Tolomatic MXP63PTP User manual

Tolomatic • URL: http://www.tolomatic.com • Email: [email protected] • Fax: (763) 478-8080 • Toll Free: 1-800-328-2174

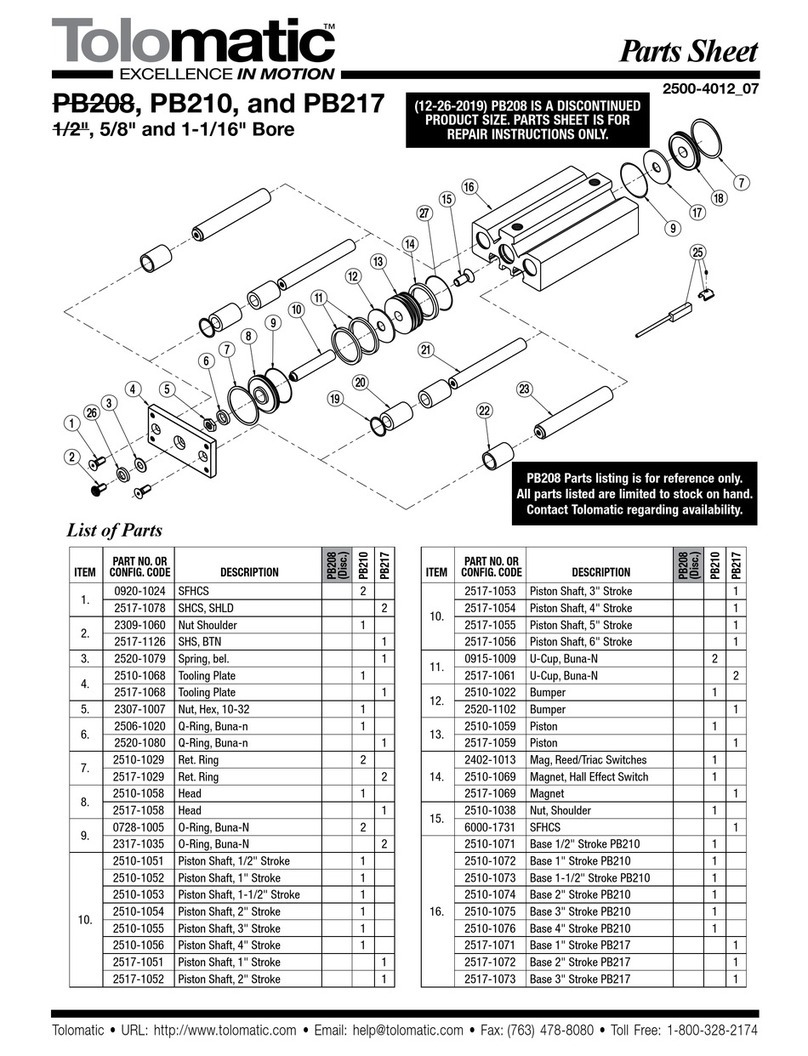

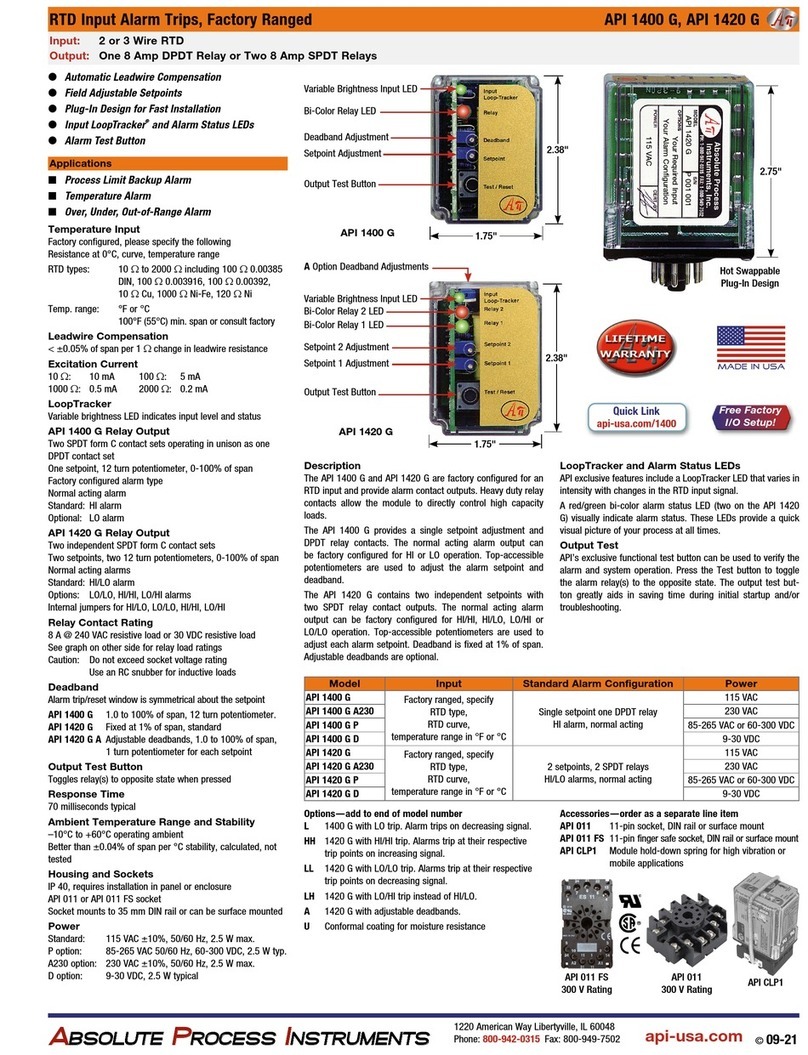

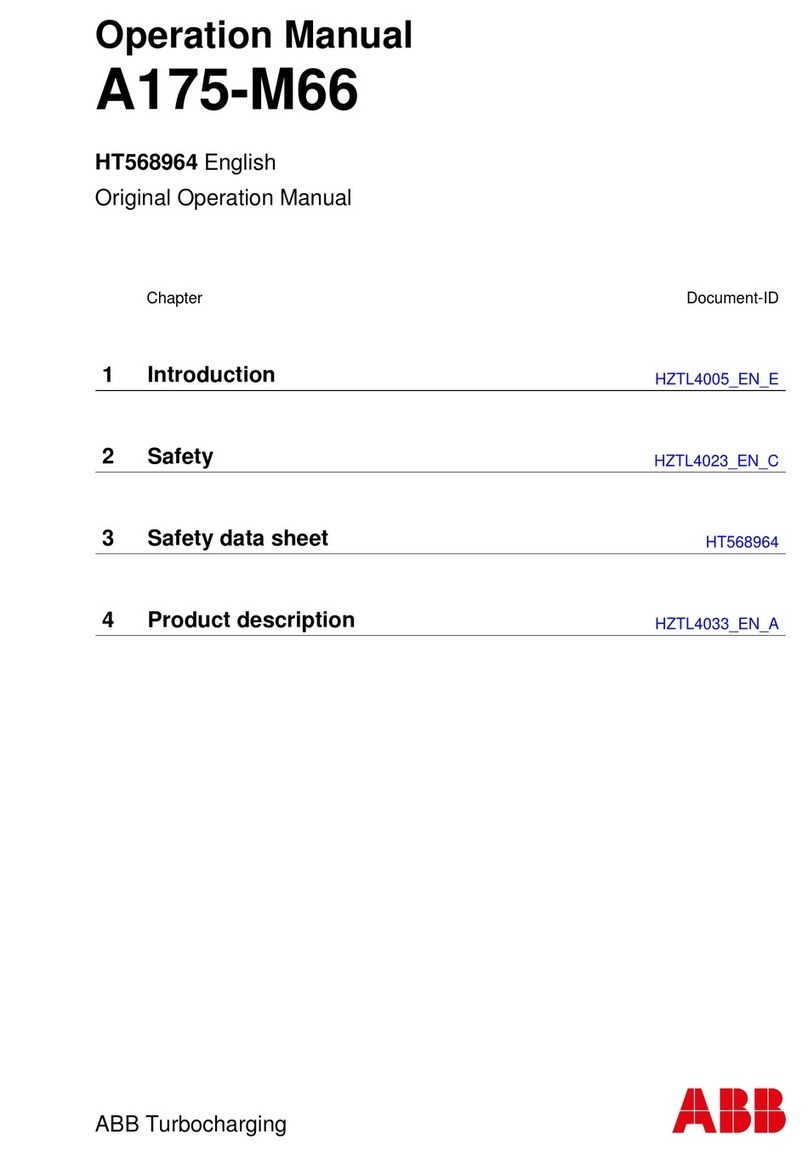

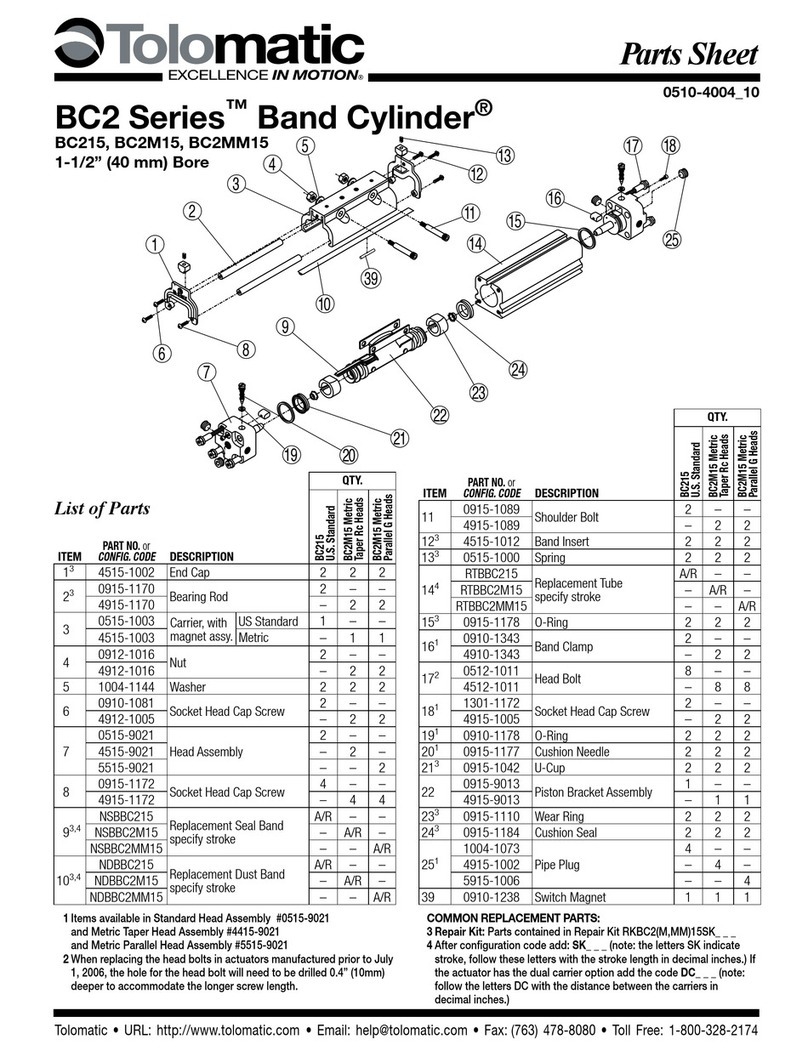

Parts Sheet

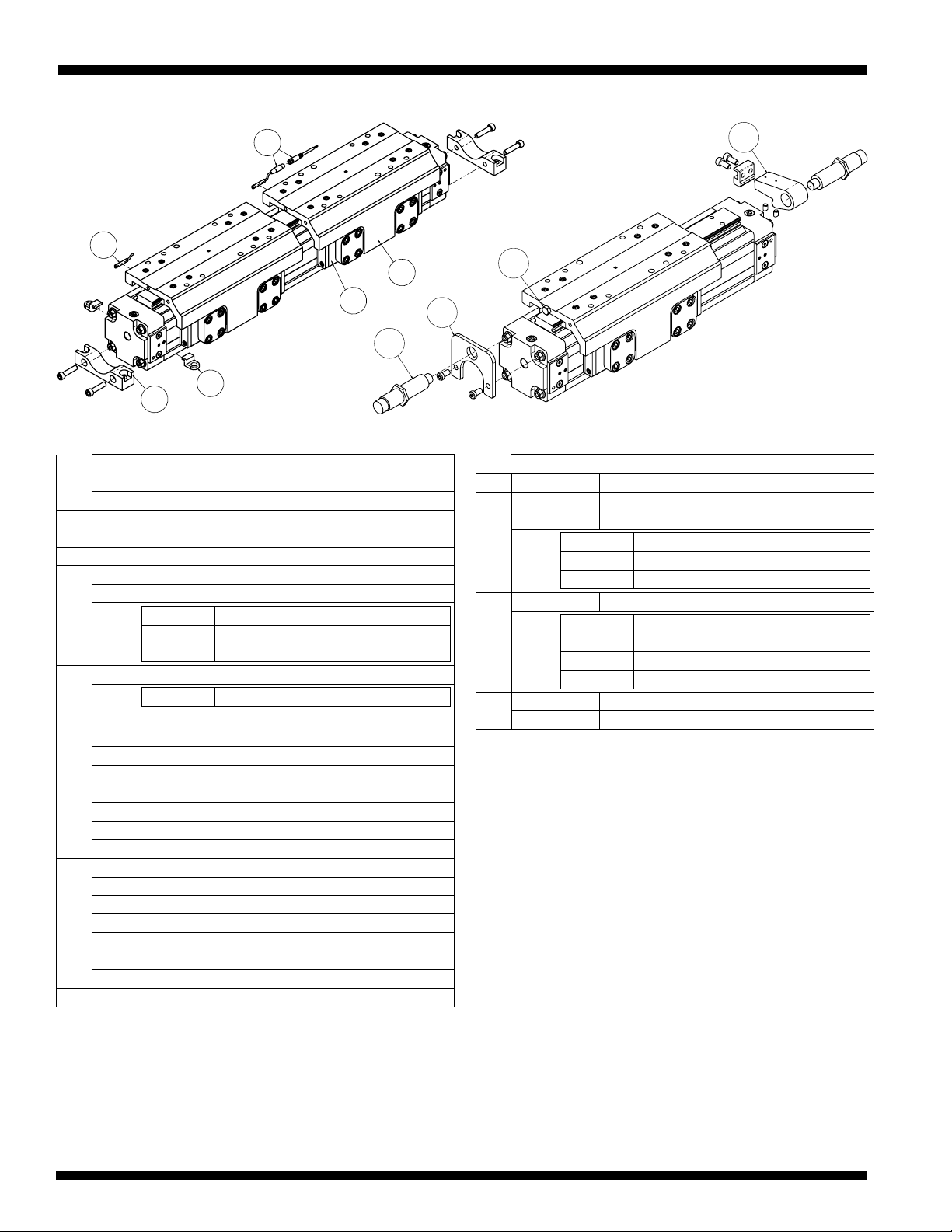

8100-4117_05_MXP63Pps

3

4

1

2

5

12

13

19

14

6

10

8

9

26

17

16

18

21

22

20

23

24

25

15

7

11

31

32

34

35

36

29

28

80

Single-end Porting Head

Return Single-end Porting Head

81

27

30b

30a

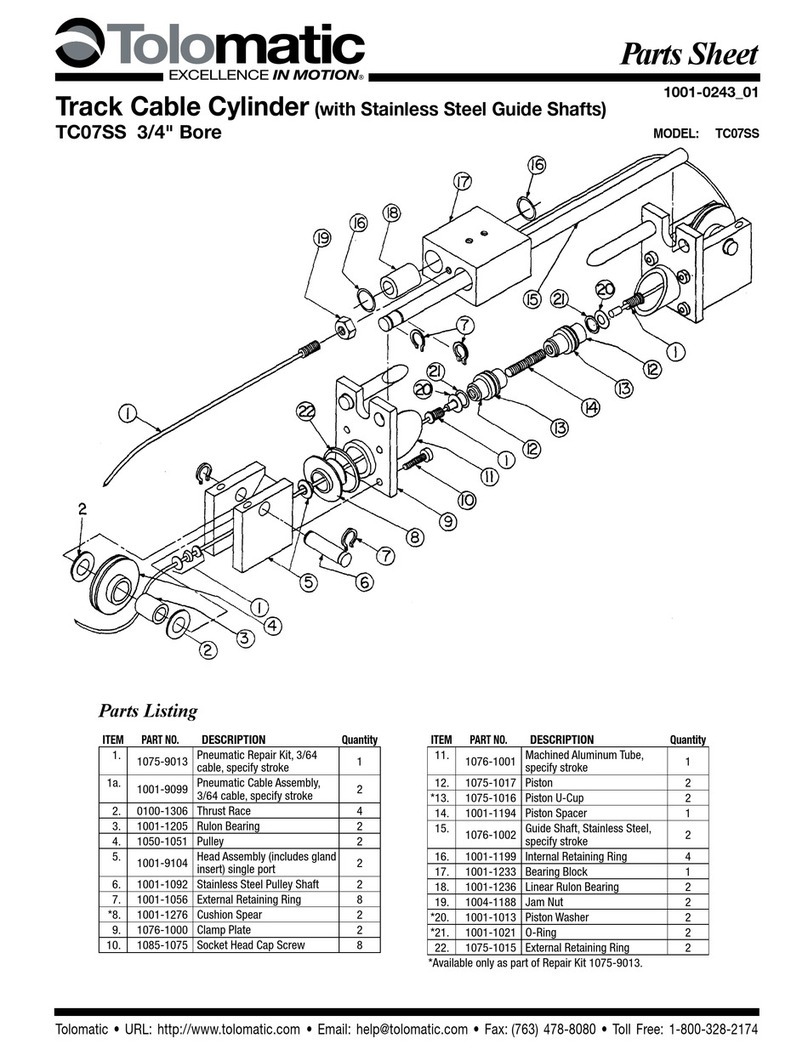

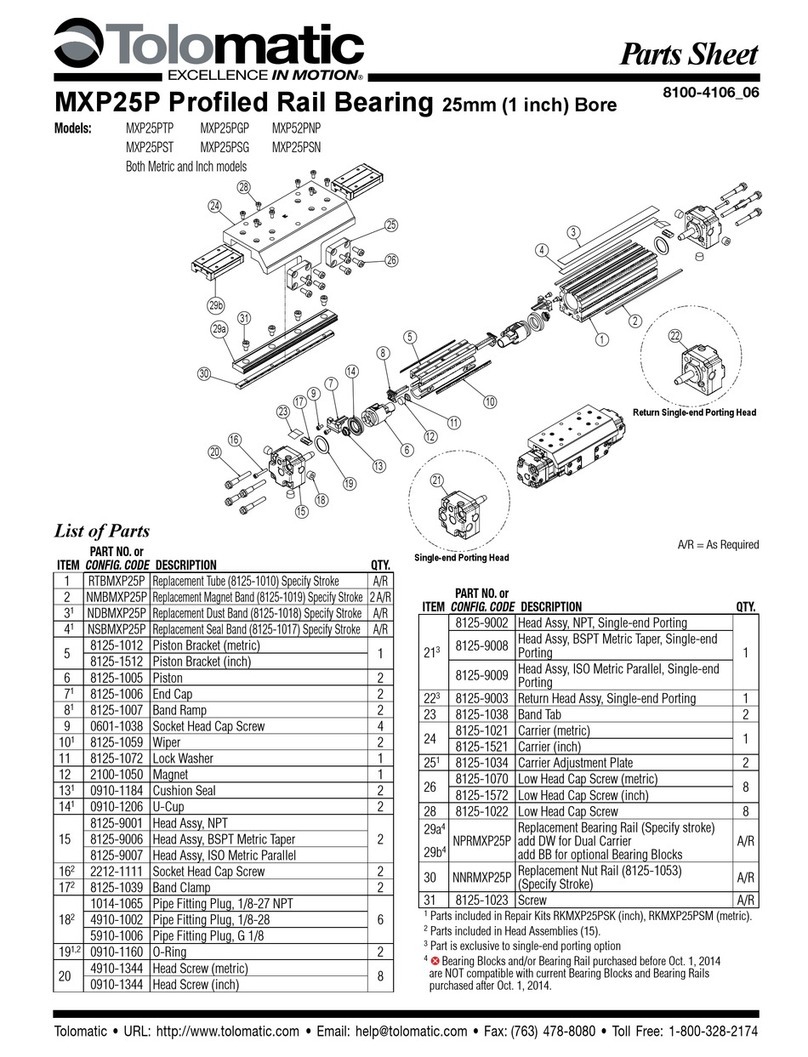

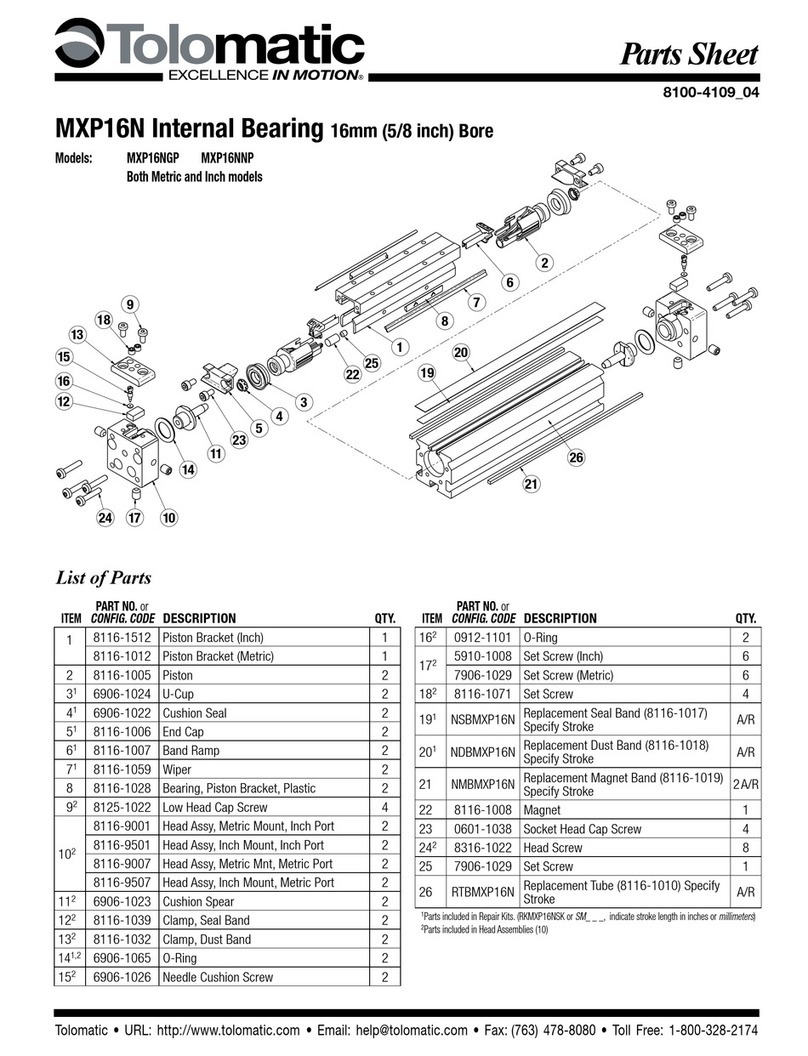

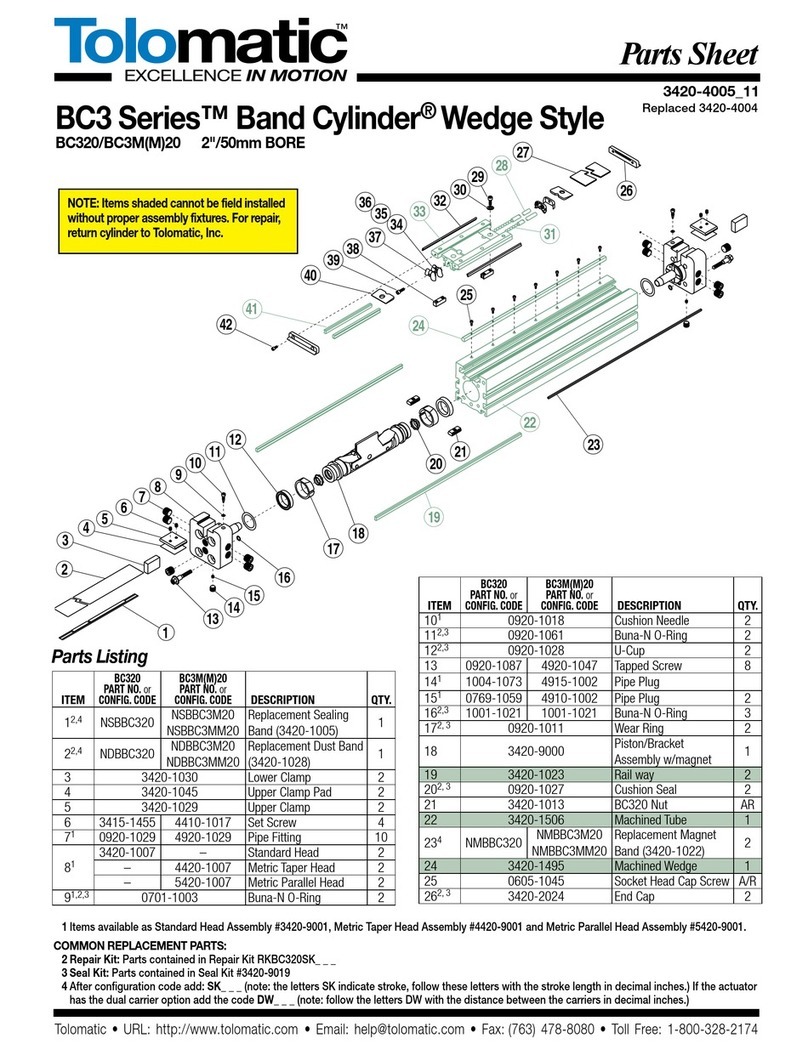

MXP63P Profiled Rail Bearing 63mm (2-1⁄2inch) Bore

List of Parts

Models:

MXP63PTP MXP63PGP MXP63PNP

MXP63PST MXP63PSG MXP63PSN

Both Metric and Inch models

ITEM

PART NO. or

CONFIG. CODE DESCRIPTION QTY.

1

RTBMXP63P

Replacement Tube (8163-1010) Specify Stroke A/R

2

NMBMXP63P

Replacement Magnet Band (8163-1019)

Specify Stroke

2A/R

1

3

