eralytics eravap User manual

User Manual

The full manual can be found on USB

eravap: Vapor Pressure Tester

eralytics® GmbH |Lohnergasse 3 |1210 Vienna, Austria

Warranty Extension Form ERAVAP

Please scan and e-mail this form (3 pages) to office@eralytics.com

or fax it to +43 1 890 50 33 - 15

DOUBLE YOUR WARRANTY COMPLETELY FREE OF CHARGE

Thank you for choosing eralytics and welcome to a new era of petroleum testing. Your eralytics

analyzer includes a standard warranty period of 12 months from date of delivery.

To double your warranty period free of charge, complete this form together with the

initial qualification form and send it to eralytics. This extends the warranty period to 24

months from the date of installation.

Company Data:

Distributor company name: ___________________________________________

End user company name: ___________________________________________

Company address: ___________________________________________

Company phone: ___________________________________________

Contact person: ___________________________________________

E-mail address: ___________________________________________

Installation date: ___________________________________________

Instrument serial number ___________________________________________

Terms and conditions of 24 months warranty period (from date of installation)

1. Warranty services will be rendered upon valid warranty registration with complete warranty information within 30 days from

date of delivery. The registration must be applied by the end-user of the analyzer. Without complete warranty registration the

warranty period is limited to 12 months (from the date of delivery).

2. The Warranty shall cease immediately and become void, if unauthorized repair, tampering, alteration or modification is done

on the product:

a. The Serial Number must not be defaced or altered in any way.

b. The owner is required to provide proof of purchase at the time of service.

c. The warranty does not cover:

i. Accessories, consumable items, wear and tear parts, corrosion, rusting or stains.

ii. Transportation costs incurred in sending the product for repair.

iii. Usage of wrong electrical supply/voltage.

iv. Usage not in accordance with the operation instruction manual.

The warranty expressly provide for herein is the sole warranty provided in connection with the product, and no other warranty

expressly or implied, is provided. We disclaim any responsibilities for any other claims, with regards to other software and any

other peripherals used with the product under warranty. Defective parts replaced shall remain at the disposal of eralytics.

Initial Qualification Test ERAVAP

Acknowledging the following points and completing the instrument performance check ensures

that the analyzer was installed successfully and is fully operational.

By completing this form it is made sure that the operator was instructed on all essential

parts of its operation and that the analyzer meets our highest quality standards at the time

of installation.

Instrument Model: ____________________

Serial No.: EVP _ _ _ _ _ _ _ _ Software version: 8 _ _ _

Information

Received manual and operations video _____________

Received test report _____________

Informed about cleaning when crude oil or other higher

viscous samples are tested (see section “Cleaning”) _____________

Informed about handling of samples with high vapor pressure

(e.g. LPG, live crude oils) _____________

Instrument performance check

Perform a reference measurement using ASTM D5191 / EN13016-1 or ASTM D6378 or ASTM

D6377 with n-Pentane (purity ≥ 99.5%) or ASTM D6897 with n-Butane (purity ≥ 99%) and fill

in the actual measured values:

ASTM D5191, EN13016-1 & ASTM D6377:

Pentane (cooled to 0°C and air saturated): Ptot = 112.8 kPa ± 1.2 kPa

____________ kPa

ASTM D6378:

Pentane: VP4 (Pabs) = 107.9 kPa ± 1.2 kPa

____________ kPa

ASTM D6897:

Butane: VPtot (37.8 °C, V/L 0.5:1) = 356.6 kPa ± 6.0 kPa

____________ kPa

Handling

Received information about the different methods _____________

Sample preparation (cooling & air saturation

for D5191, EN13016-1, D6377 and D5188) explained _____________

Measurement performed _____________

_________________

Location, Date

______________________ ____________________

Customer operator name Sales representative name

______________________ ____________________

Customer operator signature Sales representative signature

EC DECLARATION OF CONFORMITY

EG-KONFORMITÄTSERKLÄRUNG | CERTIFICAT D’HOMOLOGATION DE

L’EQUIPEMENT

Manufacturer:

eralytics GmbH

Lohnergasse 3

1210 Vienna

Austria

Products:

eracheck pro oil in water analyzer (EC01)

eracheck eco oil in water analyzer (ECO01)

eraflash flash point tester (EF01, EF10)

eraflash LT low temperature flash point tester (EF02, EF20)

eraflash S10 flash point tester with auto-sampler (EFS01, EFS10)

eraspec FTIR fuel analyzer (ES01, ES10)

eraspec oil FTIR lubricant analyzer (EO01, EO10)

eravap vapor pressure testers (EV01, EV02, EV10, EV20)

