Epiroc ER-L Series Maintenance and service guide

ER-L 100, 250, 400, 450, 600, 700, 1100, 1500, 2000

Safety and operating instructions

Longitudinal Drum Cutters

© Anbaufräsen PC GmbH | 3390 5221 01 | 2020-09-07

Original Instructions

Contents

© Anbaufräsen PC GmbH | 3390 5221 01 | 2020-09-07

Original Instructions

3

Table of Contents

1 Introduction ................................................................................................................................8

1.1 About these Safety and Operating Instructions...............................................................................................8

2 Safety instructions.....................................................................................................................9

2.1 Signal words........................................................................................................................................................9

2.2 Qualification ......................................................................................................................................................10

2.3 Intended use ......................................................................................................................................................10

2.3.1 Intended use of the longitudinal drum cutters with a drilling auger..................................................................10

2.4 Use other than intended ...................................................................................................................................11

2.5 Protective equipment........................................................................................................................................11

2.6 Carrier, precautions ..........................................................................................................................................11

2.7 Transport, precautions .....................................................................................................................................11

2.8 Hydraulic installation, precautions .................................................................................................................12

2.9 Media/consumables, precautions....................................................................................................................12

2.10 Explosion and fire, precautions.......................................................................................................................13

2.11 Electrical shock, precautions ..........................................................................................................................13

2.12 Falling stones, precautions..............................................................................................................................13

2.13 Emissions, precautions....................................................................................................................................14

2.14 Handling machines, precautions.....................................................................................................................14

2.15 Repair, precautions...........................................................................................................................................15

2.15.1 Maintenance works not allowed by the manufacturer ....................................................................................15

2.16 Changes to the hydraulic attachment, precautions.......................................................................................15

2.17 Environmental pollution, precautions.............................................................................................................15

3 Overview ...................................................................................................................................16

3.1 Equipment description .....................................................................................................................................16

3.2 Function .............................................................................................................................................................16

3.3 Modules..............................................................................................................................................................17

3.4 Signs / labels .....................................................................................................................................................19

3.4.1 Signs................................................................................................................................................................19

3.4.2 Name plate ......................................................................................................................................................19

3.4.3 Labels ..............................................................................................................................................................20

3.5 Applications.......................................................................................................................................................20

3.6 Working area and hazardous area...................................................................................................................20

3.7 Removing the packaging..................................................................................................................................20

3.8 Scope of delivery ..............................................................................................................................................20

3.9 Standard round attack picks............................................................................................................................21

3.10 Tools for round attack picks ............................................................................................................................22

4 Transport ..................................................................................................................................23

4.1 Transport using a crane ...................................................................................................................................23

4.2 Transport using a forklift truck........................................................................................................................24

4.3 Transport using a truck ....................................................................................................................................24

Contents

4 © Anbaufräsen PC GmbH | 3390 5221 01 | 2020-09-07

Original Instructions

5 Installation ................................................................................................................................25

5.1 Media/consumables ..........................................................................................................................................25

5.1.1 Mineral hydraulic oil.........................................................................................................................................25

5.1.2 Non-mineral hydraulic oil .................................................................................................................................25

5.1.3 Gear oil ............................................................................................................................................................26

5.2 Preconditions for the carrier............................................................................................................................26

5.3 Preconditions for adapter plate .......................................................................................................................26

5.4 Attaching the hydraulic attachment to the carrier .........................................................................................27

5.4.1 Mechanical mounting aspects .........................................................................................................................27

5.4.2 First installation................................................................................................................................................28

5.4.3 Making the hydraulic connections ...................................................................................................................29

5.5 Removing the hydraulic attachment from the carrier....................................................................................31

5.6 Exchangeable attachments..............................................................................................................................32

5.6.1 Mount hexagonal receiver ...............................................................................................................................32

5.6.2 Mount drilling auger .........................................................................................................................................34

5.6.3 Mount pivot adapter.........................................................................................................................................34

5.6.4 Dismount pivot adapter....................................................................................................................................35

5.6.5 Dismount drilling auger....................................................................................................................................35

5.6.6 Dismount hexagonal receiver and intermediate flange ...................................................................................36

5.6.7 Selecting the correct drilling auger ..................................................................................................................37

5.6.8 Specification of soil classes for earth & rock drilling........................................................................................37

6 Operation ..................................................................................................................................38

6.1 Preparations before starting ............................................................................................................................39

6.2 Commissioning .................................................................................................................................................39

6.2.1 Checks during commissioning.........................................................................................................................39

6.3 Switching the drum cutter on and off .............................................................................................................40

6.4 Functional test...................................................................................................................................................40

6.5 Correct operation ..............................................................................................................................................41

6.5.1 Operating the drilling auger .............................................................................................................................41

6.6 Prohibited operation .........................................................................................................................................42

6.6.1 Cylinder end positions .....................................................................................................................................42

6.6.2 Moving the carrier............................................................................................................................................42

6.6.3 Lifting/Transporting..........................................................................................................................................42

6.6.4 Impacting/chopping .........................................................................................................................................43

6.7 Activities after use ............................................................................................................................................43

