Aquila RE80 User guide

DIP - DRY ICE PRODUCTION

Aquila Triventek A/S · Industrivej 9 · DK-5580 Noerre Aaby · Tel. +45 70 22 12 92 · [email protected] · www.aquila-triventek.com

ORIGINAL

Instruction manual for

By Aquila Triventek

Recovery unit RE80

DIP - DRY ICE PRODUCTION

Aquila Triventek A/S · Industrivej 9 · DK-5580 Noerre Aaby · Tel. +45 70 22 12 92 · [email protected] · www.aquila-triventek.com

2

1 INTRODUCTION 4

1.1 What is dry Ice? 4

1.2 Recovery unit 4

2 SAFETY 4

2.1 Safety data for Carbon Dioxide (CO2) 4

2.2 Safety data for Recovery unit RE80 6

3 EQUIPMENT FOR OPERATION 7

3.1 Delivery 7

3.2 Delivered equipment 7

3.2.1 IdenticationofmaincomponentsinRecoveryunitRE80 8

3.3 Connection of the equipment 12

3.3.1 Power supply 12

3.3.2 Connecting the hoses 12

4 OPERATING LIMITATIONS 13

5 OPERATING THE EQUIPMENT 13

5.1 Operation panel 14

5.2 Pressure gauge panel 15

5.2.1 Normal gauge readings during operations 15

5.2.2 Liquid CO2 detector and reservoir 15

5.2.3 Automation 16

5.2.4 Power supply and control protection system 16

5.2.5 Pressure protection system 16

5.2.6 Main menu structure 17

5.3 Starting up the RE80 18

5.3.1 Stopping the RE80 19

6 ALARM MESSAGES 20

6.1 Emergency stop 20

Phase sequence protection 20

CO2 compressor protection 20

CO2 fan protection 21

Toomuchoilinlter 21

Low oil level 21

High temperature 1st stage 22

High temperature 2nd stage 22

Table of contents

DIP - DRY ICE PRODUCTION

Aquila Triventek A/S · Industrivej 9 · DK-5580 Noerre Aaby · Tel. +45 70 22 12 92 · [email protected] · www.aquila-triventek.com

3

6 ALARM MESSAGES 20

6.2 Cooling 22

Cooling compressor protection 22

Cooling internal protection 23

Cooling fan protection 23

Cooling low pressure 23

Cooling high pressure 24

Cooling compressor oil diff. switch 24

7 MAINTENANCE 25

7.1 Main intervals 25

7.2 Oillter 25

7.3 InspectionandrellofCO2 compresor oil 26

7.3.1 HowtorellCO2compressor oil ??

7.3.2 How to drain CO2compressor oil ??

7.4 CO2 pressure and venting 29

7.5 Maintenance and inspection of refrigeration system 30

7.5.1 Insufcientrefrigiration 30

7.5.2 Refrigerant condensation high pressure 30

7.5.3 Refrigerant evaporation low pressure 31

7.5.4 InsufcientheattransmissionintheCO2 condenser 31

7.5.5 Solution for improving heat transmission in the CO2 condenser 32

8 CLEANING THE EQUIPMENT 32

9 STORAGE 32

10 RECOMMENDED SPARE PARTS LIST 33

11 TROUBLESHOOTING 36

12 TECHNICAL DATA 39

12.1 Proporties of carbon dioxide 40

12.2 Electrical charge 41

12.3 Safetypartsidentication ??

13 EC DECLARATION OF CONFORMITY 56

14 GUARANTEE 57

15 DELIVERY REPORT 58

Table of contents

DIP - DRY ICE PRODUCTION

Aquila Triventek A/S · Industrivej 9 · DK-5580 Noerre Aaby · Tel. +45 70 22 12 92 · [email protected] · www.aquila-triventek.com

4

1 Introduction

We are pleased that you have chosen the Recovery Unit RE80 by Aquila Triventek A/S for your company. The recovery

RE80 is especially designed to be connected to the Aquila Triventek Dry Ice Pelletizer type PE80, and cannot be used for

other purpose.

This technology is the subject of a Patent application No. 0408224.4.

To obtain long and trouble-free operation of the equipment we recommend reading this manual carefully. All new opera-

tors of the equipment should also familiarize themselves with the content of this document.

1.1 What is Dry Ice?

Carbon dioxide is a chemical compound formed by combining one atom of carbon with two atoms of oxygen and is

expressed by the chemical symbol CO2. It can exist in three states: as gas, as liquid or as a solid.