NDBMXP63P

Replacement Dust Band (8163-1018)

Specify Stroke

A/R

1

4

NSBMXP63P

Replacement Seal Band (8163-1017)

Specify Stroke

A/R

5 8163-1512 Piston Bracket (inch) 1

8163-1012 Piston Bracket (metric)

16 8163-1007 Band Ramp 2

17 8163-1006 End Cap 2

18 0925-1027 U-Cup 2

19 0925-1012 Cushion Seal 2

10 8163-1004 Piston 2

11 0603-1016 Socket Head Cap Screw 4

112 8163-1059 Wiper 2

13 8163-1058 Magnet 1

14 8163-1005 Wear Ring 2

15 0925-1087 Head Screw (inch) 8

4925-1047 Head Screw (metric)

16 8163-1011 Head Assembly, NPT

28163-1046 Head Assembly, BSPT Metric Taper

8163-1047 Head Assembly, ISO Metric Parallel

217 0774-1007 O-Ring 2

218 0920-1029 Pipe Fitting Plug, 3/8 NPT

64920-1029 Pipe Fitting Plug, 3/8-19

5920-1006 Pipe Fitting Plug, G 3/8

19 4910-1004 Socket Head Cap Screw 4

220 8163-1039 Band Clamp 2

221 0915-1044 Set Screw 4

ITEM

PART NO. or

CONFIG. CODE DESCRIPTION QTY.

222 0920-1024 Flat Head Cap Screw 4

223 8163-1038 Band Wedge 2

224 0720-1003 O-Ring 2

225 8163-1065 Needle Screw 2

226 0925-1158 Cushion 2

127 8163-1028 Bearing 2

28

NNRMXP63P

Replacement Nut Rail (8163-1053)

