LB Foster PROTECTOR IV TOR Trackside User manual

www.lbfoster.com

TOP OF RAIL

PROTECTOR® IV TRACKSIDE

FRICTION MANAGEMENT SYSTEM

Installation,

Operation and

Maintenance Manual

for

TOP OF RAIL

For customer service contact the appropriate oce listed below:

United States:

415 Holiday Drive Pittsburgh, PA 15220 USA

Telephone: 412.928.3400 Facsimile: 412.920.3510

E-mail: FrictionMgmtSales@lbfoster.com

Canada:

172 Boul. Brunswick Pointe-Claire, Quebec H9R 5P9 Canada

Tél/Phone: + 1 514.695.8500 x236 Téléc/Fax: + 1 514.695.8110

E-mail: CanadaSales@lbfoster.com

Europe:

Stamford Street Sheeld S9 2TL United Kingdom

Telephone: +44-(0)114.256.2225 Facsimile: +44-(0)114.261.7826

E-mail: UKsales@lbfoster.com

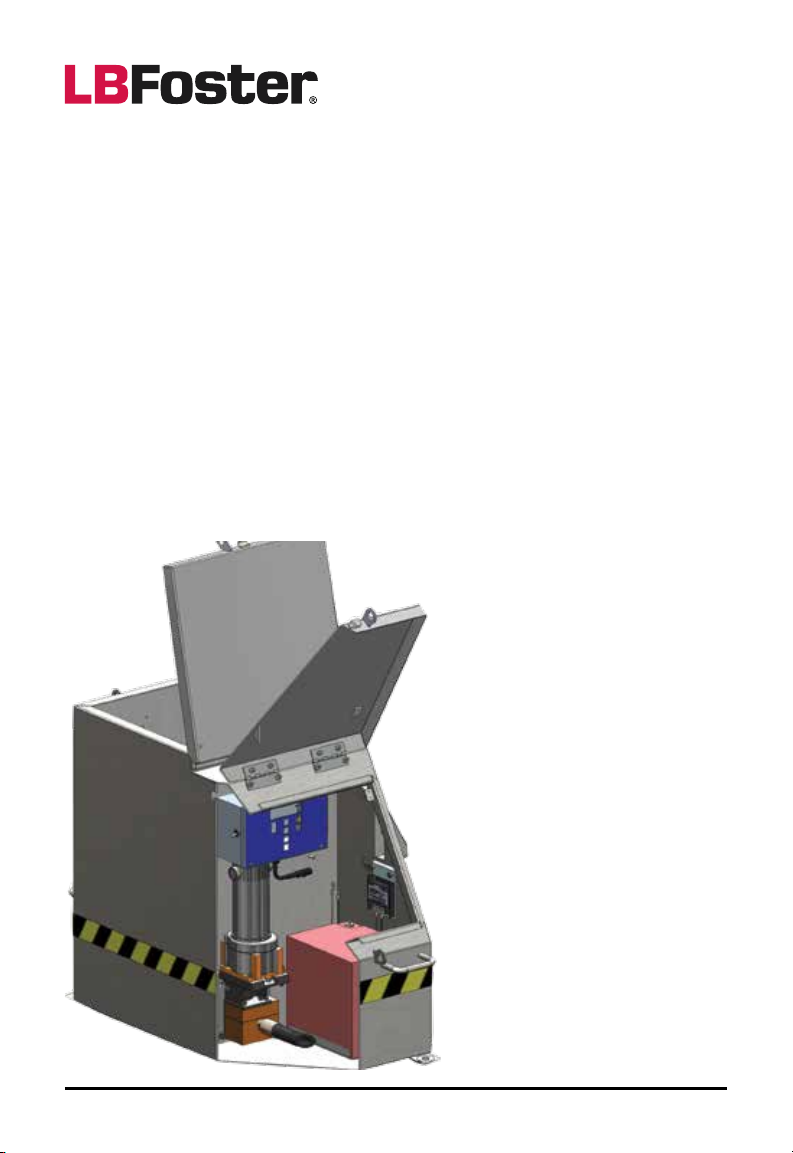

PROTECTOR® IV TOR

200/25 Tank Layout

US Patent Number

D495,974

Thank you for purchasing the

PROTECTOR IV TOR Trackside

Friction Management System. The

PROTECTOR IV TOR system is part

of L.B. Foster’s family of friction

management products designed to

improve conditions at the wheel/

rail interface. We are condent in

our product’s ability to perform and

are committed to providing the

level of product quality, innovative

engineering and customer support

that you have come to expect from us.

The purpose of the PROTECTOR IV

TOR trackside friction management

system is to control friction to an

intermediate level on the railhead

in order to reduce rail wear and the

onset of corrugations, reduce wheel

WELCOME

noise and limit the initiation of rolling

contact fatigue (RCF) and gauge

corner cracking (GCC).This is achieved

by distributing a friction modier,

KELTRACK to the top of the railhead.

