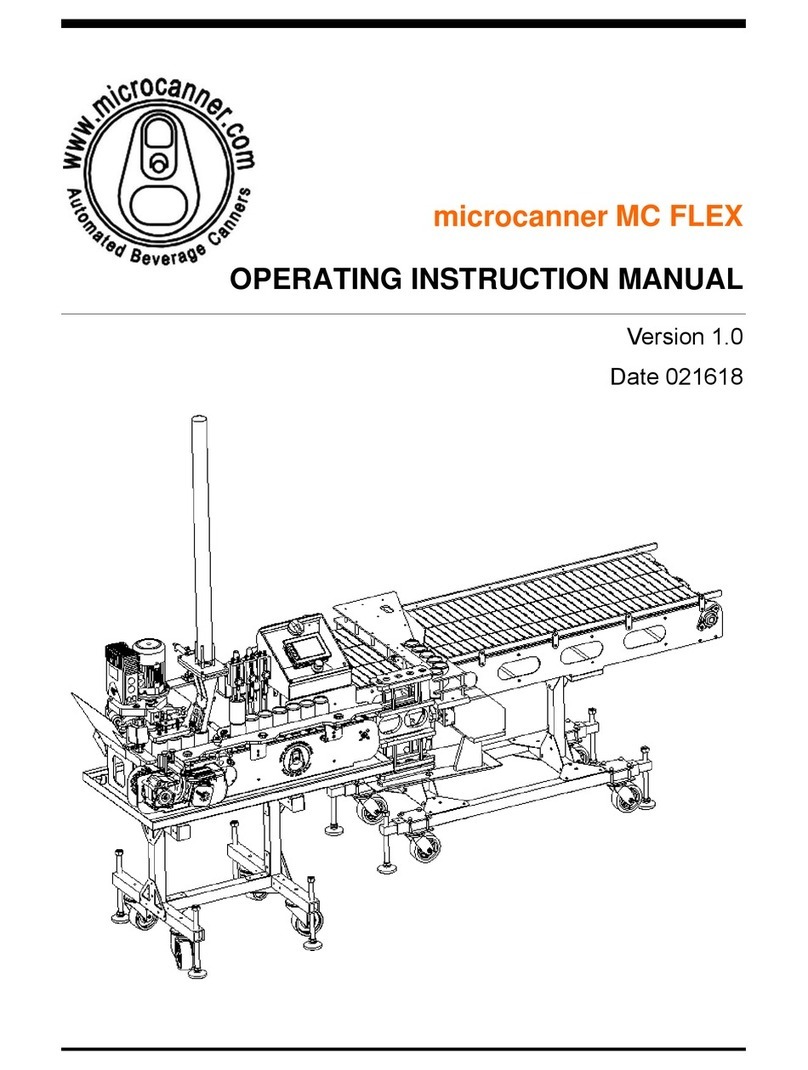

Microcanner

Microcanner MC FLEX Operating instructions manual

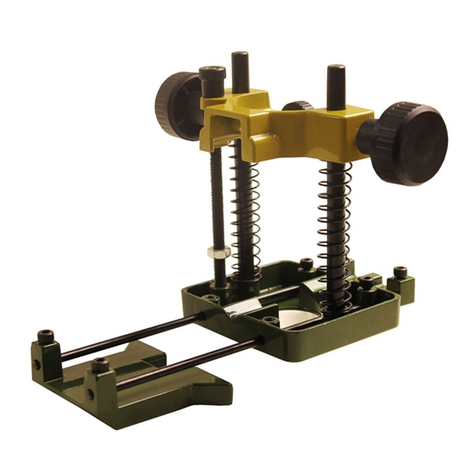

Proxxon

Proxxon MICROMOT OFV manual

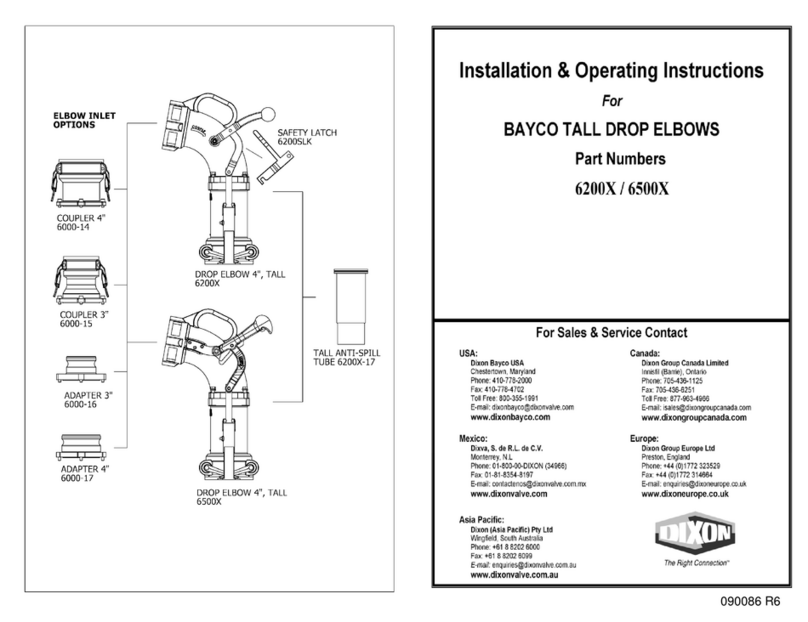

Dixon