Specify Stroke A/R

29 4415-1001 Socket Head Cap Screw A/R

430a

430b

NPRMXP63P

Replacement Bearing Rail (Specify stroke)

add DW for Dual Carrier

add BB for optional Bearing Blocks

A/R

31 8163-1034 Carrier Adjustment Plate 2

32 8163-1076 Bearing 2

33 Number is not used

34 2324-1014 Socket Head Cap Screw (inch) 8

8163-1070 Socket Head Cap Screw (metric)

35 4415-1000 Socket Head Cap Screw 12

36 8163-1521 Carrier (inch) 1

8163-1021 Carrier (metric)

380 8163-9002 Head Assy, NPT, Single-end Porting

18163-9008

Head Assy, BSPT Metric Taper, Single-end Porting

8163-9009

Head Assy, ISO Metric Parallel, Single-end Porting

381 8163-9003

Head Assembly, Return, Single-end Porting

1

1Parts included in Repair Kits RKMXP63PSK (inch), indicate stroke length in inches

RKMXP63PSM (millimeters), indicate stroke length in millimeters

2Parts included in Head Assemblies (16)

3Part is exclusive to single-end porting option

4Bearing Blocks and/or Bearing Rail purchased before Oct. 1, 2014 are NOT com-

patible with current Bearing Blocks and Bearing Rails purchased after Oct. 1, 2014.