KELTRACK is a water-based, liquid

friction modier with ‘positive’friction

characteristics. It is applied directly

to the top of the rail and distributed

along the rail by the wheels. When

the water in the liquid solution

evaporates, a thin dry lm remains

that provides friction management

benets. KELTRACK establishes an

intermediate co-ecient of friction

(µ=0.35) and therefore has no

detrimental eect on braking or

traction.

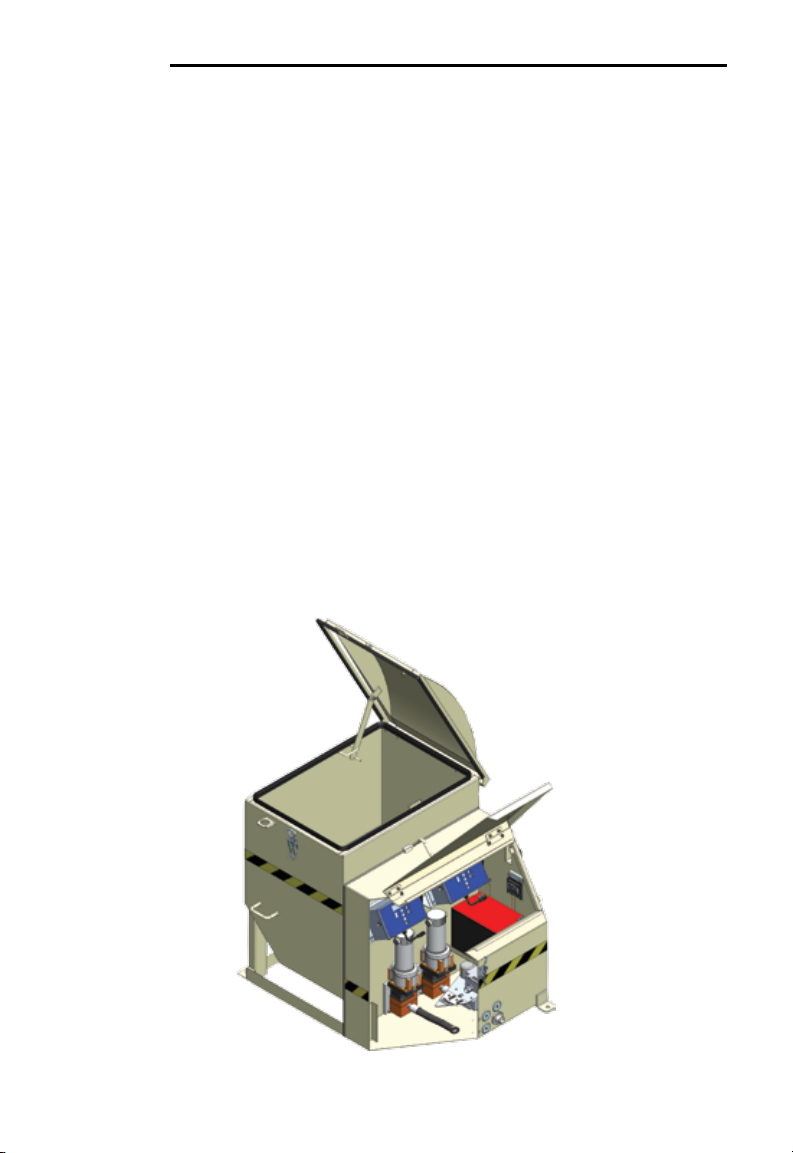

PROTECTOR IV 800/100 Tank Layout

Section 1.1

SAFETY FIRST

There are no special hazards or potential risks regarding this equipment that

cannot be made safe by good working practice.

Lifting

Only unload units onto at and stable ground taking care to keeping the

tank upright. Use mechanical lifting equipment beneath the tank or chains

secured to the four lifting handles. The tanks are equipped with a single-point

lifting strap. Ensure that the tank doors are fastened and locked in place during

moving. Never lift a partially full or full tank using the handles.

NEVER VENTURE BENEATH A TANK BEING LIFTED.

Note: Tank handles are provided for a minimum of four people to manually

maneuver the tank with the hopper empty. Ensure the tank handles are not

used in any other circumstances.

Live Rail Working

None of the equipment is to be mounted on a conductor or power rail. It

is advised that power be isolated (o) for installation and removal. Only

appropriate insulated tools should be used.

AC Power Supply

Ensure AC power source is isolated before connecting line to the power

switch in the tank. Turn power switch to OFF before touching any electrical

connections or working in the tank.

Batteries

Ensure batteries are DISCONNECTED before touching electrical connections

or working in the tank. Do not cause shorting between the battery terminals.

For operator safety, the batteries are sealed with no free acid and classied as

‘non-spillable.’

SHORTING BATTERY TERMINALS WILL CAUSE SPARKS AND CAN

RESULT IN BURNS.

