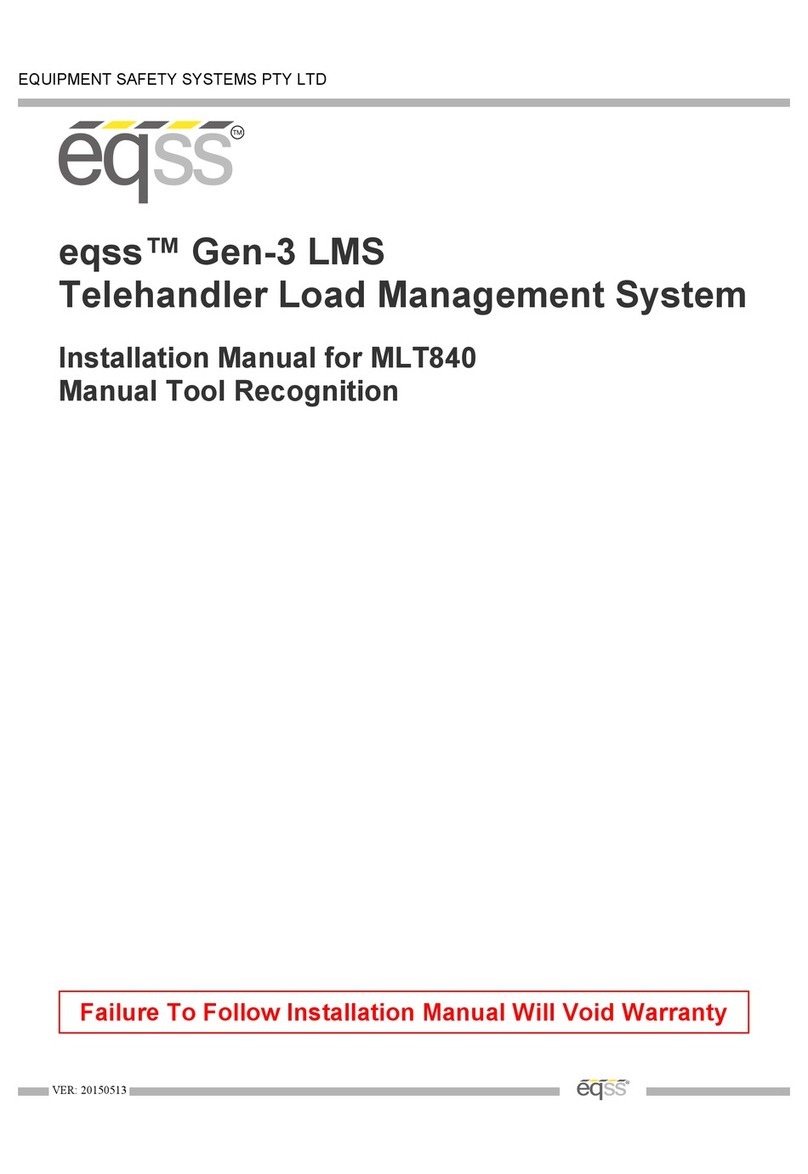

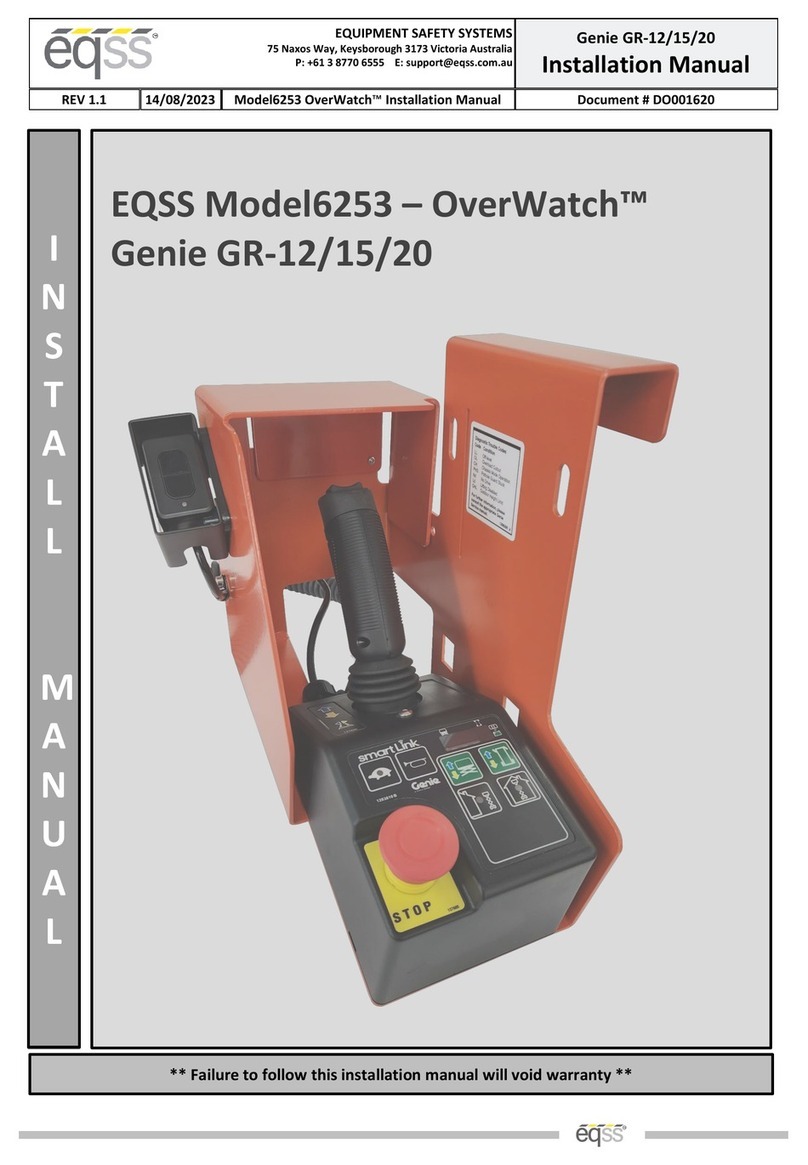

eqss OverWatch Dingli ACE Series User manual

This manual suits for next models

1

Table of contents

Other eqss Control System manuals