7 Maintenance .............................................................................................................................44

7.1 Maintenance works not allowed by the manufacturer ..................................................................................45

7.2 Maintenance schedule......................................................................................................................................46

7.3 Depressurising the hydraulic system .............................................................................................................47

7.4 Cleaning .............................................................................................................................................................47

7.5 Checking bolted connections ..........................................................................................................................48

7.6 Checking the hydraulic attachment and adapter plate for cracks ...............................................................48

7.7 Checking the adapter plate bolts for wear......................................................................................................48

7.8 Change gear oil .................................................................................................................................................48

7.8.1 Oil change intervals .........................................................................................................................................48

7.8.2 Preparation ......................................................................................................................................................49

7.8.3 Drain off gear oil ..............................................................................................................................................49

7.8.4 Fill up gear oil ..................................................................................................................................................49

7.9 Check the round attack picks and pick boxes ...............................................................................................50

Contents

© Anbaufräsen PC GmbH | 3390 5221 01 | 2020-09-07

Original Instructions

5

7.10 Replace round attack picks..............................................................................................................................50

7.10.1 Replace round attack pick with knock on retainer ...........................................................................................51

7.10.2 Replace round attack pick with retaining sleeve..............................................................................................52

7.10.3 Replace round attack picks with quick snap retainer.......................................................................................53

7.10.4 Replace round attack picks with retaining ring ................................................................................................54

7.11 Replace cutter drum .........................................................................................................................................55

7.11.1 Disassemble cutter drum ER100L - ER2000L.............................................................................................55

7.11.2 Disassemble cutter drum ERL700, ERL1100................................................................................................56

7.11.3 Assemble cutter drum......................................................................................................................................57

7.12 Checking hydraulic lines..................................................................................................................................58

7.13 Checking and cleaning the hydraulic oil filter of the carrier.........................................................................59

7.14 Replace hydraulic hoses ..................................................................................................................................59

7.15 Actions following maintenance .......................................................................................................................59

7.16 Bolt connections / Tightening torques ...........................................................................................................60

8 Troubleshooting.......................................................................................................................63

8.1 Faults table ........................................................................................................................................................63

8.2 Cutter drum does not turn / is blocked ...........................................................................................................64

8.3 Cutter drum turns too slowly ...........................................................................................................................64

8.4 Drum cutter stops moving with light pressure ..............................................................................................65

8.5 Unusual oscillation of the cutter drum ...........................................................................................................65

8.6 Round attack picks do not turn .......................................................................................................................65

8.7 Unusually loud gear noise ...............................................................................................................................65

8.8 Unusually loud noise from the hydraulic motor ............................................................................................65

8.9 Overpressure cover for the hydraulic motor deformed, oil leak on sealing surface, oil leak at the pres-

sure limiting valve.............................................................................................................................................66

8.10 Oil leaking at the cutter drum area ..................................................................................................................66

8.11 Behaviour following fault elimination .............................................................................................................66

9 Repair ........................................................................................................................................67

9.1 Sending in the hydraulic attachment for repairs ...........................................................................................67

10 Storage......................................................................................................................................68

10.1 Drum cutter........................................................................................................................................................68

10.1.1 Short storage ...................................................................................................................................................68

10.1.2 Long storage....................................................................................................................................................68

10.2 Cutter drum........................................................................................................................................................68

10.3 Round attack picks ...........................................................................................................................................68

11 Disposal ....................................................................................................................................69

11.1 Drum cutter........................................................................................................................................................69

11.2 Hydraulic hoses ................................................................................................................................................69

11.3 Hydraulic oil.......................................................................................................................................................69

11.4 Gear oil...............................................................................................................................................................69

12 Technical specifications..........................................................................................................70

12.1 Technical specifications ADU..........................................................................................................................79

13 Appendix...................................................................................................................................81

Contents

6 © Anbaufräsen PC GmbH | 3390 5221 01 | 2020-09-07

Original Instructions

13.1 Hydraulic installation version 1 for hydraulic hammer .................................................................................81

13.2 Hydraulic installation version 2 for hydraulic shear systems ......................................................................82

13.3 Hydraulic settings (explanation for following diagrams) ..............................................................................83

13.4 Hydraulic settings ER 100 L.............................................................................................................................84

13.5 Hydraulic settings ER 250 L.............................................................................................................................86

13.6 Hydraulic settings ER400L, ER450L, ER600L ..........................................................................................88

13.7 Hydraulic settings ERL 700..............................................................................................................................89

13.8 Hydraulic settings ERL1100, ER1500L.........................................................................................................90

13.9 Hydraulic settings ER 2000 L...........................................................................................................................92

14 EC Declaration of Conformity (EC Directive 2006/42/EC) ....................................................94

Contents

© Anbaufräsen PC GmbH | 3390 5221 01 | 2020-09-07

Original Instructions

7

Safety and operating instructions

8 © Anbaufräsen PC GmbH | 3390 5221 01 | 2020-09-07

Original Instructions

1 Introduction

Epiroc is a leading productivity partner for the mining, in-

frastructure and natural resources industries. With cut-

ting-edge technology, Epiroc develops and produces in-

novative drill rigs, rock excavation and construction

equipment, and provides world-class service and con-

sumables.