Digital Control Box

Ensure digital control box is switched OFF before working in tank.

INTRODUCTION

Section 1.2

INTRODUCTION

TOOLS REQUIRED

The PROTECTOR IV unit comes equipped with an Allen wrench tool (for

use on the pump mounting bolts). This tool is required for installation and

maintenance of the pump.

Along with the supplied tool, the PROTECTOR IV unit can be installed and

maintained with a minimum number of other tools. Ensure the following

list of tools are available during the installation process (tools for the metric

equivalents are in brackets):

1. Pick and ballast fork

2. Large and medium size adjustable wrench

3. Medium pipe wrench

4. ½” drive reversible ratchet

5. 1” open-end wrench for sensor cable wall connector

6. 10mm open-end wrench or socket for battery terminal

7. /” (15 mm) socket or open-end wrench to mount sensor to bracket

8. Slot and Phillips screwdrivers

9. Wire strippers and crimpers

10. Pliers or channel locks

11. For wiping bar and sensor bracket:

» 0 -250 ft.-lbs. (0-350 N-m) torque wrench

» 1 /” (30 mm) wrench or socket

» Hammer (minimum weight 3 lb. (1 kg))

Section 2.1

The following section is intended to provide a general overview of the

operation of the PROTECTOR IV with a brief description of key components.

Digital Control Box

The Digital Control Box (DCB) is the heart of PROTECTOR IV’s control system.

It provides excellent adjustability of the amount of friction modier that is

pumped from the tank to the bars. It also provides integrity checks for verifying

the electronic controls and motor(s) are working properly. The LCD screen at

the top of the box displays all of the information for the operator.

PROTECTOR IV Digital Control Box (DCB)

Pump

A double gear pump is coupled to the electric motor. The pump/motor

assembly distributes the friction modier to the rails.

Motor

The 12v DC electric motor receives power from the DCB to activate the pump.

Power Requirements

All PROTECTOR IVs are powered by a 12v deep-cycle battery. The unit is

congured with a solar panel but can also be powered by AC if ordered with an

AC/DC voltage convertor.

BASIC SYSTEMS AND COMPONENTS

A BATTERY IS AN EXPLOSION HAZARD BATTERIES CONTAIN

CORROSIVE MATERIALS AND PRESENT A SAFETY HAZARD.

Section 2.2

DC Powered Units

DC PROTECTOR IVs are powered using the provided solar panel. Supply

requirements are 12v DC nominal. Voltages in excess of 14.5v DC can cause

permanent damage to electronic controls. The solar panel charge controller

ensures the batteries are not over charged.

AC Powered Units

Units operating with AC power are equipped with an AC/DC converter

to produce DC power to maintain the battery condition. The power supply

requires 95-135v AC or 200-250v AC, 50-60Hz, single phase AC. Power is to be

supplied by the customer. The trickle charge to the battery is typically 13.8v DC.