eqss

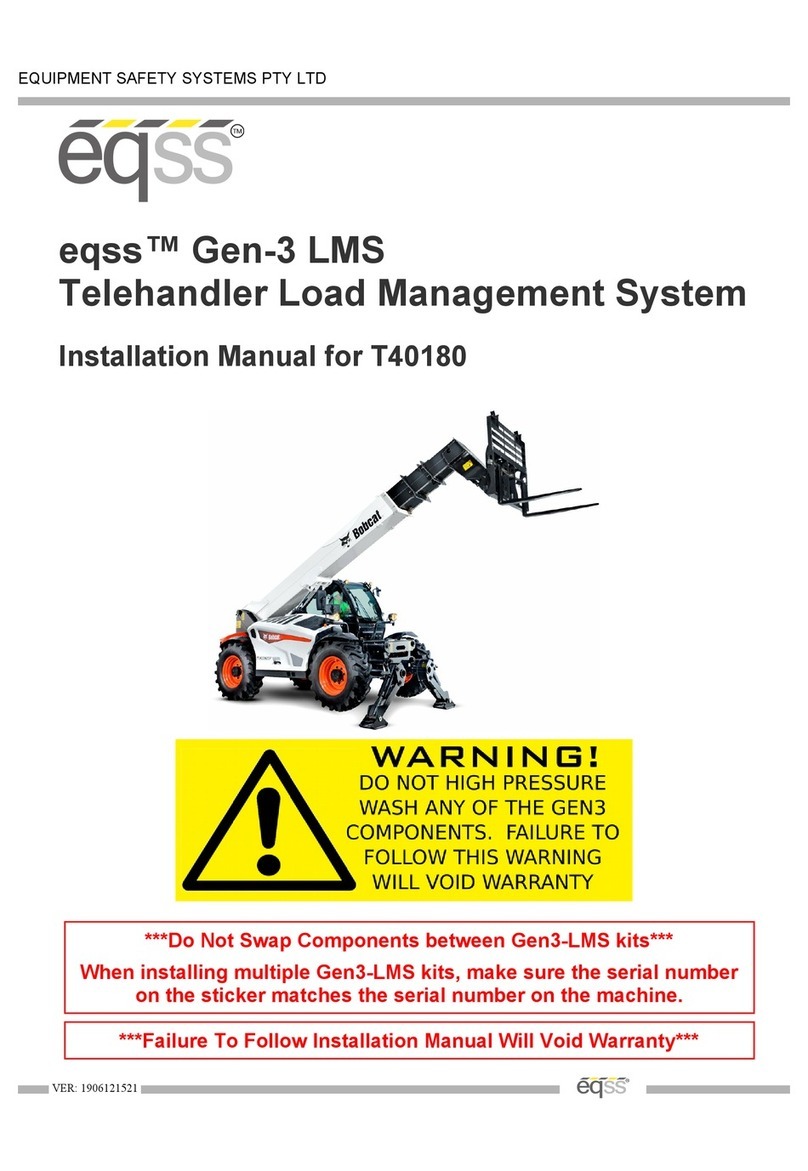

eqss Gen-3 LMS User manual

eqss

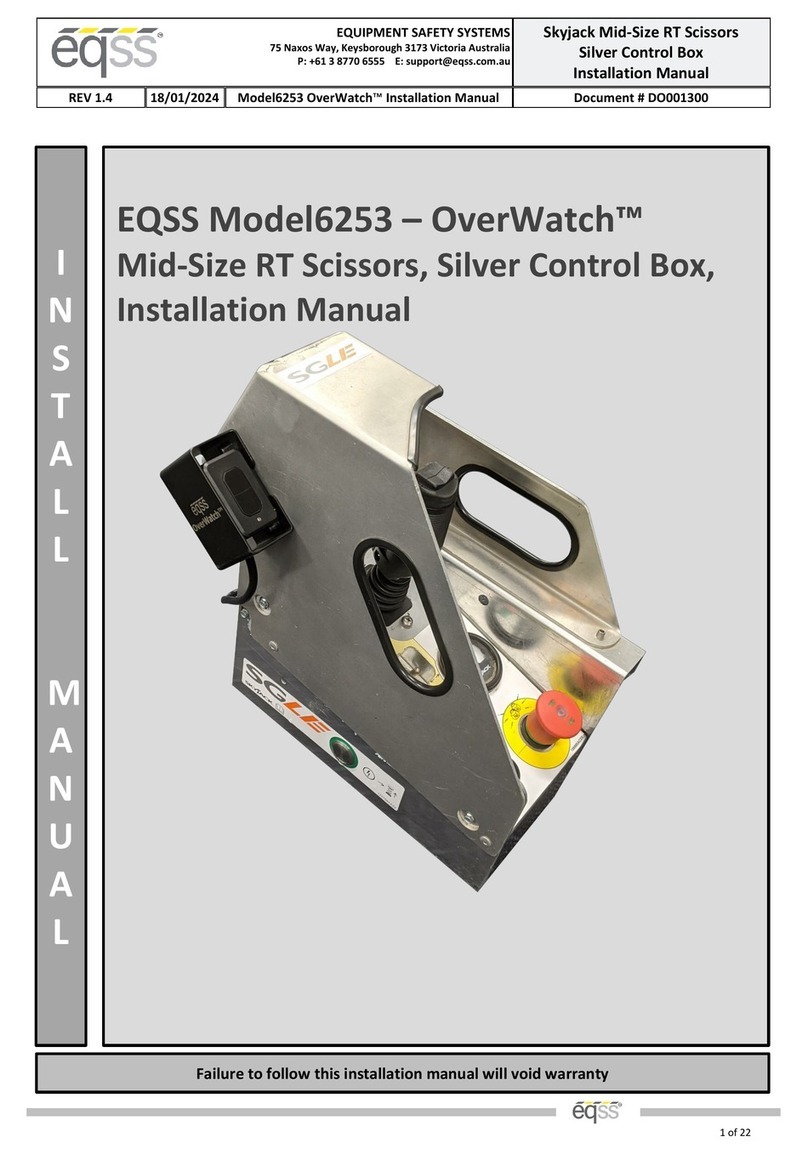

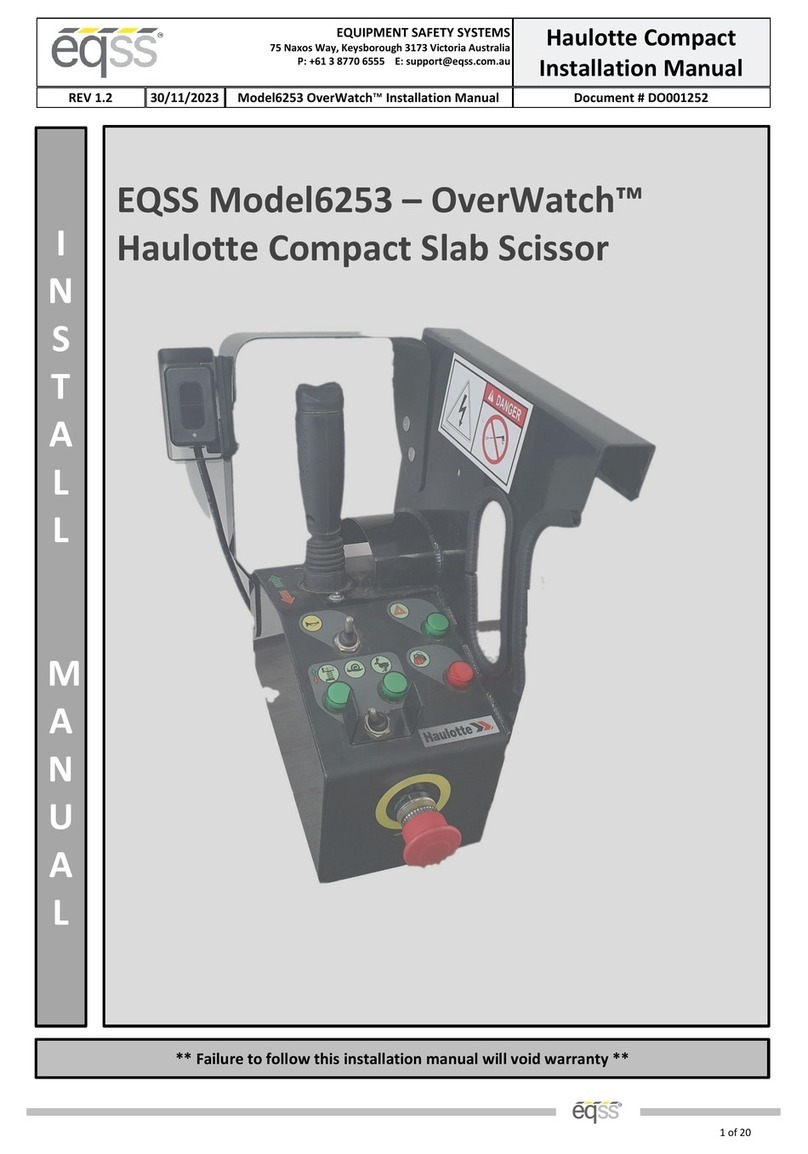

eqss OverWatch 6253 User manual

eqss

