Table of Contents

Tools Required for Installation.....................................................................................6

Installation Index...........................................................................................................7

overs.........................................................................................................................11

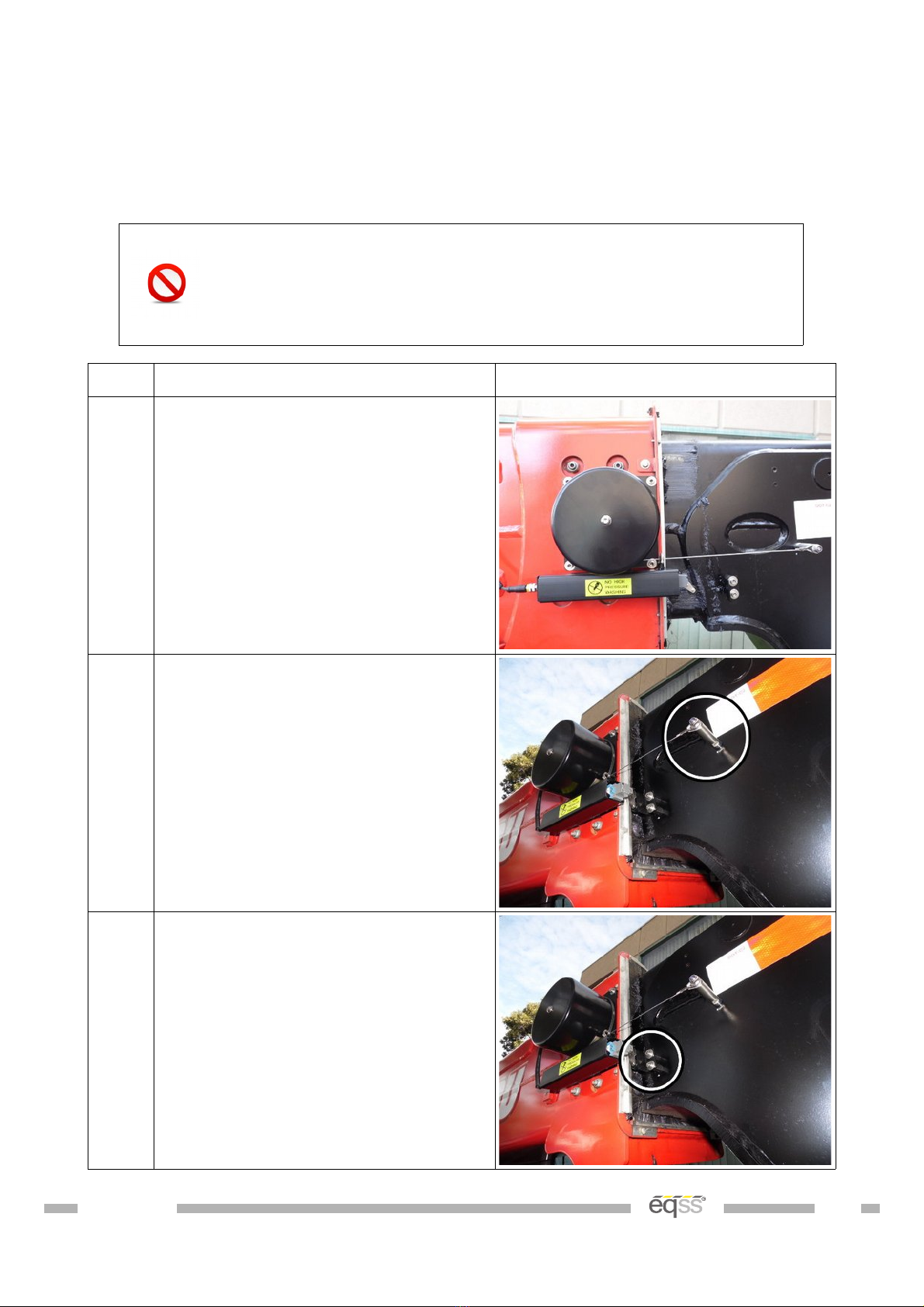

able Reeler Installation.............................................................................................13

able Reeler Mounting Position.............................................................................15