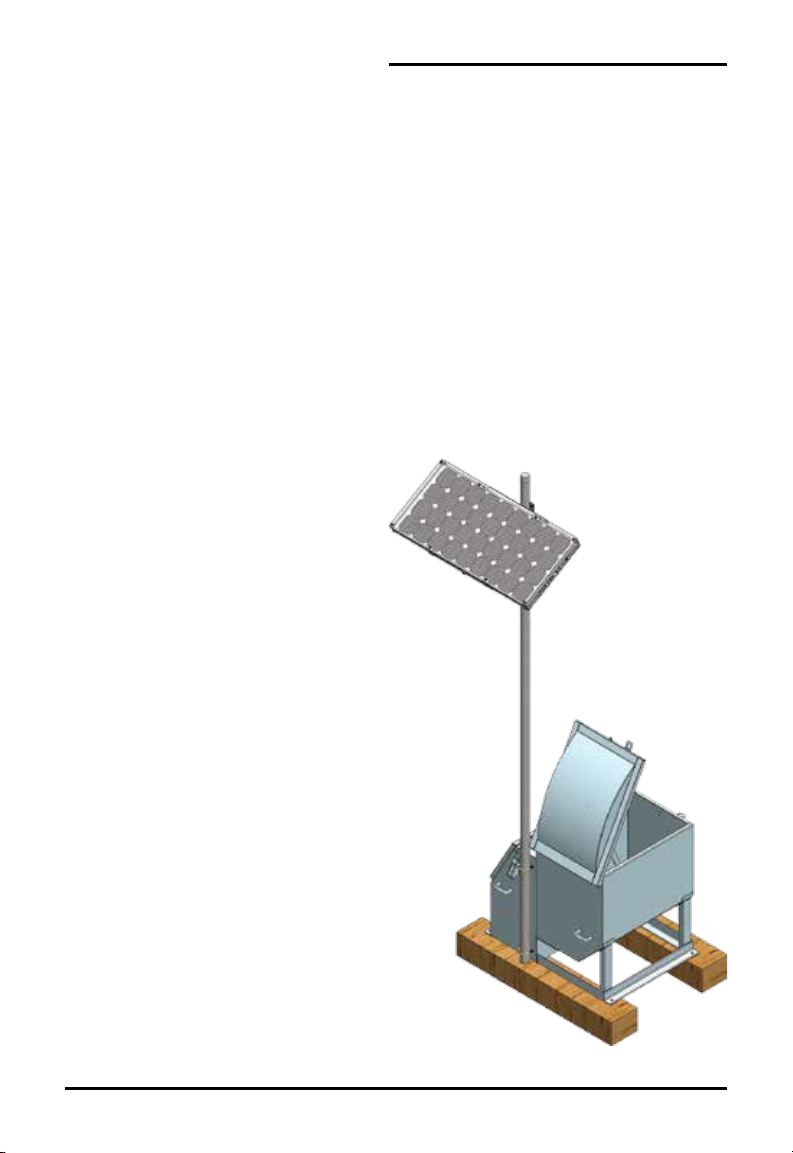

Solar Panel

Every new PROTECTOR IV shipped with a solar package contains the following

basic components:

» Solar panel with Lexan Vandal

Guard and the voltage regulator

mounted inside the clean hands

section.

» Solar panel cable wired to the

panel at the factory.

» Solar panel pole kit (if ordered).

Typical Solar Panel Arrangement

BASIC SYSTEMS AND COMPONENTS

Section 2.3

BASIC SYSTEMS AND COMPONENTS

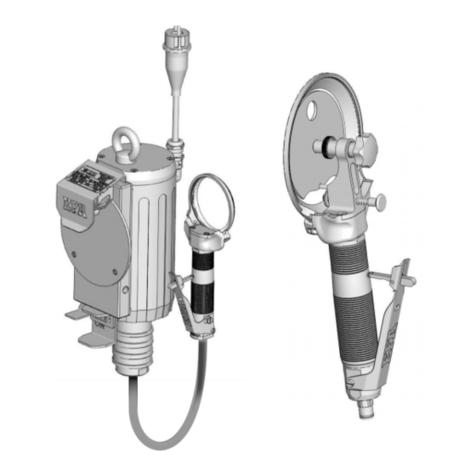

Smart Wheel Sensor

PROTECTOR IV assemblies are equipped with a bi-directional smart wheel

sensor as standard. This can be congured for one way operation if required.

The sensor detects the passage of each train and sends a signal to the DCB.

The sensor primarily consists of a small but very strong magnet connected to

the control circuitry. When a metal object, such as a wheel, enters the sensor’s

magnetic eld a signal is generated and is sent through the control circuit. The

magnet itself is encased within the body of the sensor block, surrounded by a

protective plastic casing.

There is a short length of

cable attached to the sensor

with a pigtail connection. This

mates to a length of cable

feeding directly to the DCB.

The wheel sensor is delivered

with a bracket designed for

mounting to the rail, and

shims to adjust the sensor

height.

Tank

The tank is designed with two separate sections; the materials section that

contains the friction modier and the components section. The tank body

should be secured to a base to ensure its stability and for drainage. Typically,

tanks are mounted to wooden ties or sleepers or a concrete pad.

Distribution Hoses

The distribution hoses are used to distribute the friction modier from the

tank to the rails. The hoses can be installed once the tank and the distribution

bars are in place on the rails.

Bars

The bars are designed to distribute KELTRACK to the top of the rail. When

applied properly the material distributed to the top of rail will dry and leave

behind a ne lm on the track. This will extend the rail and wheel life, reduce

noise, improve tracking through curves and oer a means to control wear at

specic sections of track.

Smart Wheel Sensor

with Fully Fitted Sensor Bracket

Section 3.1

Proper site selection for the PROTECTOR IV is one of the most important

considerationsassociatedwithachievingeectivefrictionmanagementmaterial

distribution. When selecting a site for installation, optimal performance of the

unit depends upon attaining as many of the following general considerations

as possible:

INSTALLATION AND MAINTENANCE OF THE PROTECTOR IV SYSTEM

REQUIRES PERSONNEL TO BE ON-TRACK, INCLUDING BETWEEN THE

RAILS. PRECAUTIONS MUST BE TAKEN TO ENSURE THAT THERE WILL

BE NO TRAFFIC WHILE DOING THIS WORK.

1. It should be positioned on level stable ballast. The base can be made from

either cut wooden sleepers (supplied if required) or a concrete pad. Embed

the base in the ballast and ax the cabinet to the base, lag screws are

provided for a timber base.

2. Locate the unit as close to the curve in the track as possible. Avoid locating

the unit inside a curve. This is particularly important if noise reduction is

the primary goal.

IT IS NOT RECOMMENDED TO INSTALL A UNIT IN A CURVE, AS IT MAY

AFFECT TRACK OPERATIONS.

