ERICHSEN LINEARTESTER 249 User manual

Scratch Hardness Tester LINEARTESTER 249 1

BAE 249

ATTENTION

Read Operating Instructions carefully before commissioning.

Seria-No.:

Erichsen-No.:

Year of construction: 2010

Country of origin: Germany

Stand: VI/2010

Operating Instructions

Scratch Hardness Tester

LINEARTESTER 249

Scratch Hardness Tester LINEARTESTER 249 2

BAE 249

Index Page

1. Fundamentals 4

1.1 Who should have access to the Manual 4

1.2 Duties of the user's management 4

1.3 Duties of the user's operators 4

1.4 Dangers arising from the use of the instrument 5

1.5 Proper Use 5

1.6 Guarantee and Liability 5

1.7 Copyright 6

1.8 Address of the Manufacturer 6

2. Safety Instructions 7

2.1 Meaning of Symbols 7

2.2 Availability of Safety Information 7

2.3 Training of Personnel 7

2.4 Dangers from Electrical Energy 8

2.5 Points of Special Danger 8

2.6 Care, Maintenance, Correction of Faults 8

2.7 Modifications to the Equipment 8

2.8 Cleaning of the Instrument and Disposal of Materials 8

3. Transport and Storage 9

3.1 Packing 9

3.2 Checks on Receipt by the User 9

3.3 Reporting Transport Damage and Documentation 9

3.4 Storage 9

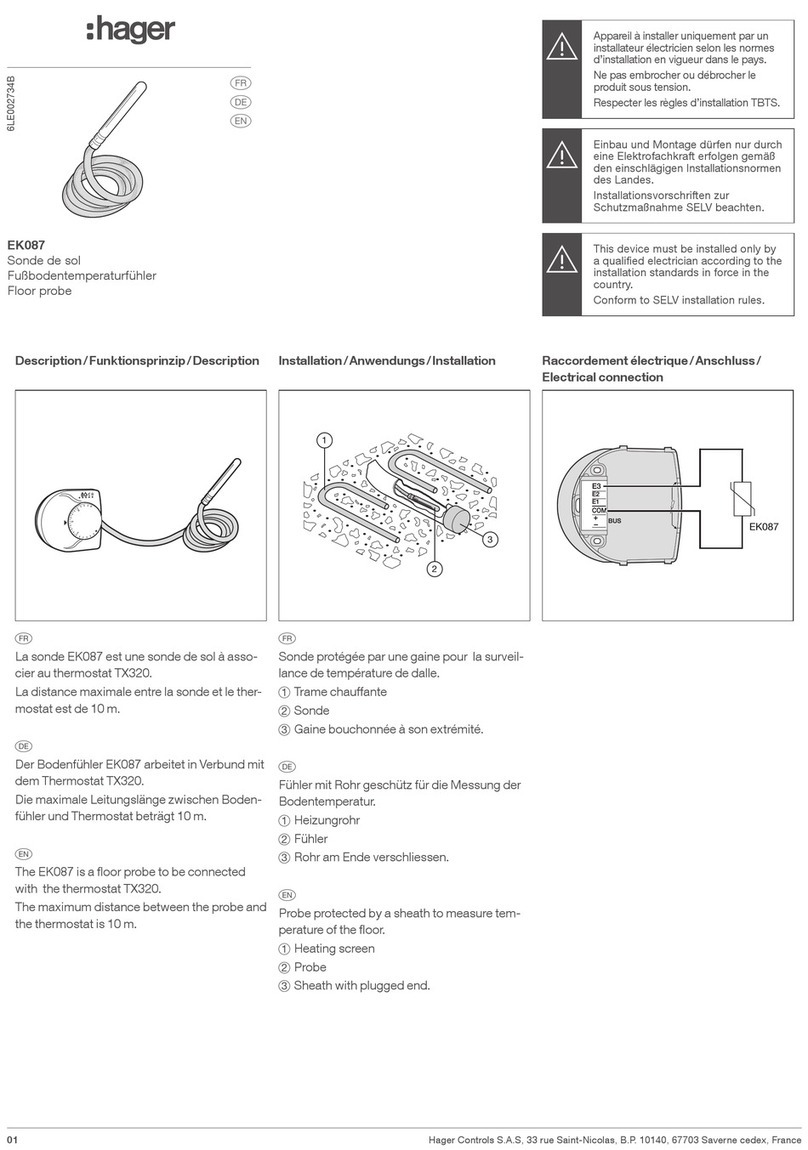

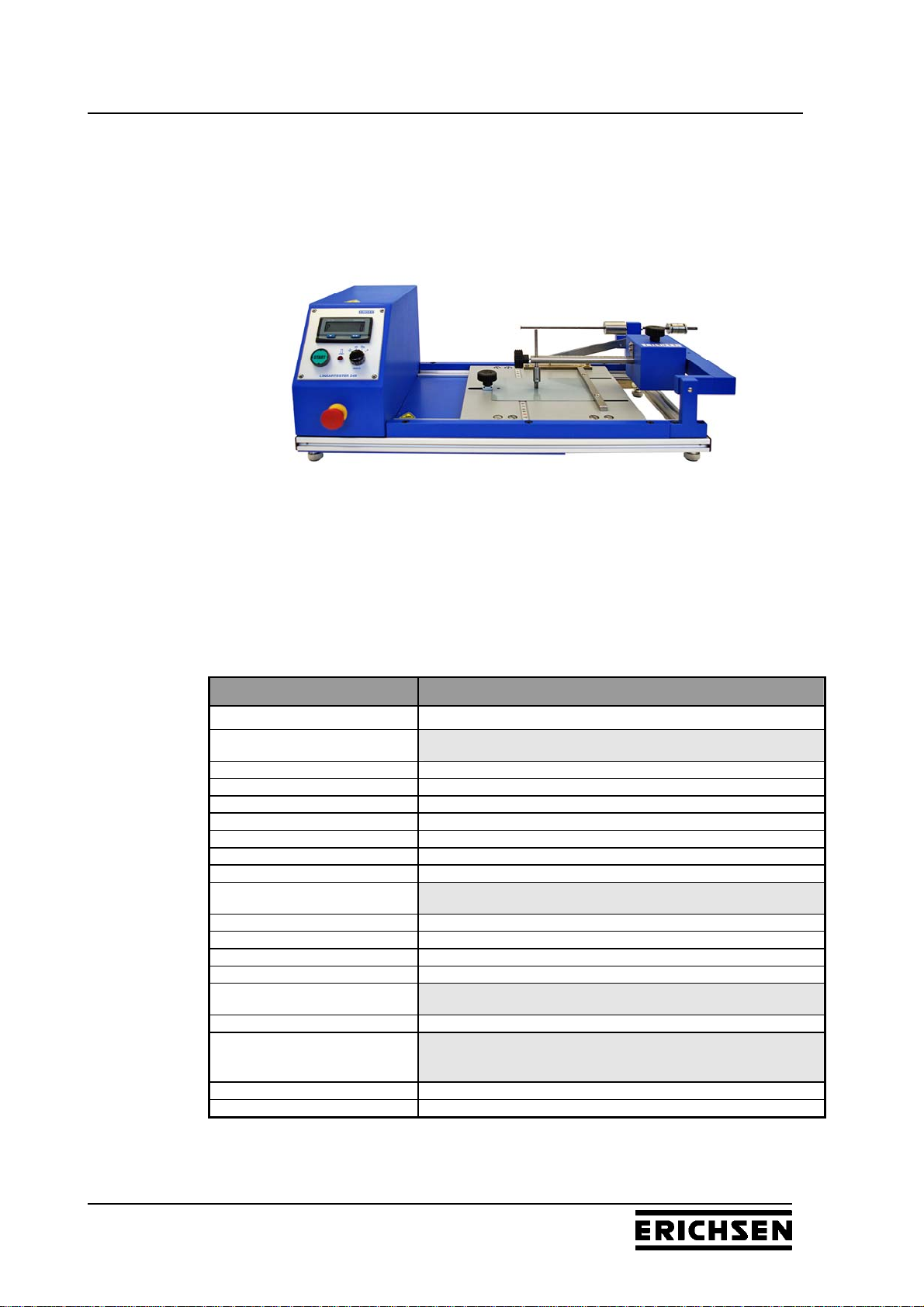

4. Instrument Data 10

4.1 Name / Type 10

4.2 Scope of supply 10

