ERKO HG200 Quick start guide

Producent / Producer / Производитель

Zakłady Metalowe ERKO R. Pętlak spółka jawna

Bracia Pętlak

ul. Ks. Jana Hanowskiego 7, 11-042 JONKOWO k/OLSZTYNA

tel./fax (+48) 089 5129273 NIP: 739-020-46-93

OPERATIONAL MANUAL

BUSBAR BENDING STATION

HG200

# VHG200020614

- 1 -

#VHG200020614

Thank you for purchasing our station.

Please read this operation manual and operation recommendations carefully.

TABLE OF CONTENTS

1. APPLICATION ....................................................................................2

2. TECHNICAL DATA.............................................................................2

3. STATION INSTALLATION .................................................................2

4. CONTROL PANEL..............................................................................3

5. OPERATION .......................................................................................4

5.1 START.................................................................................................4

5.2 WARRANTY PERIOD START............................................................5

5.3 BENDING ............................................................................................6

5.3.1 MEASURING SYSTEM RESET..........................................................7

5.3.2 OPERATING PARAMETERS AND INSERT CALIBRATION............9

5.3 CUTTING...........................................................................................10

5.4 CHANGE OF INTERFACE LANGUAGE..........................................11

5.5 COUNTER OF THE STATION RUNNING TIME AND DATE OF THE

NEXT INSPECTION ..........................................................................11

5.6 DATE AND TIME SETTING..............................................................12

6 TECHNOLOGY.................................................................................13

6.1 BENDING ..........................................................................................13

6.1.1 EQUIPPING THE BENDING STATION............................................13

6.2 CUTTING...........................................................................................16

6.2.1 EQUIPPING THE CUTTING STATION ............................................17

7 MAINTENANCE AND OPERATION RECOMMENDATIONS..........20

7.1 HYDRAULIC POWER PACK............................................................21

7.2 OPERATION AND MAINTENANCE.................................................23

7.3 MESSAGES.......................................................................................25

8 HEALTH AND SAFETY AT WORK INSTRUCTION.......... BŁĄD! NIE

ZDEFINIOWANO ZAKŁADKI.

9 SERVICE...........................................................................................28

10 DISPOSAL ..........................BŁĄD! NIE ZDEFINIOWANO ZAKŁADKI.

* Due to continuous product improvement, ERKO sp.j. reserves the right to make

design changes.

ISO 9001

ISO 14001

# VHG200020614

- 2 -

Please read the operation manual and health and safety at

work regulations before using the station.

The station is only used for operation with Al and Cu

busbars.

1. APPLICATION

HG200 is the busbar processing station with electronic angle measurement, equipped

with a touch panel. The basic functional features ensuring efficient and precise

operation are:

Possibility to adjust a bending angle within the range of 5-90° (bending

accuracy ±0.5°);

Engraved measuring ruler that enables a processed busbar to be positioned

with accuracy of 1 mm;

Control of processes with the foot switch;

Built-in reliable hydraulic power pack.

2. TECHNICAL DATA

Station weight

460 kg

Max. dimensions (L x W x H)

1226 x 1200 x 1240

Operating pressure

400 bar

Power supply

3x400/230 V 50 Hz, 1.68 kW

Control

24V DC

Power plug

16A 400V 3P N+E IP44(PCE

015-6v)

Protection degree

IP40

Range of processed busbars (Cu, Al) (TH x W)

Thickness: 5÷15; width:

50÷200 mm

Bending range

5÷90°

Operating temperature

5÷40 °C

3. STATION INSTALLATION

The station should be positioned on the hard and even surface and levelled.

The adjustable levelling feet make the station levelling easy. When the station

is positioned, please pay attention that the station rests securely on all 4 feet.

# VHG200020614

- 3 -

Use of the station on an inadequate surface may result in the station frame

deformation and problems during processing of busbars (in achieving the

accuracy offered by the manufacturer). In extreme cases, failure to follow the

above may result in the station damage.

Connect the station to the power supply system. The power supply system

parameters should be in accordance with the applied standards. A five

conductor power cable (L1, L2, L3, N, PE) is required for correct operation. The

phase sequence does not matter when the station is connected. When a four

conductor power cable is used, it is required to connect a jumper between the

PE and N conductor in the supply socket.