Tolomatic • URL: http://www.tolomatic.com • Email: [email protected] • Fax: (763) 478-8080 • Toll Free: 1-800-328-2174

2 – Instructions MXP63P Parts Sheet #8100-4117_05_MXP63Pps

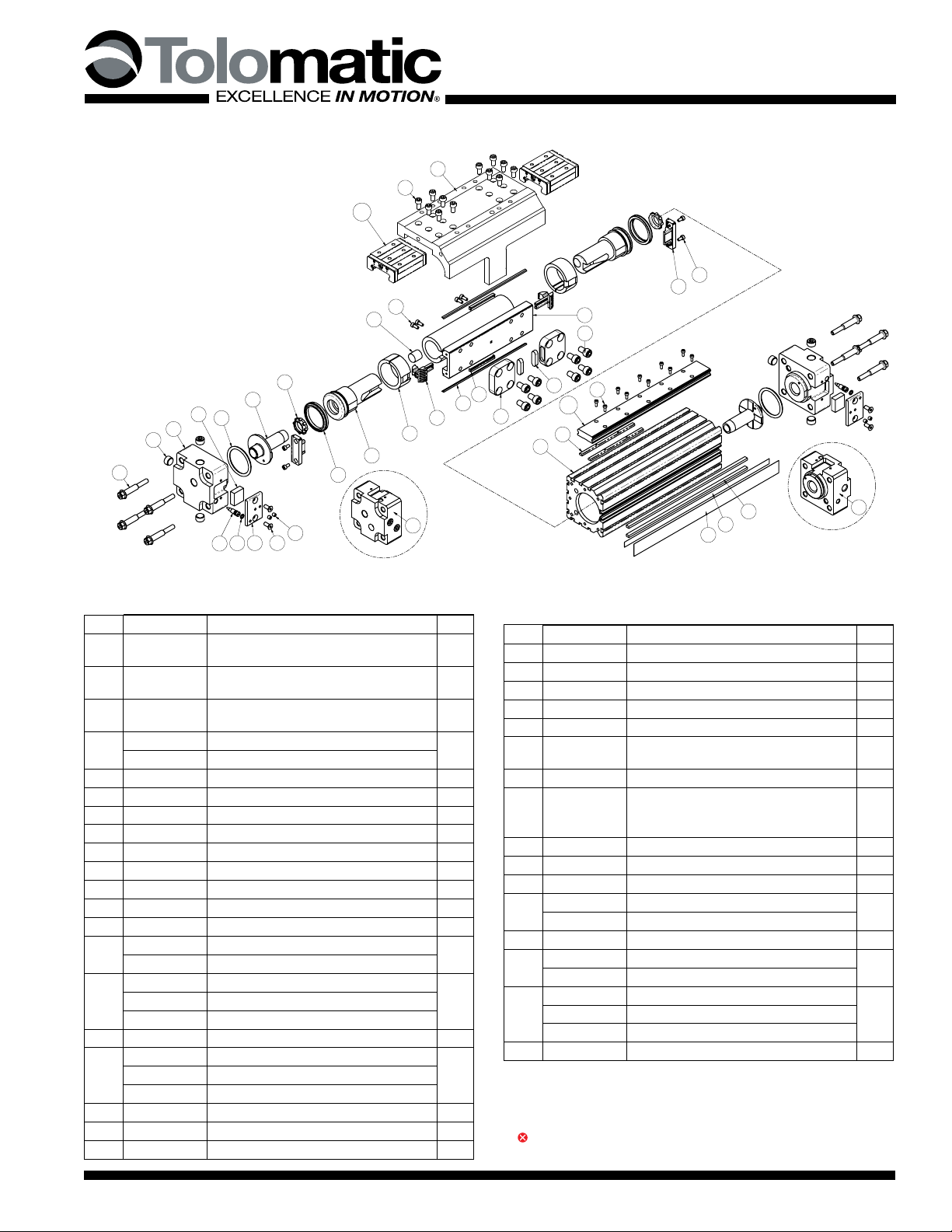

CYLINDER DISASSEMBLY INSTRUCTIONS

Begin with a clean work area. Make sure all replacement parts are avail-

able and have no visual damage or defects. The following tools and

materials are recommended for proper disassembly and assembly. (Exact

wrench sizes will vary depending on cylinder size)

• Allen wrench set (Inch and Metric)

• Small straight edge screwdriver

• Socket wrench & socket set

• Needle nose pliers

• Tin snips

• Razor Blade

• RheoGel TEK664 grease

For best actuator performance it is recommended that the following

instructions be read and followed carefully.

1. REMOVE BAND CYLINDER FROM MACHINERY

Remove all mounting hardware and air connections. If present, from the

Cylinder Heads (16) and/or Carrier (36).

2. REMOVE CARRIER FROM CYLINDER

Remove Screws (35) from Carrier (36). Slowly lift up the Carrier and

remove it from the cylinder.

CAUTION: Contaminating the Bearing Block will hinder the operation of

the cylinder. Do not remove the Bearing Blocks from the Rails. If the

Bearing Blocks need to be replaced so will the Bearing Rail.

Remove Screws (34), Adjustment Blocks (31) and Carrier Bearings (32)

from the cylinder.

3. REMOVE BEARING BLOCKS AND BEARING RAIL (OPTIONAL)

The MX Bearing System is designed to provide maximum life. Should the

Bearing Blocks need replacement, the Bearing Rail will need to be replaced

as well. Bearing Blocks (30b) and Bearing Rail (30a) must remain together.

If the cylinder stroke requires two Bearing Rails to be mounted, the cylinder

will need to be sent to the factory. It is critical that the two Rails are aligned

properly. This requires special fixtures and cannot be done in the field.

To remove both the Bearing Blocks and Bearing Rail, slide each Bearing

Block off one at a time and place in a clean area. Next remove Screws (29)

from the Bearing Rail (30a). Lift up on the Rail and place in a clean area.

4. REMOVE BAND CLAMPS

Loosen Screws (21) on Dust Band Clamp (20). Remove Screws (22)

from Cylinder Heads (16). Remove Seal Band Clamp (23) from

between Dust Band (3) and Seal Band (4). Do not adjust the point Set

Screw in the Seal Band Clamp (23). Repeat for other Cylinder Head.

5. REMOVE DUST BAND

Remove End Caps (7) from both ends of the Piston Bracket (5) by remov-

ing Screws (11). To remove Dust Band (3), lift one end and pull the Band

through the Piston Bracket. The Band is magnetically retained so some

resistance will be present when removing.

6. REMOVE HEADS

Remove the four Head Screws (15) to free each Cylinder Head (16).

Remove each head by rocking it up and down until the head is free from

the Cylinder Tube (1). DO NOT TWIST! Remove the O-Ring (17) from

both heads with a small straight edge screwdriver.

7. REMOVE SEAL BAND

CAUTION: Sealing Band edges are sharp. Grasp the top and bottom of

the Band when removing, not the edges.

Slide Piston Bracket (5) out of the Cylinder Tube (1). Remove the Sealing

Band (3) through the slot in the Tube.

8. DISASSEMBLE PISTON BRACKET

Remove Wipers (12) from the Piston Bracket (5). With the small

straight edge screwdriver, remove the U-Cups (8) from both Pistons (10).

Remove the Cushion Seal (9) from each Piston. Remove the Pistons (10)

by removing Screws (19) then sliding out of Piston Bracket (5). With

a small screwdriver, remove the Band Ramps (6) by disengaging the

side retaining tabs for each. Keep the Piston Bracket (5) and the two

Pistons (10) for reassembly.

CYLINDER ASSEMBLY INSTRUCTIONS

1. CLEAN AND LUBRICATE

Thoroughly clean all components, particularly the Tube (1) Bore, Tube

Slot, Sealing Band (4) and Dust Band (3). Thoroughly lubricate the Tube

Bore with a thin, uniform layer of RheoGel TEK664 grease.

2. PISTON BRACKET ASSEMBLY

With the Piston Bracket (5) in hand, install the Band Ramps (6), with

small end down, so the ends on each side snaps into the hole of the

Piston Bracket. Slide the Pistons (10) into the Piston Bracket (5) so the

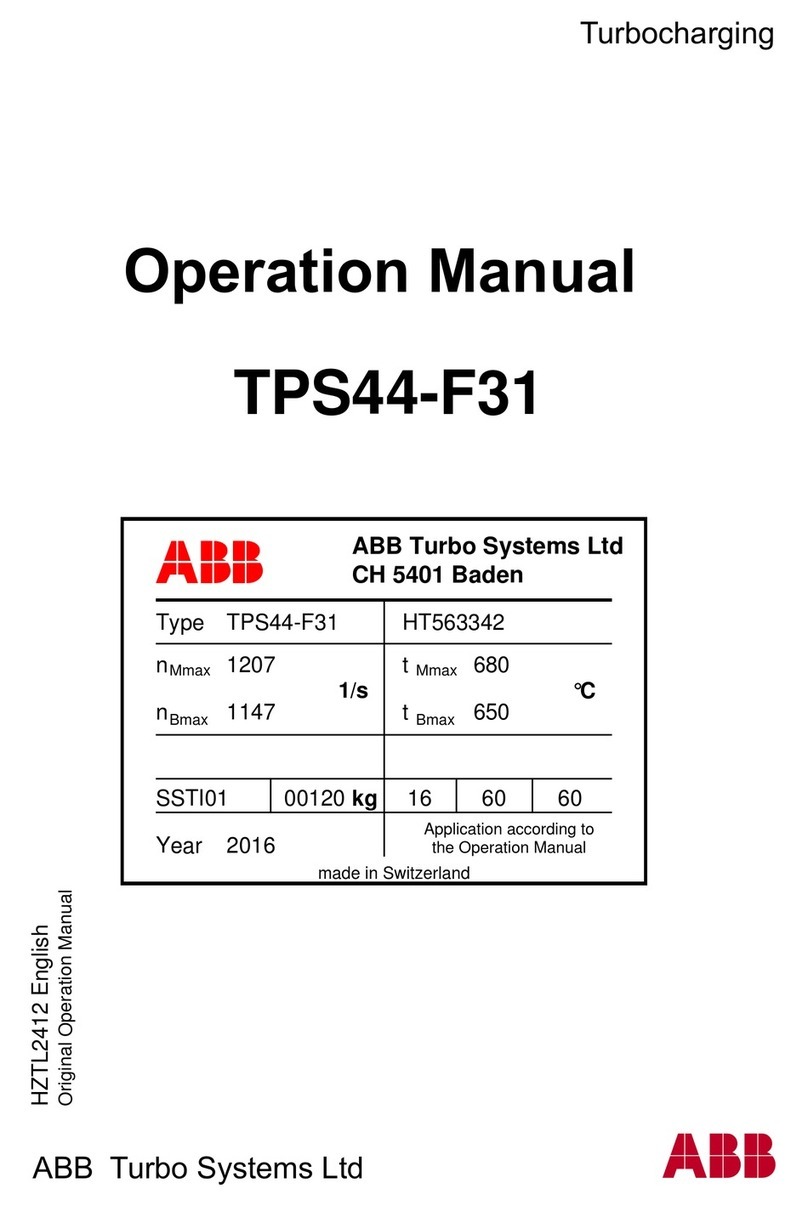

Drawing repeated for reference

3

4

1

2

5

12

13

19

14

6

10

8

9

26

17

16

18

21

22

20

23

24

25

15

7

11

31

32

34

35

36

29

28

80

Single-end Porting Head

Return Single-end Porting Head

81

27

30b

30a

Tolomatic • URL: http://www.tolomatic.com • Email: [email protected] • Fax: (763) 478-8080 • Toll Free: 1-800-328-2174

Parts Sheet #8100-4117_05_MXP63PpsParts Sheet #8100-4117_05_MXP63Pps MXP63P Instructions – 3

threads on the Piston align with the holes in the Piston Bracket and

secure using Screws (19).