The company was founded in Stockholm, Sweden, and

has passionate people supporting and collaborating with

customers in more than 150 countries.

Anbaufräsen PC GmbH

Ulmenstr. 3

D - 36469 Bad Salzungen / OT Hämbach

Tel.: +49 3695 851 09 0

Fax: +49 3695 851 0999

1.1 About these Safety and

Operating Instructions

The aim of these Instructions is to familiarise you with

the safe and effective operation of the hydraulic attach-

ment. You will also find instructions for regular mainte-

nance activities for the hydraulic attachment in this docu-

ment.

Please read these Instructions carefully prior to the first

attachment and use of the hydraulic attachment.

The different designation of the texts means as follows:

►

Action step in a safety instruction

♦

Action step

1.

2.

Established operation process

A

B

C

Explanation of the elements of a drawing

•

•

•

Listing

Symbols used in illustrations have the following mean-

ings:

permitted operation

prohibited operation

Safety and operating instructions

© Anbaufräsen PC GmbH | 3390 5221 01 | 2020-09-07

Original Instructions

9

2 Safety instructions

This is the safety alert symbol. It is used to alert

you to potential personal injury hazards. Obey

all safety messages that follow this symbol to

avoid possible injury or death.

Read these Safety and operating instructions

and specifically all safety instructions before us-

ing the hydraulic attachment. This will:

• prevent the risk of injuries and fatal accidents for

yourself and others,

• protect the environment against environmental dam-

age.

• protect the hydraulic attachment and other property

against material damage,

Follow all instructions in these Safety and operating in-

structions.

Store these Safety and operating instructions in the doc-

ument compartment of the carrier cab.

Anyone

• transporting,

• installing or removing,

• operating,

• maintaining,

• repairing,

• storing or

• disposing of

the hydraulic attachment must have read and under-

stood these Safety and operating instructions.

These Safety and operating instructions belong to the

hydraulic attachment. Keep it for the life of the product.

Ensure, if applicable, that any received amendment is in-

corporated in the instructions. Hand over the Safety and

operating instructions if ever you lend, rent out or sell the

hydraulic attachment.

All safety regulations listed in this manual comply with

the laws and regulations of the European Union. Also

observe the additional national/regional regulations.

Hydraulic attachment operation outside the European

Union is subject to the laws and regulations valid in the

country of use. Please observe any other, more stringent

regional regulations and legislation.

Read the carrier manufacturer's Safety and operating In-

structions before attaching the hydraulic attachment to

the carrier and operating it. Observe all instructions.

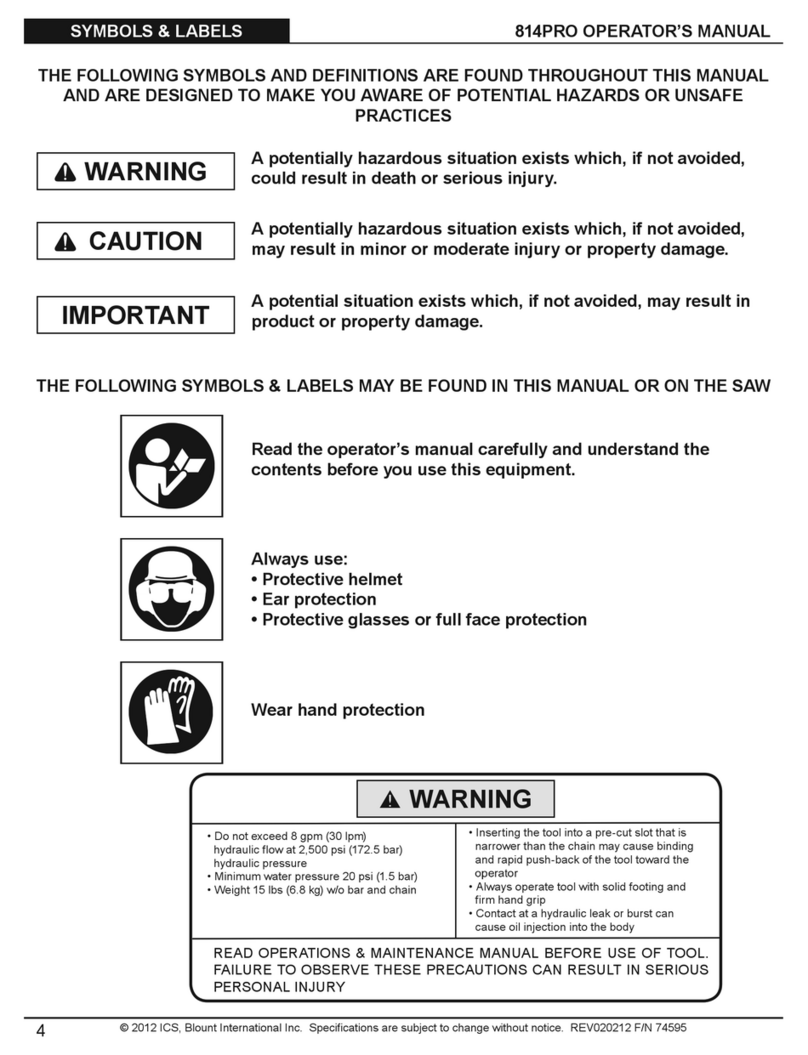

2.1 Signal words

The signal words Danger, Warning, Caution, and Notice

are used as follows in these Safety and operating in-

structions:

DANGER indicates a hazardous situation

which, if not avoided, will result in

death or serious injury.