Dry ice is frozen carbon dioxide (CO2). The unique property of carbon dioxide is that at normal, atmospheric pressure

and temperature, it changes state directly from solid to gas without going through a liquid phase.

This process, called sublimation, makes the ice ‘dry’ and is exploited both for blast cleaning and for cooling. Dry ice

isstableat(minus)-79C,atatmosphericpressure.Itexpandsupto800timesbyvolumewhenitsublimes,andthis

property is exploited in the blast cleaning application.

1.2 Recovery Unit

Normal dry ice production uses liquid CO2which when brought to normal atmospheric pressure, in e.g. a pelletizer

converts to one half snow and one half gas, called ‘revert’ gas. The snow is then compressed into dry-ice pellets.

But, by using the RE80 Recovery Unit, the revert gas, which is usually lost into atmosphere, is collected and recycled to

make more pellets. This becomes a continuous process and, as a result, will reduce production costs by up to 50%.

2 Safety

2.1 Safety data for carbon dioxide (CO2)

Hazardsidentication

Liquid carbon dioxide is stored in pressure vessels and must be handled according to the vessel manufacturers´ and the

carbon dioxide suppliers´ instructions.

1. Precautions must also be taken when mounting and dismounting the hose for liquid carbon dioxide. The liquid

may be under pressure and could spray into the surrounding area, forming dry ice and causing frostbite and eye

damage.

2. Be careful if a liquid CO2hose is blocked by dry ice. The pressure behind the dry ice blockage will rise due to evapo-

ration of liquid CO2. A powerful blast will occur when the blockage breaks. DO NOT dismount a hose if it is blocked,

or if it is suspected to be blocked by dry ice. Loosen the connection slightly so that gas can escape. Leave the hose

until the blockage is evaporated.

DIP - DRY ICE PRODUCTION

Aquila Triventek A/S · Industrivej 9 · DK-5580 Noerre Aaby · Tel. +45 70 22 12 92 · [email protected] · www.aquila-triventek.com

5

Solid

Contactwithproductmaycausecoldburnsorfrostbiteduetothelowtemperatureat(minus)-79C.

(-110F).

Solid dry ice sublimes into gas. This can cause pressure to build up in e.g. a container which is not suitably vented.

First aid measures

Ifcontactwitheyes:immediatelyusheyesthoroughlywithwaterforatleast15minutes.

In case of frostbite, spray with tepid water for at least 15 minutes. Apply a sterile dressing.

Obtain medical assistance.

Inhalation of sublimated CO2(gas)

CO2is heavier than air and may accumulate to hazardous levels in an unventilated enclosed area such as a small room,

tank, silo or pit. Always ensure adequate natural or mechanical ventilation or breathing apparatus in any hazardous area

such as a tank, silo or pit.

CO2is odourless therefore use always a CO2detector in working areas.

Low concentrations of CO2cause increased respiration and headache.

In high concentrations carbon dioxide gas can cause asphyxiation by displacing the oxygen required for breathing.

Symptoms may include loss of mobility or consciousness. Victim may not be aware of asphyxiation.

First aid measures

Remove victim to uncontaminated area, the rescuer should wear breathing apparatus e.g. an emergency breathing air

bottle and mask to ensure that he/she does not also fall victim to asphyxiation. Keep victim warm and rested. Call a

doctor.Applyarticialrespirationifbreathinghasstopped.

Exposure controls / personal protection

Exposure limit: 5000ppm

The normal concentration of CO2in the atmosphere is 300ppm.

Personal protection: Protect eyes, face and skin from contact with solid product. Protect skin, especially hands,

from cold by wearing insulated gloves.

Training

The hazard of asphyxiation can be overlooked and must be stressed during operator training. Before using dry ice in

any new process or experiment, a thorough material compatibility and safety study should be carried out.

Ensure all national / local regulations are observed. The European Industrial Gas Association (EIGA), see www.eiga.org/,

provides useful background material and guides to good practice.

DIP - DRY ICE PRODUCTION

Aquila Triventek A/S · Industrivej 9 · DK-5580 Noerre Aaby · Tel. +45 70 22 12 92 · [email protected] · www.aquila-triventek.com

6

2.2 Safety data for Recovery Unit RE80

Always use the following safety precautions:

Breathing apparatus

Wheresufcientventilation,eithernaturallyorbymechanicalmeans,can-

not be provided then a suitable supply of breathing air should be arranged.