4.3 Accessories and Spare Parts 10

4.4 Technical Data 11

4.4.1 Dimensions 11

4.4.2 Technical Data 11

4.5 Noise Level 11

5. Assembly and Commissioning 12

5.1 Installation of the Instrument 12

5.2 Preparation of Energy and Supply Connections 12

5.3 Control elements 14

6. Performance of the Scratch Tests 16

6.1 Selection of Test Tools 16

6.2 Single Scratch Test 18

6.3 Double stroke tests 22

Scratch Hardness Tester LINEARTESTER 249 3

BAE 249

7Preselection Counter (Display) 23

7.1 Control Elements 23

7.2 Operation of the preselection counter 24

7.3 Battery change (Preselection counter) 25

8Universal Adapter Set (Accessories) 26

8.1 Universal shaft 26

8.2 Clamping adapter 26

8.3 Disc adapter 27

8.4 Chucking adapter 27

8.5 Mounting instructions for the universal adapter set 28

9. Care and Maintenance 29

9.1 Inspection and Maintenance 29

9.1.1 Basic Unit 29

9.1.2 Test Tools 29

9.2 Cleaning Material 29

9.3 Disposal of Materials 29

9.4 Customer Service 29

Encl.: Declaration of Conformity

Scratch Hardness Tester LINEARTESTER 249 4

BAE 249

1. Fundamentals

1.1 Who should have access to the Manual

It is a fundamental precondition for safe and trouble-free

operation of the instrument that the safety instructions and

safety guidelines are known by all concerned.