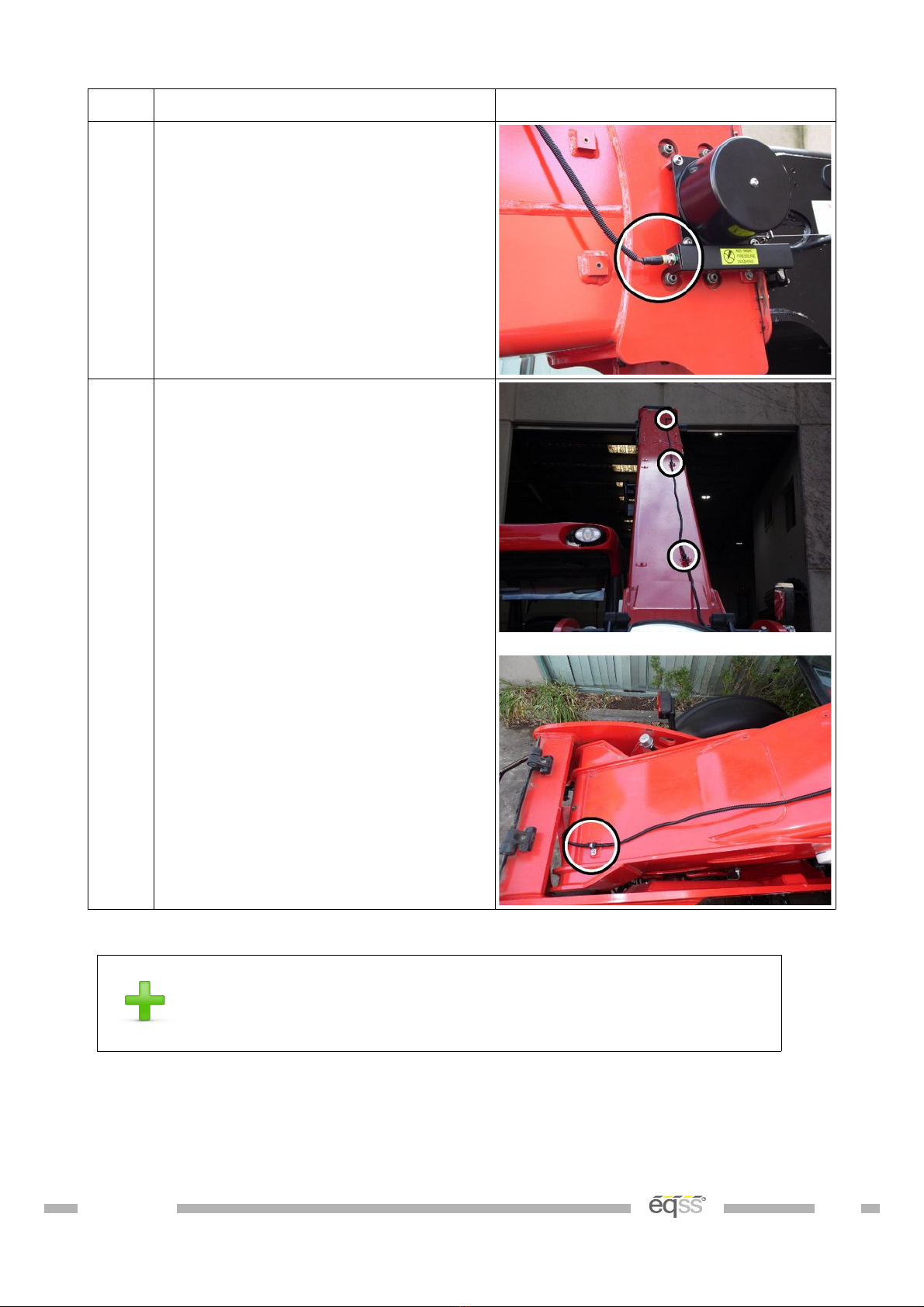

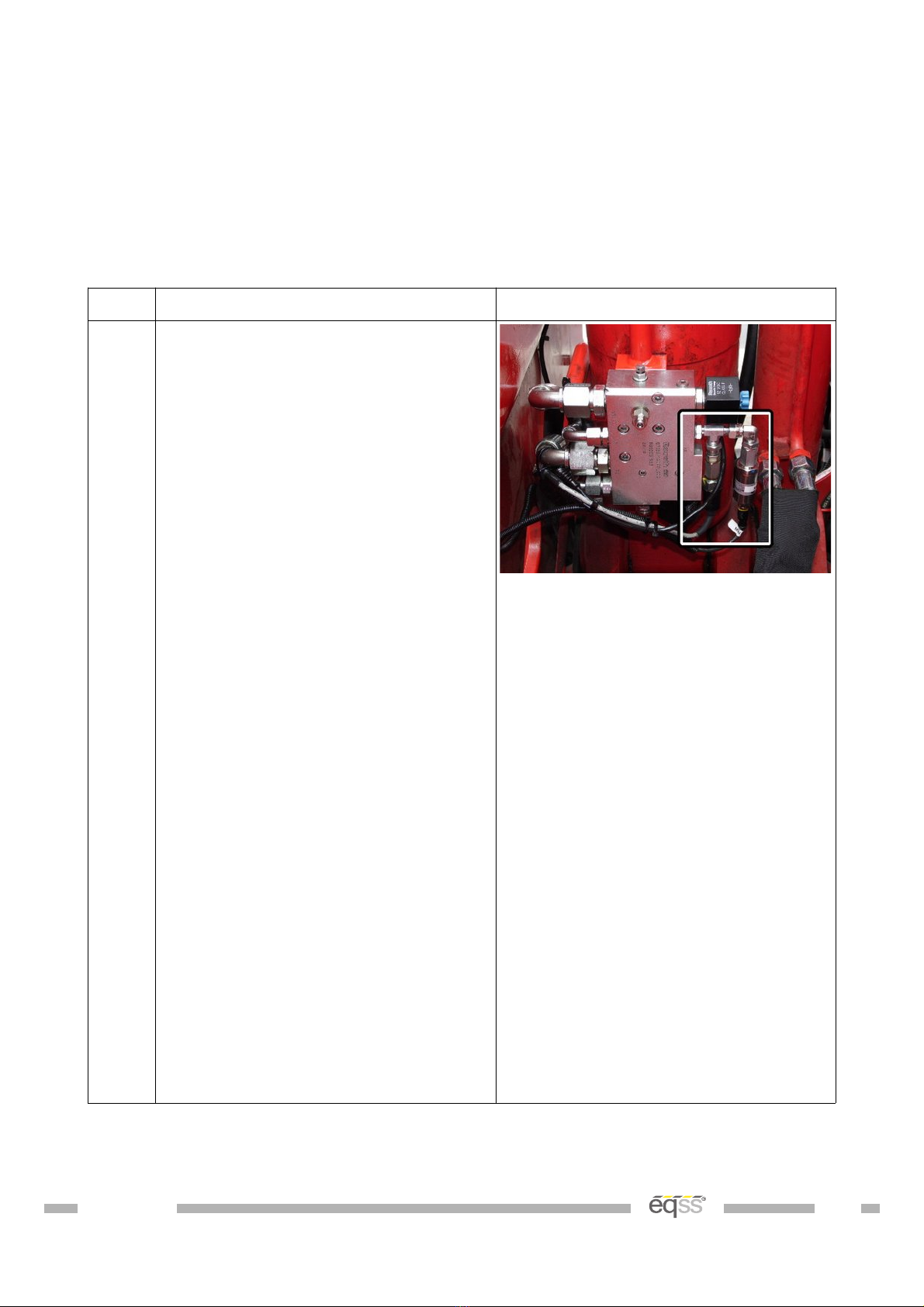