It is also recommended that an emergency breathing air bottle and mask be

provided in the vicinity of any carbon dioxide operations. The emergency

apparatus is for use by the rescuer in case of any incapacitation of a person

in an area where carbon dioxide has accumulated and could cause asphyxia-

tion to the rescuer.

System under pressure

Become aware that some part of the system is under pressure during opera-

tion. Do not disconnect hoses when pressurized.

Inhalation of vaporized CO2

Ininsufcientlyventilatedrooms,anincreasedconcentrationofCO2might

leadtobreathingdifcultiesaswellastosuffocation.Alwaysensureasup-

ply of fresh air in enclosed rooms. A CO2detectorshouldbeusedtoconrm

safe conditions. Where necessary, use a breathing mask with suitable fresh

air supply.

As CO2gas is heavier than air, please be aware of CO2build-up in lower working areas.

DIP - DRY ICE PRODUCTION

Aquila Triventek A/S · Industrivej 9 · DK-5580 Noerre Aaby · Tel. +45 70 22 12 92 · [email protected] · www.aquila-triventek.com

7

3 Equipment for operation

3.1 Delivery

Transport

After the Recovery Unit RE80 has been delivered, it must be checked for damage which may have occurred during

transport. If necessary, the transport company must be informed to register the damage. Check that all parts described

on the delivery note have been delivered.

3.2 Delivered equipment

The Recovery Unit RE80 by Aquila Triventek consists of the following items:

RecoveryUnitRE80withbuildcondensingunit

OnecompleteconnectionhoseRecoveryUnitRE80andPelletizerPE80consistingof:

1x5mof25mminsulatedhoseforCO2gas

1x5mof16mminsulatedhoseforliquidCO2

1x5mof16mminsulatedhoseforpressurecompensation

1x5controlcable.Cat5patchcable

The Recovery Unit RE80 and must be handled carefully to avoid shock damage to mechanical and electrical

components.

DIP - DRY ICE PRODUCTION

Aquila Triventek A/S · Industrivej 9 · DK-5580 Noerre Aaby · Tel. +45 70 22 12 92 · [email protected] · www.aquila-triventek.com

8

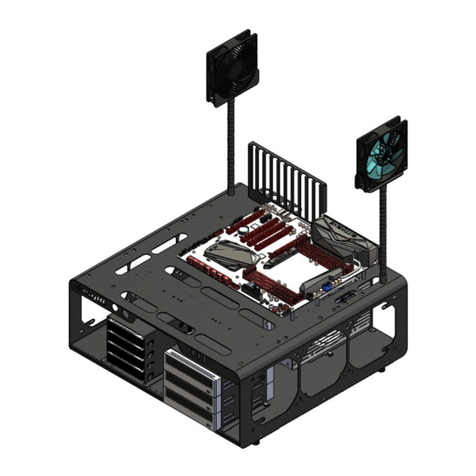

3.2.1Identicationofmaincomponentsinrecoveryunit

2RE80008 RE80004

RE80009

RE80015

RE80012

RE80017 RE80013

1

1: First stage CO2 Compressor / FK 30/32,5K - 22400001

2: Second stage CO2 compressor / FK 20/245N - 22400002

3: Plug housing

4: Female socket

N.B.:ForreferencetotheRE-numberspleaseseePartsIdenticationforRE80

DIP - DRY ICE PRODUCTION

Aquila Triventek A/S · Industrivej 9 · DK-5580 Noerre Aaby · Tel. +45 70 22 12 92 · [email protected] · www.aquila-triventek.com

9

12

5

4

3

1: St.1 motor 7,5kW 50/60Hz 44010132

2: St.2 motor 4kW 50/60Hz 22103008

3: CO2 Gas cooler 36359484

4: Filterhousing -----------

5: Complete refrigiation unit condenser Bitzer 36329626

N.B.:ForreferencetotheRE-numberspleaseseePartsIdenticationforRE80

DIP - DRY ICE PRODUCTION

Aquila Triventek A/S · Industrivej 9 · DK-5580 Noerre Aaby · Tel. +45 70 22 12 92 · [email protected] · www.aquila-triventek.com

10

3

1

RE80009 RE80006

RE80015RE80010

1: CO2 Gas cooler 36359484

2: Solenoid valve EVR6 34439301

Solenoid coil 230V AC

3: Check valve NRV16 34739502

N.B.:ForreferencetotheRE-numberspleaseseePartsIdenticationforRE80

2

DIP - DRY ICE PRODUCTION

Aquila Triventek A/S · Industrivej 9 · DK-5580 Noerre Aaby · Tel. +45 70 22 12 92 · [email protected] · www.aquila-triventek.com