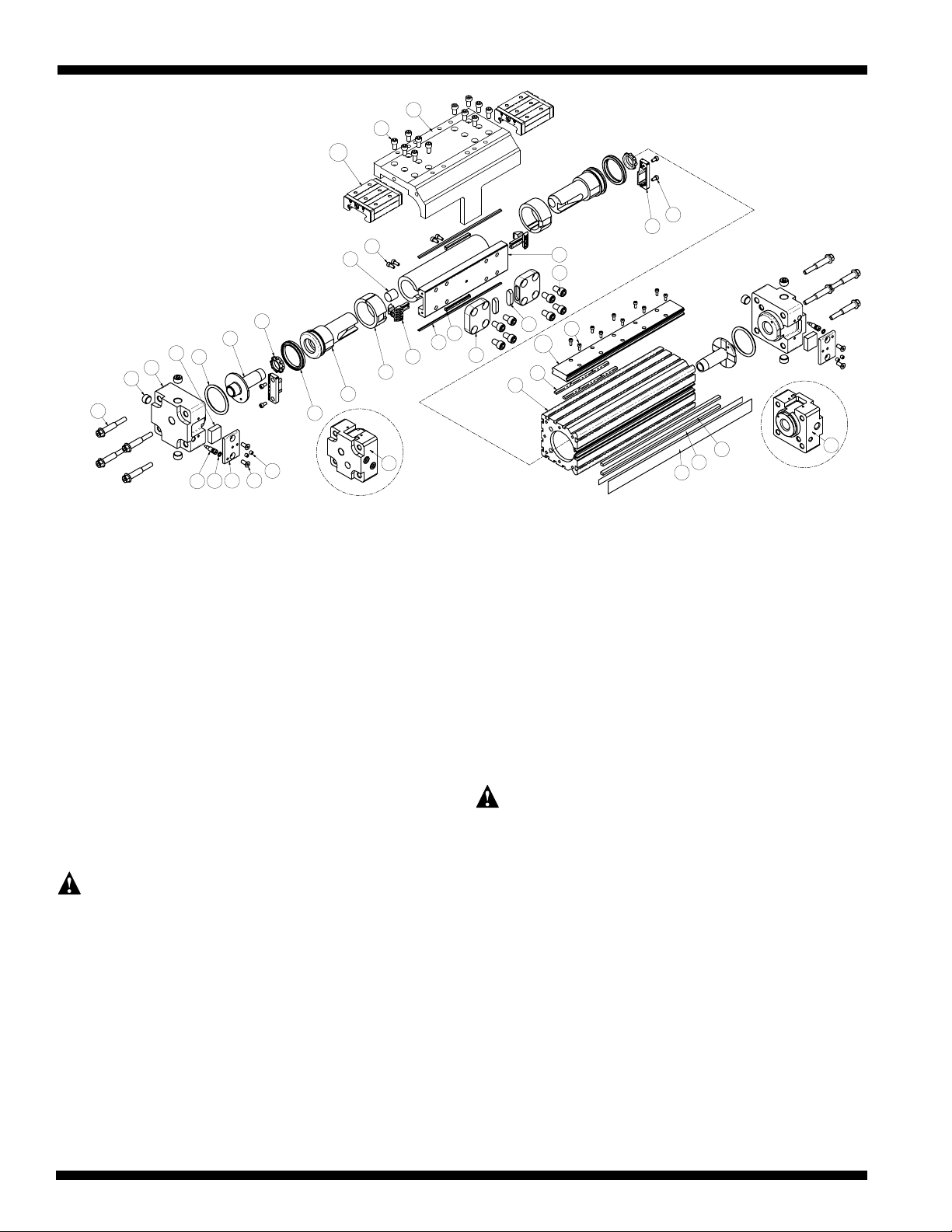

Verify surface of Piston is behind the surface of the Piston Bracket in

both places as shown in diagram.

If not aligned properly the Seal Band (4) life may be

shortened.

Install new lubricated U-Cups (8) (seal lips facing out),

and Cushion Seals (9) (small end facing out).

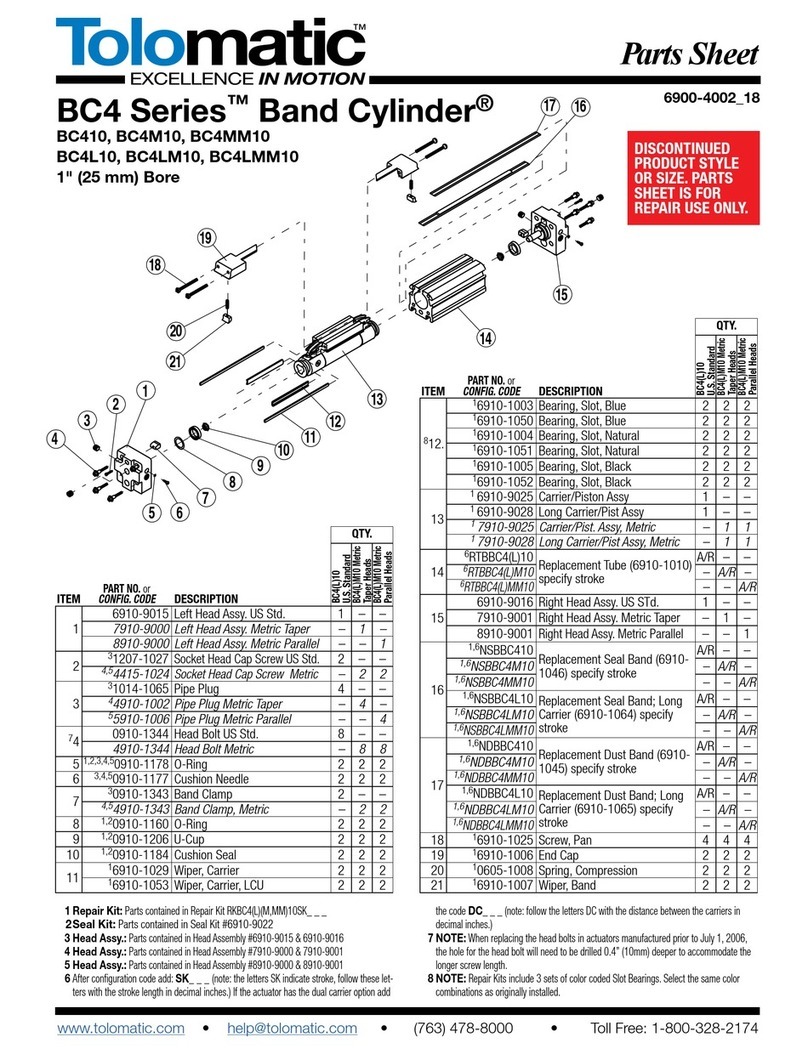

3. INSTALL SEALING BAND

CAUTION: Metal edges of Sealing Band are sharp. Exercise caution to

avoid injury to yourself while installing. Handle Sealing Band with care.

Do not damage edges while handling.

Insert Sealing Band (4) into Cylinder Tube (1) by laying the Band

out along the length of the actuator and passing it sideways

through the slot in Tube. With rubber side facing up (ground

side facing down), position the Seal Band so there is enough

sticking out the end of the Tube as long as a Piston Assembly.

4. INSTALL PISTON ASSEMBLY

Place generous amounts of grease around bore of Tube (1) and on exte-

rior surfaces of both Wear Rings (14) on Pistons (10), U-Cups (8) and

Band Ramps (6).

Create a Seal Band Guide Tool by using the 12-inch length of Seal Band

included with repair kit (without rubber), or cut a short length of the old

Seal Band. (Remove the rubber along the entire length of the Seal Band

Guide Tool if needed.) At one inch from one end of the Seal Band Guide

Tool, bend slightly upward. The bend helps to guide the Seal Band

Guide Tool through the Piston Assembly. Determine which end of the

Piston Assembly is going to be inserted into the Tube (1) first. Insert

the bent end of the Seal Band Guide Tool into the opposite end of the

Piston Assembly. Push the Tool through the opening between the Band

Ramp (8) and Wear Ring (14) on the Piston Bracket (5) and stopping

when the Tool exits the end of the Piston Assembly.

Place the Seal Band (4) on top of the Seal Band Guide Tool. Insert the

Piston Assembly into the Tube (1) until both U-Cups are captured by the

bore in the Tube. Do not force the Piston Bracket into the Tube and if

the Piston Assembly experiences resistance, use a small screwdriver to

press in the ends of the Band Ramps (6) where entering the Tube. Allow

the Seal Band (4) to pass through the Piston Assembly. Once the Seal

Band is though the Piston Assembly, pull the Seal Band Guide Tool out

of the Piston Assembly. Continue inserting the Piston Assembly into the

Tube until the 2nd U-Cup is inserted into the bore of the Tube.

Slide new Wipers (12) into the groove on the Piston Bracket (5) until flush

with end. Manually move the Piston Assembly the length of the Tube

until the end of the leading U-Cup extends out of the Tube. Wipe off any

excess grease from the end of the Piston Assembly and the Tube. Move

the Piston Assembly so the U-Cup back into the Tube bore.

