ERA ERIS GC.2 User manual

www.eraendustriyel.com.tr 1info@eraendustriyel.com.tr

ERA - ERİS®

Controller for Gas Burners GC.2

ERA ENDÜSTRİYEL RÖLE İMALAT

SANAYİ VE TİCARET LTD.ŞTİ.

Koşuyolu Mahallesi Asmadalı Sk.

No: 15

Koşuyolu 34718 Kadıköy – İstanbul / TÜRKİYE

Tel : 0216 340 80 85

Fax : 0216 340 80 57

www.eraendustriyel.com.tr

info@eraendustriyel.com.tr

GB

www.eraendustriyel.com.tr 2info@eraendustriyel.com.tr

ERA - ERİS®

INDEX

1. INTRODUCTION

1.1 DECLARATIONS AND CONSIDERATIONS 4

1.2 WARRANTY 5

1.3 ABOUT THIS MANUAL 6

1.4 SIGNS AND SYMBOLS 6

2. CONTENTS

2.1 CONTENTS OF THE MANUAL 7

2.2 GENERAL WARNINGS 7

3. INTRODUCTORY BASIC INFORMATION

3.1 INTENDED USE AND PRONCIPLES OF OPERATION 8

3.2 ERİS-GC.2 Intended use 8

3.3 SPECIFICATIONS 8

3.4 PARTS OF ERİS – GC.2 CONTROLLER 9

3.5 ERİS – GC.2 Standard circuit diagram 9

3.6 CIRCUIT DIAGRAM EXPLANATIONS 10

4. PROGRAM SELECTION EXAMPLES

4.1 PROGRAM SELECTION EXAMPLE FOR BURNERS WITH AND WITHOUT BLOWERS 11

5. ERİS – GC.2 INSTALLATION AND USE

5.1 INSTALLATION OF PARTS AND ACCESSORIES 12

5.2 TECHNICAL DATA 13

5.3 CONNECTION EXAMPLES 14

5.4 ERİS – GC.2 CONNECTION INPUT OUTPUT NUMBERS 15

5.5 CABLE CONNECTIONS 15

5.6 CONNECTION EXAMPLES FOR IGNITION TRANSFORMER 16

5.7 ULTRAVIOLET FLAME DETECTOR CONNECTION EXAMPLE 16

GB

www.eraendustriyel.com.tr 3info@eraendustriyel.com.tr

6. PRERUN CHECK

6.1 FLAMELESS TRIAL RUN (AFTER INSTALLATION IS COMPLETED) 17

6.2 CONTROLLED PRE-TEST ATTEMPT (WITH THE GAS VALVE SHUT OFF) 17

6.3 FAILURE CODES FOR THE FIRST TEST 18

7. PROGRAM SEQUENCES

7.1 PROGRAM SEQUENCE AND DURATIONS FOR BURNERS WITHOUT BLOWERS 19

7.2 PROGRAM SEQUENCE AND DURATIONS FOR BURNERS WITH BLOWERS 20

8. FLAWLESS RUNNING

8.1 BURNER START 21

8.2 DISPLAY STATUS AND SYMBOLS 21

9. MESSAGE CODES

9.1 COMMON MESSAGE CODES 22

9.2 FAILURE MESSAGES AND EXPLANATIONS 23

10. ERİS-GC.2 FLAME MONITORING

10.1 FLAME MONITORING BY IONIZATION ELECTRODE 24

10.2 QUICK INFORMATION ABOUT IONIZATION ELECTRODE 24

11. ERİS-GC.2 DIMENSIONS 25

GB

www.eraendustriyel.com.tr 4info@eraendustriyel.com.tr

1.1 INTRODUCTION

Copyright :

Target :

audience

The manual thereof has been prepared for an audience of engineers and

technicians who would work on this product and install this product. Such

persons are required to have prior experience with this sort of equipment.

ERİS Burner Controllers’ production and brand rights are owned by ERA

LTD.ŞTİ since 2015. All rights reserved throughout Turkey. The publication

thereof cannot be copied, distributed, adapted or translated into a machine

or human language without prior written consent from ERA LTD ŞTİ.

Disclaimer :

notice

GC.2xxx burner controllers which are registered under “ERA-ERİS” brand, as

per the continuous improvement policy of ERA Ltd.Şti. have been designed in

light of the state of the art technological advancements. Without any

obligation of prior notice, the specifications of the product therein can be

subject to change, within the limits permitted by international standards!