11

1 2

9

14

3

10

15

4

11 10

16 19

5

1G 3G

17 5G

6

12 13

18 20

21

7

1: Transformer protection 4-6,3A

2: Motor protection 10-16A

3: Motor protection 6,3-10A

4: Motor protection 0,4-0,63A

5: Motor protection 16-20A

6: Motor protection 4-6,3A

7: Relay for moto protection

9: Soft starter 15A

10: Contractor 3Kw

11: Contractor 7,5 Kw

1G: Contractor DILA-XHI40 for DILM7-01

12: Relay for contractor

3G: EKC315A Regulator

13: Phase monitoring relay

14: Main PLC controller

15: EPROM for PLC controller

16: Slave module

17: 1p solid state relay 24VDC/230V

18: 1p 240VDC interface relay

19: PT1000 to 4-20mA converter

5G: Transformer

20: Power supply 24VDC

21: Terminal fuse plug

DIP - DRY ICE PRODUCTION

Aquila Triventek A/S · Industrivej 9 · DK-5580 Noerre Aaby · Tel. +45 70 22 12 92 · [email protected] · www.aquila-triventek.com

12

3.3 Connection of the equipment

3.3.1 Power supply

TheRE80isdeliveredwitha63Ampcablewithoutplug.Theplughastobemountedlocallytotlocalsocket-design.

Take of the side cover and pull the cable with box out under the frame and connect to your own power supply.

Remember to turn of the main switch before applying power to the unit.

3.3.2 Connecting the hoses (RE80 + PE80 pelletiser)

TheconnectorsaredifferentforeachhoseandwillonlytintotherightconnectionsattheRecoveryUnit,andatthe

Pelletizer.

Always ensure that the hoses are arranged as straight as possible i.e. with easy radius bends and avoiding kinks which

mayincreasepressuredrop,orevenstopow.

Connection table:

1: 3/8” BSP Pressure equalisation from pelletizer (only for PE80 pelletizer)

2: 1/2” BSP Liquid CO2 to pelletizer

3: 1/2” BSP Liquid CO2 from tank (only with PE80 pelletizer)

4: 1 1/2” cam male CO2 revert gas from pelletizer

5: 1” cam male Buffer tank

6: Pressure relief

7: Main electrical power supply cable

1 6

54

2 73

DIP - DRY ICE PRODUCTION

Aquila Triventek A/S · Industrivej 9 · DK-5580 Noerre Aaby · Tel. +45 70 22 12 92 · [email protected] · www.aquila-triventek.com

13

4. Operating limitations

RE80 unit

• Forastandardcongurationmachine,thesurroundingworkingtemperatureshouldbebetween-25°Cand40°C.

(-13°F-104°F)

• Themachineshouldneverbestoredinanambienttemperatureexceeding50ºC.(122°F)

• When choosing a location for the Recovery Unit RE80, the room must be dry, clean and well ventilated.

• MakecertainthattheRecoveryUnitRE80isplacedonahorizontalplanewithamaximumslopeof2°C

• It is not recommended to locate the Recovery in dusty and/or dirty surroundings. The CO2gascoolingcoilnscan

be covered with dirt the performance of the Recovery will be reduced.

• The perforated holes at the opposite side of the electrical box is the air intake for the CO2cooler. Exhaust for CO2

cooler is located on the right hand side of the electrical box. The air intake and exhaust must have at least 2meters

offreespacetoanywallsinordertosecuresufcientairowandcooling.

Condensing system

• Themin./max.ambienttemperaturesfortheCondensingunitis-25°Cto40°C(-13°Fto104°F)atnormalair

humidity.

• Theunitshouldneverbestoredinanambienttemperatureexceeding50°C

• The unit must be protected against direct sun and rain

• Airowthroughthecondensercoilisapprox.7300m³/handrequiresawell-ventilatedroomorfacility.Iftheairow

isrestrictedthecoolingcapacitywilldecreaseasabove(2%per1°C).

• Thefoundationmustbesolidandaslevelaspossible.Max.slope2°.

• The unit is only designed to operate with R404A refrigerant. Any other refrigerant can damage the compressor and

inuencethecapacity.