WARNING indicates a hazardous situation

which, if not avoided, could result in

death or serious injury.

CAUTION indicates a hazardous situation

which, if not avoided, could result in

minor or moderate injury.

NOTICE The signal word NOTICE is used to

address practices related to possible

property damage but not related to

personal injury.

Safety and operating instructions

10 © Anbaufräsen PC GmbH | 3390 5221 01 | 2020-09-07

Original Instructions

2.2 Qualification

Transporting the hydraulic attachment is only permitted

if carried out by people who:

• are authorised to operate a crane or a forklift truck

according to the applicable national provisions,

• know all the relevant national/regional safety provi-

sions and accident prevention rules,

• have read and understood the safety and transport

chapter of these Safety and operating instructions.

First installation and commissioning of the hydraulic

attachment is only permitted if carried out by people

who:

• are authorised by AnbaufräsenPCGmbH,

• know all the relevant national/regional safety provi-

sions and accident prevention rules,

• have read and understood these Safety and operat-

ing instructions.

Installing, maintaining, storing and disposing of the

hydraulic attachment are only permitted if carried out by

people who:

• know all the relevant national/regional safety provi-

sions and accident prevention rules,

• have read and understood these Safety and operat-

ing instructions.

Operating the hydraulic attachment is only permitted if

carried out by qualified carrier drivers. Carrier drivers are

qualified if they:

• have been trained to operate a carrier according to

the national regulations,

• know all the relevant national/regional safety provi-

sions and accident prevention rules,

• have read and understood these Safety and operat-

ing instructions.

Testing the hydraulic installation is only permitted if

carried out by professionals. Professionals are people

who are authorised to approve a hydraulic installation for

operation according to the national regulations.

Repairing the hydraulic attachment is only permitted if

carried out by professionals trained by An-

baufräsenPCGmbH. These professionals must have

read and understood these Safety and operating instruc-

tions. They must follow all safety instructions and guide-

lines for repair. Otherwise the operational safety of the

hydraulic attachment is not guaranteed.

Personnel (carrier operator, maintenance personnel)

must receive instructions from the operator regularly. For

the purpose of improved traceability, the provision of in-

structions must be recorded.

2.3 Intended use

Only attach the drum cutter to a hydraulic carrier of a

suitable load-bearing capacity. Read the carrier manu-

facturer's Safety and operating instructions before at-

taching the drum cutter to the carrier and operating it.

Observe all instructions.

The drum cutter is intended exclusively for mounting on

a hydraulic excavator or, following agreement with the

authorized Customer Center / dealer in your area, with

another carrier.

The drum cutter serves exclusively to cut:

• Rock

• Concrete (reinforced and non-reinforced)

Prior to carrying out cutting work on reinforced concrete,

discuss this with the manufacturer (An-

baufräsenPCGmbH).

• Asphalt

• Frozen soil

• Ice

Furthermore, the drum cutter is suitable for cutting

ditches and tunnels and for mixing soil structures. The

drum cutter can be used to a depth of 30m (99ft) under

water. Contact the authorized Customer Center / dealer

in your area if bigger water depth is required.

When cutting with the drum cutter, check the compres-

sive strengths of the rock to be cut (see chapter Techni-

cal specifications).

Intended use also includes adhering to all specifications

contained in this manual.

Any further use which exceeds or is contrary to the in-

tended use is considered inappropriate use.

2.3.1 Intended use of the longitudinal drum

cutters with a drilling auger

The longitudinal drum cutter with drilling auger is in-

tended exclusively for mounting on a hydraulic excavator

or, following agreement with the authorized Customer

Center / Dealer in your area, with another carrier.

The longitudinal drum cutter with drilling auger serves

exclusively for creating vertical holes in:

• Ground classes 1 to 7 per DIN18300

• Stratified, fragmented and brittle rock of medium

hardness

• Frozen soil

• Ice

Typical applications are overhead line construction,

beam-type retaining construction, earth anchors, strain-

relieving boring, fencing and planting.

Safety and operating instructions

© Anbaufräsen PC GmbH | 3390 5221 01 | 2020-09-07

Original Instructions

11

The drilling auger can be used to a depth of 30m (99ft)

under water. Contact the authorized Customer Center /

Dealer in your area if bigger water depth is required.

2.4 Use other than intended

Misusing the drum cutter or the boom can lead to dan-

gerous situations.

• Do not use the drum cutter in areas with a risk for

explosions.

• Do not cut any materials other than those mentioned

in chapter Intended use.

• Do not carry out any impacting work.

• Do not operate the drum cutter if picks are broken.