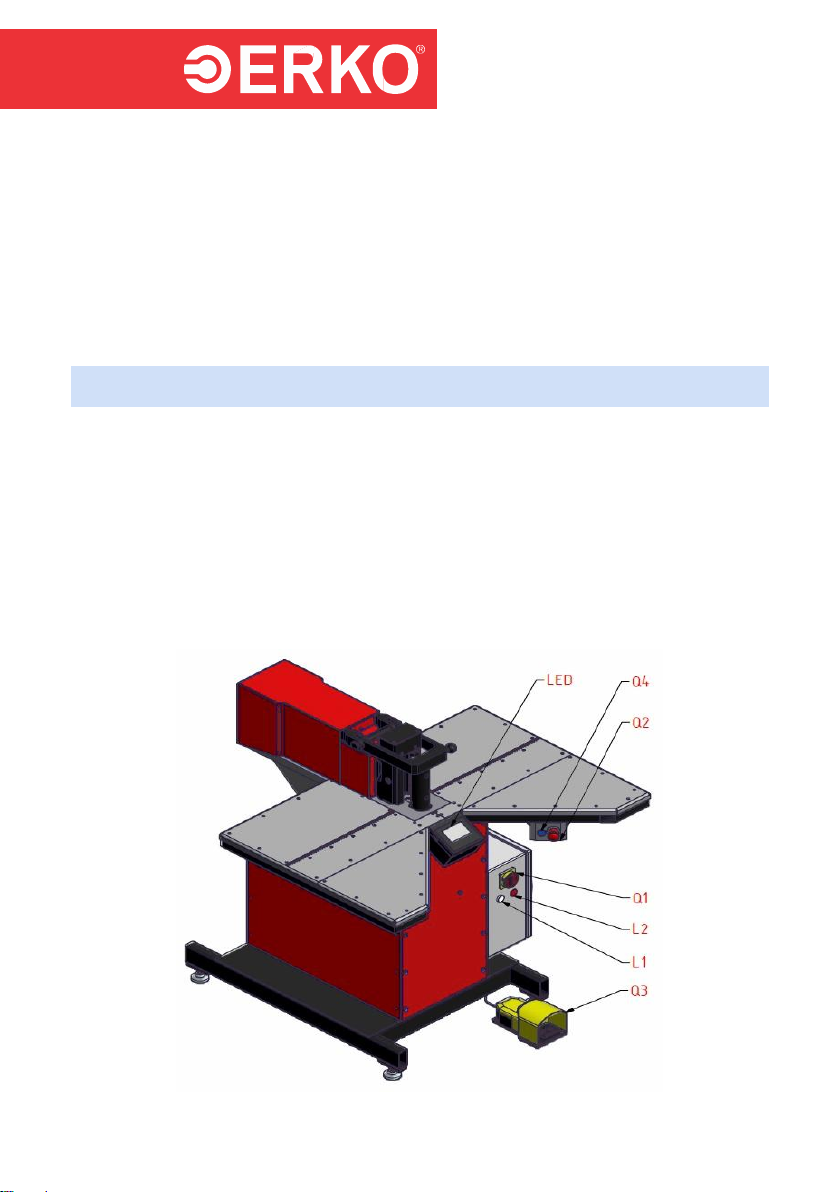

4. CONTROL PANEL

The control panel consists of the following elements:

Q1 Main switch used to start the station.

Q2 Emergency stop button.

Q3 Foot switch fulfils the function of the operating switch.

Q4 "RESET” button is used to start the safety system.

L1 White indicator lamp informs of correct power supply.

L2 Red indicator lamp informs of reaching the maximum oil operating

temperature.

LED Operator panel with the touch screen enables the station operation.

Fig. 1.

# VHG200020614

- 4 -

5. OPERATION

NOTE: The manufacturer reserves the right to change the operator panel graphics

depending on the software version.

5.1 START

To start the station, set the main switch (Q1) to position I. After setting the main switch

(Q1), the software loading and the station testing process is started. The operator

panel will show the screen with the login button (fig. 2) which, when touched, will show

the login window (fig. 3). To login, touch the white field with asterisks. Pressing the

field will show the numeric keypad (fig. 4). Using the keypad, enter the operator

password and confirm with the “ENTER” key. When an incorrect password is entered,

the window with the error message will be displayed (fig. 5). In such a situation, when

this message disappears, press the field with asterisks on the operator panel again

(fig. 3) and enter the correct password and confirm with the “ENTER” key. After correct

login, the message informing about the necessity of checking the safety system with

the “RESET” button will be shown (fig.6). After pressing the “RESET” button, the

station is ready for operation and the station enters the screen with the operation

selection (fig.7).

THE PASSWORDS PROGRAMMED FOR THE OPERATING PERSONNEL:

The factory set password for an operator is 159 and cannot be changed.

The factory set password for resetting the station measuring system is 1231 and

cannot be changed.

Fig. 2 Fig. 3

# VHG200020614

- 5 -

Fig. 4 Fig. 5

Fig. 6. Fig. 7.

When other messages are displayed or the above-mentioned messages are not

displayed, switch off the station with the main switch (Q1), wait for about 15 seconds

and proceed with the station start procedure again. If you failure to start the station

again, please contact the service personnel.

5.2 WARRANTY PERIOD START

When the station is started for the first time, the station warranty period start menu

appears after pressing the LOGIN button. After pressing the button, the window

that enables the warranty period start to be accepted will appear.

# VHG200020614

- 6 -

When you press the “NO” button, you will return to a previous window. When you

press the “YES” button and enter the password (159), the station switches to

cyclic operation mode. Counting the time interval to the technical inspection is

started.

5.3 BENDING

To proceed with the bending process:

Start the station in accordance with the procedure set out in item 5.1.

Go to the bending mode (fig. 7) or during normal operation press the

BENDING button at the bottom of the screen (fig. 8).

Find the reference point of the measuring system ("REF" is displayed in the

"CURRENT ANGLE" field (fig. 8)). To find the reference point of the encoder,

bend the rollers of the angle measuring insert (the insert must be connected

to the installation socket). The operation should be completed with the

appearance of an angle value (fig. 9). Values in the manual are represented

by the “#” sign.