Also read the Aquila Triventek “Installation guide & data sheet” before installation and start-up of the system

5. Operating the equipment

The Recovery Unit RE80 can only be used in the conjunction with the Pelletizer PE80 and no other equipment.

Use the Recovery Unit RE80 only for the designed purpose and follow the guidelines described in this manual.

DIP - DRY ICE PRODUCTION

Aquila Triventek A/S · Industrivej 9 · DK-5580 Noerre Aaby · Tel. +45 70 22 12 92 · [email protected] · www.aquila-triventek.com

14

5.1 Operation panel

The operation panel at the front of the RE80 includes the following functions:

1 2 3 4

Buttons:

1: Display

2: Manual start button

3: Manual stop button

Indicator lamps

4: Emergency stop button

DIP - DRY ICE PRODUCTION

Aquila Triventek A/S · Industrivej 9 · DK-5580 Noerre Aaby · Tel. +45 70 22 12 92 · [email protected] · www.aquila-triventek.com

15

5.2 Pressure gauge panel (from left)

1. Refrigeration Condensing Pressure

Freon pressure in the condensing unit

2. Refrigeration Evaporation Pressure

Evaporation pressure in refrigerant unit

3. CO2 Gas pressure from pelletizer

4. CO2 Gas pressure

Pressure after 1st stage compression

5. CO2 Gas high pressure

Pressure after 2nd stage compression

5.2.1 Normal gauge readings during operations

These are the readings you would expect to see after the Recovery has cooled down and commenced stable operation

(after 10-15 minutes)

Refrigeration Condensing Pressure: Between 13 and 22 bar.

Refrigeration Evaporation Pressure: Between 1 and 2 bar.

CO2 Gas Pressure from Pelletizer: Between 0,1and 0,8 bar.

Pressure after 1st stage compression: Between 4 and 5 bar.

CO2 High Pressure: Between 16 and 19,5 bar.

5.2.2 Liquid CO2detector and reservoir

TheliqueedCO2owstoasmallreservoircontainingalevelsensor.Thelevelsensorgivesasignaltothecontrol

system when liquid CO2is detected and a red light shows. The green light indicates that the level detector is electrically

connected.

Function:

Green light = Liquid

Green + yellow light = No Liquid CO2

DIP - DRY ICE PRODUCTION

Aquila Triventek A/S · Industrivej 9 · DK-5580 Noerre Aaby · Tel. +45 70 22 12 92 · [email protected] · www.aquila-triventek.com

16

5.2.3 Automation

The following operations and features are automated

5.2.4 Power supply and control protection system.

A voltage monitoring relay in the panel stops the recovery and lights up the electrical failure lamp on the panel. The relay

switches off if the voltage is too low, the phases order is wrong or a phase is missing.

The Recovery can only run if the pelletizer is producing. The recovery stops instantly if the stop button on the pelletizer is

activated.

5.2.5 Pressure protection system.

The recovery will only run if the 1” gas hose from the pelletizer is pressurized (0.1-0,8 bar (1.45-8.7 Psi)). The pressure is

constantly measured in order to prevent air from entering the Recovery. When the pressure drops to 0,1 bar, the internal

pressure relief is opened in order to keep the unit running (in case some small disturbance between the pelletizer and

Recovery takes place).

When the pressure drops down to 0,0 bar the CO2 compressors stop after 60 seconds. Message “CO2 INLET LOW” shows

on the display. The refrigeration part in the unit keeps working for maximum 30 minutes. If the pressure will rise back

the unit will start automatically (immediately if the refrigeration part was still running or after few minutes if the whole

machine was stopped (see the starting and stopping sequence described page 18-19).

If the pressure rises above 0,8 bar, the AV304 valve is opened in order to drop the CO2 gas. When the pressure keeps

rising and reaches 1,0 bar, second valve - AV302 – opens in order to lower the pressure.

DIP - DRY ICE PRODUCTION

Aquila Triventek A/S · Industrivej 9 · DK-5580 Noerre Aaby · Tel. +45 70 22 12 92 · [email protected] · www.aquila-triventek.com

17

5.2.6 Main menu structure - RE80 UNI PLC

For detailed explanation on error messages go to page 20-24

RUN

HOUR COUNT...

COOLING COND.

PRESSURE ... BAR

COOLING EVAP.