DO NOT INSTALLTOR BARS CLOSERTHAN 60 ft. (60.5 m)TO AN INSULATED

JOINT. THIS WILL MINIMIZE ANY POTENTIAL FRICTION MODIFIER BUILD-

UP AT THE JOINT WHICH COULD AFFECT SIGNALING.

3. In areas with multiple curves, select a site in a short tangent section of track

between curves. At this location the friction modier material is carried in

both directions and into adjacent curves.

4. Select a site where there is no pronounced railhead wear and railhead is

in excellent condition. If transposed or relay rail with material ow on the

eld side is present, the ow should be ground o at the unit site, before

attempting to install the wiping bars.

5. Select a site where the tie conditions are good and install the unit as close

to zero grade as possible. Installing the unit in a location where the tank

outlet is lower than the track will reduce eciency.

6. Select a site that provides access to the unit for regular maintenance and

relling.

SITE SELECTION

Section 3.2

SITE SELECTION

7. Install the tank far enough from the track to safely clear the operation

of ballast regulators, snow plows, and other track equipment, but close

enough to allow the supply hose to be shortened for maximum eciency.

8. Select a site where power source can be easily routed to the unit. Be sure

the length and size of the power cable does not cause an unacceptable

line loss. In remote locations with no AC power availability, the solar panel

option is recommended.

Note: Outside AC electrical currents from overhead power wires, third rail power

or signal system power sources can interfere with the wheel sensor detection

capabilities.

9. Avoid selecting a site where trains routinely slow down or come to a

complete stop.

10. Site selection should be in an area which will discourage acts of vandalism.

11. The friction modier works best where both the rails and wheels are clean.

Section 4.1

Solar Panel Location and Installation

As you consider solar panel mounting options, be sure that the nal

conguration positions the panel to a Southern exposure in the Northern

Hemisphere and Northern exposure in the Southern Hemisphere. This will

ensure the most consistent exposure to sunlight through the course of a day.

The panel should be unobstructed, so that it receives direct sunlight during

daylight hours all year long.

The standard units are DC powered and charged by a solar panel. This

supplies power to either one or two 12v batteries depending on the number of

pumps. Brackets can be supplied so the solar panel can be mounted to a pole

attached to the tank, or a pole can be

supplied that will allow the panel to

be erected away from the tank if this

will provide better sunlight.

Solar Panel

Solar Panel Mounted to Tank Solar Panel Mounted Away from Tank

ELECTRICAL POWER SOLAR PANEL

Section 4.2

ELECTRICAL POWER SOLAR PANEL

Solar Panel Adjustment – NORTH AMERICA

The pivot arrangement included with the solar panel’s mounting bracket

provides an adjustment for the angle of the panel. To gain maximum eciency

and output from the solar panel; the tilt angle is based upon the latitude of the

location. Panels should always face south (see below).

Using the table below you can determine the optimal angle for your solar

panel. The panel tilt is the latitude +10º. This will optimize the panel’s ability to

collect the sun’s energy. Use the angle gauge on the mounting bracket to set

the desired angle (see picture on next page) or alternatively, use the distance

from the pole to the base of the panel, also included in this table.

Optimum Angle for Sunlight

Site Tilt Base

Latitude

(degrees)

Angle

(degrees)

Distance

(inches)

Distance

(millimeters)

35 45 17 ¾ 451

36 46 17 ½ 444

37 47 17 / 437

38 48 16 / 430

39 49 16 / 423

40 50 16 / 416

41 51 16 / 409

42 52 15 / 402

43 53 15 / 395

44 54 15 ¼ 388

45 55 15 381

Solar Panel Outline

Section 4.3

Solar Panel – Tank Mounted Assembly Instruction

1. Before beginning the assembly ensure the side of the tank hangs over the

tie.

2. Assemble the pole into one piece and mount the solar panel to the pole.

Use four bolts to help position the pole’s clamp blocks to the tank. These

bolts must be /" -16 NC x 1-¼" threads and be approximately 10” long.

3. Using the studs, position two of the clamp block halves at their mounting

locations top and bottom. Screw the four studs into the tapped holes in the

tank body to properly locate the clamp blocks and help hold their position

during this assembly.

4. Raise the assembled pole and solar panel into the vertical position against

the tank and into the clamp block halves.

5. Turn the solar panel so that it is facing south.

6. Position the second pair of clamp block halves, sliding them over the studs

and against the back halves. Remove one stud at a time, replacing them

with the provided Allen head bolts and lock washers. The solar panel pole

kit includes an Allen wrench for tightening these four bolts.

Solar Panel – Away from Tank Assembly Instruction

Locate the panel so that the supplied cable (35 ft. / 10.7 meter long) will reach

the tank. Do not use a longer cable than the one supplied, as longer lengths will

result in a voltage drop which may not allow the system to operate properly. If

longer lengths are necessary, please contact us.