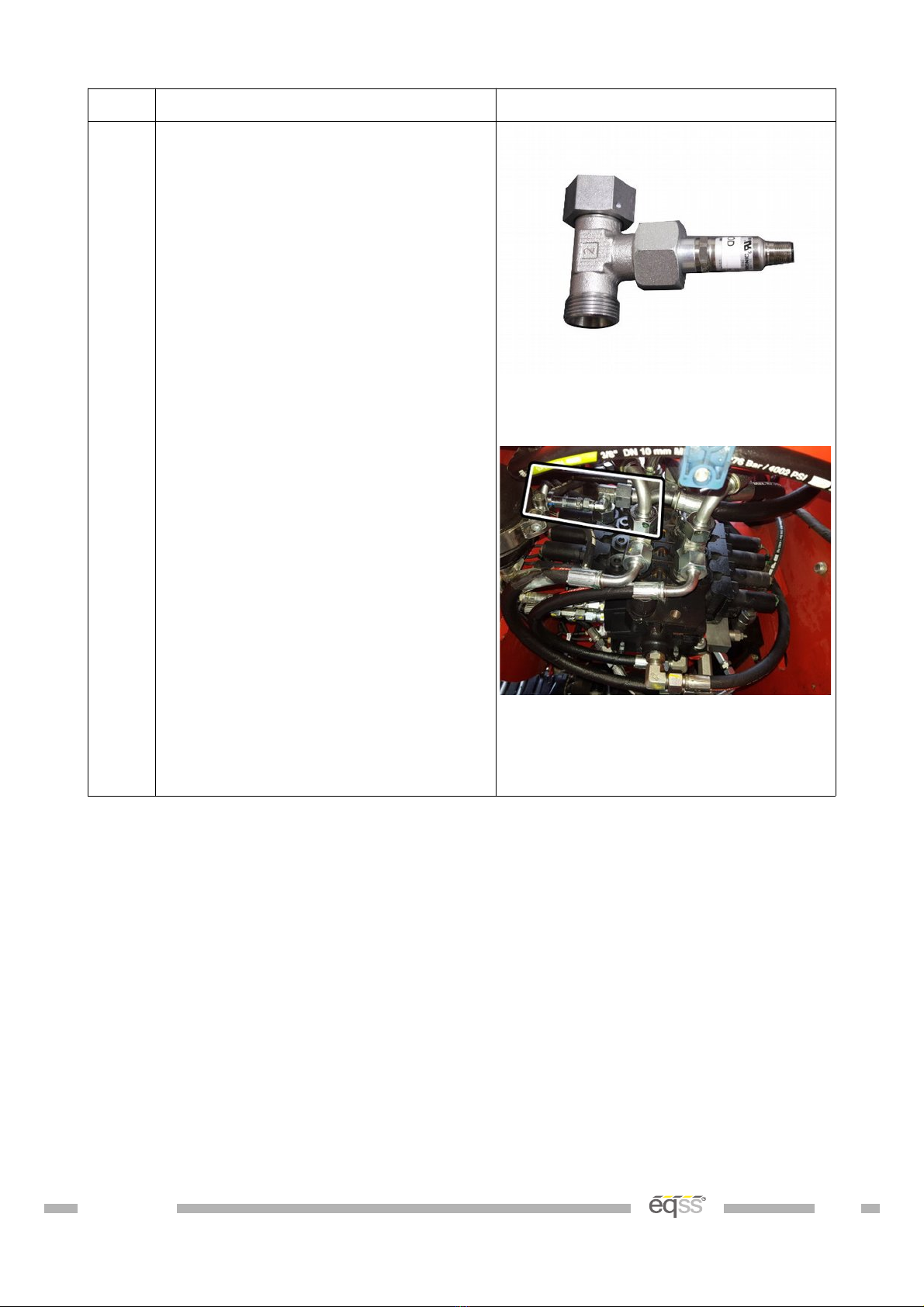

Pressure Sensor Installation.......................................................................................16