Guidelines of use presented in this manual have been arranged to comply

with corresponding international standards. If such are to be used outside its

mentioned context, a validity and conformance approval must be acquired

first.

ERA LTD.ŞTİ. guarantees that ERİS GC.2 xxx burner control relays under the

brand ERA-ERİS do not violate any patent rights of any other product within

Turkey.

Due diligence and attention have been given in preparation of the manual

thereof. However, if you happen to discover any neglected points or errors

please inform us so that we can correct. We are expecting to keep updating

our documentation this way, in order to present to our clients. Please send

your correction inquiries to info@eraendustriyel.com.tr

ADVICE

!

1.1 DECLARATIONS AND CONSIDERATIONS

GB

www.eraendustriyel.com.tr 5info@eraendustriyel.com.tr

1.2 Warranty

ERİS GC.2 xxx type burner controllers manufactured under ERA-ERİS brand are under liability of Era Endüstriyel

Röle İmalat San.ve Tic.Ltd.Şti as the producing firm. ERA LTD. ŞTİ’s liabilities for ERİS brand burner controllers

is limited to servicing and spare parts even when the reason is negligence or warranty breach. Accordingly, ERA

LTD.ŞTİ.is not liable for any cost and expenses, loss and damages, loss of use which may directly or indirectly

arise from the sales, installation, use or non-use of the product or from any other reason.

Every function of ERİS burner controllers is tested before sale. If end user wishes to make a

functionality check, this must be done in supervision of a qualified staff member who is specialized

in that particular type of system.

ERİS burner control relays are under ERA LTD.ŞTİ warranty for a duration of 1 year from the date

of production. ERA LTD.ŞTİ. accepts possible production defects upon technical review of the

item. However, for any failures which may arise later, it accepts no responsibility.

Improper opening of the ERİS burner control unit housing, might result in product failure. ERA

LTD. Co.is not responsible for any mechanical or electrical mistakes which might be made during

installation.

GB

www.eraendustriyel.com.tr 6info@eraendustriyel.com.tr

WARNING

!

ERA - ERİS®

1.3 About this manual

Before starting the installation, please read this manual carefully!

ERİS-GC.2 xxx burner controllers’ installation must be implemented

by staff members who are particularly trained in commissioning of

burner systems and authorized for gas safety.

This manual basically mentions how to install, use, handle the ERİS

GC.2 xxx burner controller and other considerations for you on how to

stay safe.

This manual will help you during initial installation and commissioning

of the ERİS GC.2 xxx burner controller, for you to implement correct

methods and proper use.

In the meanwhile, you must make sure that the ERİS GC.2 xxx product

you have purchased is a match for your burner type, fuel type and

capacity specifications.

If you need advice and assistance during the purchase or use of ERİS-

GC.2 xxx burner controller, please do not hesitate to call the producing

company which is ERA END.LTD.ŞTİ. [email protected]r

1.4 Signs and symbols

DANGER

!

ADVICE

!

ATTENTION

!

It is beneficial to use this!

In cases of active electricity supply line, gas leak, open fire; do not

begin the installation. It may cause fire or electric shock. Please fol-

low legal regulations!

Follow all instructions carefully! Otherwise, you may be subject to

electric shock, fire or end up with improper installation as well as

unit failure!!

Lack of required attention can be very dangerous!

GB

www.eraendustriyel.com.tr 7info@eraendustriyel.com.tr

2.1 Contents of the Manual

Introduction to manual – Installation guideline

Types of application/implementation

Product specifications

Principle of operation

Hazards

1.5 General Warnings

This product is a microprocessor controlled gas ignition automat which is meant to be used with single or

multi stage atmospheric burners or other burners which work with an air fan.

Please do not start the installation without reading the user manual!

Follow the accident prevention guidelines!

If there are ongoing gas or electric welding works in your work site, do not proceed.

Install the item so that it won’t be subject to heat or flame! Follow the commonly accepted work

safety rules and accident prevention guidelines. Take necessary precautions for installation staff

as well as other workers.

WARNING!

Make sure that you duly understand the content of the manual!

Strictly adhere to all safety rules! Without written consent of ERA LTD.ŞTİ, do not implement any

other practice or operational limits, than those suggested thereby.

If there is a section which you don’t understand, do not proceed. Contact ERA LTD.ŞTİ.

engineering department.

Contact address: info@eraendustriyel.com.tr

2CONTENTS

www.eraendustriyel.com.tr 8info@eraendustriyel.com.tr

3.1 ERİS-GC.2 xxx Intended use

ERİS - GC.2 xxx controllers are designed for flame control on mid-scale atmospheric or blast-sweeping

gas burners with 1 or 2 stages. It is suitable for use with gas burners which are manually stopped or

have automated thermostat which stops, at least once in every 24 hours.