• Do not use the drum cutter as a device for lifting

people or materials.

• Do not use the drum cutter as a surface for carrying

or transporting machines, materials or tools.

• Do not use the drum cutter to take the weight of the

carrier.

Claims of any kind as a result of damages arising from

misuse are excluded.

2.5 Protective equipment

Personal protective equipment must comply with the ap-

plicable health and safety regulations.

Always wear the following personal protective equip-

ment:

• protective helmet

• safety glasses with side protectors

• protective gloves

• protective shoes

• warning vest

• Light respiratory protection

• Protective work clothing

Protective work clothing is tight-fitting work clothing with

low resistance to tearing, with tight sleeves and without

projecting parts. It is primarily used to protect against en-

tanglement by moving machine parts. Do not wear rings,

chains or other jewellery.

2.6 Carrier, precautions

WARNING Falling carrier

If the load-bearing capacity of the carrier used is insuffi-

cient, the carrier will not be stable. It can topple over and

cause injuries and damage.

Using a carrier whose load-bearing capacity is too high

will greatly burden the hydraulic attachment causing it to

wear faster.

uOnly attach the hydraulic attachment to a hydraulic

carrier of a suitable load-bearing capacity.

uThe carrier must remain stable at all times.

uRead the carrier manufacturer's Safety and operating

Instructions before attaching the hydraulic attach-

ment to the carrier and operating it. Observe all in-

structions.

NOTICE Damage to the hydraulic attachment

Working with a hydraulic attachment mounted to a long

reach boom may cause damage to the hydraulic attach-

ment.

uBefore working with a hydraulic attachment mounted

to a long reach boom consult the Epiroc Customer

Center / Dealer in your area.

2.7 Transport, precautions

WARNING Risk of death due to suspended loads

When lifting loads these can swing out and fall. This can

result in serious injuries or even death.

uNever stand underneath or in the swinging range of

suspended loads.

uOnly move loads under supervision.

uOnly use approved lifting equipment and lifting gear

with sufficient load bearing capacity.

uDo not use worn lifting gear (ropes, belts, chains,

shackles etc.).

uDo not place lifting gear such as ropes and belts on

sharp edges or corners, do not knot these or twist

them.

uWhen leaving the workplace, set down the load.

WARNING Injury due to swivelling load

When transporting the load by crane it can swivel and

cause severe injuries and considerable damage to prop-

erty.

uEnsure that no personnel, objects or obstacles are

located in the swivel range of the load.

Safety and operating instructions

12 © Anbaufräsen PC GmbH | 3390 5221 01 | 2020-09-07

Original Instructions

2.8 Hydraulic installation,

precautions

WARNING Hydraulic pressure too high

If the hydraulic pressure is too high, the parts of the hy-

draulic attachment will be exposed to excessively high

loads. Parts can break loose or burst causing serious in-

juries.

uLay the drain line of the pressure relief valve directly

in the tank to ensure the safe functioning of the pres-

sure relief valve!

uThe pressure relief valve must be set at the maxi-

mum static pressure.

uThe pressure relief valve setting must be checked to

ensure that the maximum static pressure (see chap-

ter Technical specifications) of the hydraulic instal-

lation is not exceeded at any time. Attach a lead seal

to the pressure relief valve.

uPrior to their first use, the safety facilities on the hy-

draulic installation must be checked by a profes-

sional/authorised monitoring body for their quality

(CE mark etc.), suitability and proper functioning.

uIf any significant changes are made to the hydraulic

installation, a new acceptance inspection is to be

carried out in accordance with the relevant national

safety provisions.

WARNING Hot hydraulic oil squirting out

The hydraulic system is under high pressure. Hydraulic

lines may spring a leak or burst. Hydraulic oil squirting

out can lead to serious injury.

uWhen attaching the hydraulic attachment do not

route any hydraulic lines through the carrier's cab.

uOnly use hydraulic lines which comply with the fol-

lowing quality requirements: Hydraulic hoses with 4

reinforcement steel wires 4SP and 4SH according to

DINEN856, Hydraulic hoses with high tensile steel

wire braid 1SN and 2SN according to DINEN853,

Hydraulic pipes, seamless cold-drawn steel pipes to

DINEN10305.

2.9 Media/consumables,

precautions

WARNING Hot hydraulic oil under high pressure

Hydraulic oil will squirt out under high pressure if there is

a leakage. The jet of oil might penetrate people's skin

and cause permanent damage. Hot hydraulic oil can

cause burns.

uNever use your hands to find leaks.

uAlways keep your face away from a possible leak.

uIf hydraulic oil has penetrated your skin consult a

doctor immediately.

WARNING Hydraulic oil spills

Spilt hydraulic oil can make a floor slippery. If people slip

they can be injured. Hydraulic oil is environmentally

harmful and must not penetrate the ground or enter the

water table or water supplies.

uMake sure not to spill any hydraulic oil.

uImmediately clean the floor if you have spilt hydraulic

oil.

uObserve all safety and environmental protection pro-

visions when handling hydraulic oil.