eqss OverWatch 6253 User manual

eqss

eqss OverWatch 6253 User manual

eqss

eqss Gen-3 LMS User manual

eqss

eqss OverWatch 6253 User manual

eqss

eqss OverWatch 6253 User manual

eqss

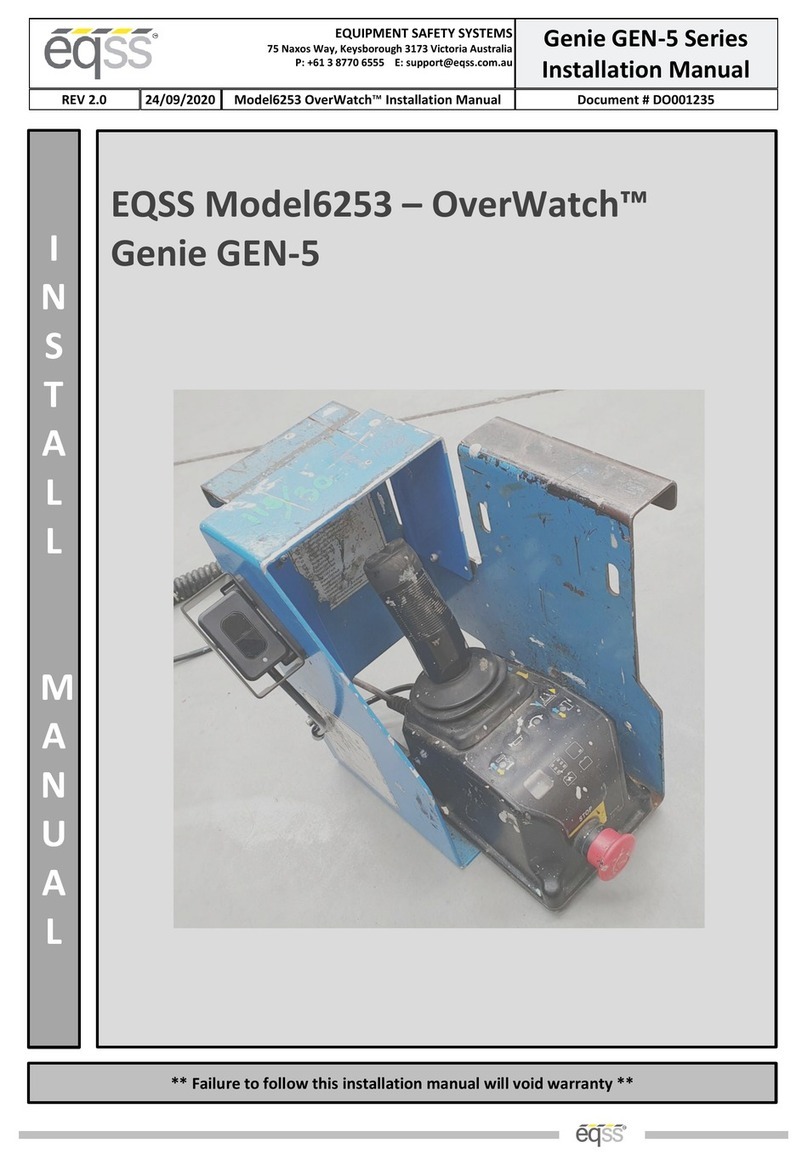