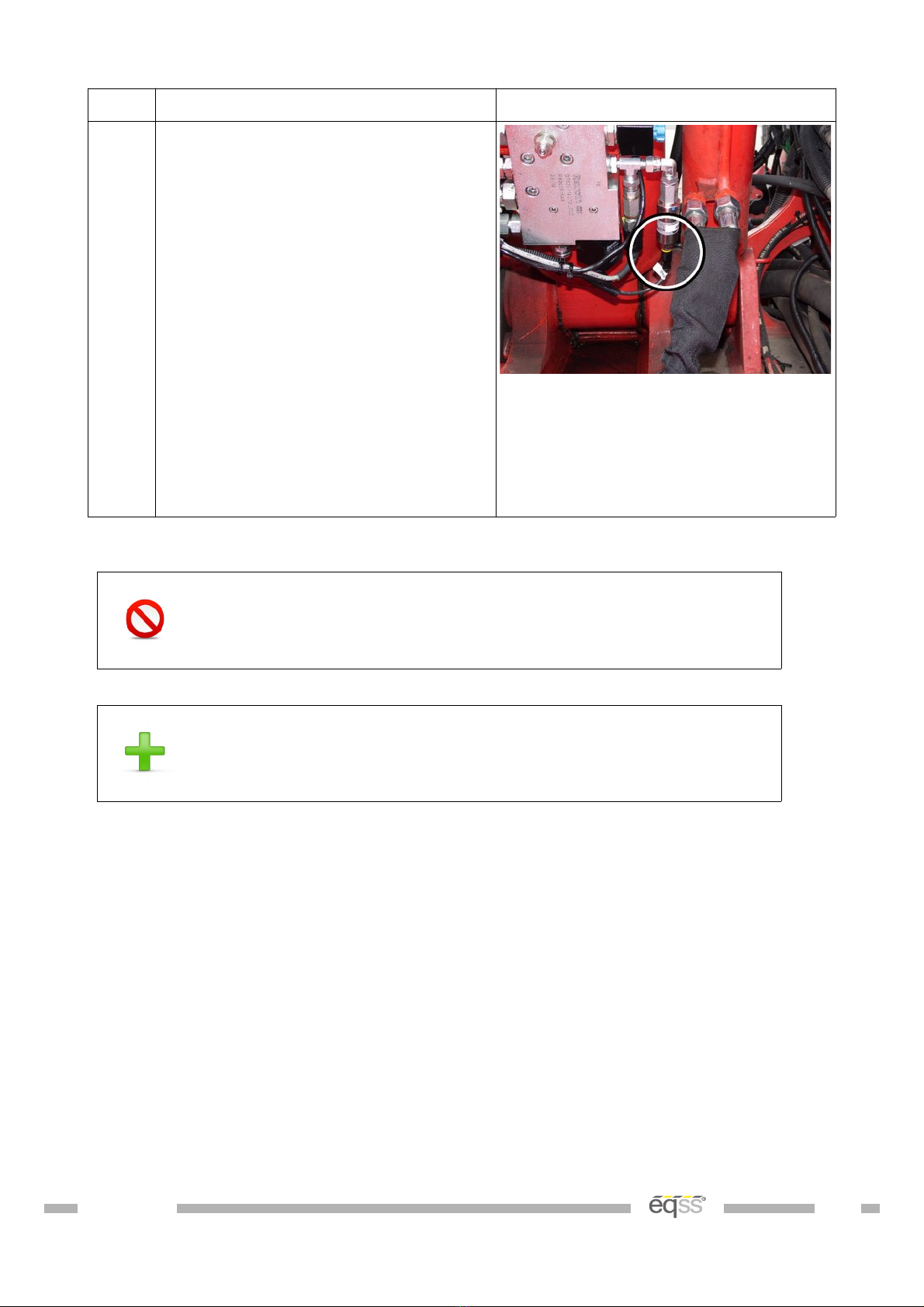

Main Lift ylinder...................................................................................................16