The products to which this statement relates are manufactured and duly carried out in compliance with

the provisions of European Community Directive 2014/35/EU, 2014/30/EU and 2011/65/EU. The

products conform to the following standards:

EN61326-1:2013 Electrical equipment for measurement, control and laboratory use - EMC

requirements

EN61010-1:2011 Safety requirements for electrical equipment for measurement, control, and

laboratory use

EN 50581:2012 Technical documentation for the assessment of electrical and electronic

products with respect to the restriction of hazardous substances

eralytics GmbH, Austria

__________________________

Niklas Christensson,

CEO | eralytics GmbH

Document Revision: ERAVAP_a-8018 1

1General Information

We wish to thank you for the purchase of the vapor pressure analyzer ERAVAP from eralytics.

The ERAVAP is the ultimate solution for the automated vapor pressure measurement of

automotive and aviation gasoline, hydrocarbon solvents, crude oil and LPG as well as for the

vapor/liquid ratio measurement of gasoline. It follows in each detail the requirements of the

latest International standards EN 13016, ASTM D5188, D5191, D5482, D6377, D6378,

D6897and many more.

The unmatched precision, speed and versatility make it the preferred analyzer for volatility

specification compliance testing, refining streams quality follow-up, fuel blending and research

or mobile applications.

This Instruction Manual contains all essential information for installation of the instrument and

measurements of standard sample types. Please contact your local eralytics supplier or

eralytics GmbH for latest versions of the documents and firmware updates.

While every precaution has been taken in the preparation of these documents, eralytics GmbH

assumes no responsibility for technical or printing errors or omissions.

Nor is any liability assumed for damages resulting from the use of the information contained in

this manual.

Critical information for the operation of the instrument that might be necessary to

prevent damage of the instrument or harm of the user is marked with a red “!” on the

right side of the paragraph.

Important information for the operation of the instrument inside this manual is marked

with a black “i” on the right side of the paragraph.

eralytics GmbH does not make a commitment to update the information in this manual.

Specifications are subject to change without notice.

All rights reserved (including translation). No part of this document may be translated,

reproduced or distributed in any form (print, photocopy, microfilm or any other process) without

the prior written permission of eralytics GmbH.

Trade marks may be used in this instruction manual without being marked as such. They are

the property of their respective owners and are legally protected.

Published by eralytics GmbH. Copyright © 2019 eralytics GmbH, Vienna, Austria

Contact:

eralytics GmbH

Lohnergasse 3; 1210 Vienna, Austria

www.eralytics.com

support@eralytics.com

Document Revision: ERAVAP_a-8018 2

Telephone: +43 1 890 50 33 0

Document Revision: ERAVAP_a-8018 3

1.1 Safety and Warning

This instruction manual does not claim to address all of the safety issues

associated with the use of the instrument and samples. It is the responsibility

of the user to establish health and safety practices and determine the

applicability of regulatory limitations prior to use.

Make sure you read and understand all instructions and safety precautions listed in this

instruction manual before installing or operating the equipment to ensure smooth operation

and avoid damage to the equipment or its accessories. If a malfunction occurs, consult chapter

Errors and Warnings If a problem persists or if there are any questions concerning the

operation of the equipment or about the information in this manual, please contact your local

eralytics distributor or eralytics.

Performance of installation, operation, or maintenance other than those described in this

manual may result in a hazardous situation and may void the manufacturer’s warranty.

Never operate equipment that is not correctly installed. Ensure that all operators are fully

trained to use the analyzer correctly and safely. Unqualified personnel must not operate the

equipment. Avoid causing damage to the equipment or its accessories through incorrect

operation.

Always consult the material safety datasheet for any sample, chemical used for measurement,

cleaning and maintenance and ensure that proper safety equipment is available and used by

the operator.

Follow the precautions below for the handling and measurement of flammable

samples and cleaning agents:

•Observe all safety regulations regarding the handling of the samples to be

measured, rinsing agents and waste liquids (e.g. use of safety glasses, gloves,

respiratory protection...).