eqss Genie GEN-5 Series User manual

eqss

eqss OverWatch Dingli S03-ACE Series User manual

eqss

eqss OverWatch Skyjack SJ12 User manual

eqss

eqss Gen-3 LMS User manual

eqss

eqss Gen-3 LMS User manual

eqss

eqss Overwatch JLG ES Series User manual

eqss

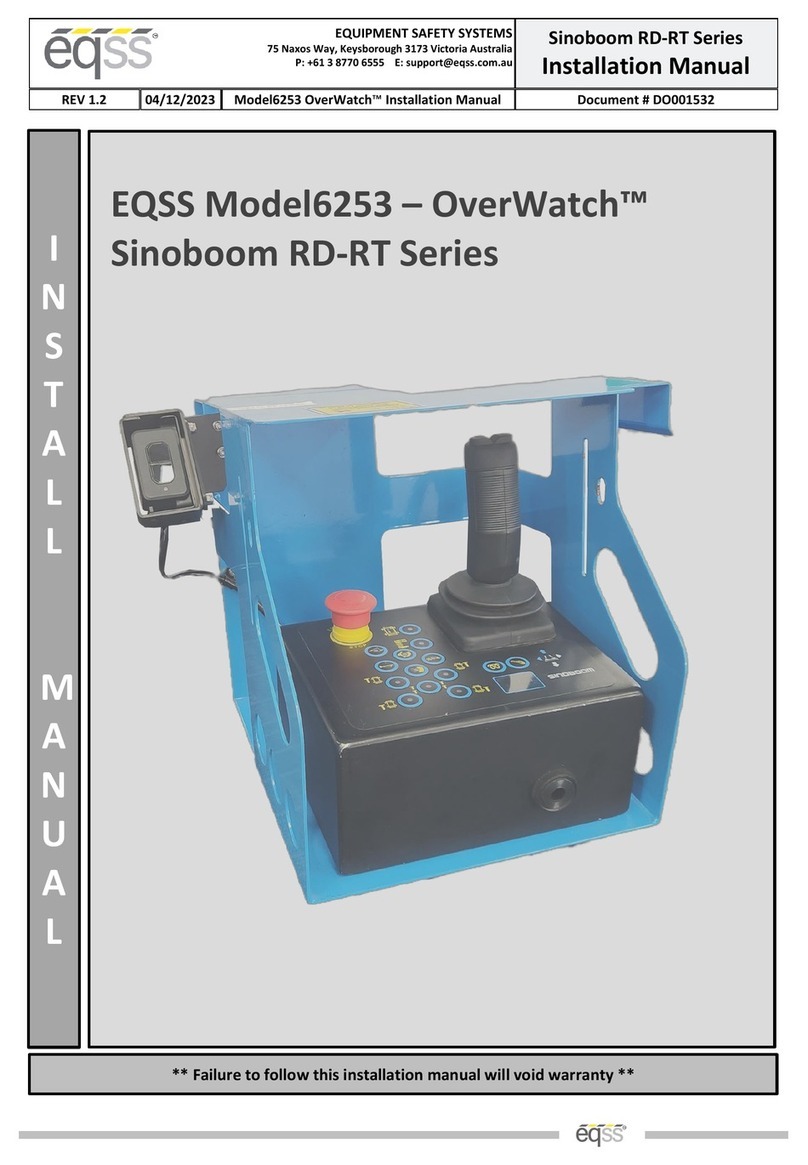

eqss OverWatch Sinoboom RD-RT Series User manual

eqss

eqss OverWatch 6253 User manual

eqss

