1 Notes on safety Operating instructions SCORP

4 (06.07) MT_SCORP_BA_04_790014762_09.doc

orbitalum tools gmbh

1.3 Working with safety in mind

"Make your contribution to safety in the workplace."

•Report any deviations from normal operation to the person responsible

immediately.

•Always keep safety in mind while working.

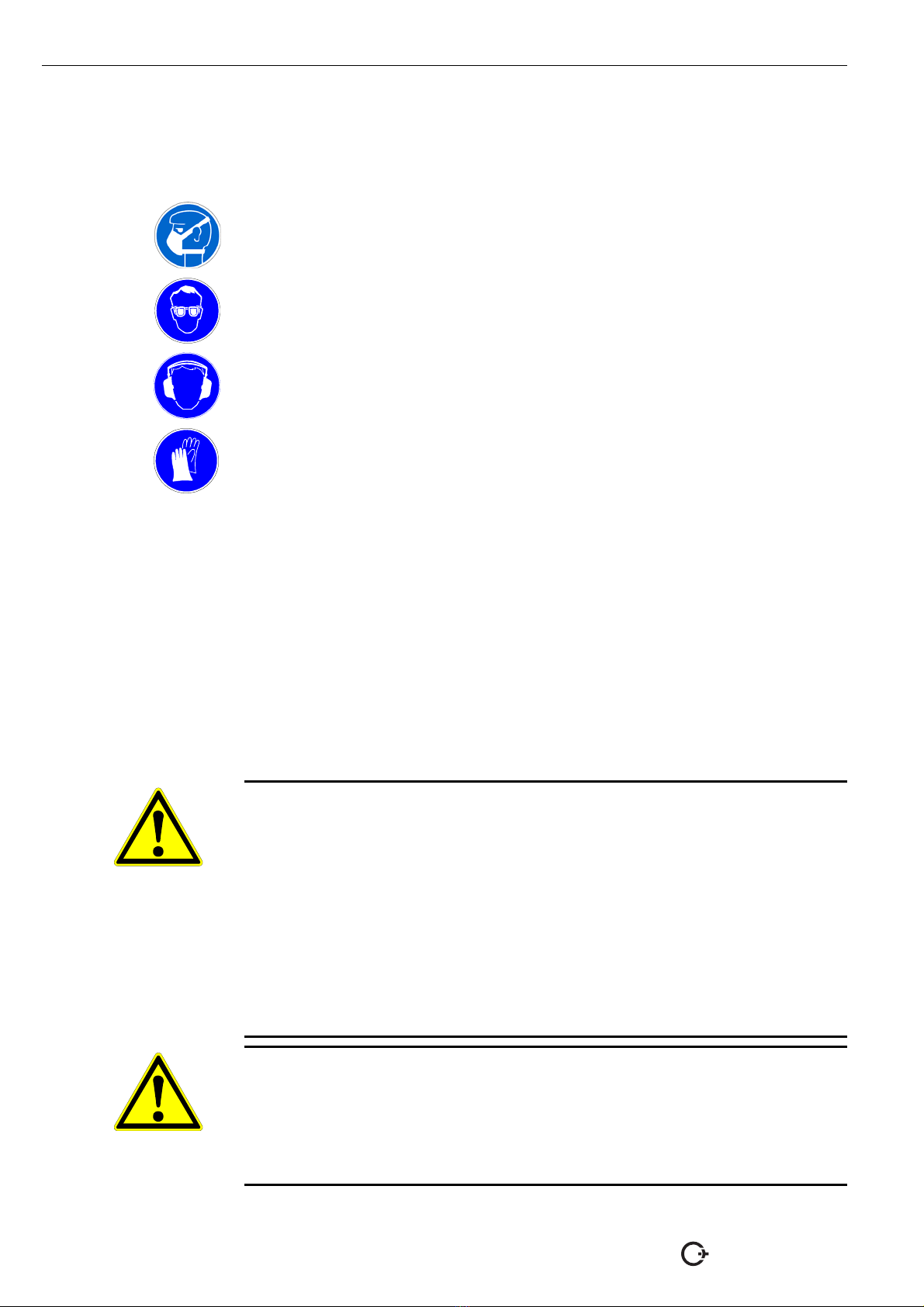

•When working with the SCORP, wear mask, protective goggles, safety

gloves and ear muffs.

•Tie up long hair (hair-net); do not wear wide clothing.

Attention: Jewellery, loose fitting clothing and ties can be caught in

rotating parts!

•Turn the SCORP off at the end of each operating cycle and allow the

machine to run to a stop.

•Keep hands away from the tools during processing.

•Before carrying out a tool change, cleaning, performing any maintenance

work, adjustments or repair work on the SCORP, pull out the mains plug

and allow the machine to run to a stop.

•Do not carry the electric tool holding it at the cable and do not use it to pull

the plug out of the socket. Protect the cable against heat, oil and sharp

edges (chips).

•Pay attention to the surroundings. Do not use any electric tools in a damp

or wet area. Make sure to have good illumination. Do not work near

combustible liquids or gases.

•The power-on time is max. 25%. With higher power-on time the machine

can be overloaded.

Danger of death by electric shock!

If the mains cable is damaged, live parts may cause death when being touched

directly.

:Keep the mains cable of the cutter motor away from the saw blade or

cutting blade.

XWhile processing the pipe, always keep an eye on the position of the mains

cable.

:Do not let the cut-off pipe piece drop in an uncontrolled way.

:Do not run the machine unattended.

Danger of being injured by sharp cutting edges!

Non-observance could result in serious injury.

:Keep hands away from the tools during cutting.

XWear safety gloves.

DANGER

WARNING