•Do not store inflammable material near the instrument.

•Do not leave sample/solvent containers uncovered.

•Clean all spillages immediately.

•Prior to starting a measurement, make sure that the filling and waste hoses and

the cell connection tube are properly connected.

•Ensure that the ERAVAP is located in a sufficiently ventilated area, free from

inflammable gases and vapors.

•Keep a fire extinguisher at hand.

•Keep any sources of ignition, like sparks and unshielded flames, at a safe

distance from the instrument.

Document Revision: ERAVAP_a-8018 4

Important:

Read the manual before removing the metal casing. Never operate the instrument

without the metal casing unless required to do so during service and maintenance.

Always disconnect the line cord of the apparatus when performing maintenance or

moving the apparatus. Do not use any accessories or wearing parts other than those

supplied or approved by eralytics GmbH. If a problem persists, please call your

supplier or eralytics GmbH. Repair and service procedures may only be carried out

by authorized personnel or by eralytics GmbH.

Document Revision: ERAVAP_a-8018 5

1.2 Warranty terms

Any product manufactured by eralytics GmbH is sold to the purchaser (herein after referred to

as Customer) on the following basis and none other. All implied warranties of merchantability

and of fitness for a particular purpose are hereby expressly excluded.

(a) Products are warranted against defects in material and workmanship for a period of

one year (Warranty Period) from the date of purchase.

(b) eralytics GmbH will, without charge, at its option, replace or repair Products that fail as

a result of defective materials or workmanship within the Warranty Period.

(c) None of the obligations assigned to eralytics GmbH by this paragraph shall apply to

any Products which have been repaired, altered or modified at the instance of Customer,

unless Customer has disclosed the nature and full extent to any proposed repair, alteration or

modification to eralytics GmbH in writing before it has been effected, and obtained an

undertaking from eralytics GmbH that any outstanding warranty obligations in respect of such

Products will continue to apply to such Products despite such repair or alteration. eralytics

GmbH retains an unfettered discretion to grant or refuse any such undertaking.

(d) None of the obligations of eralytics GmbH in this Warranty shall apply to any Products

which have been subjected to misuse, neglect, accident, or (without restricting the generality

of the foregoing) any extreme environmental condition or improper handling.

(e) lf defective Products are returned to eralytics GmbH, the costs of such return will be

borne by the customer, and those of delivering the repaired or replacement Products to the

customer will be borne by eralytics GmbH.

eralytics GmbH ‘s sole liability hereunder shall be to repair or replace any product which proves

to be defective. In no event shall eralytics GmbH be liable for any special incidental,

consequential, indirect or other similar damages arising from failure of its Products.

LIMITATION OF REMEDIES

Neither eralytics GmbH nor the Customer will be liable to the other for any special, incidental,

consequential, indirect or other similar damages arising from breach of warranty,

indemnifications, breach of contract, negligence, strict liability or any other kind of civil liability.

eralytics GmbH ‘s total liability in connection with this agreement shall in no event exceed the

amount paid or payable by the Customer in respect of the product which is the cause of such

liability on the part of the company.

OBLIGATION OF THE CUSTOMER

The Customer agrees, as a condition of purchase of a product from eralytics GmbH, not to

reproduce any part of the Product. The Customer also agrees not to make unauthorized use

of the proprietary information which belongs to eralytics GmbH.

Document Revision: ERAVAP_a-8018 6

1.3 Copyright

ERAVAP and this manual are protected by copyright. Reproduction of the unit will result in

prosecution. All rights to the manual are reserved. Reproduction in any form, including in the

form of excerpts, shall require written permission from the copyright holder.

We reserve the right to make technical and content changes including without prior notice.

1.4 Licenses

The kernel, operating system and application software of this device are based on open source

projects licensed under GPL-v2 and/or GPL-v3. The complete list of libraries and their license

used can be viewed in the detailed software version information field and in the update menu

under "software licenses", respectively.

The source code required to build the above-mentioned libraries can be obtained on a DVD

for a period of three years after the last shipment of this product by making a request to

followed by a money transfer of €10 to:

eralytics GmbH

Raiffeisenbank Langenlois

Address: Kornplatz 9

3550 Langenlois

Austria

IBAN: AT433242600000063818

BIC: RLNWATWW426

This offer is valid to anyone in receipt of this information.