eqss Gen-3 LMS User manual

eqss

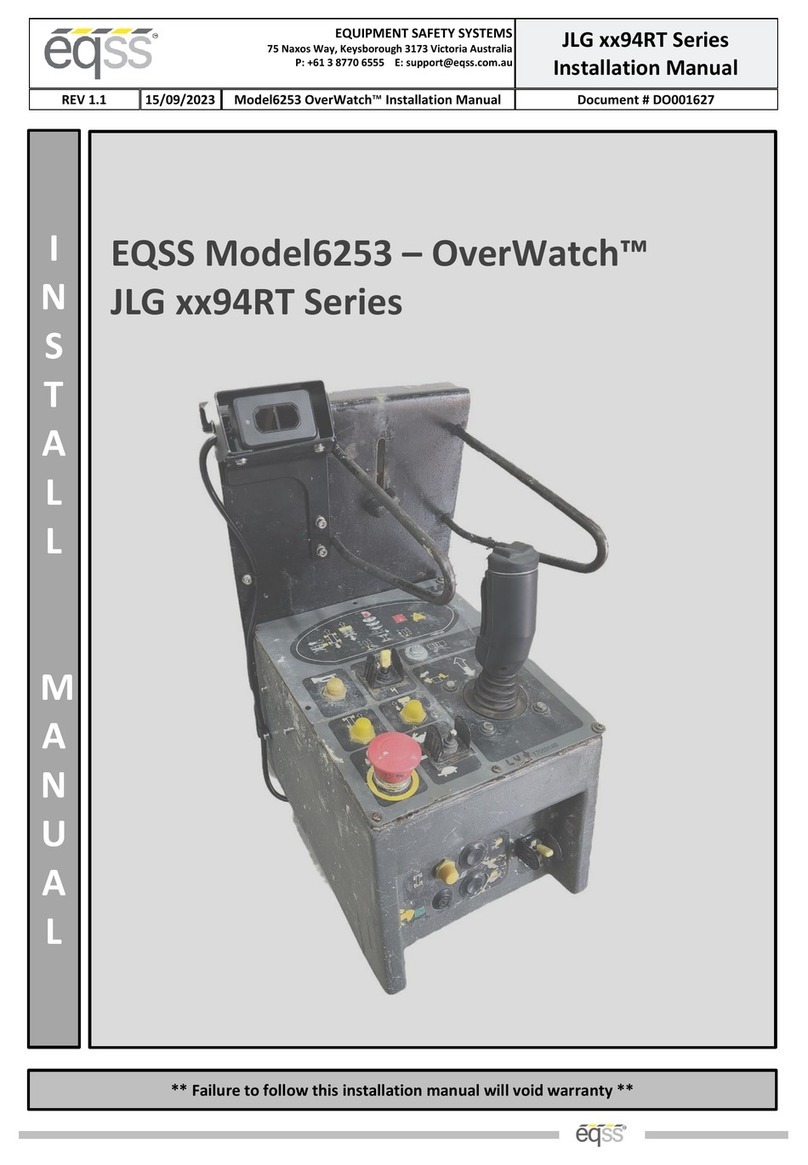

eqss OverWatch JLG 94RT Series Manual

eqss

eqss OverWatch Genie GR-12 User manual

Popular Control System manuals by other brands

ITW