To specify the bending angle, enter the value edition using the button located

next to the yellow field entitled “SET BENDING ANGLE” (the default value

displayed is a dimension that was used during the last bending). Using the

displayed numeric keypad enter a bending angle value. Confirm the edition

with the “ENTER” button (fig. 10).

Specify the material type to be bent (fig. 12, AL - aluminium, CU - copper).

Insert a busbar into the working space.

Determine the distance from the bending edge to the punch axis with the

scale engraved on the table top.

Press and hold the foot switch (Q3) to start the bending cycle. When the

operation is finished, the piston rod returns automatically to the initial position.

To repeat the operation, release the foot switch and press it again.

Releasing the foot switch during the cycle results in the operation interruption

and return movement of the piston rod to the start position (performance of

the next bending is only possible after the piston rod returns to the start

position).

Fig. 8. Fig. 9.

# VHG200020614

- 7 -

Fig. 10. Fig. 11.

Fig. 12. Fig. 13.

To accelerate and improve working comfort, the station is equipped with two additional

functions. The first function is the possibility of entering one’s own bending angle

correction, where a user may enter a correction value using the numeric keypad after

pressing the grey field next to the "ANGLE CORRECTION" field (fig. 12).

The second function entitled "FAST CYCLE" (fig. 11) enables a busbar bending in a

shorter time, but without overbending. Bending with overbending is performed during

the first bending to determine a springback value of a busbar being bent. Then,

activate the "FAST CYCLE" function by pressing the button (fig. 11). Thereafter, the

program memorizes the overbending value and it bends to an angle considering a

correction during the next bending. This function significantly accelerates operation.

When an angle value or material is changed, the correction is cancelled and

determined again during the first bending.

Note: Connection and disconnection of the communication cable of the bending insert

is only permitted when the station power supply is switched off.

The insert delivered with the station is calibrated with the program. In case it is

necessary to replace the insert, a new one must be calibrated. To do this, contact the

authorized service.

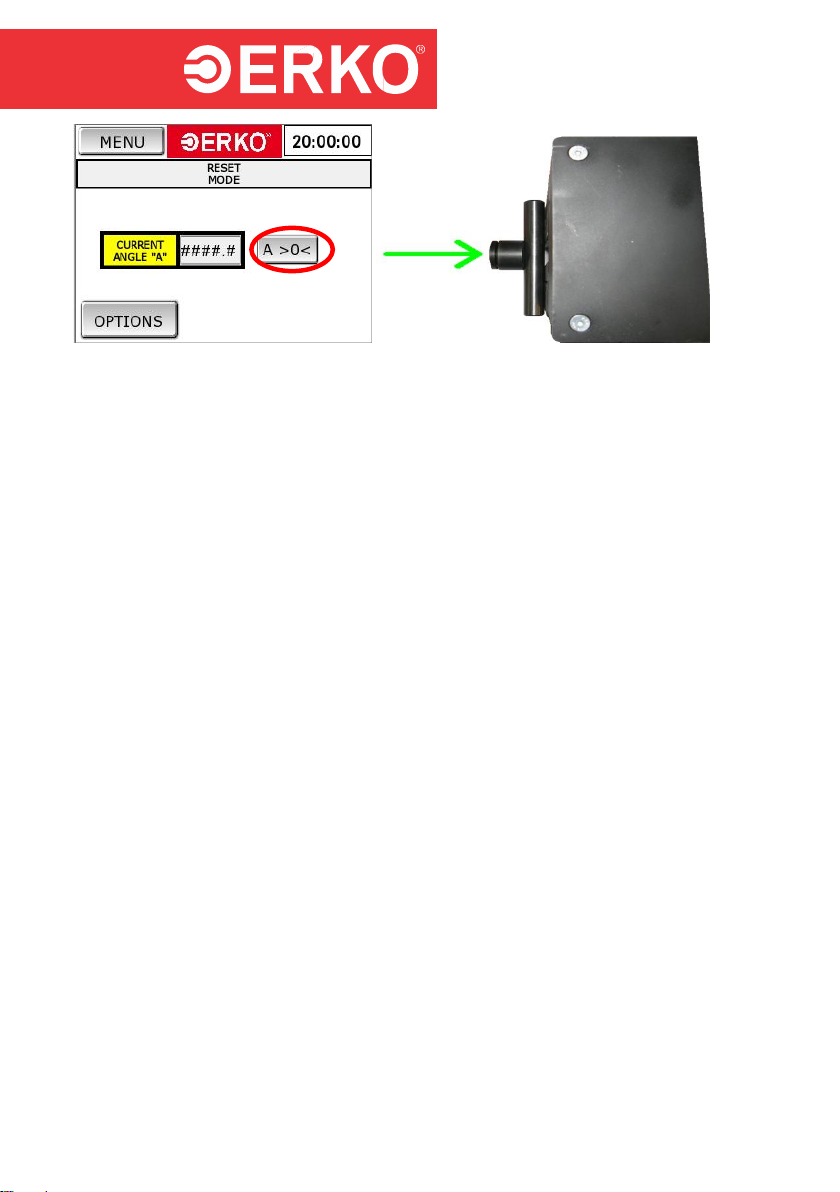

5.3.1 MEASURING SYSTEM RESET

The purpose of the measuring system reset is to calibrate measuring elements of the

station.