This instruction manual contains the most important guidelines

for the safe operation of the instrument.

The contents of this instruction manual and especially the

safety guidelines must be observed by all persons who work

with the instrument.

In addition all local safety regulations and instructions for

accident and prevention must be observed.

1.2 Duties of the user's management

It is the user's management's duty:

a) only to permit persons to work on the machine who

are familiar with the regulations for safety at work and

accident prevention and who have been trained to operate the

instrument, and

who have read the Chapter on Safety and the warnings given

in this instruction manual and have understood what they have

read and have confirmed this by signing a statement to that

effect, and

b) to check at regular intervals that personnel are aware of the

essential need for a safe working

1.3 Duties of the user's operators

All persons whose duty it is to work with the instrument must

before starting work:

take note and follow the fundamental instructions for safe

working and accident prevention

read the Safety Instructions chapter and warnings given in this

instruction manual and to confirm that they have done this and

have understood what they have read with their signature.

Scratch Hardness Tester LINEARTESTER 249 5

BAE 249

1.4 Dangers arising from the use of the instrument

The instrument is built in accordance with the state of technology

and the recognised safety regulations. In spite of this, dangers to life

and limb can arise for the user or third parties. Damage on the

instrument of other objects can arise in its use. The instrument must

only be used:

for the application for which it is intended.

with all safety features in fault-free condition.

Faults that could influence safety must be corrected immediately.

1.5 Proper Use

The Scratch Hardness Tester LINEARTESTER 249, is intended for

determining the scratch resistance of protective surface coatings,

such as paint and lacquer finishes, plastic coatings etc.

Also for other tests:

Scribe/Scratch tests, to and fro-cycle abrasion tests, Crockmeter

tests, MEK tests, tests determining the resistance against solvents in

general or wipe test, respectively.

If the instrument is employed for any other purposes, this will be

improper use. Erichsen GmbH & Co. KG will not be liable for any

damage resulting from this.

Proper use also implies:

observance of all guidelines contained in the instruction manual

and

full attention to laid down inspection and maintenance

procedures.

1.6 Guarantee and Liability

Fundamentally our general Conditions of Sale and Supply apply.

These will be available to the user at the latest at the time of

completion of the contract. Claims under guarantee or liability in the

event of injury to persons or damage to equipment cannot be

accepted if these are the result of one or more of the following

causes:

- Improper use of the instrument.

- Incorrect assembly, commissioning, operation and maintenance of

the instrument.

- Operation of the instrument when safety equipment was faulty or

incorrectly fitted.

- Failure to observe guidelines in the instruction manual in respect

of transport, storage, assembly, commissioning, operation,

maintenance, and setting up the instrument.

- Unauthorised modifications to the instrument

- Inadequate monitoring of parts of the instrument that are subject

to wear, or incorrectly made repairs.

- Catastrophic damage caused by external effects or force majeur.

Scratch Hardness Tester LINEARTESTER 249 6

BAE 249

1.7 Copyright

The copyright of this instruction manual remains with ERICHSEN

GmbH & Co. KG, D-58675 Hemer. The instruction manual is

intended solely for the user and his personnel.

The instruction manual contains instructions and guidelines that

may not be duplicated, distributed or otherwise passed on either in

full or in part.

Infringement of these restrictions can lead to criminal prosecutions.

1.8 Address of the Manufacturer

ERICHSEN GmbH & Co. KG

Am Iserbach 14

D-58675 HEMER

Tel.: +49(0) 2372 96 83-0

Fax: +49(0) 2372 6430

Internet: http://www.erichsen.de

Scratch Hardness Tester LINEARTESTER 249 7

BAE 249

2. Safety Instructions

2.1 Meaning of Symbols

The following symbols for dangers are used in this instruction

manual.

2.2 Availability of Safety Information

The instruction manuals must always be kept at the place of

operation of the instrument.

In addition to the information contained in the instruction

manual, general and local regulations for accident

prevention and environmental protection shall be kept

available and observed.

• It is essential to ensure that all guidelines in respect of

safety and dangers on the instrument are kept in readable

condition.

2.3 Training of Personnel

Only properly trained personnel may operate the instrument.

Who is responsible for what must be clearly established in

respect of installation, commissioning, operation, setting up

maintenance and repair.

Personnel in training must only be allowed to work on the

instrument when supervised by an experienced person.

This symbol means possible immediate danger to the life or

health of personnel.

If this guideline is not noted it can lead to severe danger to

health, up to fatal injury.

This signal signifies a situation that could be dangerous.

Non observance of this guideline can lead to injury or to

damage to equipment.

This symbol draws the attention to special tips for the user and

information that is particularly useful.

•It refers to aspects which will enable you to use your

Instrument to optimum effect.