ITW SIMCO ION IQ Power HLC Installation and operating instructions

Dormakaba

Dormakaba SVP-S 4 DCW Series Mounting instructions

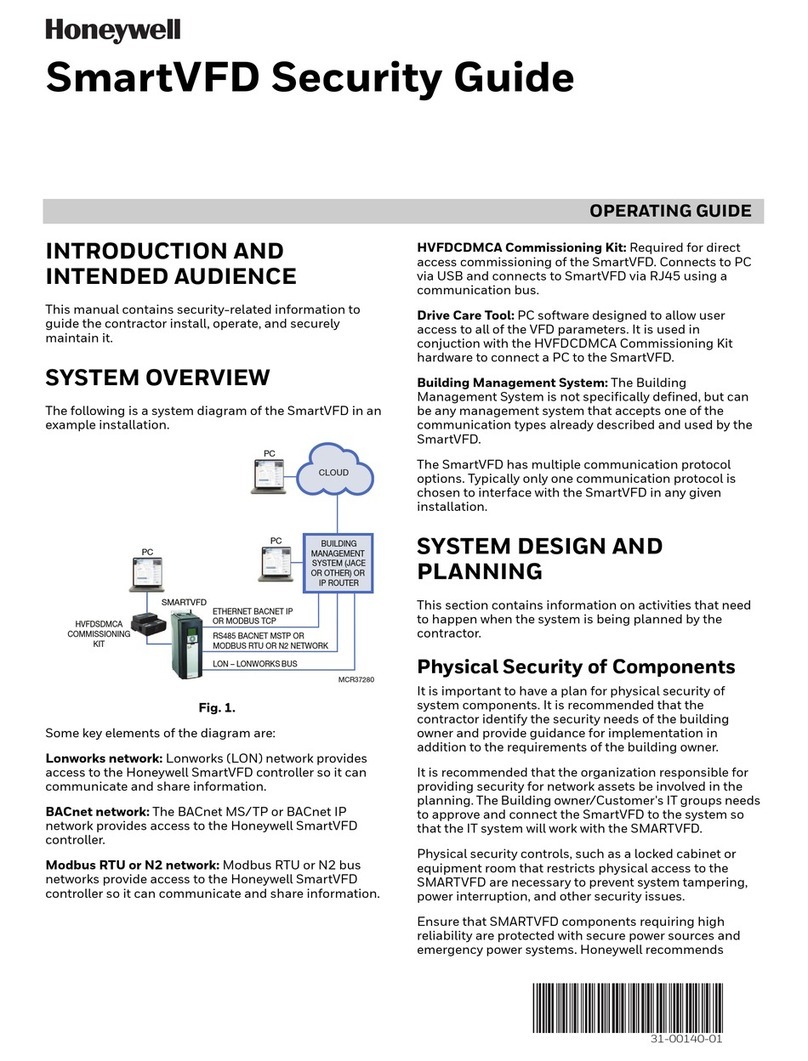

Honeywell

Honeywell SmartVFD operating guide