Only the bending insert can be calibrated.

# VHG200020614

- 8 -

To reset the measuring system:

Start the station in accordance with the procedure set out in item 5.1.

Press the “MENU” button located in the left upper corner of the panel (fig. 3).

Press the “RESET MODE” button (fig. 14).

The numeric keypad will appear (fig. 15) where the reset password must be

entered (the reset password is 1231), and then confirmed with the “ENTER”

button.

The station enters the reset mode (fig. 16).

Fig. 14. Fig. 15.

Fig. 16.

Using a flat element, adjust the levers in the parallel position to the measuring

insert body (fig. 18). Holding the immovable levers, press the "Reset" button on

the panel (fig. 17).

# VHG200020614

- 9 -

Fig. 17. Fig. 18.

When calibration is finished and a flat element is taken away from the measuring

levers, a value displayed on the operator panel takes a negative value different

from zero.

To check for correct calibration of the measuring insert, put the flat element again

and check if a value displayed on the operator panel is 0.

Note: The "TECHNICAL INSPECTION RESET" button is active when the station has

been operating for the period after which the manufacturer recommends a technical

inspection.

5.3.2 OPERATING PARAMETERS AND INSERT CALIBRATION

Depending on the range of bent busbars and bending parameters, i.e. bending radius,

busbar thickness etc., it is required to use different bending inserts. The HG200 station

offers this possibility. As standard, it is equipped with the insert suitable for a bar with

maximum height of 200 [mm] and thickness of 15 [mm]. At the customer’s request, it is

possible to make a special insert according to the instructions if there are no design

limitations.

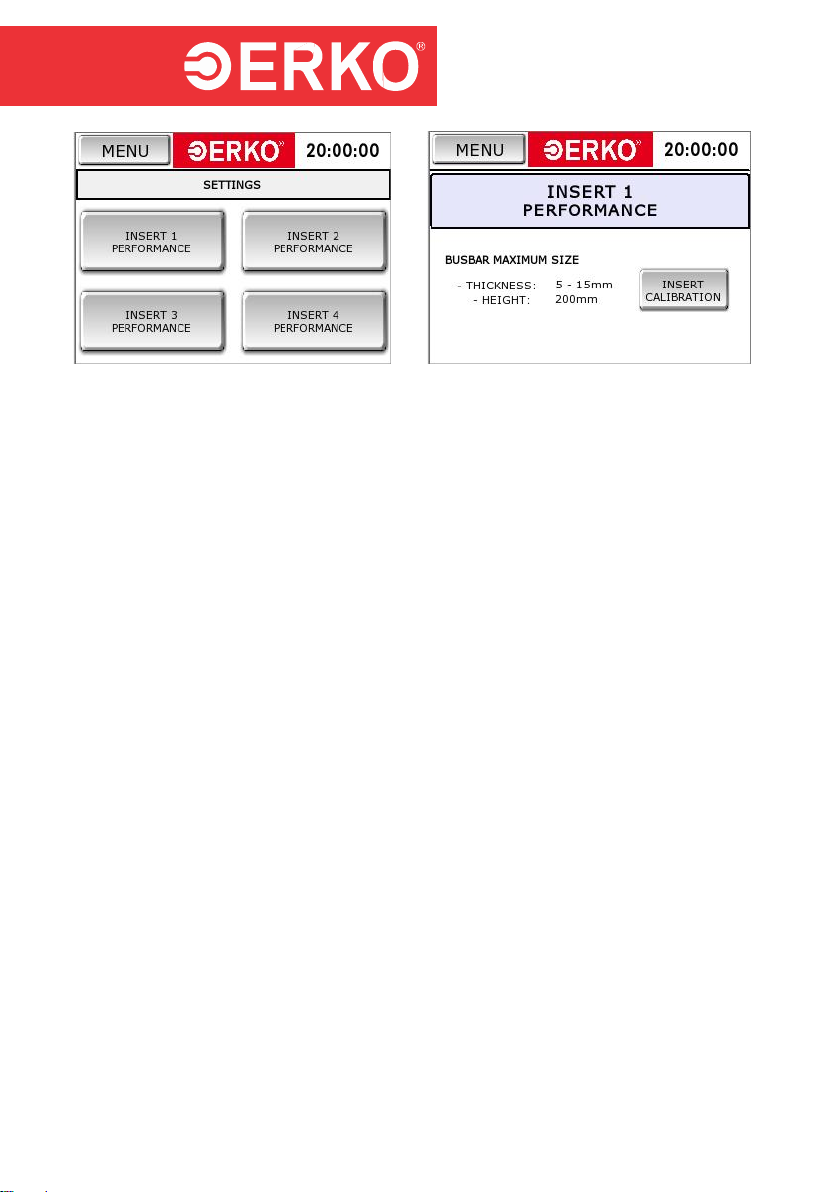

To use the settings:

Start the station in accordance with the procedure set out in item 5.1.

Press the “MENU” button located in the left upper corner of the panel (fig. 3).

Press the “SETTING” button (fig. 14).

Select the insert number (fig. 19).

Enter the insert calibration (fig. 20). The password to change the insert

parameters will be provided by the manufacturer if required.

# VHG200020614

- 10 -

Fig. 19. Fig. 20.