Document Revision: ERAVAP_a-8018 7

2Unpacking

When unpacking the analyzer, please ensure the analyzer is not subjected to excessive

vibration or shock and that the following items are available:

•EV10 ERAVAP OR EV20 ERAVAP LPG

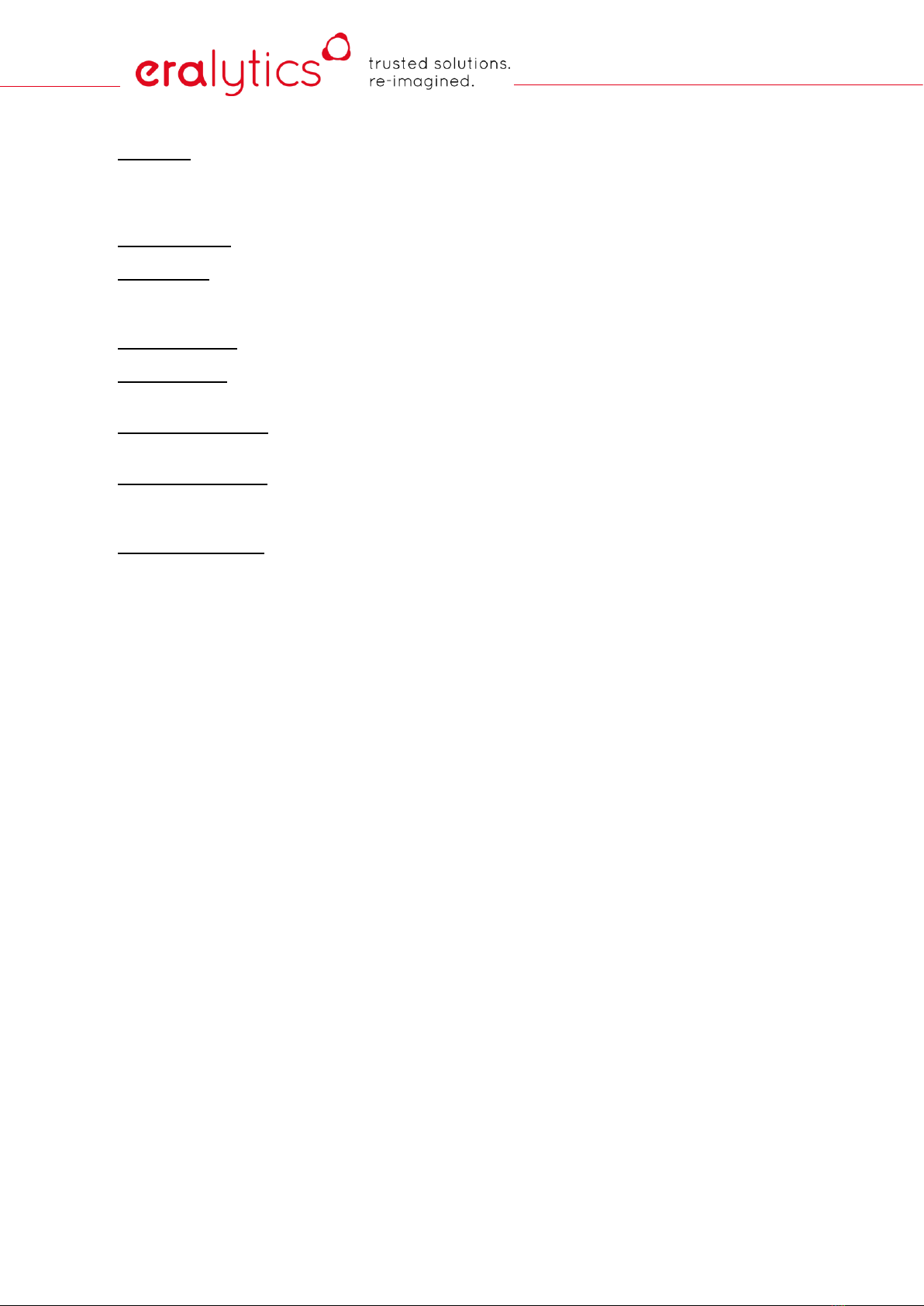

•EV01-A001 Sampling tube with luer connector (EV10 only)

•EV01-A029a Quick-fit inlet nut (EV01-A039a) and Sampling tube with 1x Quick

connector (EV01-A033a) (EV20 only)