Dixon 6200X Installation & operating instructions

HYTROL

HYTROL 190-E24MC Installation and maintenance manual

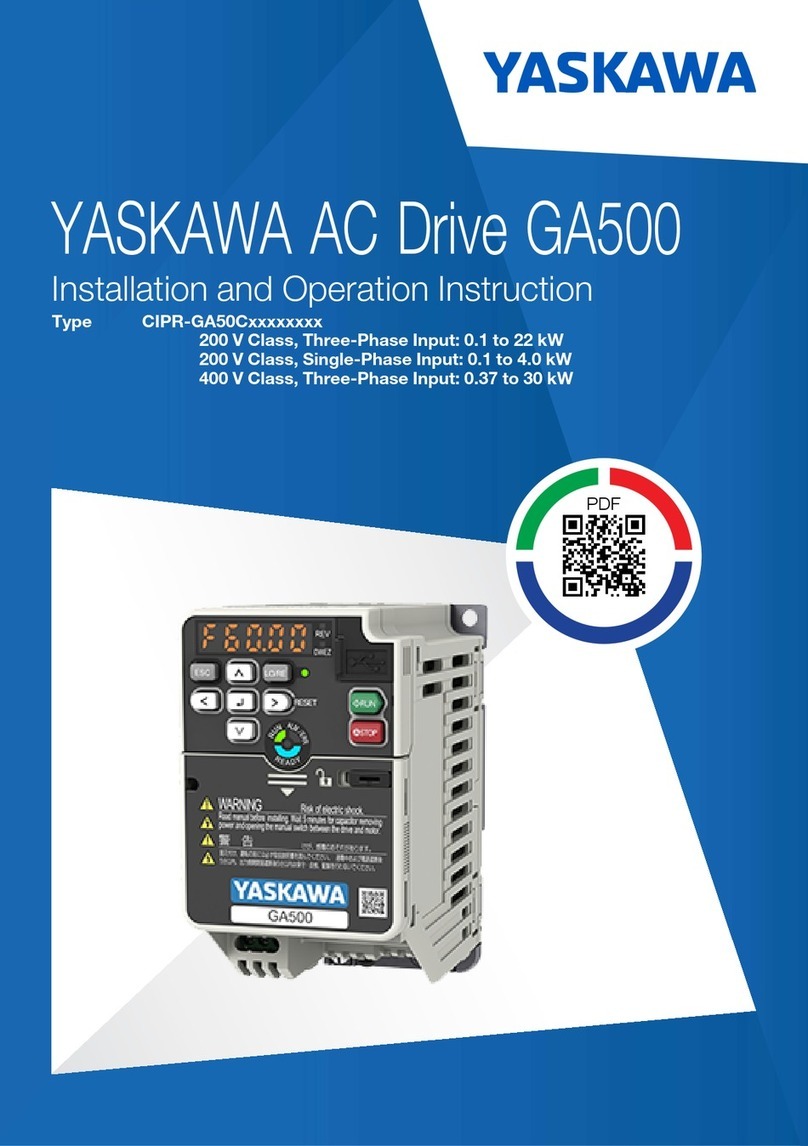

YASKAWA

YASKAWA GA500 series Installation and operation instruction