Note: When the bending insert is replaced with a different one, it is to be

parameterised with the station software ("INSERT CALIBRATION" fig. 20). To do this,

please contact the ERKO authorized service.

5.3 CUTTING

To proceed with the cutting process:

Start the station in accordance with the procedure set out in item 5.1.

Go to the cutting mode (fig. 7) or during normal operation press the CUTTING

button at the bottom of the screen (fig.8). The cutting mode screen is shown

in figure 21.

Insert a busbar into the working space.

Determine the distance from the cutting edge to the knife axis with the scale

engraved on the table top.

Press and hold the foot switch (Q3) to start the cutting cycle. When the

operation is finished, the piston rod returns automatically to the initial position.

To repeat the operation, release the foot switch and press it again.

Releasing the foot switch during the cycle results in the operation interruption

and return movement of the piston rod to the start position (performance of

the next cutting is only possible after the piston rod returns to the start

position).

# VHG200020614

- 11 -

Fig. 21.

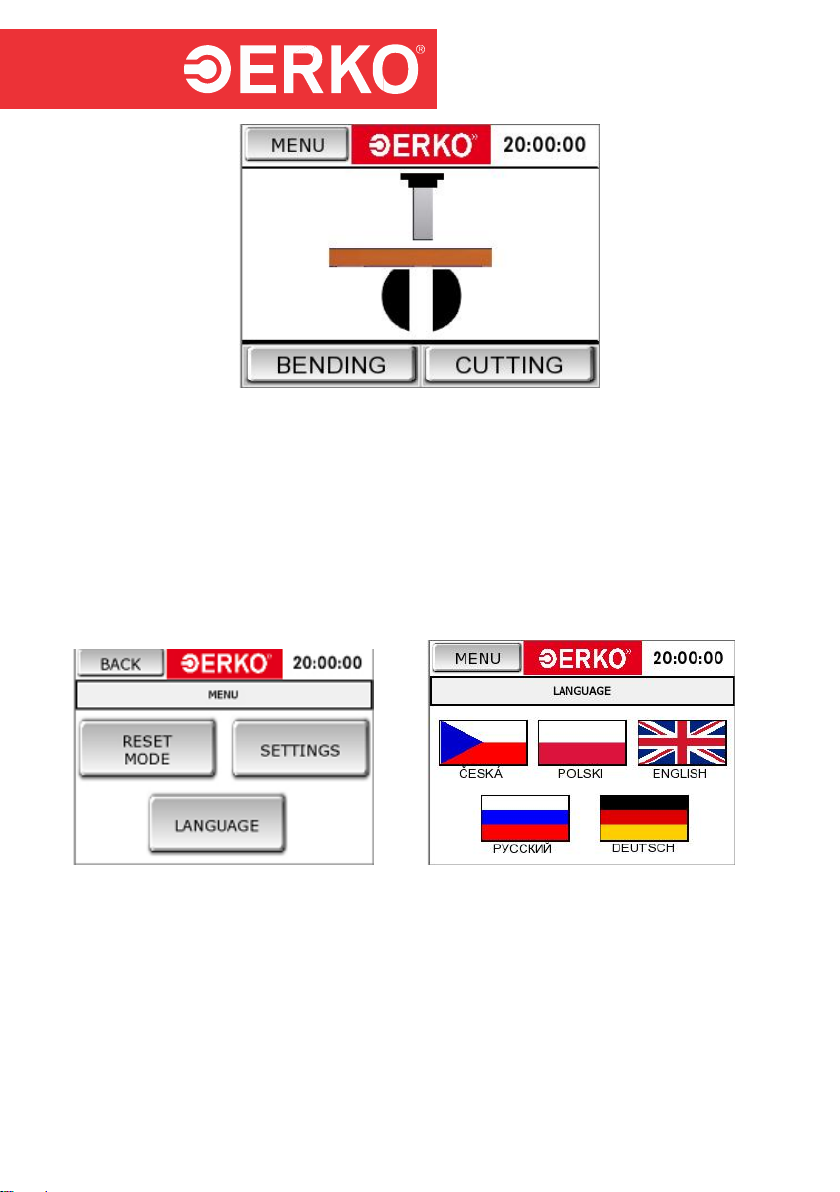

5.4 CHANGE OF INTERFACE LANGUAGE

To change a user interface language:

Switch on the station power supply and follow in accordance with item 5.1.

Press the “MENU” button located in the left upper corner of the panel (fig. 8).

Press the “LANGUAGE” button (fig. 22).

Select a language by touching the suitable flag on the screen (fig. 23).

Fig. 22. Fig. 23.

5.5 COUNTER OF THE STATION RUNNING TIME AND DATE OF THE NEXT

INSPECTION

To read the station running time and a date of the next technical inspection:

Press the “MENU” button located in the left upper corner of the panel (fig. 8).

Press the “RESET MODE” button (fig. 22).

After entering the reset password in the dialogue window, press the

“OPTION”button.

# VHG200020614

- 12 -

After pressing the button the dialogue window with the counter of the station

running time and a date of the next technical inspection will show.

Fig. 24. Fig. 25.

5.6 DATE AND TIME SETTING

To set time:

Press the “MENU” button located in the left upper corner of the panel (fig. 8).