Dan

g

e

r

Warnin

g

Scratch Hardness Tester LINEARTESTER 249 8

BAE 249

2.4 Dangers from Electrical Energy

Work on the electrical supply may only be done by

qualified electrician.

The electrical equipment of the instrument must be checked

regularly. Loose connections and cable damaged by heat

must be corrected immediately.

2.5 Points of Special Danger

2.6 Care, Maintenance, Correction of Faults

Carry out maintenance and inspection at the correct

intervals.

Inform operating personnel before starting with

maintenance or repair work.

The instrument must be isolated from the elctrical supply

whenever maintenance, inspection or repair work is done.

2.7 Modifications to the Equipment

No modifications or additions or alterations to the instrument

may be made without permission from the manufacturer.

All measures involving modifications require written

confirmation of approval from ERICHSEN GmbH & Co. KG

Instruments not in fault-free condition must be switched off

immediately.

Use only replacement parts from the original supplier.

- If parts from other sources are used there is no guarantee

that they are designed to take the loading and meet the

safety requirements.

2.8 Cleaning of the Instrument and Disposal of Materials

Materials must always be used and disposed of correctly.

This applies particularly when cleaning with solvents.

There is a special point of danger in the working area of the

instrument:

Do not move hands into the radius of action of the working

stylus.

Dan

g

e

r

Scratch Hardness Tester LINEARTESTER 249 9

BAE 249

3. Transport and Storage

3.1 Packing

One of the factors on which the type of packing depends is the

method of transport involved. Unless otherwise agreed in the

Contract, the packing will be in accordance with the HPE guidelines

laid down by the Federal Association for Timber, Pallet and Export

Packing (German registered association) and from the German

Association of Machine Builders.

Note must be taken of the pictorial symbols on the packing.

3.2 Checks on Receipt by the User

Check packing for damage

After unpacking check complete supply.

3.3 Reporting Transport Damage and Documentation

Reports of damage should be documented as accurately as

possible (possibly photographed) and reported to the relevant

insurers or, in the case of sales "delivered to customers works",

to the supplier.

3.4 Storage

The instrument must be stored in a dry place at a temperature

between 10 - 40°C (if possible in the original packing).