Product Introduction:

Manufacturer Co. :ERA END.Röle İML.SAN.ve TİC.LTD.ŞTİ.

Brand :ERA-ERİS

Model : GC.2 xxx (micro-processor controlled)

Intended use : Gas burner flame controller

Control system : 2 staged structure

PCB Structure : UL 94 – V0 + Protective Coating

Operating voltage : 230 VAC. 50/60 Hz.

Operation principle : Electronic controller which utilizes ionization electrode or

UV photo-detector for 1 or 2 stage burners

Outer casing : PC+ABS

Connection socket : PC+ABS

3.3 Specifications

Front panel displays failure codes “in letters and numbers”,

In case of a flame failure prior to program, initiates lock phase and gives a failure notice,

Remote reset is available

2 outputs for solenoid valves

1 output for ignition transformer,

1 output for ignition transformer,

A two color status lamp on controller unit, (Red – Green)

Can work with ionization electrode or ERİS-3 UV photocell with rectification output

Detection and ignition via single electrode (with TAR-10 transformer, see Picture 7)

Low voltage detection,

Microprocessor controlled

During the production, product can be custom-programmed as per customer requirements upon

request (See program examples, Figure 3 and Figure 4)

3.2 Structure of Controllers

3. INTRODUCTORY BASIC INFORMATION

www.eraendustriyel.com.tr 9info@eraendustriyel.com.tr

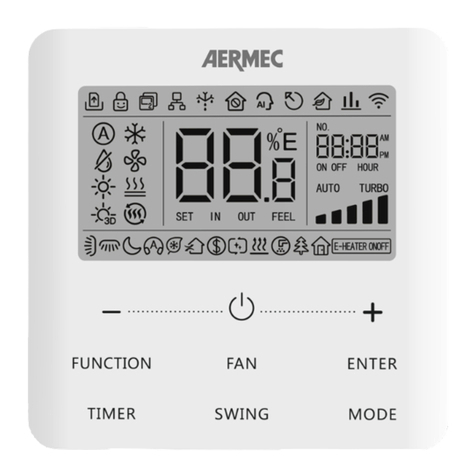

3.4 Parts of ERİS - GC.2 xxx Controller

1. Outer casing (PC+ABS)

2. Casing fixing screws

3. PCB fixing part

4. PCB (mainboard) (UL94-V0)

5. PCB fixing screws

6. Protective cover (UL94-V0)

7. Mounting socket (PC+ABS)

8. Failure and operation notifications

display

9. Reset button

10. Failure/Operation indicator light

(Failure: Red – Functioning: Gr een)

Figure:1 ERİS - GC2 Parts

Figure 2 : ERİ S - GC.2 xxx Electric circuit diagram

3.5 ERİS – GC.2 xxx Standard circuit diagram

www.eraendustriyel.com.tr 10 info@eraendustriyel.com.tr

K1 : Main Relay

K2/1 : Failure output contact

K2/2 : Ignition output contact

K3 : 1. Valve relay

K4 : 2. Valve relay

K5 : Protective relay (1)

FE : Functional Ground

N: Neutral

L: Phase (220 – 230 VAC. 50-60Hz.)

MS : Main switch (ON-OFF)

Si : External protective fuse

Pg : Gas pressurestat

T: Thermostat

M: Air blower

B: Bridge between 4 – 5 (DI not connected)

DI : Air pressurestat (B and DI not connected)

IT : Ignition Transformer

V1 : 1. Solenoid valve

V2 : 2. Solenoid valve

ER : External reset

AL : External alarm light

EK1 : Internal reset

IE : Ionization electrode

BR : Burner

(1) Protective relay stands for protecting the flame detector circuit from ignition transformer’s spark

3.6 Circuit Diagram Explanations (Figure : 2)

www.eraendustriyel.com.tr 11 info@eraendustriyel.com.tr

0

60

1

10

0

10

S

K

/

H

/

1...3

T

Min. Seconds

Max. Seconds

Min. Seconds

Max. Seconds

Min. Seconds

Max. Seconds

CONTINUDUS

INTERMITTEN

BRIDGE

AIR SWITCH

NONE

NUMBER OF REPETITIONS

TERMOSTATE INPUT

PRE. SWEPING

SAFETY DURATION

V1 TYPE OF OPERATION

DIGITAL INPUT FUNCTION

AUTO - REPEATDURATION BETWEEN V1 - V2

4.1 Program Durations Selection Examples for Burners

with and without Blowers (Customer should choose.)