Press the “RESET MODE” button (fig. 22).

Click the clock in the right upper corner to start the clock setting panel.

Fig. 26.

# VHG200020614

- 13 -

6 TECHNOLOGY

6.1 BENDING

When the station has just been started, carry out the operations according to

item 5.1

Equip the station with the bending mandrel and measuring insert according to

item 6.1.1 and enter the settings according to item 5.2

Slide a busbar in a space between the mandrel and measuring insert and

slide a busbar close to the mandrel.

Close the clamp (fig. 33).

Press and hold the foot switch (Q3) to start the bending cycle. When the

operation is finished, the piston rod returns automatically to the initial position.

To repeat the operation, release the foot switch and press it again.

Releasing the foot switch during the cycle results in the operation interruption

and return movement of the piston rod to the start position.

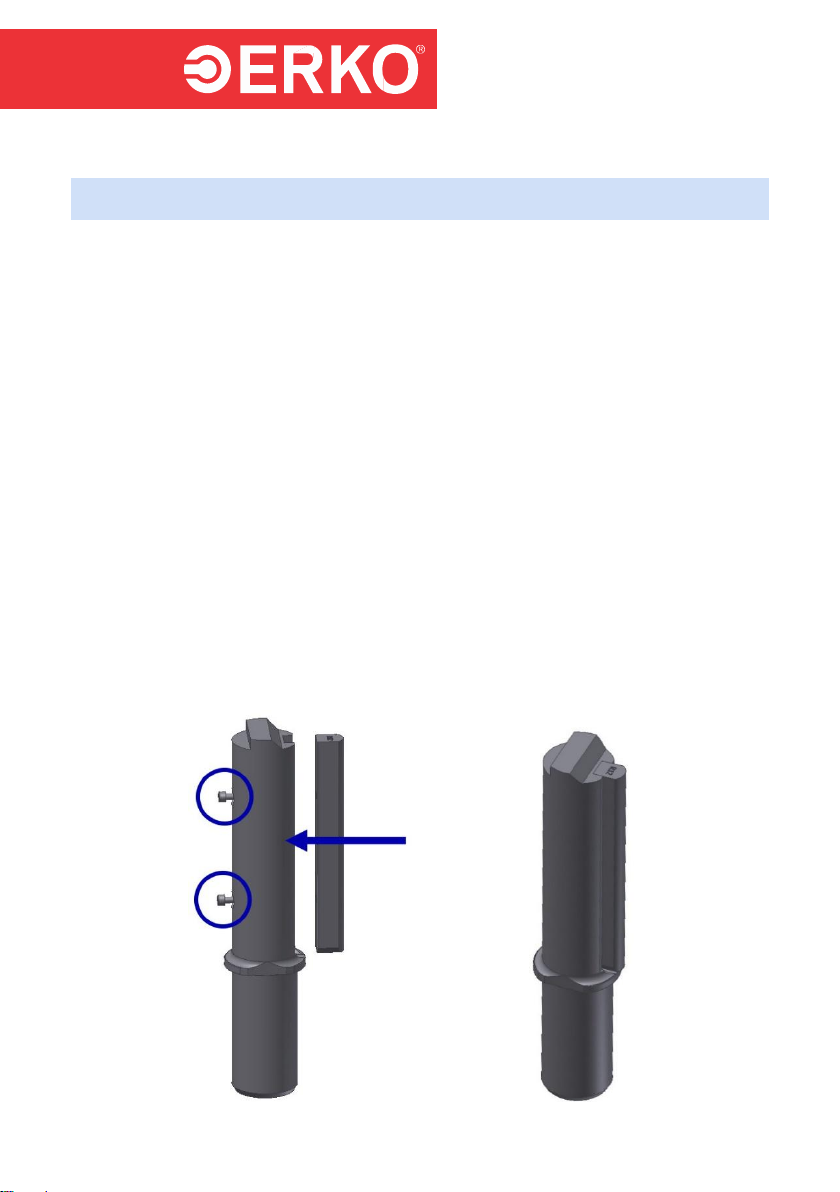

6.1.1 EQUIPPING THE BENDING STATION

To equip the bending station:

Mount the suitable bending radius in the bending mandrel and fasten it with

two bolts (fig. 27). The mounted mandrel is shown in figure 28.

# VHG200020614

- 14 -

Fig. 27. Fig. 28.

Slide the bending mandrel into the hole in the body (fig. 29) (fig. 30).