Note: If Tube and Piston Assembly were greased properly, excess grease

should be present as the Piston exits the end of the Tube. If there is no

excess grease present, remove the Piston Assembly and re-grease the

Tube, then re-install the Piston Assembly.

5. INSTALL HEADS

CAUTION: Twisting the Head (16) during installation may cut the

O-Ring (17) resulting in excessive leakage during operation.

Install new lubricated O-Ring (17) onto each Head (16). Position Piston

Assembly near the end of the Tube in which the Head is being installed.

Position or trim the Seal Band (4) so 1.25" (31.8mm) is protruding from

the end of the Tube (1). Use a razor blade to cut the rubber along the

end of the Tube then remove all rubber outside the end of the Tube.

Keep the rubber on the Seal Band aligned with the end of the Head (16).

Install Head into Tube using a slight up and down rocking motion (not

side-to-side or twisting) until the Head is flush with the end of the Tube.

Secure Head to Tube by installing Head Screws (15) applying a torque of

190 in-lbs (21.47 N-m). Verify rubber on Seal Band (4) is still aligned

with end of Tube. If not, use needle nose pliers to pull on Seal Band

until aligned. Place Band Wedge (23) with point of Set Screw down

into slot of Head and on top of Seal Band. Push Band Wedge so it is

against the end of the Tube. Secure Band Wedge with Band Clamp (20),

FHCS (22) and Set Screws (21). Make sure hole in Band Clamp aligns

with the Cushion Needle (25) in Head.

Move Piston Assembly to other end of the Tube and repeat the steps

above to install the other head. Trim Seal Band with tin snips if needed

to achieve 1.25" (31.8mm) from end of Tube. While pulling Seal Band

tightly with needle nose pliers, use razor to cut rubber at the end of

the Tube. Remove rubber from the end of the Seal Band to the cut

just made. Install the Head (16) to the Tube and secure with the Head

Screws (15). Use needle nose pliers to pull on the Seal Band remov-

ing any slack and aligning the rubber on Seal Band with the end of the

Tube. If rubber is past end of Tube, trim excess rubber. If rubber is not

up to end of Tube, pull on Seal Band with needle nose pliers to remove

slack. Secure Seal Band with Band Clamp, FHCS and Set Screws.

Once both ends of the Seal Band are secured, manually move the Piston

Assembly the entire length of the Tube two times to see if there is any

slack or issues with the Seal Band.

6. INSTALL AND SECURE DUST BAND

Position the Piston Assembly at mid-stroke of the cylinder. Slide Dust

Band (3) through the upper slot of Piston Bracket (5) and lay on top of

the cylinder tube slot. Position the Dust Band 1.25" (31.8mm) from

each end of Tube. Install End Caps (7) using SHCS (11) into ends of

Piston Bracket (5). Loosen Set Screws (21) and FHCS (22) on both ends

of the Tube. Slide Dust Band (3) between Band Wedge (23) and Band

Clamps (20). Tighten the FHCS then the Set Screws to secure the Dust

Band. Move the Piston Assembly to each end of the Tube to verify the

Dust Band is positioned properly.

7. CHECK ASSEMBLY

Manually push the Piston Assembly back and forth along the entire

length of stroke to make certain that the cylinder is properly assembled

before reconnecting to the pneumatic supply. The Piston Assembly

should move consistently with minimal friction along the stroke. The

Dust Band should not kink at end of stroke. If it does, loosen Set

Screws (21) until kinking is eliminated and retighten.

8. INSTALL BEARING BLOCKS AND BEARING RAIL (OPTIONAL)

If you completed Step 3 in the disassembly procedure place the new

Bearing Rail (30a) on top of Nut Rail with the reference mark located on

the bottom of the Rail towards the Piston Bracket (5). Next start all the

Screws (29) that hold the Rail, but do not tighten. Center the Bearing

Rail along the length and width of the cylinder, making sure the ends of

the Rail do not cover the Heads. Also, once the Rail has been centered,

tighten all Screws (29). Slide on the new Bearing Blocks (30b) one at a

time, with the reference mark facing you.

9. INSTALL THE CARRIER

Slide the two Bearing Blocks so they are lined up with both ends of

the Piston Assembly. Place the Carrier (36) over the top of the Bearing

Blocks, guiding the Carrier around the Carrier Adjustment Plates (31).

Carefully slide the two Bearing Blocks under the Carrier (36), until the

holes from the top of the Carrier and the Bearing Blocks align. Install

Screws (35) into the Carrier and tighten.

Replace Carrier Adjustment Plates (31) and then install the Carrier

Bearing (32) into the indent on the Adjustment Blocks. Install and tighten

Screws (34) making sure Carrier is captured.

10. REMOUNT THE CYLINDER ONTO THE MACHINE

Be certain any flow controls are in place and adjusted prior to applying

compressed air to the cylinder.

RUBBER

SIDE

GROUND SIDE

Parts Sheet #8100-4117_05_MXP63Pps

Tolomatic • URL: http://www.tolomatic.com • Email: [email protected] • Fax: (763) 478-8080 • Toll Free: 1-800-328-2174

Parts Sheet #8100-4117_05_MXP63Pps

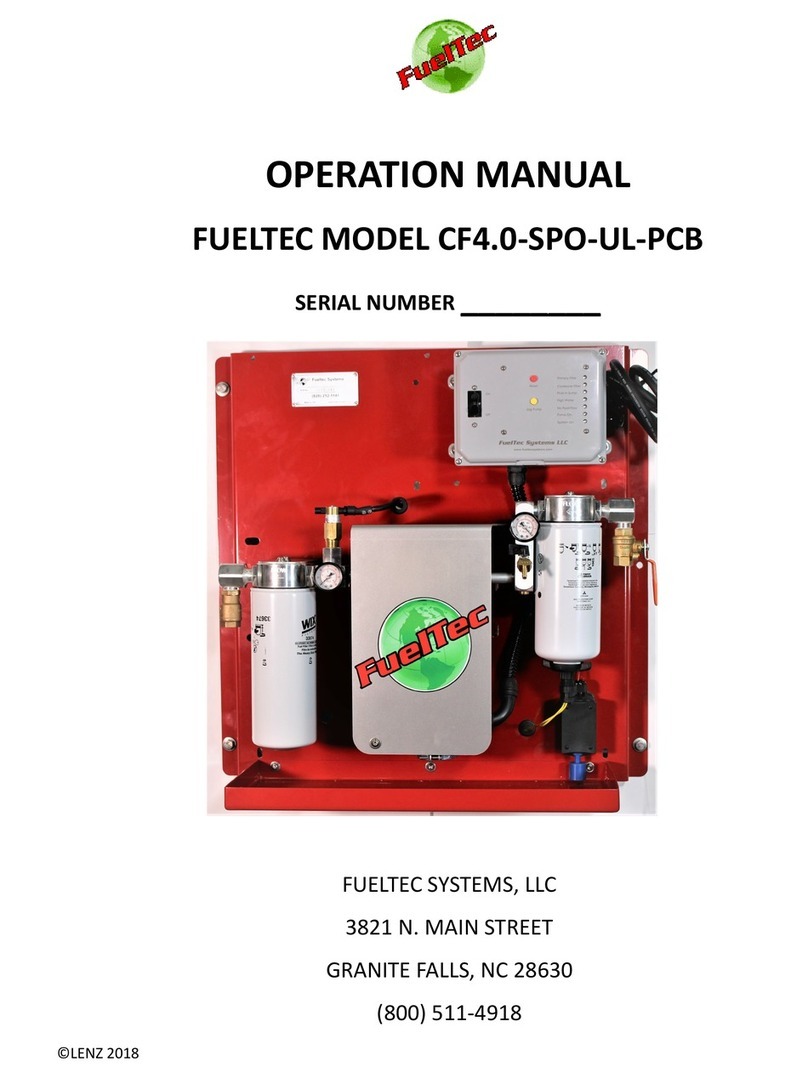

4 – Options MXP63P

Options - List of Parts

42

41

44

43

45

46

65

63

62

64

ITEM PART NO. DESCRIPTION

AUXILIARY CARRIER

41 8163-9504 Auxiliary Carrier Assembly (inch)

8163-9004 Auxiliary Carrier Assembly (metric)

42 8163-9528 Auxiliary Carrier Piston Bracket Assembly (inch)

8163-9028

Auxiliary Carrier Piston Bracket Assembly (metric)

MOUNTING KITS

432

8163-9519 Foot Mount Kit (inch)

8163-9019 Foot Mount Kit (metric)

8163-1055 Foot Mount

1104-1011 Screw (inch)

3420-1638 Screw (metric)

4418163-9018 Tube Clamp Mounting Kit

8163-1050 Tube Clamp

SWITCHES

45

Switches without Quick-Disconnect Couplers

SWMXP63 RY Reed Switch, SPST Normally Open

SWMXP63 NY Reed Switch, SPST Normally Closed

SWMXP63 TY

Solid State Switch, PNP (sourcing) Normally Open

SWMXP63 KY

Solid State Switch, NPN (sinking) Normally Open

SWMXP63 PY

Solid State Switch, PNP (sourcing) Normally Closed

SWMXP63 HY

Solid State Switch, NPN (sinking) Normally Closed)

46

Switches with Quick-Disconnect Couplers

SWMXP63 RK Reed Switch, SPST Normally Open

SWMXP63 NK Reed Switch, SPST Normally Closed

SWMXP63 TK

Solid State Switch, PNP (sourcing) Normally Open

SWMXP63 KK

Solid State Switch, NPN (sinking) Normally Open

SWMXP63 PK

Solid State Switch, PNP (sourcing) Normally Closed

SWMXP63 HK

Solid State Switch, NPN (sinking) Normally Closed

NOTE: Female Connector for Quick-Disconnect is included

ITEM PART NO. DESCRIPTION

SHOCK ABSORBERS

62 4415-1003 Impact Bolt

634

8163-9520 Fixed Shock Mounting Kit (inch)

8163-9020 Fixed Shock Mounting Kit (metric)

8163-1060 Fixed Shock Bracket

2317-1015 Screw (inch)

8163-1061 Screw (metric)

645

8163-9024 Adjustable Shock Mounting Kit

8163-1084 Shock Bracket

8163-1086 Shock Bracket Clamp

2212-1104 Socket Head Cap Screw

8125-1035 Dowel Pin

65 4920-1068 Light Duty Shock Absorber

4920-1069 Heavy Duty Shock Absorber

1Tube Clamp Kit contains 2 tube clamps.