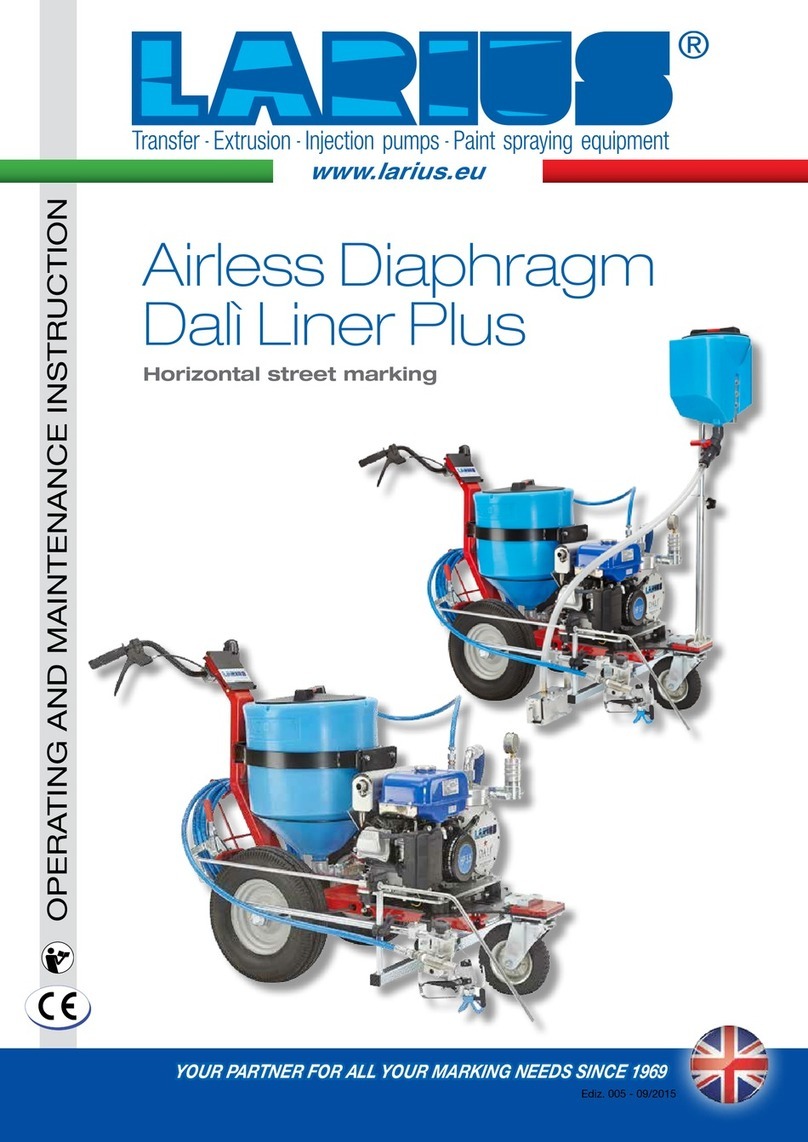

Larius

Larius MIRO LINER PLUS HAND PUSH Operating and maintenance instruction

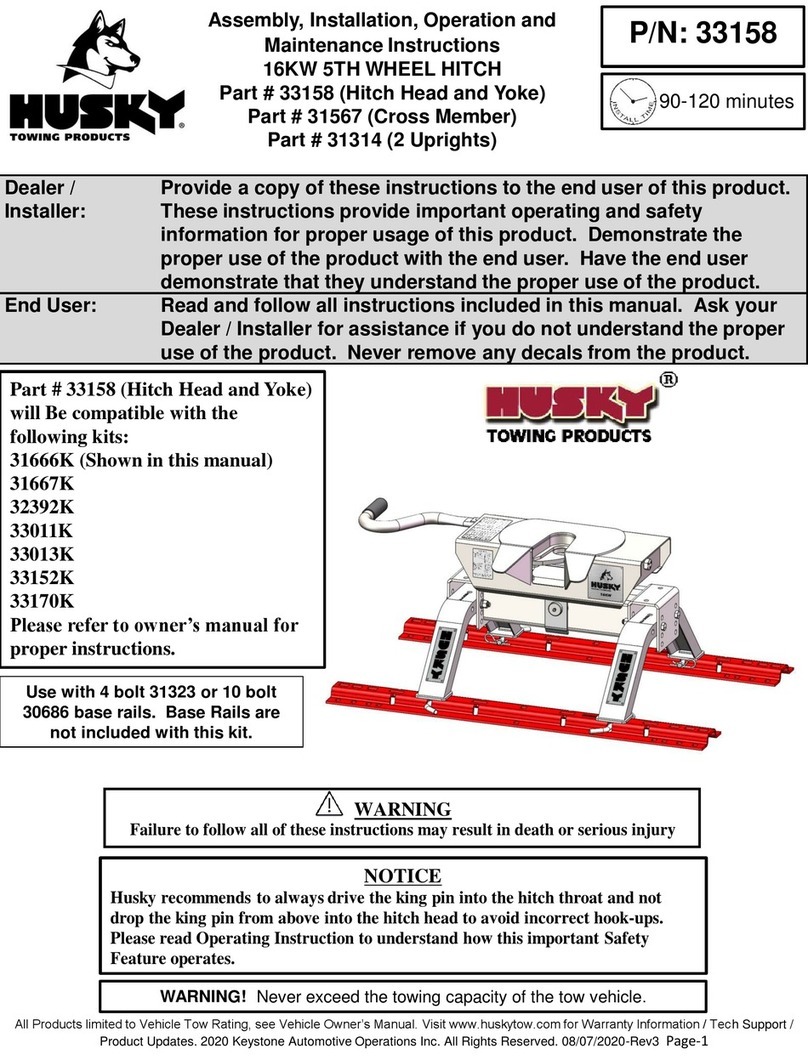

Husky

Husky 33158 Assembly, Installation, Operation and Maintenance Instructions