BURNERS WITHOUT BLOWERS

ORDERING CODE ( 1 )

05 10 //S

PRODUCT CODE

ERİS-GC.2 05

BURNERS WITH BLOWERS

ORDERING CODE ( 2 )

0

60

1

10

0

10

S

K

/

H

/

1...3

T

Min. Seconds

Max. Seconds

Min. Seconds

Max. Seconds

Min. Seconds

Max. Seconds

CONTINUDUS

INTERMITTEN

BRIDGE

AIR SWITCH

NONE

NUMBER OF REPETITIONS

TERMOSTATE INPUT

PRE. SWEPING

SAFETY DURATION

V1 TYPE OF OPERATION

DIGITAL INPUT FUNCTION

AUTO - REPEATDURATION BETWEEN V1 - V2

05 10 /HS

PRODUCT CODE

ERİS-GC.2 30

Figure 3 : Duration options for

burners without blowers

Time durations of GC.2 xxx unit will be adjusted during production as per customer requirements, as shown in table.

Alphanumerical characters are timing values and together they form the model number.

4. ERİS-GC.2 PROGRAM SELECTION EXAMPLES

Figure 4 : Duration options for

burners with blowers

www.eraendustriyel.com.tr 12 info@eraendustriyel.com.tr

WARNING

!

5. ERİS – GC.2 xxx Installation and Use

5.1 Installation of parts and accessories

Before starting the installation, check whether your gas burner capacity and working

principles match with those of ERİS GC.2 xxx control unit data sheet. See page 12,

technical data. ERİS-GC.2 xxx control unit can perform flame control in two different

ways depending on the user preference and burner structure.

a) With ionization electrode

b) With ERİS - 3 Ultraviolet photocell.

Ionization and ignition electrodes are often integrated into the gas burners. If you need

to use UV detector in gas burner system, you can use ERİS-3 UV Photocell for ERİS –

GC.2 xxx controller. See Picture 6

For ionization electrode and UV photocell guidelines of use, please see page 24.

ERİS-GC.2 xxx Auxiliary components for flame control :

Picture 5 :

ERA - 402 Connection socket

Picture 6 :

ERİS-3 UV.Photocell

Picture 7 :

Ignition transformer (TAR-10)

* Picture 5 : Connection socket consists of 11 pcs energy input-output terminals and 3 pcs neutral

(N), 2 pcs ground (FE) terminals located just underside of the terminals.

ADVICE

!

www.eraendustriyel.com.tr 13 info@eraendustriyel.com.tr

5.2 TECHNICAL DATA

Technical Data :

Supply voltage : 230 VAC. +%10 - %15

Minimum operation voltage : 185 VAC. (During operation <175 VAC. Stop)

Maximum operation voltage : 265 VAC. (Short term)

Frequency : 50 / 60 Hz.

Maximum power drawn from control unit : 3 Watt. Max.

Remote reset : 100 Pf/m 20m. Non-shielded cable (If laid separately

from other cables)

Flame control with ionization electrode : Voltage between chassis and ionization electrode

( Ri <10 MΩ) AC 153V.

Current when there is flame : > 1,5 uA. (Minimum)

Current when there is no flame : < 1 uA. (Maksimum)

Regular operating current : 3 ± uA.

Short circuit current between ion/chassis (Ri<10 MΩ): AC. 60 uA.

Flame control with UV detector : (with ERİS-3 detector)

Flame detection with a 1 m.cable (candle flame) : 8,6 uA. (Detector Current)

Flame detection with a 20 m.cable (candle flame) : 7,9 uA. (Detector Current)

Max.current drawn from control outputs

Terminal 6,7,8 : 1.0 Amp.

Terminal 10 : 0.5 Amp.

Terminal 4 : 2.5 Amp

Max.current drawn from terminals : 5.0 Amp. 10 seconds 1 minute Max.

Cable lengths

Terminal 11 (GC… dedektör arası kablo mesafesi : 10 Mt. Max. (With an ignition rod cable laid separately from other cables)

Terminal 1 – 3 – 4 : <20 mt. 1,5 mm2 max.

Terminal 5 – 6 – 7 – 8 – 9 –10 : <20 mt. 1,5 mm2 max.

Other information

Protection class : IP 40

Operable ambient temperature : -20 / + 60 °C Max.