•EV01-A002a Mesh inlet filter 80 µm (5 pcs, 1 already inside sample inlet)

•EV01-A003 Outlet tube

•EV01-A004 Waste container

•EV01-A005 Power cable

•EV01-A009 Test certificate

•EV01-A010 Instruction manual abstract & 1-page short version

•EV01-A011 Instruction manual (saved as PDF file on USB memory stick)

Operating range:

•EV10…up to 10bar

•EV20…up to 20bar

•Preinstalled software modules:

oEV01-D6378 software module for VP-measurement of gasoline (D5191,

D6378, EN13016-1, EN13016-2, IP394, IP409; excellent correlation to ASTM

D323 & D4953)

oEV01-D5188 Software module for the measurement of the vapor/liquid ratio

according to ASTM D5188

oEV01-D6377 Software module for the measurement of the vapor pressure of

crude oil according to ASTM D6377; IP481; GOST 52340

oEV01-D6897 Software module for the measurement of the vapor pressure of

LPG according to ASTM D6897 (excellent correlation to ASTM D1267)

required optional accessory: EV10-A029a: Quick-connector inlet nut (EV10-

A039a) and Sampling tube with 1 x Quick-connector with check valve (EV01-

A033a)

•Optional modules:

oEV01-COOL Low Temperature Module -20 to 0°C (-4 to 32°F)

oEV01-VISC High Viscosity Module

oEV01-VPL Low Vapor Pressure Module

oEV01-RCS ERASOFT RCS - remote control Windows software for

instrument remote control from a PC and for easy data exchange

oEVx0-A031 Auto sampler 10 positions (x = 1 for gasoline and non-

pressurized crude oil, x = 2 for LPG and pressurized crude oils)

Document Revision: ERAVAP_a-8018 8

If any of the items is missing or was damaged during shipment, please contact your local agent

or eralytics GmbH (at +43 1 890 50 330 or office@eralytics.com) immediately.

Retain and reuse the shipping boxes and packing materials as they provide optimal

protection for the equipment(s) during transport (e.g. for service).

Reordering Supplies

Please refer to http://eralytics.com/distribution/ or contact your local dealer if supplies are

required.

Document Revision: ERAVAP_a-8018 9

3Measuring principle

ERAVAP measured the vapor pressure of liquid materials. By definition, the vapor pressure,

or equilibrium vapor pressure is the pressure, extorted by a vapor in thermodynamic

equilibrium with its condensed phases at a given temperature in a closed system.

Within a measurement, the following parameters are controlled, pre-defined or measured:

•V/L ratio

As for of the filling parameters, the amount of liquid sample related to the total volume of

the measuring cell is adjusted, or pre-defined by the used method.

•Measuring time

In order to ensure that the liquid and vapor phases are in a stable equilibrium state a

measuring time is specified.

•Temperature

As the vapor pressure is a function of the temperature, this parameter is pre-defined and

monitored, ensuring that the measuring cell is temperature regulated.

•Pressure

For most common methods the pressure in the measuring cell is determined.