2Foot Mount Kit contains 1 foot mount and 2 fasteners.

3Floating Mount Kit contains 1 floating mount, 1 lower strap, 1 pin and 4

fasteners.

4Fixed Shock Mounting Kit contains 1 shock bracket, and 2 fasteners.

5Adjustable Shock Mounting Kit contains 1 shock bracket, 2 bracket clamps,

and 4 fasteners.

3800 County Road 116, Hamel, MN 55340

http://www.Tolomatic.com • Email: Help@Tolomatic.com

Phone: (763) 478-8000 • Fax: (763) 478-8080 • Toll Free: 1-800-328-2174

8

© 2017 Tolomatic 201702060827

Information furnished is believed to be accurate

and reliable. However, Tolomatic assumes no

responsibility for its use or for any errors that

may appear in this document. Tolomatic reserves

the right to change the design or operation of the

equipment described herein and any associated

motion products without notice. Information in

this document is subject to change without notice.

Parts Sheet #8100-4117_05_MXP63Pps

MXP63P Switches / Maintenance – 5

Parts Sheet #8100-4117_05_MXP63PpsParts Sheet #8100-4117_05_MXP63Pps

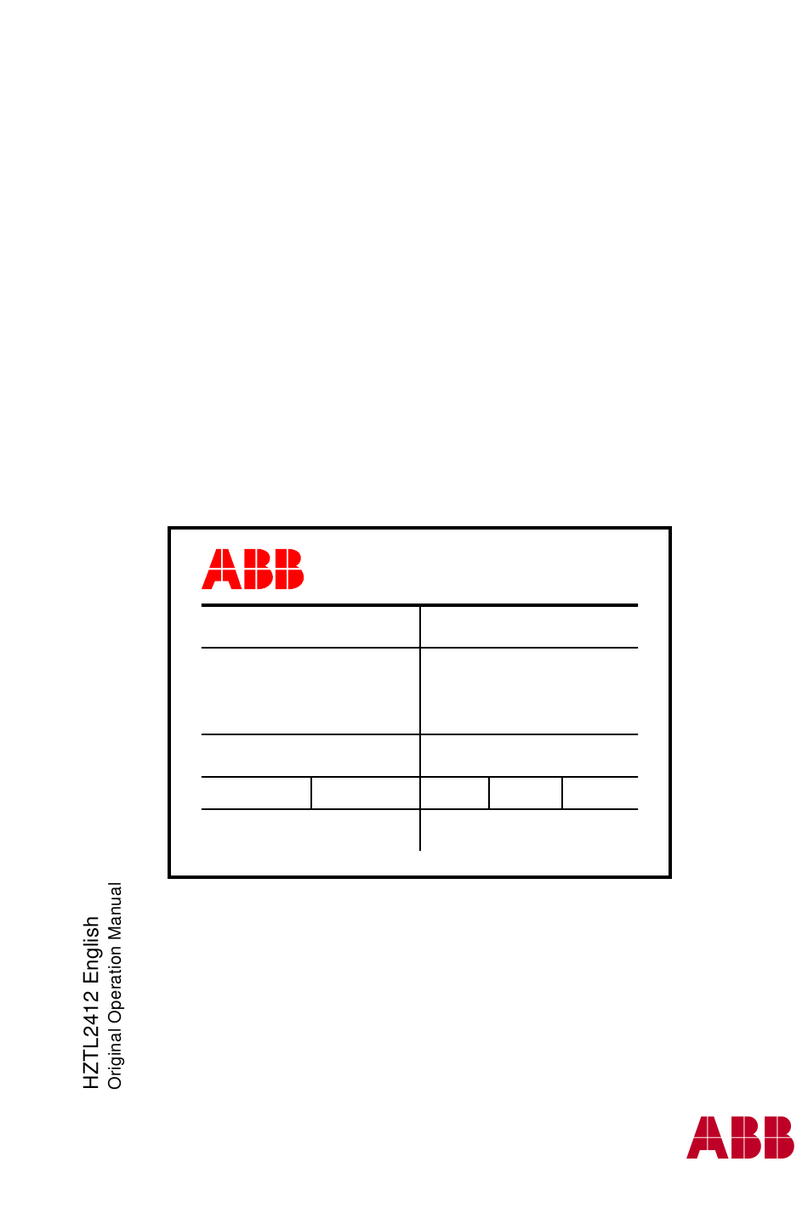

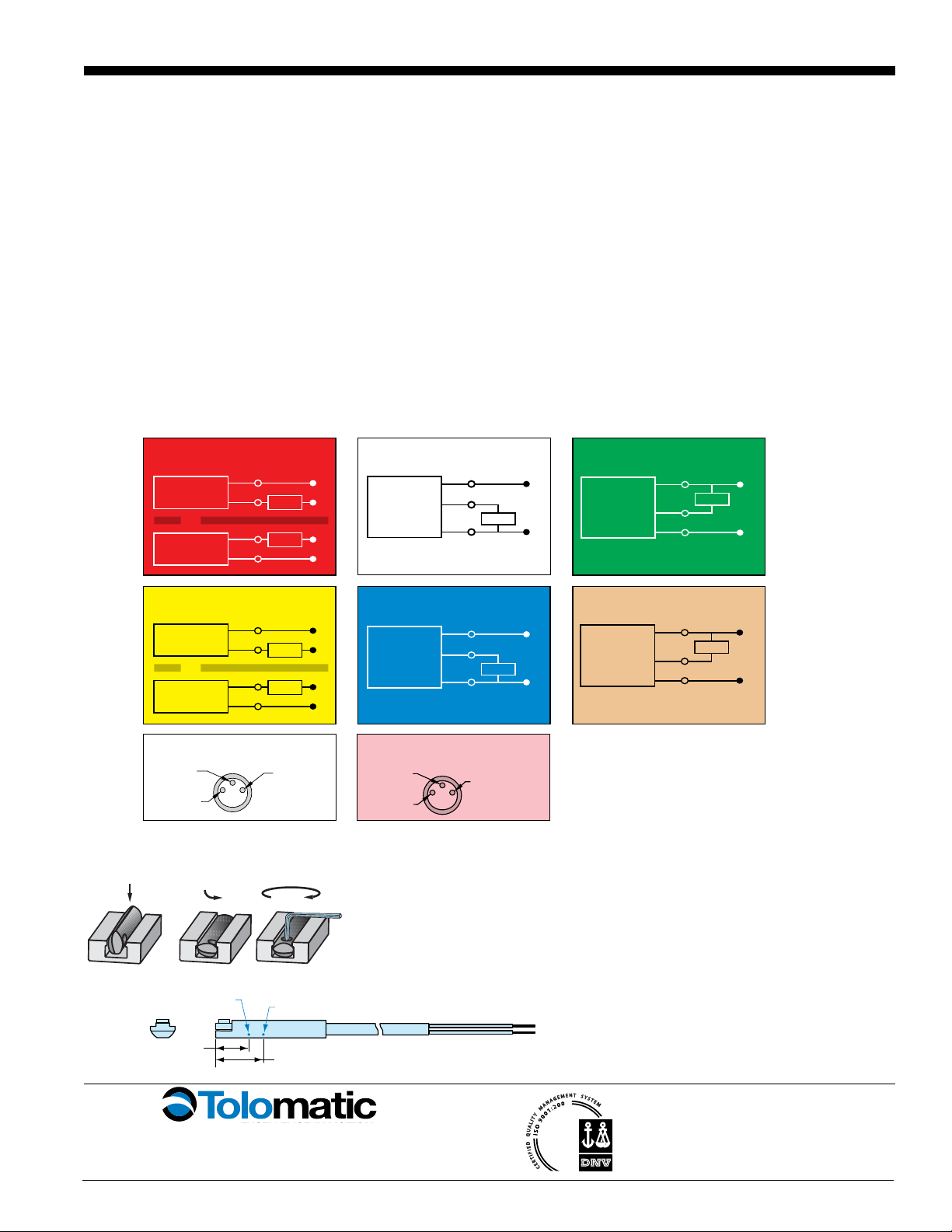

SWITCH WIRING DIAGRAMS AND LABEL COLOR CODING (CE and RoHS Compliant)

NORMALLY

CLOSED

BRN

BLU

+

-

LOAD

NORMALLY

CLOSED

BRN

BLU

+

-

LOAD

or

NORMALLY

OPEN PNP

(SOURCING)

BRN

BLK

+

SIGNAL

LOAD

BLU

-

NORMALLY

OPEN NPN

(SINKING)

BRN

BLK

+

SIGNAL

LOAD

BLU

-

NORMALLY

CLOSED PNP

(SOURCING)

BRN

BLK

+

SIGNAL

LOAD

BLU

-

NORMALLY

CLOSED NPN

(SINKING)

BRN

BLK

+

SIGNAL

LOAD

BLU

-

NORMALLY

OPEN

BRN

BLU

+

-

LOAD

NORMALLY

OPEN

BRN

BLU

+

-

LOAD

or

TY • TK

SOLID STATE • NORMALLY OPEN • PNP

NY • NK

REED • NORMALLY CLOSED

QUICK DISCONNECT MALE PLUG PINOUT #8100-9080 QUICK DISCONNECT

FEMALE SOCKET PINOUT

RY • RK

REED • NORMALLY OPEN

KY • KK

SOLID STATE • NORMALLY OPEN • NPN

PY • PK

SOLID STATE • NORMALLY CLOSED • PNP

HY • HK

SOLID STATE • NORMALLY CLOSED • NPN

BROWN (+)

BLUE (-)

BLACK

(SIGNAL)

BLUE (-)

BROWN (+)

BLACK

(SIGNAL)

SWITCH DETECTION POINT

16, 25, 32

MOUNTING DIMENSIONS

SWITCH DIMENSIONS

40, 50, 63

1.18 [30]

.31 [8]

Ø.28 [7]

.95 [24.1]

1.26 [32.1]

.51 [13]

DETECTION POINT REED

DETECTION POINT

SOLID STATE

13.35 [339]

M8x1

M8x1

197 [5000]

197 [5000]

_K- QD (Quick-disconnect) switch

8100-9080 - QD Cable

_Y- direct connect

U

SWITCHES SIT BELOW

TUBE EXTRUSION PROFILE

SWITCHES SIT BELOW

TUBE EXTRUSION PROFILE

V

U

Ø.35

[9]

W

V

X

Switches for MX:

• Include retained mounting hardware

• In slot, sit below extrusion profile

• Same for all sizes and bearing styles

LUBRICATION AND MAINTENANCE

All Tolomatic MX Band Cylinders are prelubricated at the factory. To ensure

maximum cylinder life, the following guidelines should be followed.