Mounting position : Optional

Weight

Control relay( Without Connection Socket) : 177 gr.

Connection socket : 95 gr.

www.eraendustriyel.com.tr 14 info@eraendustriyel.com.tr

5.3 CONNECTION EXAMPLES

For a burner without a blower

EXAMPLE CONNECTION DIAGRAM

For a burner with a blower

Figure 8 : Connection diagram for a burner without a blower

Figure 9 : Connection diagram for a burner with a blower

www.eraendustriyel.com.tr 15 info@eraendustriyel.com.tr

WARNING

!

Input

1. 230 VAC. 50/60 Hz. Supply voltage

2. FE – Functional ground

3. Neutral (For neutral conductives use 12-13-14)

5. Start input 220/230 VAC.

9. External reset input

11.Ionization electrode input

Output

4. 220 VAC. Control output

6. Ignition transformer output

7. 1. Solenoid valve output

8. 2. Solenoid valve output

10.External failure lamp output

5.4 ERİS – GC.2 xxx Connection input output numbers

Terminal : 1 – 3 – 4 : <20 mt. 1,5 mm. max.

Terminal : 2: Functional ground

Terminal : 5 – 6 – 7 – 8 – 9 –10 : <20 mt. 1,5 mm. max.

Terminal : 11 – (Between the detector – GC.2) : 10 Mt. Max. (With a spark plug cable which is

laid separately from other

cables)

5.5 Cable Connections

Connection lines must be compliant to at least 70 °C of ambient temperature.

ERİS – GC.2 xxx control unit connection cables are according to Picture 5 connection socket num-

bers. Cable sections and lengths must comply with below specifications.

Picture 8 You must apply either B or DI mark!

a) For IT transformer connection and choice, please see Figure 10.1 – 10.2 !

b) For standard ignition transformer connection, please see Figure 10.3 !

ADVICE

!

www.eraendustriyel.com.tr 16 info@eraendustriyel.com.tr

5.6 CONNECTION EXAMPLES FOR IGNITION TRANSFORMER

Ignion transformer must be chosen according to the electrode, which is to be used with the ERİS - GC.2

burner controller. Ignion and detecon through single electrode, as shown on Figure 10.1, requires

special transformer TAR -10 or any other ignion transformer of the same category. On Figure 10.2,

ignion and detecon are separate. As for Figure 10.3 the system requires a standard transformer along

with two or single ignion electrode and one ionizaon electrode.

Figure 10.1: Ignition and detection via

single electrode

5.7 ULTRAVIOLET FLAME DETECTOR CONNECTION EXAMPLE

Controllers must be selected according to process structure. You might need to use a UV detector for flame

detection. Ionization electrodes work with gas burners. They don’t work with diesel, fuel-oil and other liquid fuel

burners. Loss of flame cannot be detected immediately due to ionization currents interference above 1000°C. For

these reasons ultraviolet photocell monitoring is recommended. ERİS-3 UV. Detector can be connected to

ERİS-GC.2 xxx controller as shown on Figure 11.

Figure 10.2: Ignition and detection via

separate electrodes

Figure 11 : ERİS - 3 UV. Detector Connection Figure 10.3: With standard transformer and

two electrodes. Ignition and

detection electrode sare separate.

www.eraendustriyel.com.tr 17 info@eraendustriyel.com.tr

6.1 Flameless Trial Run (after installation is completed)

Gas valve is shut off!

Flameless trial run

Fixing screw

Reset

Button

After checking the electric connections, place the

upper case onto the socket vertically, as shown in

the Picture!

With a matching screwdriver, screw in the fixing

screws into the lower socket!

See. Figure 12

ERİS - GC.2 xxx control unit and burners to be

commissioned must be disconnected from mains from

both directions.

Otherwise, electric shocks might occur!

Shut the burner gas input off!

Do the connections match with controller input/output

information?

Do cable section and specifications match with

required specifications?

During the installation or at any other time, if you drop the unit to the floor; do not operate it. A

visible or invisible damage might have occurred to its elements. In this case, please send the unit to our technical

service for a fault check

Contact address : [email protected]

ERİS - GC.2 xxx is in “failure” mode, right after

production.

Failure lamp is lit red. Message display shows the most

recent failure code. Figure 13

Turn the burner start switch “on”!

Push the “Reset” button with your finger!

Do not use a sharp tool to push Reset button. Electric

shock might occur or the unit can be damaged.

Reset is done.

Red light disappears. GC.2 xxx becomes active.

Message display

6.2 Controlled pre-test attempt

Please check failure codes on Page 17.