PRESSURE ... BAR

CO2 GAS PRESSURE

... BAR

CO2 HIGH PRESSURE

... BAR

BRIGHTNESS

<DOWN UP>

DIP - DRY ICE PRODUCTION

Aquila Triventek A/S · Industrivej 9 · DK-5580 Noerre Aaby · Tel. +45 70 22 12 92 · [email protected] · www.aquila-triventek.com

18

5.3 Starting up the Recovery Unit RE80

• Check equipment visually before starting to ensure that all hoses and cables are properly connected.

• Ensure that main power has been turned on for min.2 hours

• If “STOP” status shows on the display push the green “ON” button – the status should change for “WAIT”

• As soon as pelletizer starts running and revert gas pressure exceeds 0,2bar, the start-up sequence is initiated

on the Recovery Unit. Some blow-off will occur until the Recovery has stabilized (ab 60 seconds). After that

time message “READY” will show on the display.

The unit can be started manually by pressing the “ON” button or if not then it will start automatically after 5

minutes. During production some minor intermediate blow-off can occur due to variations in production, high

surrounding temperatures or too big pelletizer capacity compared to the Recovery capacity.

Caution!

At start up after more than 3 hours stand still the power has to be turned on for min. 2 hours due to the crankshaft

heating in the Cooling unit of the RE80. Any attempt to start earlier will damage the compressor of the Cooling unit.

DIP - DRY ICE PRODUCTION

Aquila Triventek A/S · Industrivej 9 · DK-5580 Noerre Aaby · Tel. +45 70 22 12 92 · [email protected] · www.aquila-triventek.com

19

5.3.1 Stopping the Recovery Unit RE80

Stopping without depressurising the system.

The Recovery and pelletizer can be stopped at any time. It is not advisable to switch off the power or use the emer-

gencystopbuttonwithoutrstemptyingtheRecoveryofliquidCO2. The liquid CO2will evaporate through the safety

valve. The purpose of the safety valve is to protect the Recovery and the surroundings against damage caused by too

high CO2pressure. The safety valve is not supposed to be used regularly. If the power is switched on the CO2vapour

will evacuate through the blow-off solenoid valve.

Note: The Recovery Unit, Pelletizer and the hoses are under pressure. DO NOT attempt to disconnect any hoses

before depressurising.

Depressurising the system before stopping.

1. Close liquid CO2valve at vessel.

2. The pelletizer and CO2part of the Recovery stops automatically after a short time from the moment when

the supply of liquid from the tank has been closed. The cooling unit in the Recovery will continue to work for

maximum 30 minutes. Either it will shut down automatically anytime during the 30 minutes period or it can be

manually shut down by pressing the “OFF” (red) button.

CAUTION : After manual shut – off (by pressing the OFF button) the unit will not restart automatically. The status

“STOP” will be displayed on the panel. If the “OFF” button will not be pressed, the Recovery will also shut down

automatically with “C02 INLET LOW” message on the display, but it is possible that the unit will try to restart

several times.

3. Now it is possible to disconnect the depressurised hoses.

Note: Some overpressure must be expected. Disconnect with caution.

Depressurising the system if there is a power failure.

1. Close liquid CO2valve at vessel.

2. The automatic valve system of the PE80 will ensure that close-down and depressurisation will commence

correctly.

3. WAIT until the pressure has dropped (no more gas coming out).

4. Now it is possible to disconnect the depressurised hoses.

DIP - DRY ICE PRODUCTION

Aquila Triventek A/S · Industrivej 9 · DK-5580 Noerre Aaby · Tel. +45 70 22 12 92 · [email protected] · www.aquila-triventek.com

20

6 Alarm messages

EMERGENCY STOP

PHASE SEQUENCE

PROTECTION

CO2 COMPRESSOR

PROTECTION

Release the emergency stop on the recovery.

See page 14 picture 5.1-4

Press “ OFF “ to clear the error

Check if all 3 phases in the recovery

See page 11

Try to change two phases

See page 12 picture

Press “ OFF “ to clear the error

Check the settings and status on the motor protection in the

electrical box.

See page 11

Press “ OFF “ to clear the error

Table of contents

Other Aquila Test Equipment manuals

Popular Test Equipment manuals by other brands

Extech Instruments

Extech Instruments VT30 user guide

EXFO

EXFO CT440 Series user guide

Tektronix

Tektronix 2230 Operator's manual

Microchip Technology

Microchip Technology CSIII user guide

Agilent Technologies

Agilent Technologies 16034H manual

Ecom Instruments

Ecom Instruments Magnet-Ex 12 operating instructions