ELECTRICAL POWER SOLAR PANEL

Section 4.4

ELECTRICAL POWER SOLAR PANEL

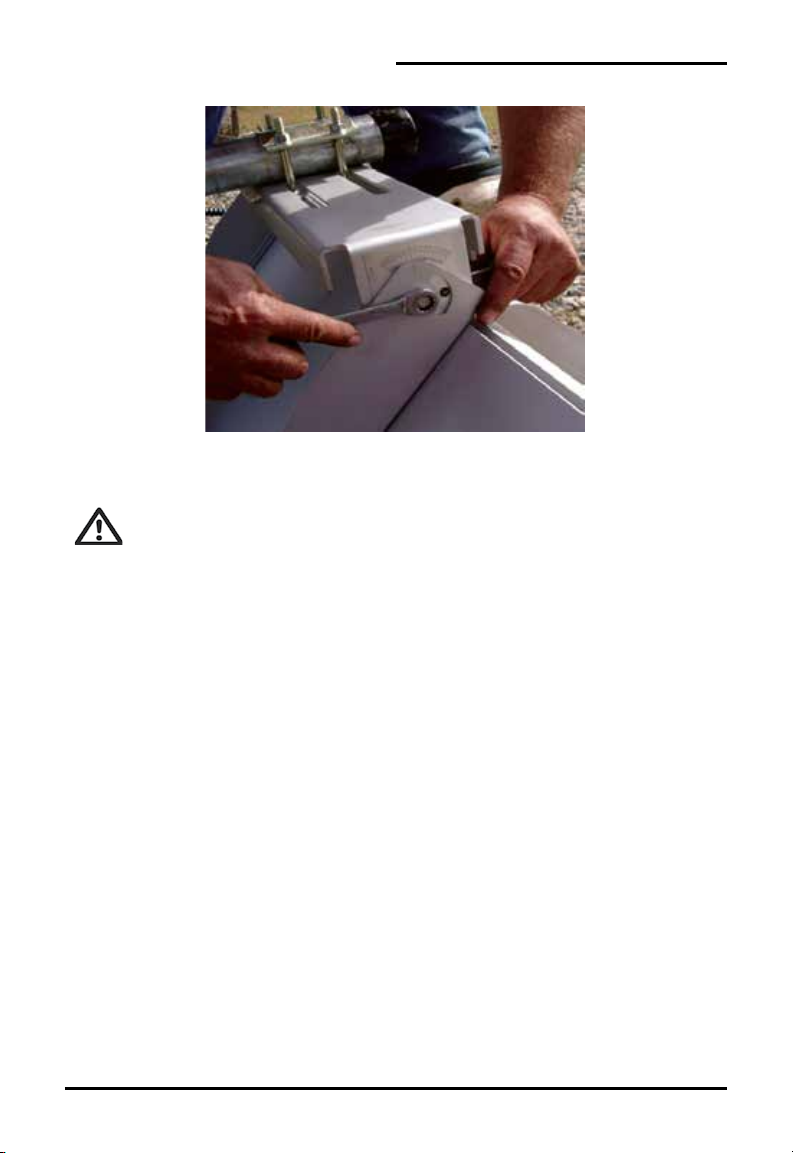

Gauge on the Solar Panel Mounting Bracket used to Adjust the Angle

Solar Panel Wiring

EXERCISE EXTREME CARE WHEN HANDLING THE SOLAR PANEL AND

WORKING WITH SOLAR PANEL WIRING. FAILURE TO DO SO MAY

RESULT IN EQUIPMENT DAMAGE OR BODILY INJURY.

The 35 ft. (10.7 meter) long power cable is factory installed to the solar

panel at the junction box with spade terminals. The wall connector nut of the

junction box is tightened securely, causing the bushing to grip the cable rmly,

so a liquid tight seal is formed. Secure the cable to the panel-mounting pole as

required.

Electrical Connections

Connect the solar panel to the PROTECTOR IV battery as follows:

1. Remove any cover you have placed over the panel and peel away the

protective panel guard protection.

2. Perform the following tests before beginning installation:

a) Using a voltmeter capable of reading 25v DC, check the panel output

between the battery (+) and (-) in the junction box or at the end of

the cable. If the panel output exceeds 15v DC, check regulator wiring

for proper connections, as shown in troubleshooting. Replace the

regulator if defective.

b) Check the battery’s voltage. If the voltage is below 11.5v DC, the

PROTECTOR IV will not function properly and the battery will need to

be charged.