(with the gas valve shut off ) Reset Button Failure lamp

Figure 12 : ERİS - GC.2

Fixing of the lower/upper case

Connection Socket

Figure 13 : GC.2 in Failure state

6. Prerun Check

ADVICE

!

ATTENTION

!

WARNING

!

www.eraendustriyel.com.tr 18 info@eraendustriyel.com.tr

ERİS - GC.2 xxx

Controller Display status

Pre-test started

Pre-sweeping started

Pre-ignition started

Valve 1 activated

“No flame !”

Led light is lit red

GC2… in failure status

Internal tests,

Pre-test or pre-sweeping, Pressurestat

Ignition system

1. valve is activated. (For trial, gas is shut off.)

Detector cannot detect a flame.

4.3 Failure Codes for the First Test

During flameless trial, GC.2 xxx has performed below checks, respectively.

www.eraendustriyel.com.tr 19 info@eraendustriyel.com.tr

0

60

1

10

0

10

S

K

/

H

/

1...3

T

Min. Seconds

Max. Seconds

Min. Seconds

Max. Seconds

Min. Seconds

Max. Seconds

CONTINUDUS

INTERMITTEN

BRIDGE

AIR SWITCH

NONE

NUMBER OF REPETITIONS

TERMOSTATE INPUT

PRE. SWEPING

SAFETY DURATION

V1 TYPE OF OPERATION

DIGITAL INPUT FUNCTION

AUTO - REPEATDURATION BETWEEN V1 - V2

05 05 10 //S

7.1 Program sequence and durations for burners without blowers

ORDER CODE (1) (See.Page 11 - Figure: 3)

Figure 14 : GC.2 xxx P rogram sequence

GC.2 xxx program sequence and durations

A—B : Pre-test duration = tw : 2.0 s.

B—C : Waiting duration = t1 : 5.0 s. Apporx.

C—D : Pre-ignition = t3 : 2.0 s.

D—E : Final ignition = t3a : 4.0 s.

D—F : Safety duration = t2 : 5.0 s. Max.

E—F : Flame occurring duration = t3b : 0.5 s.

F—G : Duration between V1–V2 = t4 : 10.0 s. Approx.

G—H : Burner operation =

Controlled operation

Symbol explanations

Pg/T : Gas pressurestat / thermostat

B: Bridge

DI : Digital input

IT : Ignition transformer

V1 : 1. Solenoid valve

V2 : 2. Solenoid valve

AL : Failure message

IE : Ionization Electrode , or

UV.Detector (ERİS-3)

7PROGRAM SEQUENCES

Example sequence and durations for burners without blowers

I/O Signal off

I/O Signal on

I/O Signal is on or off

www.eraendustriyel.com.tr 20 info@eraendustriyel.com.tr

15 : GC.2 xxx PrograProgram sequence

0

60

1

10

0

10

S

K

/

H

/

1...3

T

Min. Seconds

Max. Seconds

Min. Seconds

Max. Seconds

Min. Seconds

Max. Seconds

CONTINUDUS

INTERMITTEN

BRIDGE

AIR SWITCH

NONE

NUMBER OF REPETITIONS

TERMOSTATE INPUT

PRE. SWEPING

SAFETY DURATION

V1 TYPE OF OPERATION

DIGITAL INPUT FUNCTION

AUTO - REPEATDURATION BETWEEN V1 - V2

05 10 /30 KH

7.2 Program sequence and durations for burners with blowers

ORDER CODE (2) (See.Page 11 - Figure: 3)

Example sequence and durations for burners with blowers

GC.2 xxx program sequence and durations

A—B : Pre-test duration = tw : 2.0 s.

B—C : Waiting duration = t1 : 5.0 s. Yaklaşık

C—D : Pre-ignition = t3 : 2.0 s.

D—E : Final ignition = t3a : 4.0 s.

D—F : Safety duration = t2 : 5.0 s. Max.

E—F : Flame occurring duration = t3b : 0.5 s.

F—G : Duration between V1–V2 = t4 : 10.0 s. Yaklaşık

G—H : Burner operation =

Controlled operation

Symbol explanations

Pg/T : Gas pressurestat / thermostat

B: Blower motor

DI : Digital input

IT : Ignition transformer

V1 : 1. Solenoid valve

V2 : 2. Solenoid valve

AL : Failure message

IE : Ionization Electrode , or

UV.Detector (ERİS-3)

I/O Signal off

I/O Signal on

I/O Signal is on or off

Table of contents