Scratch Hardness Tester LINEARTESTER 249 10

BAE 249

4.InstrumentData

4.1 Name / Type

Scratch Hardness Tester LINEARTESTER 249

Ord.-No. 0263.01.31

4.2 Scope of supply

1 Basic unit

1 Circular level

1 Power pack

1 Operating manual

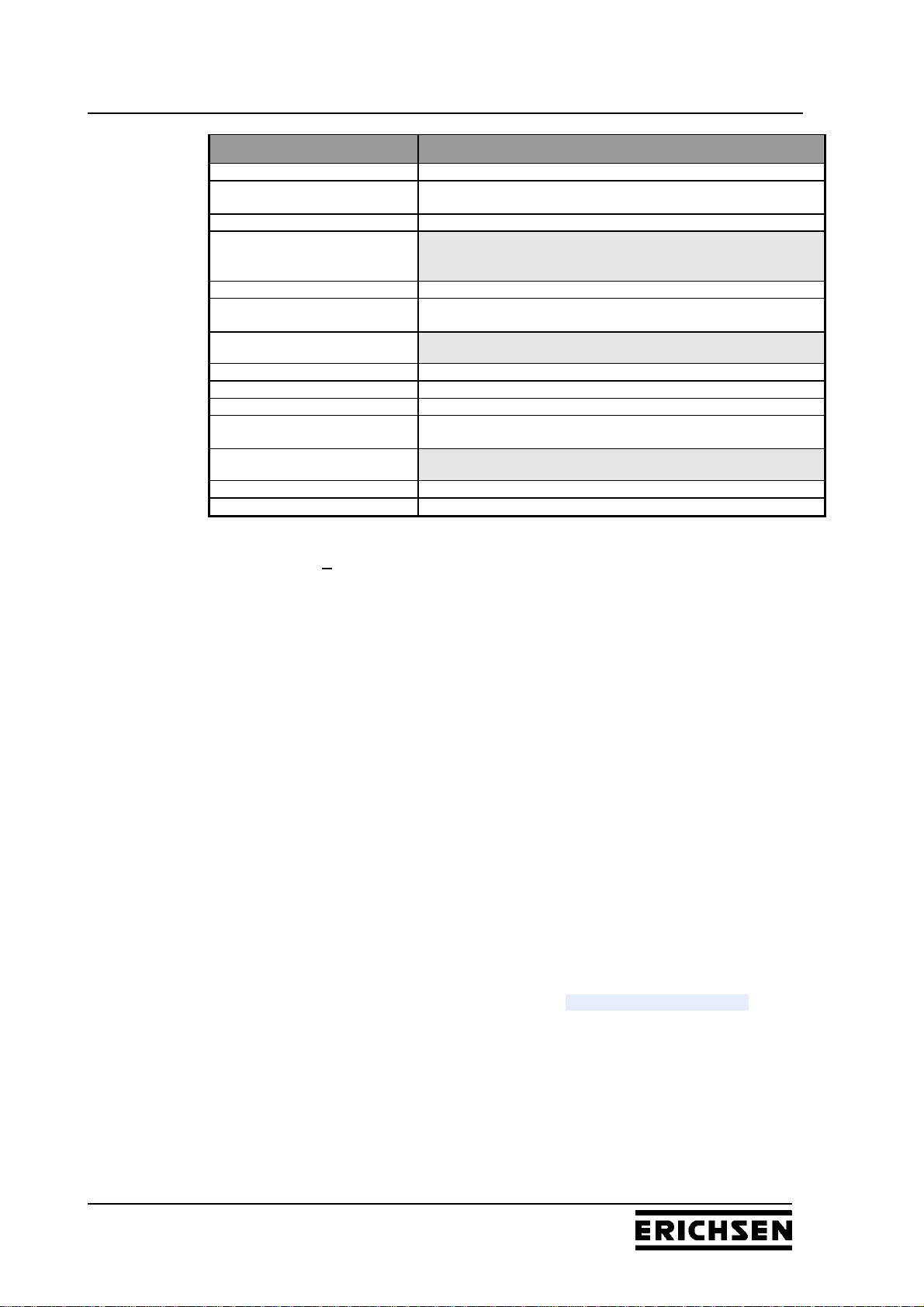

4.3 Accessories and Spare Parts

Ord.-No. Product Description

0839.01.32 Load weight (1 - 40) N

Test Tip with long shaft

915030241 Test tip acc. to Clemen (R 1.0 mm)

0693.01.32 Test tip acc. to van Laar (Ø 0.5 mm)

0842.01.32 Test tip acc. to IHD (Ø 0.6 mm)

0208.02.32 Test tip acc. to ISO (Ø 1.0 mm)

915030441 Test tip acc. to VW (3 mm/60°)

0741.01.32 Test tip acc. to (0.5 mm/90°)

0740.01.32 Test tip acc. to (1.0 mm/90°)

Equipment for MEK test

0840.01.32 MEK-Attachment

0841.01.32 Test plugs made of high dense special felt (per 100 pcs.)

0849.01.32 Test set for MEK test

0364.08.53 Crocking cloth (per 1000 pcs.)

Universal adapter set and accessories

0690.01.32 Universal Adapter Set

Spherical inserts for the clamping adapter (short

shaft without clamping device)

0539.01.32 Test tip acc. to van Laar (Ø 0.5 mm)

0539.02.32 Test tip acc. to Bosch (Ø 0.75 mm)

Scratch Hardness Tester LINEARTESTER 249 11

BAE 249

Ord.-No. Product Description

0539.03.32 Test tip acc. to ISO (Ø 1.0 mm)

0539.07.32 Test tip acc. to ISO (Ø 1.0 mm) – additionally covered with an

extremly hard layer

0539.04.32 Test tip acc. to BMW (Ø 3.0 mm)

Asymmetric inserts (short shaft with clamping

device)

0218.02.32 Test tip acc. to Clemen (R 1.0 mm)

0564.01.32 Test Tip for cross hatch cutting (30°) – additionally covered with

an extremly hard layer

Inserts (Ø 16 mm/R 0.5 mm) for the disc adapter

0430.01.32 Test discs made of Duroplast (p. 10 pcs.)

0430.02.32 Test discs made of copper (p. 10 pcs.)

0430.03.32 Test discs made of stainless steel (p. 10 pcs.)

0539.05.32 Test discs made of stainless steel, additionally covered with an

extremly hard layer (p. 10 pcs.)

Adapter for abrasion tests

0844.01.32 Squarish adapter (egde length 25 mm)

0845.01.32 Cylindrical adapter (dia. 25 mm)

4.4 Technical Data

4.4.1 Dimensions

Width: approx. 280 mm

Length: approx. 580 mm

Height: approx. 210 mm

Net weight: approx. 13 kg

4.4.2 Technical Data

Power supply: (100 - 240) VAC, (47 - 63) Hz

Power consumption: 25 VA

Scratch force: - range: (0,5 - 20) N *)

- increment: 0,5 N *)

- accuracy: 0,2 N *)

Test speed: 22/35/200 mm/s (fixed)

(20 - 200) mm/s programmable

Test distance: 60 mm

Specimen dimensions max. 150 x 210 mm (DIN A 5) **)

Length of cycles: 60/110 mm (with/without guide plate)

*)Using the 40 N load weight (optional) all force levels doubles up.

**)Only flat specimens can be tested.

4.5 Noise Level

The continuous noise level from the instrument does not exceed

<70 dB(A).

Scratch Hardness Tester LINEARTESTER 249 12

BAE 249

5. Assembly and Commissioning

5.1 Assembly of the Instrument

The Scratch Hardness Tester LINEARTASTER 249 is a table

model, which must be installed in a suitable place with normal

ambient temperature. Special fixings are not required.