Section 4.5

ELECTRICAL POWER SOLAR PANEL

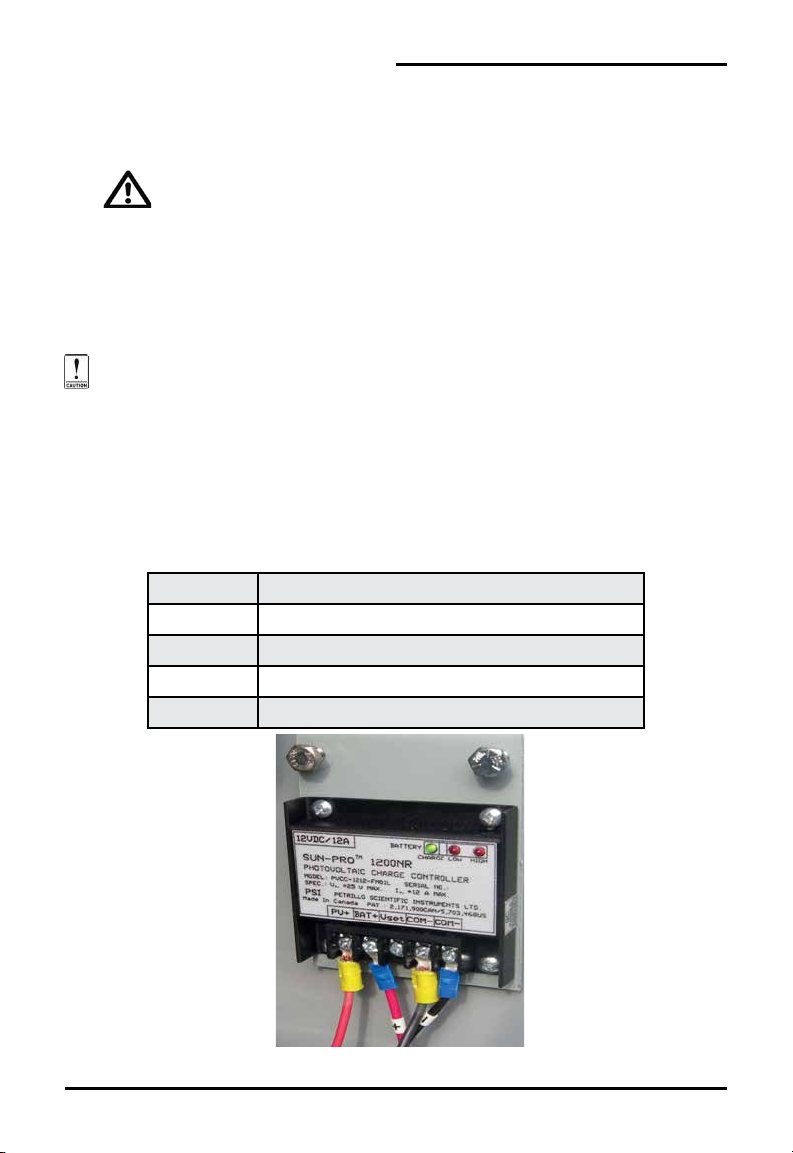

Solar Charge Controller

Solar panel charge controller in use on the PROTECTOR IV, which is located

inside the clean hands section of the tank.

The wires should be attached as follows:

PV+ Positive lead from solar panel

BAT+ Positive lead from battery

Vset Not used

COM- Negative lead from battery or solar panel

COM- Negative lead from battery or solar panel

Photovoltaic Charge Controller

Note: Charge battery through solar panel output until battery voltage

exceeds 12v DC.

BEFORE PROCEEDING, MAKE SURE THE SOLAR PANEL IS

COVERED TO ELIMINATE ELECTRICAL POTENTIAL AND TO AVOID

SHOCK HAZARD DURING THE NEXT PHASE OF ASSEMBLY.

3. Attach ring terminals to the solar panel cable wires, connecting the red

wire to the positive battery terminal and the black wire to the negative

battery terminal.

ENSURE RED WIRE IS CONNECTED TO THE POSITIVE (+) AND BLACK

WIRE IS CONNECTED TO THE NEGATIVE (-) TERMINAL OF THE BATTERY.

CROSSED WIRES WILL CAUSE EQUIPMENT DAMAGE.

Section 4.6

ELECTRICAL POWER AC POWER

AC Electrical Power and Battery Charger Connections

1. Remove the bolts on the battery terminals using a 10mm socket or wrench.

Look at battery and charger safety precautions. Be careful not to short the

battery terminals with a tool.

2. Through the terminal bolt, connect the ring terminals of red wire from the

charger and from the control box power harness to the positive battery

terminal (+) and in the same manner connect the black wires to the

negative battery terminal (-).

3. A qualied electrician must wire the units through the junction box and onto

the on/o disconnect box according to local regulations.

ALL WIRING MUST COMPLY WITH LOCAL AND NATIONAL

ELECTRICAL CODES. USE ONLY THE WIRE SIZES SPECIFIED IN THE

INSTALLATION INSTRUCTIONS. WE RECOMMEND HAVING THE

INSTALLATION WIRED BY A CERTIFIED ELECTRICIAN.

