7

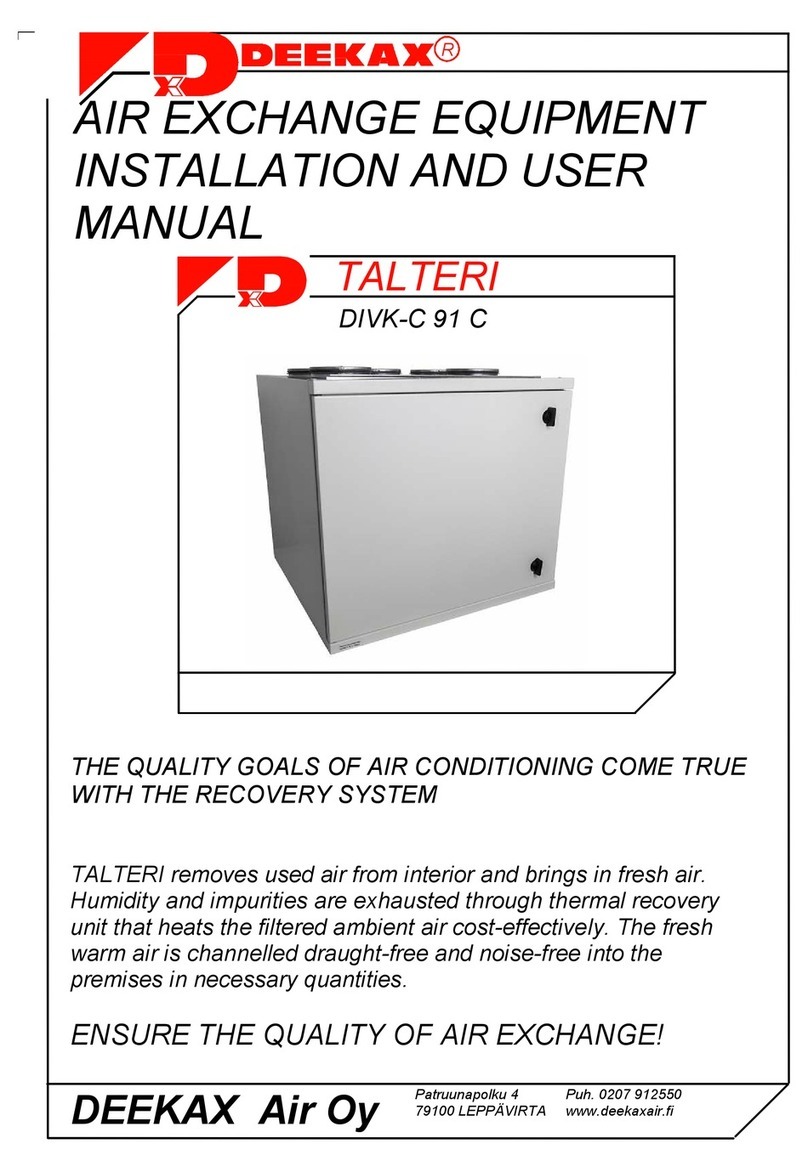

INTRODUCTION OF THE AIR EXCHANGE SYSTEM

BEFORE OPERATING YOUR AIR EXCHANGE SYSTEM,

MAKE SURE THAT:

- There are no loose objects within the unit or the air impeller;

- The coverings of construction-time are removed from

the outlet- and exhaust air holes;

- All isolations and steam barriers are in order;

- The heat transfer and fans are in their places;

- The condensing water outlet is installed and the water

is drained out;

- The air impellers and their adjusters are in working order;

- Afterheating is regulated and working.

USAGE DURING INSTALLING

The air exchange unit should be started as soon as

installation permits.

Efficient air exchange promotes drying of the constructions

and prevents damage.

In case channelling has not been completed, fans and adjustments

are missing,filter paper must be used in place of fans to keep

the channels clean andprovide sufficient counterpressure for

preventing overload. The unit must be used with full power and

check the drainage of the condensing water.

The appliance, filters and heat exchangers must be cleaned

and the systemadjusted after the construction works are

completed.

BASIC ADJUSTMENT OF AIRFLOW

The unit alone can not produce good interior ear in case

the channels and fans are installed carelessly and main

adjustments are not made.

Regulate the inlet and outlet fans to the planned positions

and start the unit

at design power speed. Measure the airflow in outside- and

exhaust air channels.

The outlet must be 5-10% higher than inlet. Check the

pressure level of thechannels by checking from the fans and

adjust it accordingly to obtain the pressure levels

for vents; adjust and lock the pattern.Draw measuring- and

adjustment records!

USAGE AND CORRECT LEVEL OF AIR EXCHANGE

The air exchange level is regulated by changing the

working speed of the air impeller from the operating panel.

Airflow of different adjustable positions can be seen

from table 2.

Adjustable position 1 is for basic air exchange for an empty house.

Adjustable position 2 and 3 are normal working positions.

Adjustable position 4 and 5 are efficiency positions (i.e. for saunas).

The correct usage positions will be found by experience;

observing the purity of the air or sultriness when coming in

from outside, observing moisture on the windows or drying

of the sauna.

AFTERHEATING AND SUMMER BYPASS OF INLET AIR

The unit is equipped with 500 W electrical battery operated

by the means of triac-adjuster operated by the operating device

for afterheating the heat recovered inlet air.

The temperature of inlet air is usually regulated to +17C.

The temperature may be adjusted to higher during winter so there

would be no draught like feeling. In case of severe frost and

efficiency mode the heating power might turn out insufficient –

in such circumstances, the air exchange should be reduced.

The overheating protection launched during malfunctioning

must be annulled manually.

During summertime, the bypass plate will be opened so the extract air will

not warm up the inlet air.

CONDENSING WATER AND FREEZING PREVENTION

Exhaust air heat exchanger cools the moisture exchanger condenses

into water, Which flows the condensation water in the pool and from

there through a hose through a water trap open sewer.

In freezing temperatures the water to Prevent freezing of the exchanger

-acting blocking That first frost the preheater is switched on

and the temperature rises over the set value switched off.

If the preheater resistor power It is not enough, and the exhaust air

temperature drops less than a "waste of cold air" limit-value power

supply fan stepwise dropped until the threshold is reached.

SERVICE MENU

INTRODUCTION OF THE AHU CONTROL PANEL

Settings are applied via the service menu

SETTINGS

NOTE! SWIPE RIGHT AT THE TOP OF THE SCREEN

Touch screen buttons:

Boosting

Fireplace switch

(pressure compensation)

Out-of-house mode

Fan speed adjustment 1....5

The button can be used to browse

the menu upwards and change settings.

The button can be used to browse

the menu downwards and change setting value.

Return to the previous or main menu.

THE SUMMER BYPASS OF THE HEAT RECOVERY UNIT MUST BE IN THE WINTER POSITION WHEN THE

AIRFLOWS ARE BEING ADJUSTED.