To align the instrument horizontally use the four adjustable leveling

feet at the bottom of the device as well as the included spirit level.

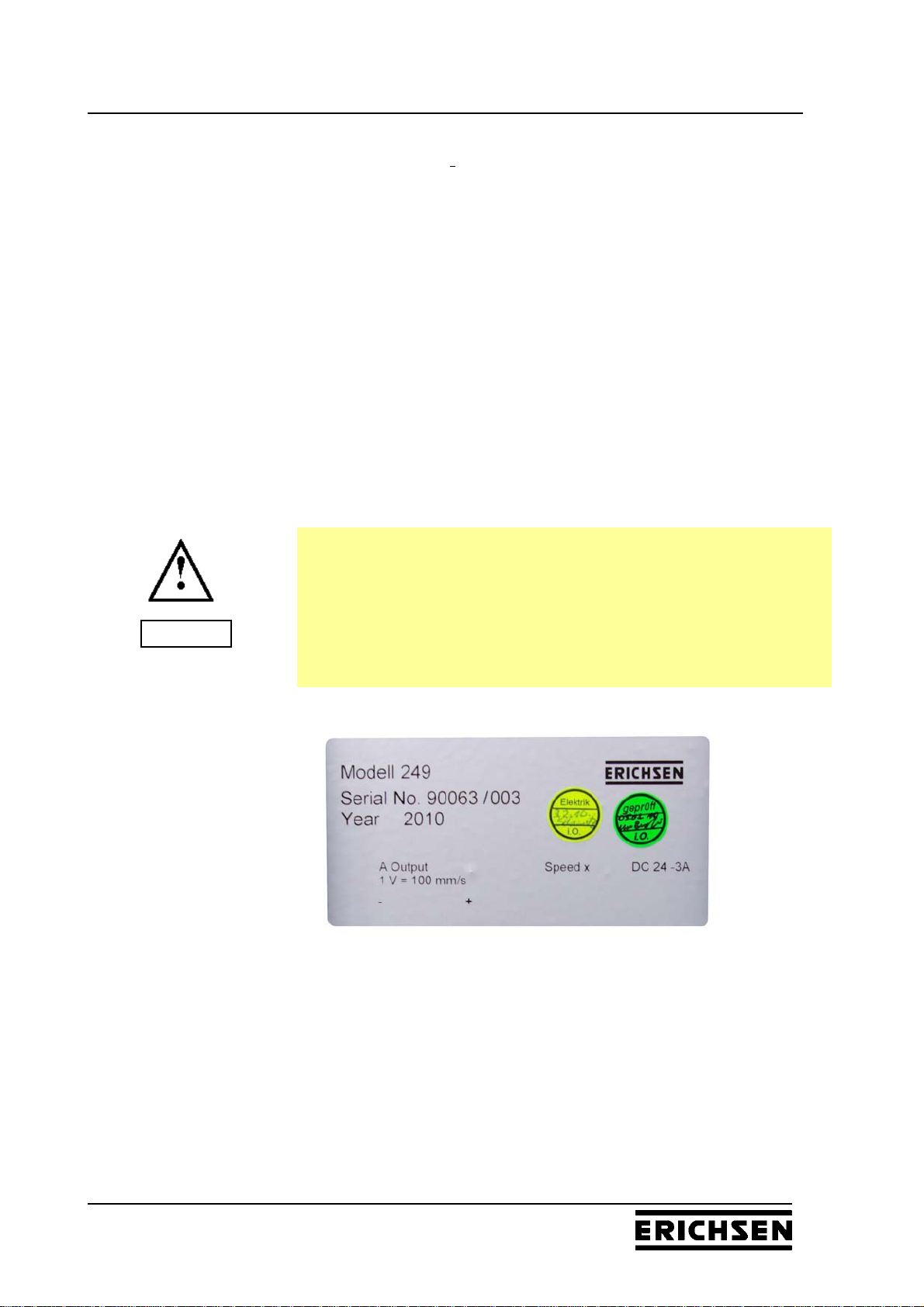

5.2 Preparation of Energy and Supply Connections

For the power supply please use the delivered power pack 24V 3A

only.

• Connect the low tension jack (c) to the instrument.

• Connect mains plug to the AC mains supply.

Prior to connecting the instrument check whether the voltage

indicated on the name plate corresponds to the local mains

voltage.

If these ratings are not compatible, the instrument should under

no circumstances be connected!

The input voltage range is 100 V AC – 240 V AC. Please make

sure that this range is not exceeded.

Attention

Scratch Hardness Tester LINEARTESTER 249 13

BAE 249

Rear panel of the housing

A out

1V=100mm/s Speed X

DC 24V-3A

+

-

LINEARTESTER 249

a Potentiometer for speed setting

b Analogue output

c Low tension jack

The analogue output (b) consists of two telephone jacks (black =

pole / red = +pole).