WARNING Skin infections/diseases due to oil and

grease

Hydraulic oil and grease can cause rashes (or even

eczema) if they come into contact with the skin.

uAvoid all skin contact with hydraulic oil and grease.

uUse a suitable skin protection product.

uAlways wear safety gloves when working with hy-

draulic oil or grease.

uImmediately clean any skin that has been contami-

nated by oil or grease with water and soap.

Safety and operating instructions

© Anbaufräsen PC GmbH | 3390 5221 01 | 2020-09-07

Original Instructions

13

2.10 Explosion and fire,

precautions

DANGER Explosion and fire

Explosions cause serious injury or death.

If the hydraulic attachment encounters explosives in op-

eration, it may cause an explosion.

uNever operate the hydraulic attachment in the direct

vicinity of explosives.

uMake sure that no explosives are hidden in the

ground.

uCheck gas line position plans of the complete con-

struction area.

DANGER Explosion and fire

Operating the hydraulic attachment may create sparks

which ignite highly flammable gases.

This may lead to fire or an explosion.

uNever work in an environment with highly flammable

substances.

uMake sure that there are no hidden sources of gas in

the work area.

uCheck gas line position plans of the complete con-

struction area.

DANGER Explosion and fire

Dust-rich air can form an explosive atmosphere which

may ignite when operating the hydraulic attachment.

This may lead to fire or an explosion.

uNever operate the hydraulic attachment in an explo-

sion-hazard atmosphere.

uAlways provide sufficient ventilation when working in

buildings or in a confined area.

2.11 Electrical shock, precautions

DANGER Electrical shock

Any contact of the hydraulic attachment with electric cir-

cuits or other sources of electricity will lead to an electric

shock, resulting in serious injury or death. The hydraulic

attachment is not electrically insulated.

uNever work in the vicinity of electric circuits or other

sources of electricity.

uMake sure that there are no hidden circuits in the

work area.

uCheck wiring diagrams.

2.12 Falling stones, precautions

DANGER Fragments flying around

Fragments of material which come loose while operating

the hydraulic attachment may be flung away and can

cause serious injury if people are hit by them. Small ob-

jects falling from a great height can also cause serious

damage.

During hydraulic attachment operation the danger zone

is considerably greater than during the excavation oper-

ation due to fragments of stone and pieces of steel flying

around, and for this reason the danger zone must, de-

pending on the type of material to be worked on, be en-

larged correspondingly, or secured in a suitable manner

through corresponding measures.

uSecure the danger zone.

uEnsure that no persons are within a distance of 15m

(50ft) during cutting work.

uEnsure that no persons are within a distance of 50m

(165ft) during cutting work on reinforced steel.

uStop the hydraulic attachment immediately if anyone

enters the danger zone.

uClose the windscreen and the side windows of the

driver's cab.

uThe cabin of the hydraulic carrier must be protected

by means of suitable measures (e.g. armoured glass,

min. class P4A according to DINEN356) against

damage due to flying rock.

uMake sure no flying fragments can leave the danger

zone (e.g. safety fence).

Safety and operating instructions

14 © Anbaufräsen PC GmbH | 3390 5221 01 | 2020-09-07

Original Instructions

2.13 Emissions, precautions

WARNING Noise hazard

Operating the hydraulic attachment creates a loud noise.

Long term high sound pressure level can affect your

hearing.

uWear suitable hearing protection.

WARNING Lung disease

Dust may be generated when operating the hydraulic at-

tachment. If dust from rocks or silica dust, produced

when operating the hydraulic attachment on rocks, con-

crete, asphalt or other such materials, is inhaled this

may lead to silicosis (dust lungs, a severe lung disease).

Silicosis is a chronic disease which may lead cancer and

death.

uWear a suitable breathing mask.

WARNING Vibration hazards

When working with the drum cutter severe vibrations can

occur and may cause considerable significant injuries

and chronic damage to health.

uOperate the drum cutter with a constant load, in or-

der to minimise existing vibrations.

uAvoid abrupt starting up or stopping of the cutter

drums.

WARNING Risk of death if exhaust gases are not

vented

When working in buildings or tunnels, exhaust gases

from the carrier (diesel motor) can collect and cause poi-

soning or even death.

uEffectively vent exhaust gases from buildings or tun-

nels using a ventilation system.

uKeep the cabin doors of the carrier closed.

WARNING Hot surfaces

The cutter drums of the drum cutter can become very

hot in operation. Skin contact with hot surfaces results in

severe burns to the skin.

uAlways wear heat-resistant protective work clothes

and protective gloves, when working in close proxim-

ity to hot surfaces.

uPrior to all work, check the drum cutter to ensure that

all surfaces have cooled to the ambient temperature.

2.14 Handling machines,

precautions

WARNING Injuries due to incorrect operation

Incorrect operation can result in severe injuries and may

cause considerable damage to property.

uCarry out all operating steps in accordance with

these Safety and operating instructions.

uPrior to starting work, ensure that:

- All covers and safety devices are installed and are

fully functional.

- No persons are in the hazardous area.

uNever switch off any safety devices during opera-

tions or bridge these.