ENSURE POWER SUPPLY CABLE GAUGE IS PROPERLY SIZED TO

ALLOW FOR REQUIRED POWER LEVELS GIVEN THE DISTANCE FROM

THE ORIGINAL SOURCE.

Section 5.1

Conguration at Track

Top of rail distribution bars should be installed in a position that agrees with

the site selection criteria mentioned previously in this manual. The common

conguration at track for PROTECTOR IV units is on both rails of a single track

with uni-directional trac. The set up described here is shown below.

The top of rail wiping bars assembly can be installed in a four bar

conguration, as shown above.This provides required friction modier for areas

with continuous curvature, high trac and other factors requiring a maximum

of friction modier. The installation time required depends on the installer’s

familiarity with components and labor available to complete the task.

Other Congurations

» Two bars with single pump with distribution in center.

» Two bars with double pump and supply hoses routed from tank to bars.

4-Bar Conguration

A PASSING TRAIN CAN DAMAGE IMPROPERLY INSTALLED COMPONENTS.

ALLOW SUFFICIENT TRACK TIME TO FULLY COMPLETE INSTALLATION.

TOR INSTALLATION

Section 5.2

Install the MC-4TR® wiping bars as follows:

1. Ensure selected tank location is such that the friction modier supply

hose(s) can be routed from tank and where rail is in good condition.

2. To conrm clamp locations mate with existing cribs, lay out wiping bars on

eld-side of rail.

3. Ensure bars mounted on the same rail are located at a distance of 56 ½”

(143 cm) between centers.

Note: Based on a 36” (91 cm) wheel diameter, the 56 ½” (143 cm) spacing allows

bars to distribute material uniformly over opposing sections of each wheel's

circumference. If track conditions do not permit a 56 ½” (143 cm) distance to

be respected, install bars closer together but maintain at least one bar length

in between.

4. Ensure inlet elbows clear rail hardware. On smaller rail sizes, it is best to

attach the wiping bar supply hose (and adapter where necessary) before

assembling to rail. The piping adapter is used to gain additional clearance

with track hardware.

5. Loosely assemble wiping bars to mounting clamps.

6. Clean dirt and scale from rail in appropriate areas.

7. With a pick and ballast fork, remove ballast from selected cribs for

installation of rail clamps.

8. Lay wiping bar assemblies adjacent to selected mounting locations.

9. Ensure mounting clamps are square to rail and fasten them to the base of

rail. As the “J” bolt nuts are being tightened using a hammer, occasionally

tap clamp blocks driving the “V” slot on to the rail base. Torque mounting

bolts to approximately 200-250 ft-lbs (340 N-m).

10. When clamps are secured tighten the safety nuts.

11. Position wiping bar assemblies on top of rail clamp blocks and against rail.

12. Adjust the wiping bar height as follows:

a) Mount the TOR bar such that the tip of the seal is not higher than the top

of the railhead (shown in the "MC-4TR Wiping Bar Installation" gure). A

simple level can be used to help establish this position.

TOR INSTALLATION

Section 5.3

MC-4TR Wiping Bar Installation

DO NOT STORE EXTRA SPACERS UNDER THE HEAD OF MOUNTING BOLTS.

b) Remove or add spacers between TOR clamps and wiping bar mounting

feet.

c) Adjust blade height until the inner (thin) blade is just at top of the side of

railhead. Store excess spacers in clean hands section of the tank.

Note: With newer rail, or where the radius has been ground on the top of the

railhead, the curvature of the railhead allows the end of the seal to be located

onto the railhead and still be below the TOR.

This helps the ow of friction modier from the bar to the contact patch

without risk of damage to keep the seal below top of rail, the required lower bar

mounting draws the seal end away from the contact patch.

13. Secure the mounting bolts to the clamp blocks tightening the right bolt

rst to ensure the top of rail wiping bars is pushed securely against the rail.

14. Occasionally tap the outside edge of the mounting foot with a hammer

during tightening to insure TOR wiping bars remain tight to the rail.

15. Torque mounting bolts to approximately 200-250 ft-lbs (340 N-m).

ML Top of Rail Wiping Bars

The installation of ML TOR distribution bars should be carried out using the

same instructions as the MC-4TR TOR distribution bars. The drawing below

illustrates how the installed bar should be assembled.

TOR INSTALLATION

Table of contents

Other LB Foster Industrial Equipment manuals

Popular Industrial Equipment manuals by other brands

Bosch

Bosch Rexroth HQ 2/C-H Assembly instructions

Rodix

Rodix FEEDER CUBE FC-40 Plus Series Adjustments and Set Up

Siemens

Siemens MFI Technical manual

Stepp

Stepp SRM Operation, maintenance and parts manual

Palazzetti

Palazzetti TERMOPALEX HWT Use and maintenance manual

CommScope

CommScope 864 FDH RESKIN KIT installation instructions