The analogue output is short-circuit proof and must be connected to a

commercial digital voltmeter <2% and an input resistance >

1 MOhm. Adjust the measuring range to 2 V DC (direct current).

The test weight with the test tip must be lifted safely.

Set the preselection counter to a value of >50 strokes to have time

enough available for the adjusting procedure.

Reasonable values for the speed are recommended in the range of

10 mm/s to 190 mm/s (resolution: 1 V – 100 mm/s; medium test

speed with an accuracy of ±2.5 %.

The 15-gear potentiometer (a) serves for the setting of the speed.

With the help of a calibration screw driver and the reading of the

proportional analogue output voltage it is possible to adjust the speed

simply and precisely.

b a c

Scratch Hardness Tester LINEARTESTER 249 14

BAE 249

5.3 Control elements

1 Main switch EMERGENCY-OFF

2 Slide

3 Test tip

4 Limit stop / Movable clamping bar

5 Counterpoised lever with scale

6 Taring weight

7 Weight block with locking screw

8 Weight of 0.5 N

9 Fastening screw for test tip

10 Clamp screw for fixing the test panel

11 Setting test speed

12 LED display

13 Start key

14 Visual through-cutting signal

15 Scratch guide plate

16 Scratch depth adjusting groove

17 Rest position of sliding guide ball

18 Sliding guide ball

19 Ruler

Scratch Hardness Tester LINEARTESTER 249 15

BAE 249

1 2

3

4 5

6

7

8

9

10

11

12

13

14

19

18

16

15

17

Scratch Hardness Tester LINEARTESTER 249 16

BAE 249

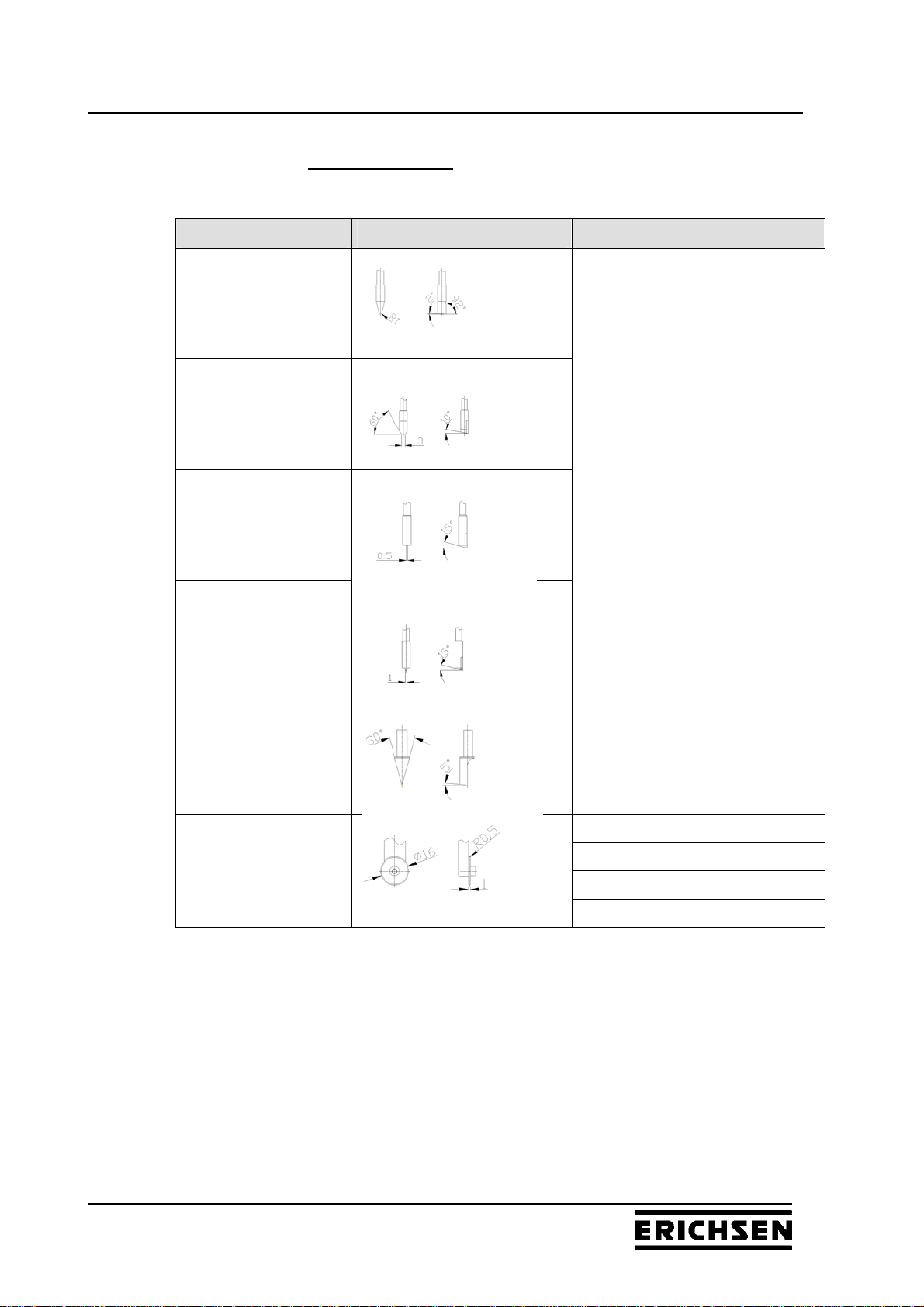

6. Performance of the Scratch Tests

6.1 Selection of Test Tools

For the performance of scratch hardness tests with the

LINEARTESTER 249 following test tools are available:

Spherical Inserts

Description Test geometry Material

test tip

acc. to van

Laar 1) 2)

test tip

acc. to IHD 1)

carbide insert

test tip

acc. to Bosch 2)

test tip

acc. to ISO 1) 2)

carbide insert *)

test tip

acc. to BMW 2)

hardened

steel

*)additionally covered with an extremly hard layer

1) long shaft, directly assembled

2) short shaft, only for using with the adapter set

3) only for using with the disc adapter of the universal adapter set

Scratch Hardness Tester LINEARTESTER 249 17

BAE 249

Asymmetric Inserts

Description Test geometry Material

test tip

acc. to

Clemen 1) 2)

test tip

acc. to VW 1)

carbide insert

test tip

acc. to

Sikkens 1)

test tip

acc. to

Sikkens 1)

test tip for

cross hatch cutting 2)

hardened

steel *)

duroplast

copper

stainless steel

test disc

acc. to

Oesterle 3)

stainless steel *)

*)additionally covered with an extremly hard layer

1) long shaft, directly assembled

2) short shaft, only for using with the adapter set

3) only for using with the disc adapter of the universal adapter set