Document Revision: ERAVAP_a-8018 10

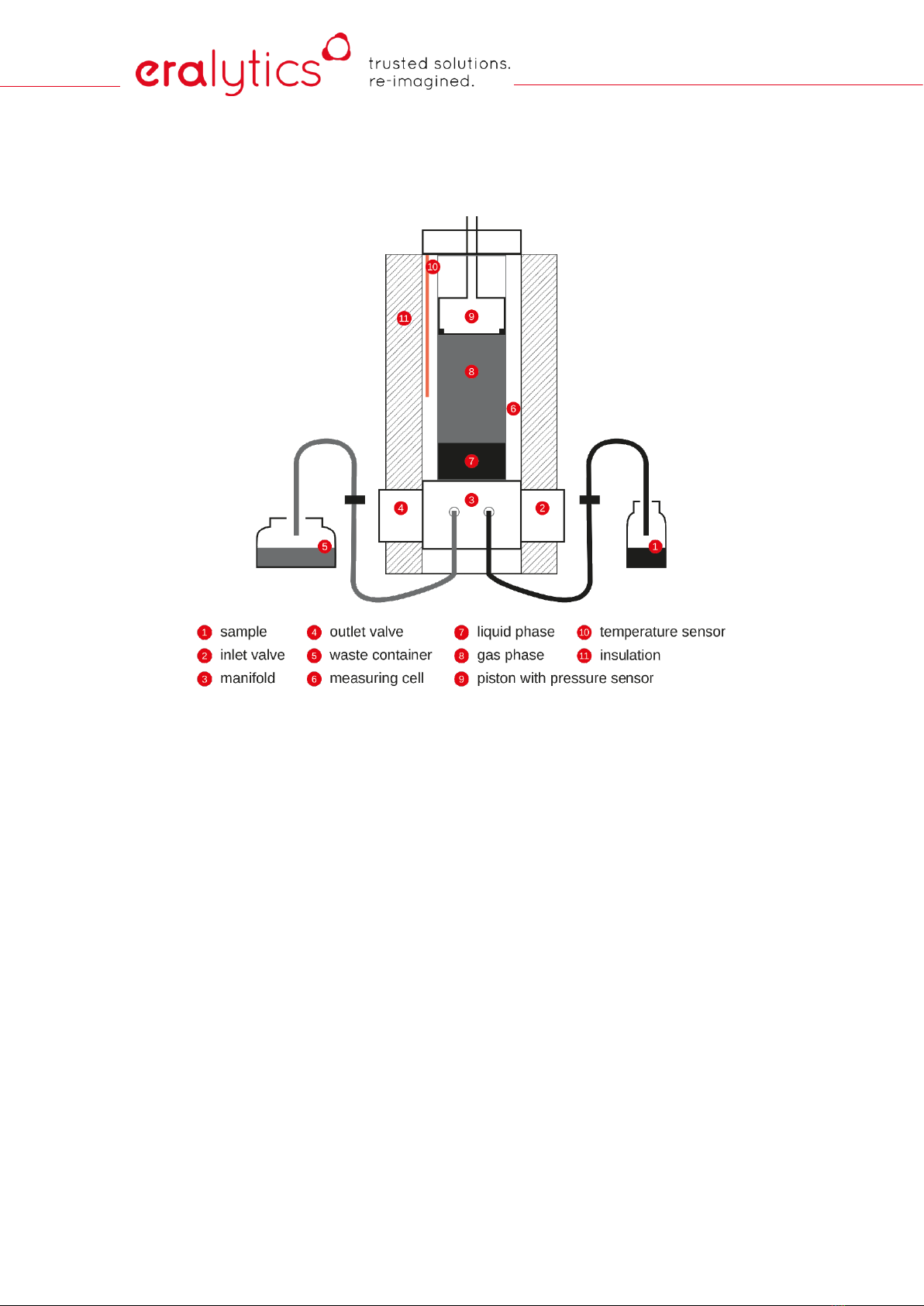

A typical measurement with ERAVAP can be described as follows:

The sample tube is put into the sample container (1). After starting the measurement, the

measuring cell (6) is regulated to the specified filling temperature and the piston (9) moves to

the down position simultaneously the outlet valve (4) is opened to release the pressure. The

outlet valve is the closed, the inlet valve (2) is opened and the piston moves upwards to

introduce the sample into the measuring cell. The piston then is reset to the down position

again to expel the liquid via the outlet valve.

After this rinsing procedure has been repeated a pre-defined number of times, the piston draws

in a specified amount of sample, then the inlet valve is closed. The piston moves further up

(extension against vacuum) and the measuring cell is regulated to the specified measuring

temperature.

When a pre-defined measuring time is elapsed the pressure inside the measuring cell is

determined by the pressure sensor (9) and used for calculating the method dependent result

data.

Document Revision: ERAVAP_a-8018 11

3.1 Specifications

Available Test Methods:

ASTM D5188, D5191, D6377, D6378, D6897; EN 13016-1,

EN 13016-2, EN 13016-3; IP 394, IP 409, IP 481; JIS K2258-

2; SHT 0769, SHT 0794; SNT 2932; GOST 52340, EPA /

CARB / CCQTA / US Military and NATO reference methods,

TVP measurement VP-V/L Speed TestTM –Combined T(V/L)

and vapor pressure measurement

Correlation to:

ASTM D323, D1267, D2533, D4953, D5190, D5482, D2879

(optional low vapor pressure extension)

Fuel Specifications:

ASTM D910, D1655, D4814, D6227, EN 228

Hardware Feature:

Built-in shaker for crude oil and accelerated V/L

measurements

Pure SamplingTM valve technology for minimized cross-

contaminations

Temperature Range:

0°C –120°C (32°F –248°F) with Peltier technology –No

external cooling required

Optional extension EV01-COOL: -20°C –120°C (-4°F –

248°F) –External cooling required

Extrapolated range: -100°C –300°C (-148°F –572°F)

Temperature Stability

0.01°C (0.02°F)

Pressure Range

EV10 ERAVAP: 0 kPa –1000 kPa (0 psi –145 psi) –High

precision pressure transducer

EV20 ERAVAP LPG: 0 kPa –2000 kPa (0 psi –290 psi) –

Extended range pressure transducer

Pressure Resolution

0.01 kPa (0.0014 psi)

Vapor / Liquid Ratio

Variable from 0.02/1 –100/1 –Single-point, multi-point and

curve measurements

Precision

Repeatability: r ≤ 0.15 kPa (0.022 psi) measured with EV10

and cyclopentane at 37.8°C

Reproducibility: r ≤ 0.5 kPa (0.073 psi)

Sample Introduction

Automated via built-in piston –No external vacuum pump

required; 80 µm reusable filter

Sample Volume

1 mL (2.2 mL per rinsing cycle)

Measurement Time

5 minutes for a standard measurement

Display:

Industry proven 8" color touchscreen

Languages:

English, German, French, Spanish, Russian, Chinese

Additional languages available upon request

Document Revision: ERAVAP_a-8018 12

Interfaces:

Built-in PC with Ethernet, USB and RS232 interfaces

Direct LIMS connectivity and output to printer or PC

Optional input by external keyboard, mouse and barcode /

QR-code reader

Remote Control:

Remote service capability via Ethernet interface

PC Software:

ERASOFT RCS - remote control Windows®software for

multi-instrument remote control, convenient data transfer and

result analysis

Result Database:

Over 100 000 detailed test reports stored in internal memory

Alarm Tracking:

All alarm messages are stored in the database together with

the results

Operating Conditions:

Temperature range 10°C to 40°C

Humidity up to 90% RH, non-condensing

Power Requirements:

Auto-switching 85-264 V AC, 47-63 Hz, max. 150 W (multi-

voltage power supply)

Field application: 12 V DC (vehicle battery) adapter available

Dimensions / Weight:

29 x 35 x 34 cm (11.4 x 13.8 x 13.4 in) / 9.7 kg (21.4 lb)

Document Revision: ERAVAP_a-8018 13

4Getting started

4.1 Operating Environment

When setting up the analyzer, select a location away from heat, smoke, electrical interference

and avoid any electrostatic discharges (ESD) to the analyzer unit. The bench top should be a

level surface and free of vibration.

Ensure that the vent holes of the analyzer are not obstructed. The analyzer requires an

environment with ambient room temperature in the range of 10°C to 45°C.

Before making any connections, make sure that the power cable at the back of the

analyzer is not plugged into an electrical outlet.

Only one set-up utility is required: an A.C. electrical outlet. It is recommended that the analyzer

is plugged into its own circuit to avoid power line interference and voltage surges or drops,

which may occur if the circuit is shared with devices with high electrical draw.

For protection against scratches and spills, it is recommended that the screen protection film

is placed on the touch screen monitor –one protection film is already placed on the touch

screen monitor! (to reorder, please contact your local agent or eralytics GmbH).

4.2 Dimensions & space requirement

Below dimensions are valid for a single position instrument, without considering space needed

for the user sample bottles. For dimensions of an instrument with autosampler, please contact

your local eralytics distributor or eralytics GmbH.

*: dimensions in brackets are related to an extended handle in the corresponding direction

Document Revision: ERAVAP_a-8018 14

4.3 Connecting and starting the analyzer

Place the analyzer on a stable benchtop. Connect the power cable as well as the waste

container and the inlet tube to the analyzer as described in the pictures below.

Waste container

Mains

Sample outlet

RS232 interface

Housing

USB Type B plug (slave)

Display

Ethernet connector

Filling tube with Luer connector

3x USB Type A plug (master)

Sample inlet

Audio connectors

Sample container

Handle

On/Off button

2x Buttons to remove housing

2x USB Type A plug (master)

Serial number plate

Document Revision: ERAVAP_a-8018 15

If the instrument is used for measuring non-pressurized samples (e.g.: gasoline) the sampling

tube with the Luer connector can be used:

For pressureized samples (e.g. LPG, crude oil with high amount of volatile substances) the

sampling tube with quickconnector (right picture) must be used. Otherwise, volatile substances

might be lost when exposing the sample to ambient pressure, thus leading to a too low result.