1. Filtration

We recommend the use of dry, filtered air in our products. “Filtered

air” means a level of 10 Micron or less. “Dry” means air should be

free of appreciable amounts of moisture. Regular maintenance of

installed filters will generally keep excess moisture in check.

2 External Lubricators (optional)

The factory prelubrication of Tolomatic Band Cylinders will provide

optimal performance without the use of external lubrication. However,

external lubricators can further extend service life of pneumatic

actuators if the supply is kept constant.

Oil lubricators, (mist or drop) should supply a minimum of 1 drop per

20 standard cubic feet per minute to the cylinder. As a rule of thumb,

double that rate if water in the system is suspected. Demanding con-

ditions may require more lubricant.

If lubricators are used, we recommend a non-detergent, 20cP @

140˚F 10-weight lubricant. Optimum conditions for standard cylinder

operation is +32˚ to +150˚F (+0˚ to 65.5˚C).

NOTE: Use of external lubricators may wash away the factory installed

lubrication. External lubricants must be maintained in a constant sup-

ply or the results will be a dry actuator prone to premature wear.

3. Sanitary Environments

Oil mist lubricators must dispense “Food Grade” lubricants to the air

supply. Use fluids with ORAL LD50 toxicity ratings of 35 or higher

such as Multitherm®PG-1 or equivalent. Demanding conditions can

require a review of the application.

4. Cushion Adjustment

Adjust the Cushion Needles in the Cylinder Heads carefully to obtain

optimum deceleration for your particular application. If there are

questions on proper adjustment, please consult Tolomatic.

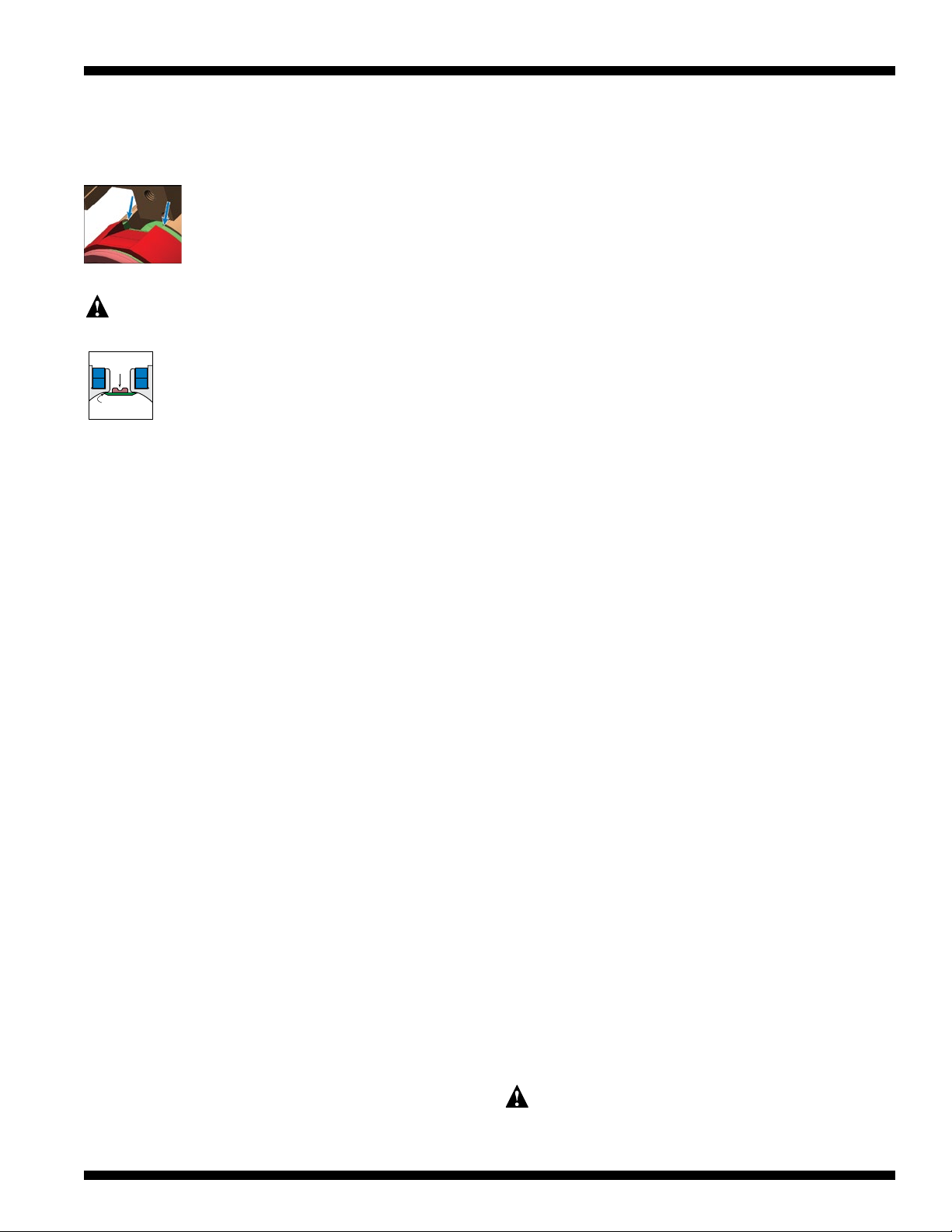

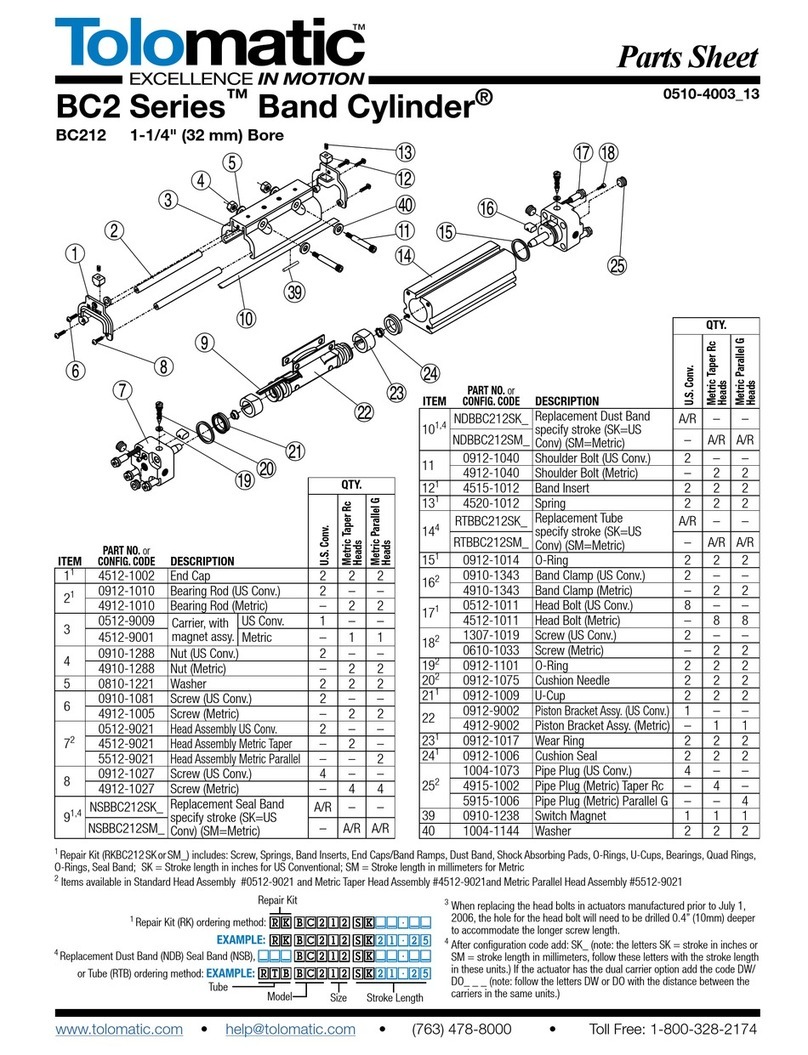

SWITCH INSTALLATION AND REPLACEMENT

Place switch in side groove on tube at desired location with "Tolomatic" facing

outward. While applying light pressure to the switch, rotate the switch halfway

into the groove. Maintaining light pressure, rotate the switch in the opposite

direction until the switch is fully inside the groove with "Tolomatic" visible.

Re-position the switch to the exact location and lock it securely into place by

tightening the screw on the switch.

Insert

switch

Rotate

switch

Secure

switch

Tolomatic

Tolomatic

Tolomatic

Dimensions in inches [brackets indicate dimensions in millimeters]

This manual suits for next models

5

Other Tolomatic Industrial Equipment manuals

Tolomatic

Tolomatic Band Cylinder BC2 Series User manual

Tolomatic

Tolomatic BC4 Series User manual

Tolomatic

Tolomatic TC15 User manual

Tolomatic

Tolomatic TC07SS Use and care manual

Tolomatic

Tolomatic MXP25PTP User manual

Tolomatic

Tolomatic MXP32N Series Use and care manual

Tolomatic

Tolomatic MXP50N User manual

Tolomatic

Tolomatic MXP16N User manual

Tolomatic

Tolomatic BC3 Series User manual

Tolomatic

Tolomatic Band Cylinder BC2 Series User manual