Scratch Hardness Tester LINEARTESTER 249 18

BAE 249

Fig. 1

Fig. 2

Fig. 3

Fig. 4a

Fig. 4b

6.2 Single Scratch Test

Loosen clamp screw (10) for fixing the

specimen and draw it backwards.

Loosen movable clamping bar/ limit stop (4) and

draw it backwards (if desired, tighten it in this

position or in any other). (Fig. 1)

Place test panel onto the slide (2) and push it

against the clamping bar / limit stop (4). (Fig.2)

Fix test panel with the clamp screw for fixing the

specimen (10). (Fig.3)

Place weight block (7) into zero position and fix

it with the locking screw. (Fig. 4a/4b)

Scratch Hardness Tester LINEARTESTER 249 19

BAE 249

Fig. 5

Fig. 6

Fig. 7a

Fig. 7b

Fig. 8

Move the weight of 0.5 N (8) to the right into

the zero position (clicks into place behind).

(Fig.5)

Insert test tip (3), according to the correct

direction of effect, into the corresponding holder

in the counterpoised beam (5) and fix it slightly

with the fastening screw (9). (Fig.6)

Then set the sliding guide ball (18) into the

scratch depth adjusting groove (16) of the

scratch guide plate (15).

At this the fastening screw (9) must be loosened

again, so that the test tool rests on the test

panel. (Fig. 7a)

Now tighten the fastening screw (9) finally.

(Fig.6)

Then lift the counterpoised lever (5) for a

moment using the fastening screw (9) and

replace it immediately.

At this the sliding guide ball (18) automatically

jumps from the scratch depths adjusting groove

(16) into the rest position (17) of the guide plate

(15). (Fig.7b)

The tip of the test tool (3) is now located in a

“pending / resting position” just over the test

panel.

Adjust the position of the taring weight by

turning so that the weight of the test tip (3) is

compensated and the counterpoised lever (5)

shows already a corresponding upward trend

when it is slightly touched. (Fig. 8)

Scratch Hardness Tester LINEARTESTER 249 20

BAE 249

Fig. 9a

Fig. 9b

Fig. 10

Fig. 11a

Fig. 11b

Fig. 11c

Now set the required test force by moving the

weight block (7) along the scale on the

counterpoised lever (5) (steps of 1 N).

(Fig. 9 a/9b)

By moving the weight of 0.5 N (8) to the left

into the first catching position the test force is

increased by 0.5 N, when moving further into

the next catching position by totally 1 N.

(Fig. 10)

Now push the left arrow key under the display

(12) until “P” (programme/preset) appears on

the left side of the display. (Fig. 11a)

Then set the number „1“ (= 1 double stroke

cycle) using the left and the right key. (Fig. 11b)

Now push the left key again so that „C“(cycles

completed) instead of „P“ appears on the left

side of the display.(Fig. 11c)

(see page 25 – Operation of the preselection counter)

Table of contents

Other ERICHSEN Test Equipment manuals