WARNING Injuries due to unclean workplace

A dirty workplace can cause accidents and may result in

severe injuries.

uAlways keep the accesses to the carrier cabin clean.

uAlways keep the cabin windows clean.

uDo not leave parts or objects lying around the work-

ing area.

WARNING Injuries due to missed inspection and

repair work

Disregarding or neglecting daily inspections can result in

serious accidents and lead in turn to the severe injuries

associated with them.

uCarry out all daily inspections before and after work.

uReport any faults or damage to maintenance person-

nel immediately and instruct them to repair them.

uOnly restart the carrier once the fault or damage has

been repaired.

WARNING Narcotics, alcohol and drugs

Narcotics, alcohol and medicinal drugs make their users

less alert and affect their ability to concentrate. Negli-

gence and incorrectly assessing a situation can result in

serious injury or death.

uNever work on or with the hydraulic attachment when

under the influence of narcotics, alcohol or drugs

which affect your alertness.

uNever allow other people who are under the influ-

ence of narcotics, alcohol or drugs which affect their

alertness to work on or with the hydraulic attach-

ment.

Safety and operating instructions

© Anbaufräsen PC GmbH | 3390 5221 01 | 2020-09-07

Original Instructions

15

2.15 Repair, precautions

Maintenance work must be conducted exclusively by au-

thorised and trained maintenance personnel.

2.15.1 Maintenance works not allowed by

the manufacturer

Some maintenance activities must be carried out exclu-

sively by the manufacturer. If such maintenance activi-

ties are required, consult the authorized Customer cen-

ter / Dealer in your area in order to ensure that they pro-

ceed safely.

The following maintenance activities are not allowed by

the manufacturer:

• Repairs to the gear and hydraulic motor

• Replacing wear sleeves and pick boxes

• Welding work on the cutter drums

• Welding work on the gear housing

2.16 Changes to the hydraulic

attachment, precautions

WARNING Changes to the hydraulic attachment

Changes to the hydraulic attachment or the adapter

plate may lead to serious injury.

uNever carry out any changes to the hydraulic attach-

ment or the adapter plate.

uOnly use original parts or accessories approved by

the manufacturer.

uModifications that entail new hazards may require a

new procedure for assessing conformity.

WARNING Injuries due to the use of incorrect

spare parts

The use of incorrect or defective spare parts can result

in risks to personnel as well as damage, malfunctioning

or a total failure of the drum cutter.

uOnly use original parts or accessories approved by

the manufacturer.

uIf there are any questions, consult the authorized

Customer Center / Dealer in your area.

2.17 Environmental pollution,

precautions

NOTICE Environmental pollution due to hydraulic oil

Hydraulic oil is permanently environmentally harmful. Es-

caped hydraulic oil will lead to groundwater and soil con-

tamination. Organisms may die.

uCollect any hydraulic oil which escapes to avoid envi-

ronmental pollution. For minor volumes use an ab-

sorbing medium (in case of an emergency use soil).

In case of major leakages contain the hydraulic oil. It

must not drain off and penetrate the ground or enter

the water table or water supplies.

uCollect contaminated absorbing medium or soil in a

watertight box/container and close it tight.

uContact an authorized waste management company.

uDispose of all contaminated material in accordance

with the applicable environmental regulations.

Safety and operating instructions

16 © Anbaufräsen PC GmbH | 3390 5221 01 | 2020-09-07

Original Instructions

3 Overview

3.1 Equipment description

The illustration gives an overview of the main parts and

components of the hydraulic attachment. Actual details

may differ.

A. Intermediate bracket

B. Drive shaft with hydraulic motor

C. Round attack pick

D. Pick box

E. Cutter drum

F. Oil filler/drain screw

G. Transport lug

3.2 Function

The operation of a drum cutter is described in a simpli-

fied version below:

The drum cutter is an attachment for hydraulic carriers.

The cutter drum is powered by the hydraulic motor of the

drum cutter. The round attack picks are attached to the

cutter drum at a defined angle. A rotating motion of the

cutter drum facilitates the cutting process and thus re-

duces the size of the rock.

The longitudinal drum cutter can be reconfigured as a

drive for a drilling auger. This drilling auger is an optional

accessory part and is not contained within the scope of

deliverables.

Safety and operating instructions

© Anbaufräsen PC GmbH | 3390 5221 01 | 2020-09-07

Original Instructions

17

3.3 Modules

Cutter drum

The longitudinal drum cutter is equipped with a cutter

drum driven by the drive shaft.

ER 100 L - ER 2000 L:

The cutter drum is fastened directly to the drive shaft

with screws and special clamping sleeves.

ERL 700, ERL 1100:

The cutter drum is attached via a hexagonal connection

to the output shaft and fixed with locking screws(H).

A certain number of pick boxes are attached to the sur-

face of the cutter drum. These hold the round attack

picks in position.

Transport lug

The transport lug(G) serves as an anchor point for the

lifting gear when transporting the drum cutter.

The transport lug is an eyebolt and can be unscrewed

after transportation. After removal of the transport lug the

thread must be protected from dirt and damage by a

blank plug.