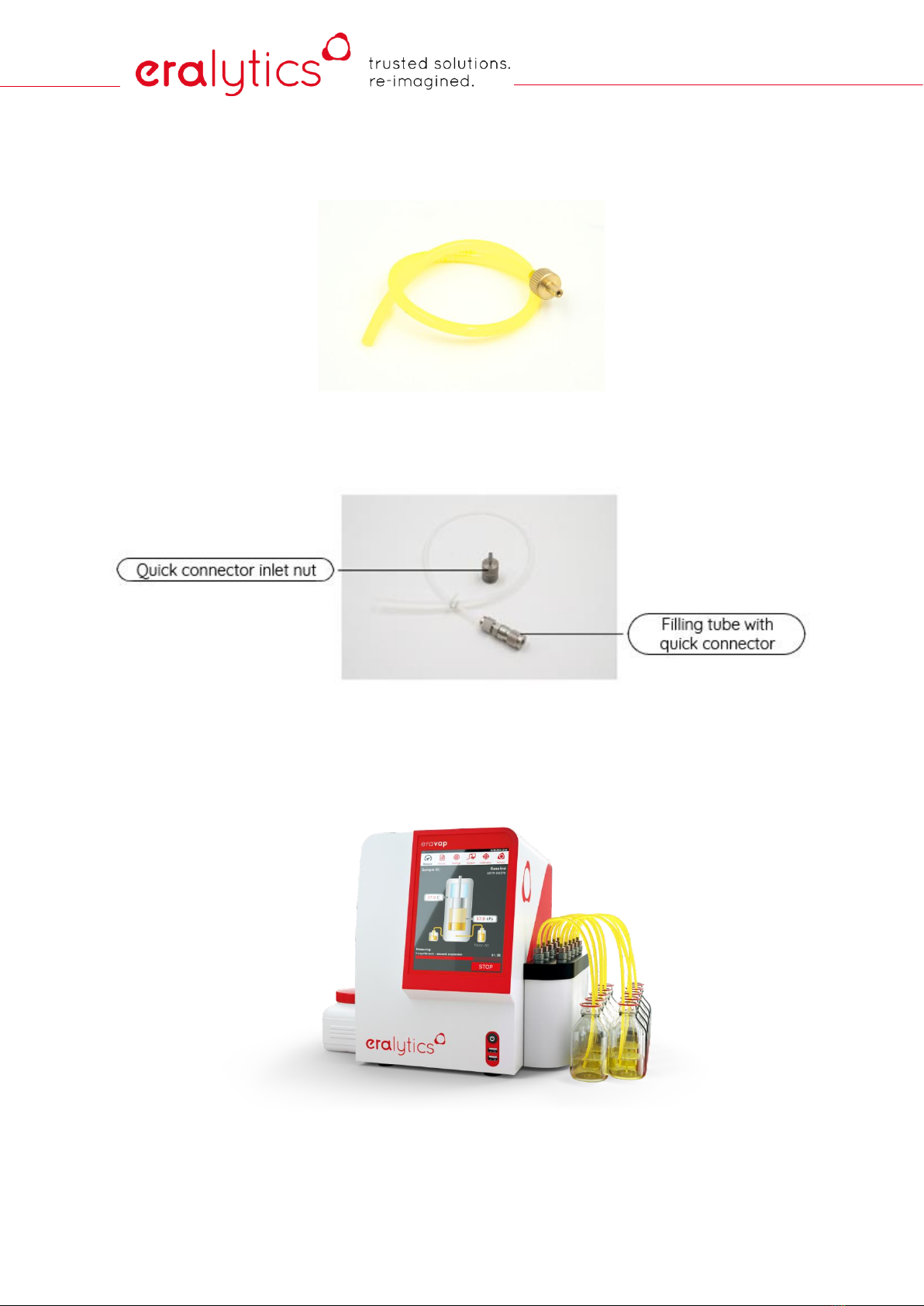

ERAVAP with 10 position autosampler:

This manual suits for next models

2

Table of contents