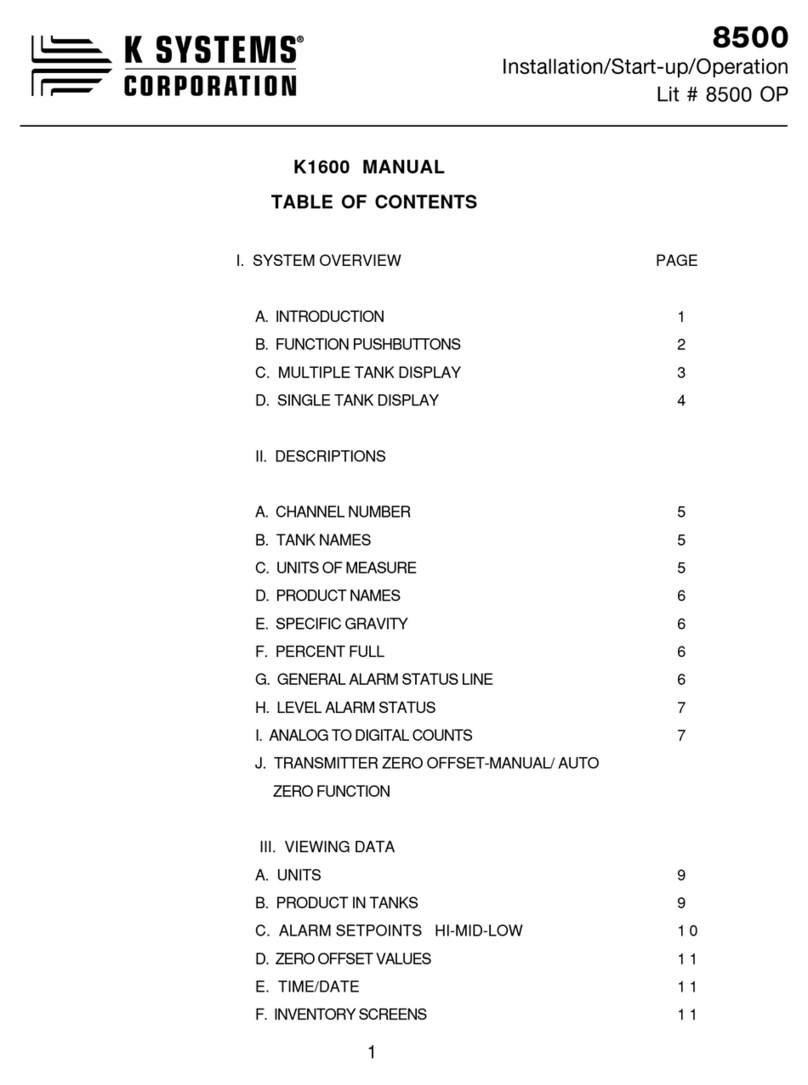

K-Systems

K-Systems K1600 Installation, start-up, operation

Aimco

Aimco AM-45 instruction manual

Worthington

Worthington CS200 Operation & maintenance instructions