Drive, hydraulic motor, intermediate bracket

The drum cutter is fastened to a suitable adapter plate

on the carrier boom via the intermediate bracket(A). The

intermediate bracket is bolted to the adapter plate.

The drive(B) carries the cutter drum. The hydraulic mo-

tor transfers the drive moment through the drive shaft to

the cutter drum.

Oil drain/filling plug

Actual details may differ.

The screw/screws is/are used for draining, filling and

venting the drive while changing gear oil.

Safety and operating instructions

18 © Anbaufräsen PC GmbH | 3390 5221 01 | 2020-09-07

Original Instructions

Round attack picks

The round attack picks are made of steel and have a

brazed tungsten carbide tip. The round attack picks are

held in the pick boxes.

The appearance of the round attack picks may deviate

from the image shown here.

Pick boxes

The pick boxes are welded onto the cutter drums for

holding round attack picks. Some pick boxes may have a

wear sleeve, which can be exchanged.

Drilling auger

C

A

D

B

The drilling auger(C) can be mounted on the longitudi-

nal drum cutter as an accessory part. To do so the cutter

drum must be disassembled and the drilling auger

mounted onto the drive shaft via appropriate auger

adapter(B) . In addition, a pivot adapter(A) is mounted

between the carrier stick and the intermediate bracket.

The complete drilling auger has a drilling head(D) to

loosen the material and the auger removes the soil from

the bore hole.

Pivot adapter

The pivot adapter is an accessory part. The swivel

adapter must always be mounted when using the op-

tional drilling auger. This swivel adapter enables the

drilling auger to be aligned vertically and relieves the drill

drive of inadmissible bending forces.

Safety and operating instructions

© Anbaufräsen PC GmbH | 3390 5221 01 | 2020-09-07

Original Instructions

19

3.4 Signs / labels

WARNING Missing warnings

The name plate and the labels on the hydraulic attach-

ment contain important information about the hydraulic

attachment and for personal safety. A missing warning

can lead to overlooking or misinterpretation of possible

risks and cause personal hazards. The signs and labels

must always be clearly legible.

uImmediately replace any defective name plates and

labels.

uUse the spare parts list to order new name plates

and labels.

3.4.1 Signs

The warning symbol and the

book symbol indicate that the

Safety and Operating Instruc-

tions must be read prior to use of

the hydraulic attachment and in

particular the chapter on Safety.

3.4.2 Name plate

A. Model

B. Year of construction of hydraulic attachment

C. Max. hydraulic pressure

D. Weight of hydraulic attachment

E. Serial number

F. Name and address of manufacturer

G. The warning symbol and the book symbol indicate

that the Safety and Operating Instructions must be

read prior to use of the hydraulic tool and in particu-

lar the chapter on Safety.

H. The CE symbol indicates that the hydraulic attach-

ment was produced in conformity with CE. You can

find further information about this in the enclosed EC

Declaration of Conformity.

Safety and operating instructions

20 © Anbaufräsen PC GmbH | 3390 5221 01 | 2020-09-07

Original Instructions

3.4.3 Labels

A

A. Danger zone

Danger zone

No persons should be within

the danger zone. Fragments of

material which come loose

while operating the hydraulic at-

tachment may be flung away

and can cause serious injury if

people are hit by them. Small

objects falling from a great

height can also cause serious

damage.

3.5 Applications

The drum cutter is suitable for use in trenching and tun-

nelling, for demolition and renovation works, quarrying

and in special underground engineering.

3.6 Working area and hazardous

area

A. Working area for operating personnel

B. Hazardous area when working with the drum cutter

• The working area for the operating personnel is in

the cabin of the carrier.

• The hazardous area is in the direct vicinity of the

drum cutter.

• Whilst operating the drum cutter, the minimum dis-

tance around the carrier is 15m (50ft).

• When cutting reinforced concrete, the minimum dis-

tance around the carrier is 50m (165ft).

3.7 Removing the packaging

nRemove all the packaging material.

nDispose of it in accordance with the applicable provi-

sions.

nCheck that the delivery is complete.

nCheck the delivery for visual damage.

nIf any defects are found, consult the Epiroc Customer

Center / dealer in your area.

3.8 Scope of delivery

The drum cutter is delivered complete with:

• Drum cutter including rotatable upper part

• Safety and operating instructions

• Spare parts list

• EC Declaration of Conformity

• Hoses:

- Pressure line

- Tank line including precharge valve

- Leakage oil line

• Overpressure cover plate including O-ring and

screws

• Set of standard round attack picks including retain-

ers (see table below)

• Set of tools for round attack pick assembly and dis-

assembly (see table below)

This manual suits for next models

9

Table of contents

Other Epiroc Cutter manuals

Popular Cutter manuals by other brands

Univex

Univex BC18 Operator's manual

Mr Beam

Mr Beam II dreamcut ready quick start guide

WOLFF

WOLFF FRASMASTER 230 V Translation of the original instruction

ICS

ICS SpeedHook 814PRO Operator's manual

Textron

Textron Greenlee Gator ES20L Operation manual

Gastrodomus

Gastrodomus TA25K Installation, use and maintenance