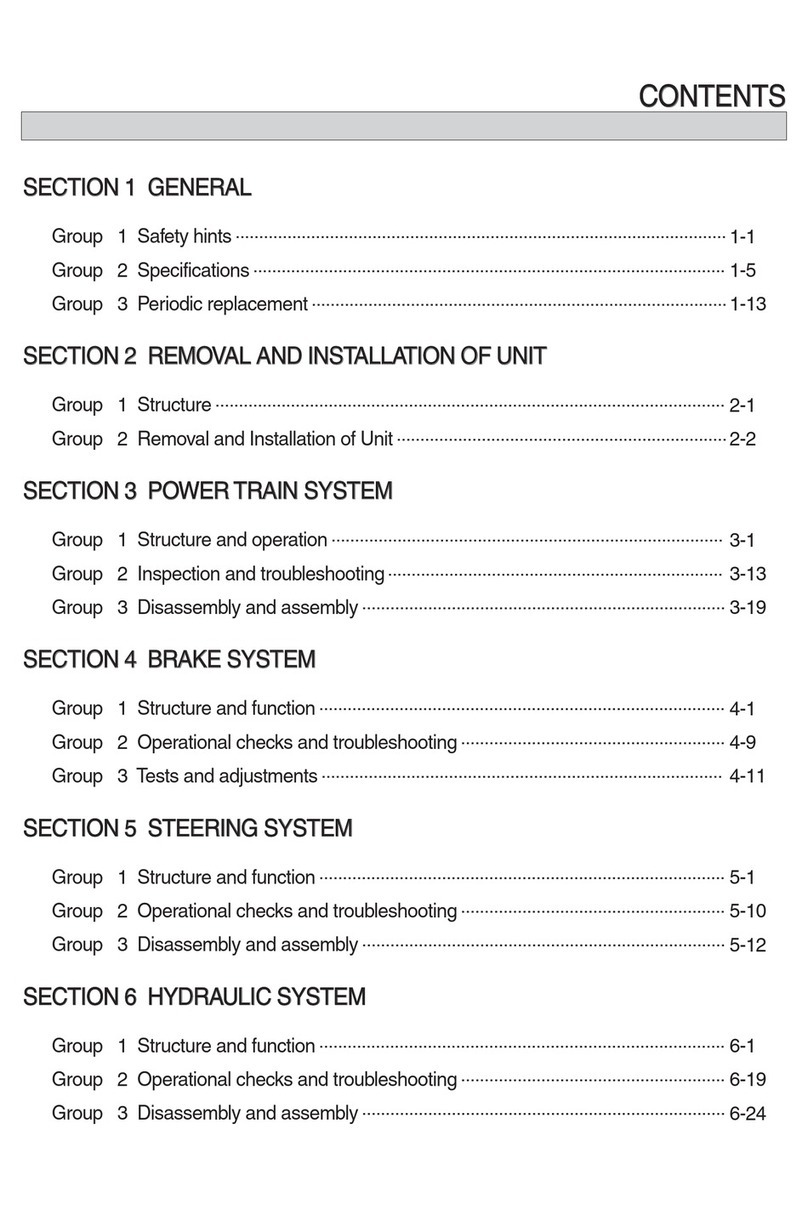

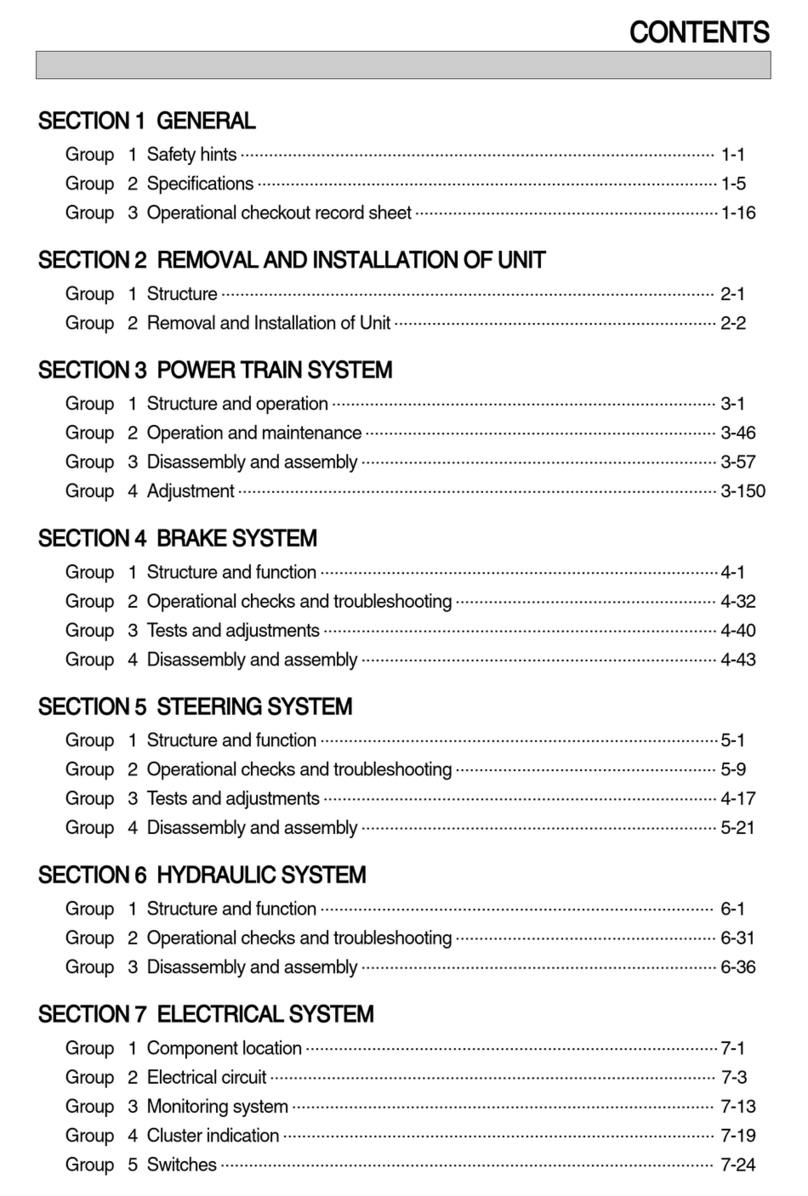

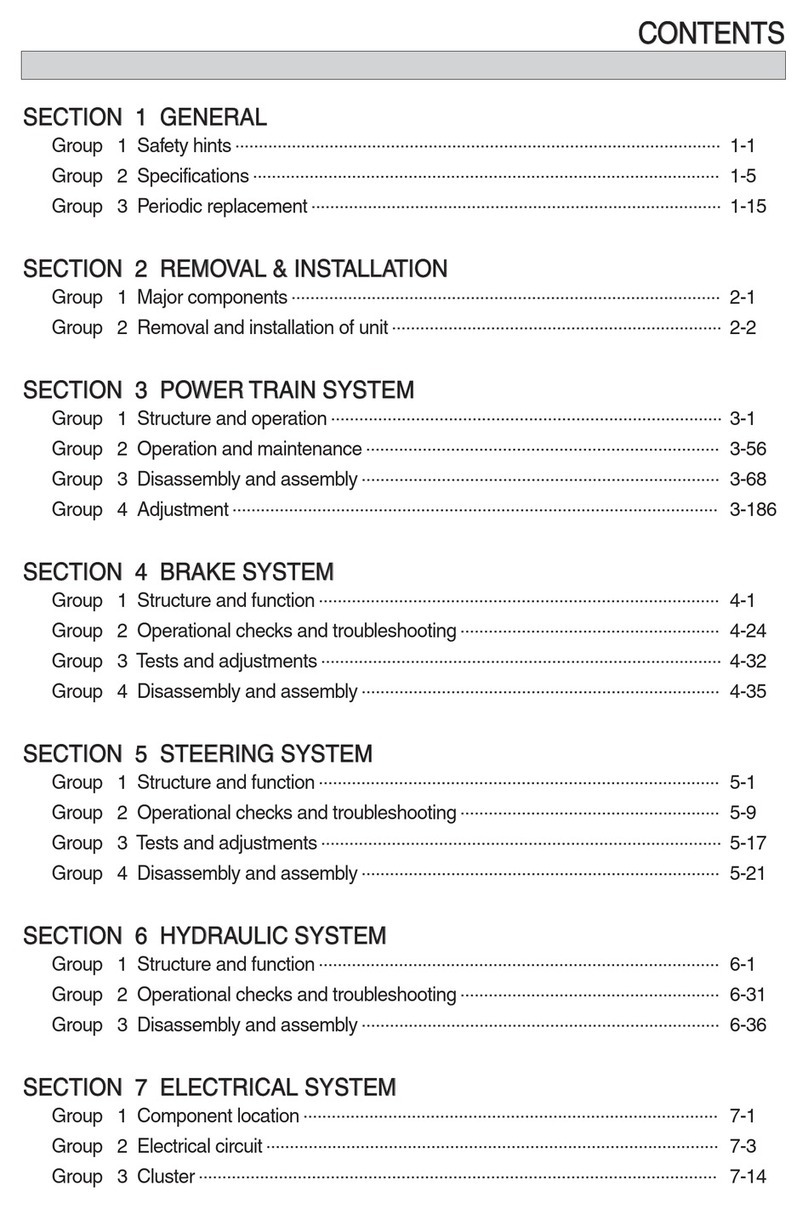

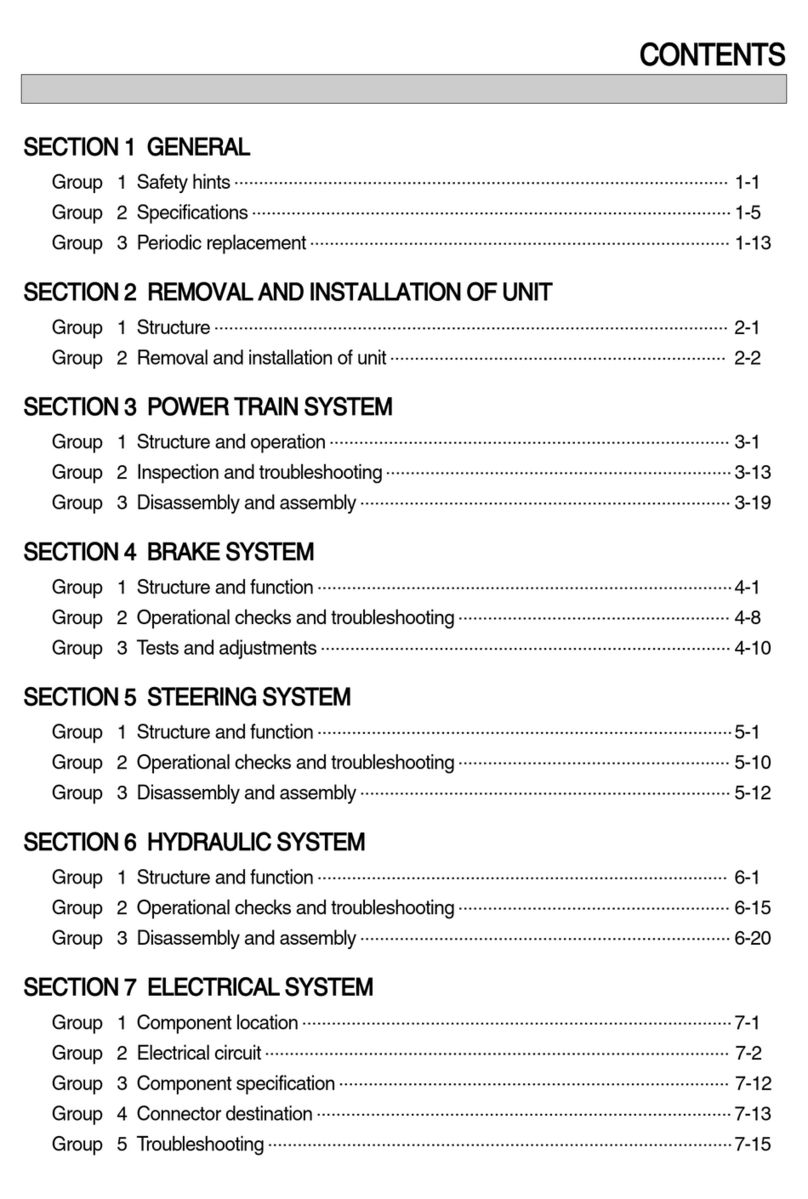

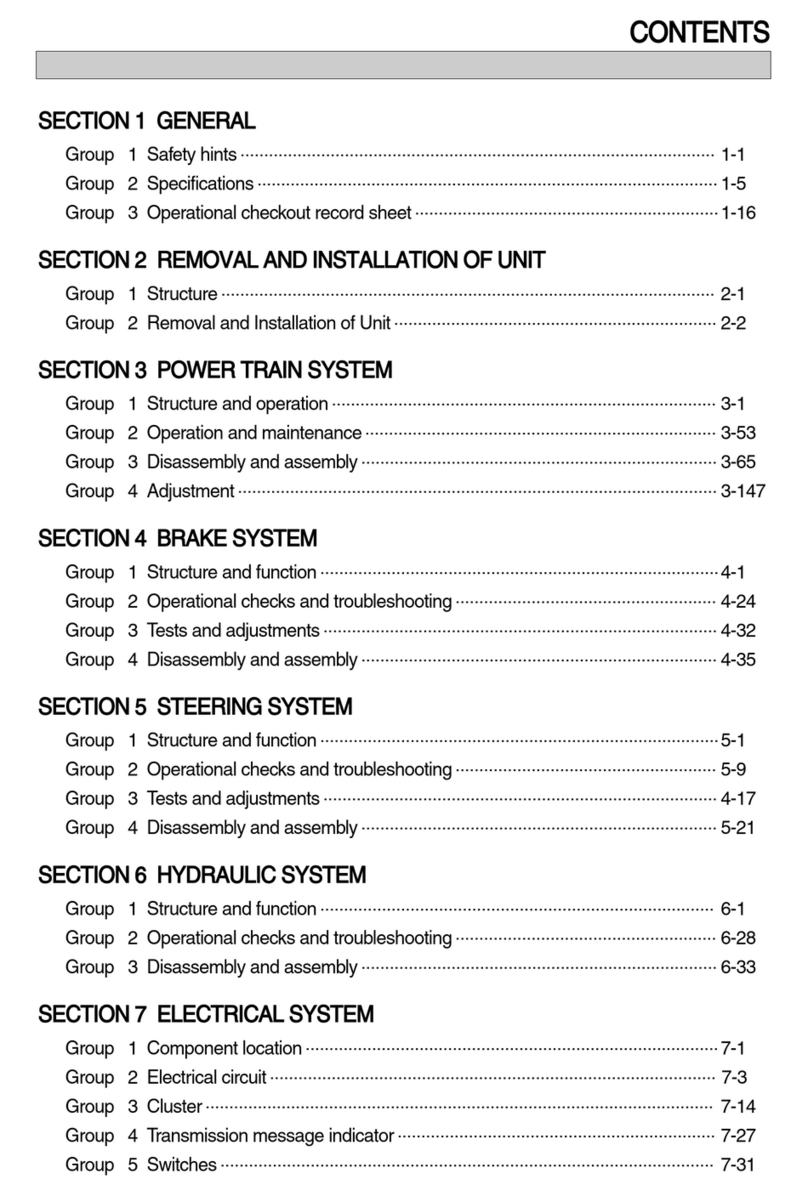

Table of Contents

Introduction ........................................................................................ 1

I. Forklift Truck Main Technical Parameters ................................................ 4

II. Description about Forklift Truck Main Parts .....8

III. Structure, Principle, Adjustment, and Maintenance of Forklift Truck .......... 10

. Power System ................................................................................ 10

1.1 Engine Overview ............................................................................. 10

1.2 Items to be Observed for Installation & Operation of Engine(LPG/Gasoline) ...... 13

1.3 Engine Adjustment .......................................................................... 15