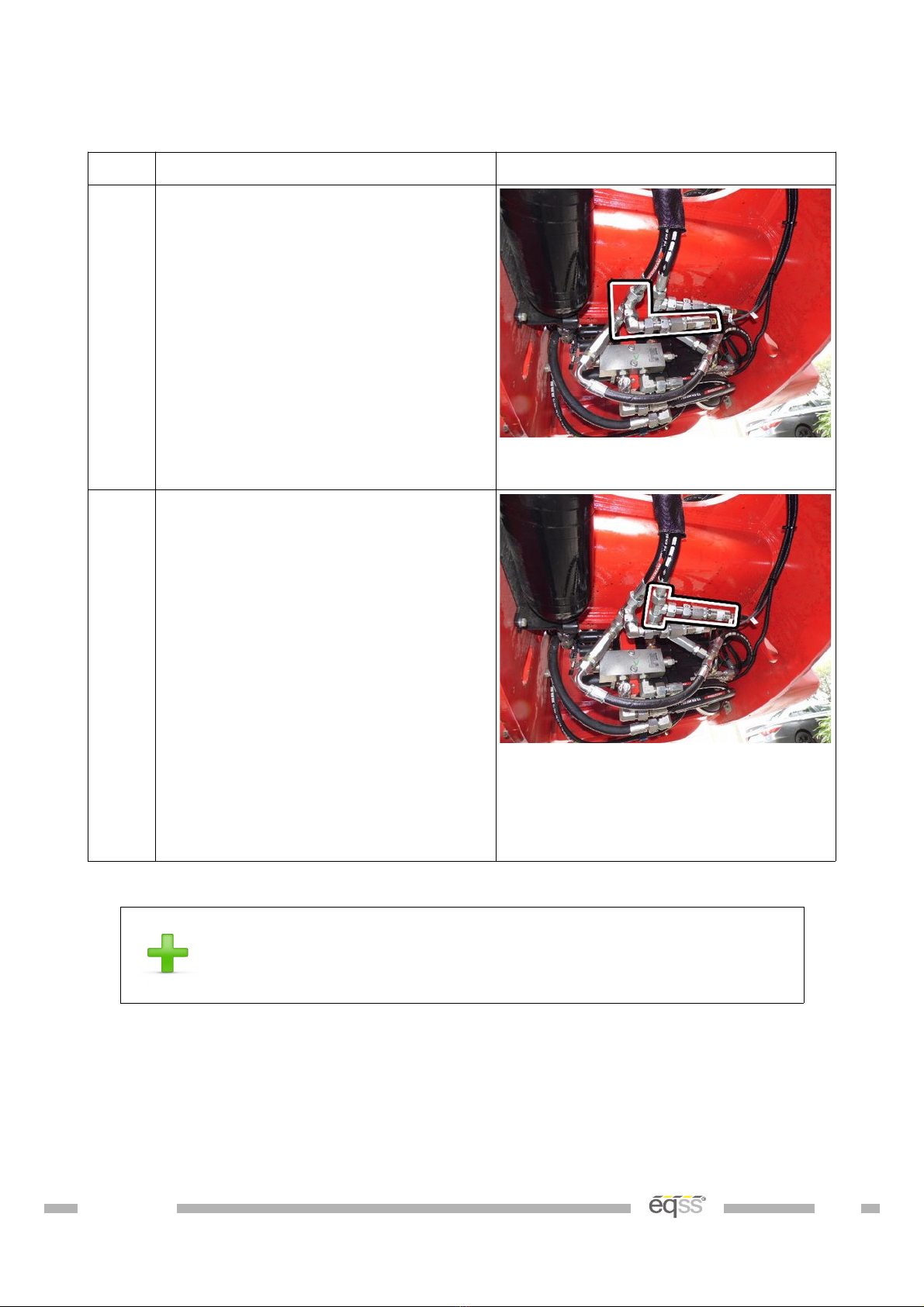

ompensation Pressure Sensors............................................................................19

Reverse amera..........................................................................................................20

utout able Harness.................................................................................................22

Forward amera..........................................................................................................25

Signal Light Installation..............................................................................................27

an Pressure Input Module ( PIM)............................................................................29

External able ompletion.........................................................................................30

Display Installation......................................................................................................32

User ontrol................................................................................................................33

an abin Interface Module ( IM)...........................................................................34

Machine Input Harness...............................................................................................35

Override Wiring...........................................................................................................36

abin Loom..................................................................................................................37

Finalisation..................................................................................................................40

Set Time & Sensor alibration...................................................................................44

Appendix A: Attaching Display onnectors...............................................................47

VER: 1805241756 4 of 53