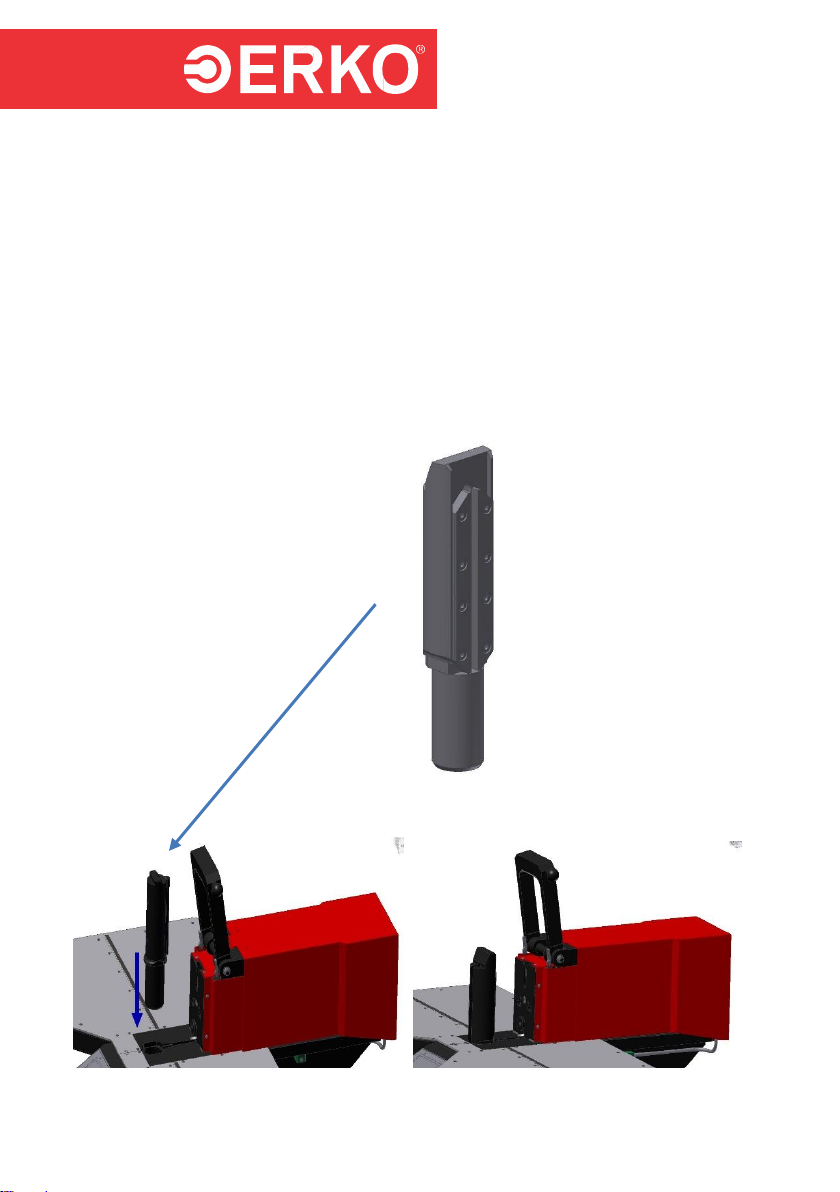

Fig. Bending mandrel

Fig. 29. Fig. 30.

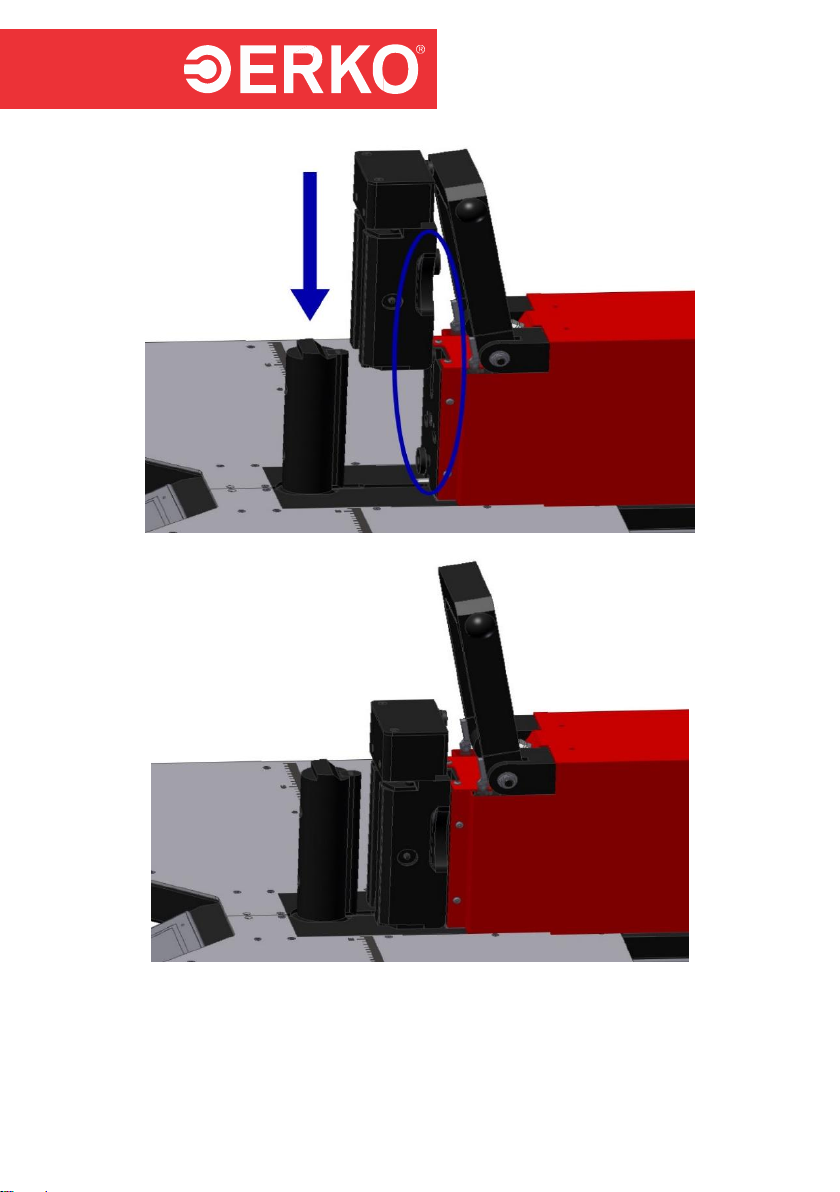

Mount the bending insert using the guiding elements (fig. 31) (fig. 32).