1.4 Fuel S stem: ................................................................................. 16

2. Clutch and Its Pedal ......................................................................... 21

2.1 Overview ...................................................................................... 24

2.2 Method for Replacement of Brake Shoe Assembl .................................... 24

3. Hydraulic Transmission Case and Torque Converter ............................... 26

3.1 Overview ...................................................................................... 26

3.2 Torque Converter ............................................................................ 28

3.3 H draulic Clutch ............................................................................. 29

3.4 Control Valve, Safet Valve, and Inching Valve ......................................... 30

3.5 Transmission Case .......................................................................... 31

3.6 Oil Feed Pump ............................................................................... 31

3.7 H draulic Oil Circuit (H draulic Transmission) .......................................... 32

3.8 Speed Reducer and Speed Differential .................................................. 33

3.9 Traction of Forklift Truck to be Repaired .................................................. 33

3.10 Oil Port Joint Positions .................................................................... 33

4. Drive Axle ...................................................................................... 34

4.1 Overview ...................................................................................... 34

4.2 Maintenance of Drive Axle ................................................................. 35

5. Steering System ............................................................................. 36

5.1 Overview ...................................................................................... 36

5.2 Examination after Reassembl of Steering S stem .................................... 38

5.3 Failure Removal for Steering S stem .................................................... 39

6. Cross Cylinder Drive Axle ................................................................. 40

6.1 Overview ...................................................................................... 40

6.2 Steering Knuckle and Steering King Pin ................................................. 42

6.3 Adjustment for Pre-Tightened Load of Steering Wheel Bearing ..................... 42

7. Brake System ................................................................................. 43

7.1 Overview ...................................................................................... 43

7.3 Wheel Brake .................................................................................. 44

7.4 Automatic Clearance Regulator ........................................................... 46

7.5 Parking Brake ................................................................................ 46