# VHG200020614

- 15 -

Fig. 31.

Fig. 32.

Connect the bending insert.

# VHG200020614

- 16 -

Fig. 33.

Close the safety clamp (fig. 34).

Fig. 34.

6.2 CUTTING

In case the station has just been started, carry out the operations according to

item 5.1

# VHG200020614

- 17 -

Equip the station with the cutting mandrel and cutting insert according to item

6.2.1.

Slide a busbar in a space between the mandrel and cutting insert and slide a

busbar close to the mandrel.

Close the clamp (fig. 34).

Press and hold the foot switch (Q3) to start the cutting cycle. When the

operation is finished, the piston rod returns automatically to the initial position.

To repeat the operation, release the foot switch and press it again.

Releasing the foot switch during the cycle results in the operation interruption

and return movement of the piston rod to the start position.

6.2.1 EQUIPPING THE CUTTING STATION

To equip the cutting station:

Slide the cutting mandrel into the hole in the body (fig. 35) (fig. 36).

Fig. Cutting mandrel.

Fig. 35. Fig. 36.

# VHG200020614

- 18 -

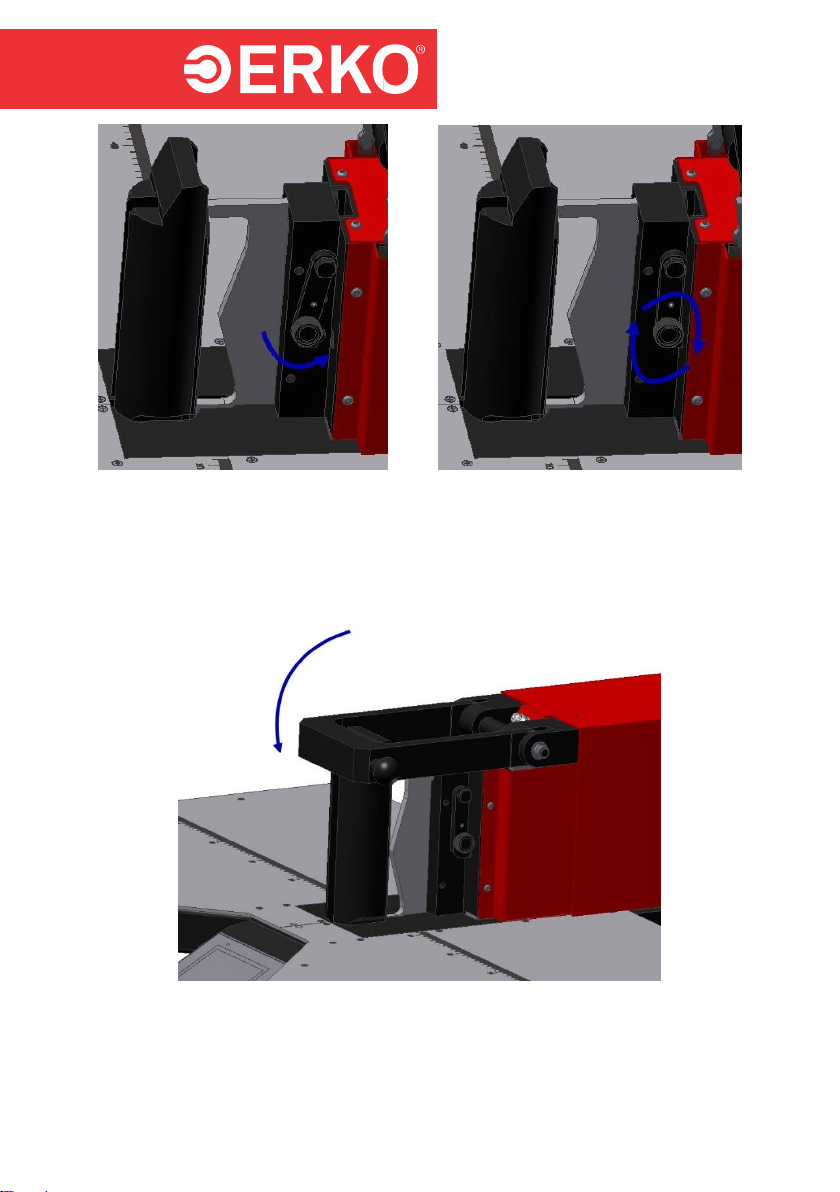

Mount the bending insert using the guiding elements (fig. 37) (fig. 38).

Fig. 37.

Fig. 38.

Catch the lock (fig. 39) and fasten (fig. 40).

# VHG200020614

- 19 -

Fig. 39. Fig. 40.

Close the safety clamp (fig. 41).

Fig. 41.

Table of contents