ermaf GP 40 ACU User manual

➔

www.docuthek.com

D GB NL RUS PL F E UA CN

© 2018 Elster GmbH · Edition 07.18

03251543 Safety

Please read and keep in a safe place

Please read through these instructions

carefully before installing or operating. Following the

installation, pass the instructions on to the opera-

tor. This unit must be installed and commissioned

in accordance with the regulations and standards

in force. These instructions can also be found at

www.docuthek.com.

Explanation of symbols

• , , , ... = Action

▷= Instruction

Liability

We will not be held liable for damage resulting from

non-observance of the instructions and non-com-

pliant use.

Safety instructions

Information that is relevant for safety is indicated in

the instructions as follows:

DANGER

Indicates potentially fatal situations.

WARNING

Indicates possible danger to life and limb.

CAUTION

Indicates possible material damage.

All interventions may only be carried out by qualified

gas technicians. Electrical interventions may only be

carried out by qualified electricians.

Persons under the age of 18 as well as persons with

reduced physical, sensory or mental capabilities or

lack of experience and knowledge are not allowed

to use, clean or service this device. Staying near the

device or its use is prohibited, even if said persons are

supervised or have been instructed on the safe use of

the devices and are aware of the resulting dangers.

Conversion, spare parts

All technical changes are prohibited. Only use OEM

spare parts.

Contents

Operating instructions

GB-1

Translation from the German

D

GB

NL

RUS

PL

F

E

UA

CN

Heater GP 40 ACU

Heater GP 40 ACU ......................

Contents ..............................

Safety.................................

Checking the usage .....................

Installation ............................

Tightness test ..........................

Wiring ................................

Connection diagram......................4

Burner Chip Card (BCC) ..................6

Setting the switch-on delay ................6

Commissioning.........................6

ACU control panel ....................... 7

Switching on ........................... 7

Switching off ........................... 7

Setting mode ...........................8

Adjusting the heater.....................8

Cleaning .............................0

Assistance in the event of malfunction ....

Maintenance ..........................8

Checking the safety functions and burner

operation.............................0

Accessories ..........................0

Spare parts ...........................

Technical data ........................

Declaration of conformity ...............

Logistics .............................

Goods return form . . . . . . . . . . . . . . . . . . . . . 4

Contact ..............................4

Safety

Contents

GB-2

D

GB

NL

RUS

PL

F

E

UA

CN

Checking the usage

GP 40

Heater with direct, open combustion for animal sheds

and horticultural greenhouses. Depending on the

type and setting, the heater can be operated with

natural gas or LPG (propane/butane).

This function is only guaranteed when used within

the specified limits– see page23 (Technical data).

Any other use is considered as non-compliant.

Type code

Code Description

GP Heater

40 Capacity 40 kW, jet length 40 m

Part designations

MODE RESET ON/OFF

4

1, 2

3

Burner control unit ACU

Gas combination control CG

Vane

4Assembly accessories

Type label

Air circulation, electrical connection rating, voltage,

rated heat input, gas type, category, supply pressure,

burner pressure, enclosure: see type label.

Elster s.r.o.

Dr. A. Schweitzera 194

SK-91601 Stará Turá

UA.TR012-13

● Before installation, check whether the device is

suitable for the regional gas type and the specified

limits, see type code and page23 (Technical

data).

Installation

DANGER

Danger of death! Gases are generated during the

storage of slurry which remain partly dissolved in

the liquid. If the slurry is strongly agitated during

mixing and purging, poisonous, explosive gases

such as hydrogen sulphide and methane are re-

leased. If an ignition source is present, the released

gas can explode.

To avoid damage during operation, please observe

the following:

– Switch off the heater before mixing and purging

the slurry.

– Close the slide valves when storing slurry out-

side.

– The fan for the air supply must not be part of a

closed pipe system.

– The space to be heated must be adequately

ventilated.

For mechanical extraction equipment: at least

10m3/h of air per installed capacity.

In the case of natural ventilation, the structure

must have two apertures with a free opening

area of 60x B in cm2. “B” is the installed capac-

ity in kW. Replacement of the full air volume per

hour is thus ensured.

– In the case of natural ventilation, the maximum

allowable total capacity of the heater is 1kW

per 20m3of volume.

– Respect the safety distance of the heater to

inflammable materials, see “Installation position”.

– Consult your fire insurance provider and/or local

fire protection engineer to assess the foresee-

able, general risk of fire.

– For cleaning, care and maintenance, note the

applicable national regulations and directives.

– No condensation permitted. Comply with ambi-

ent temperature, see page23 (Technical data).

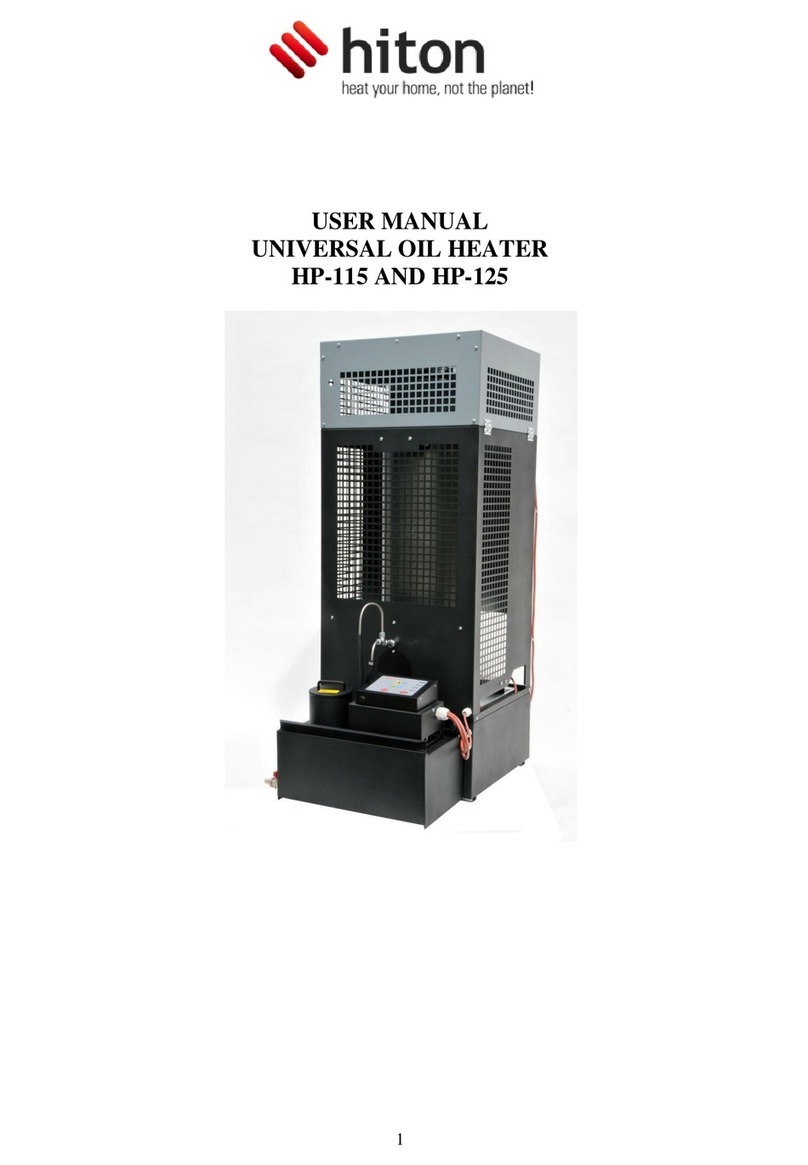

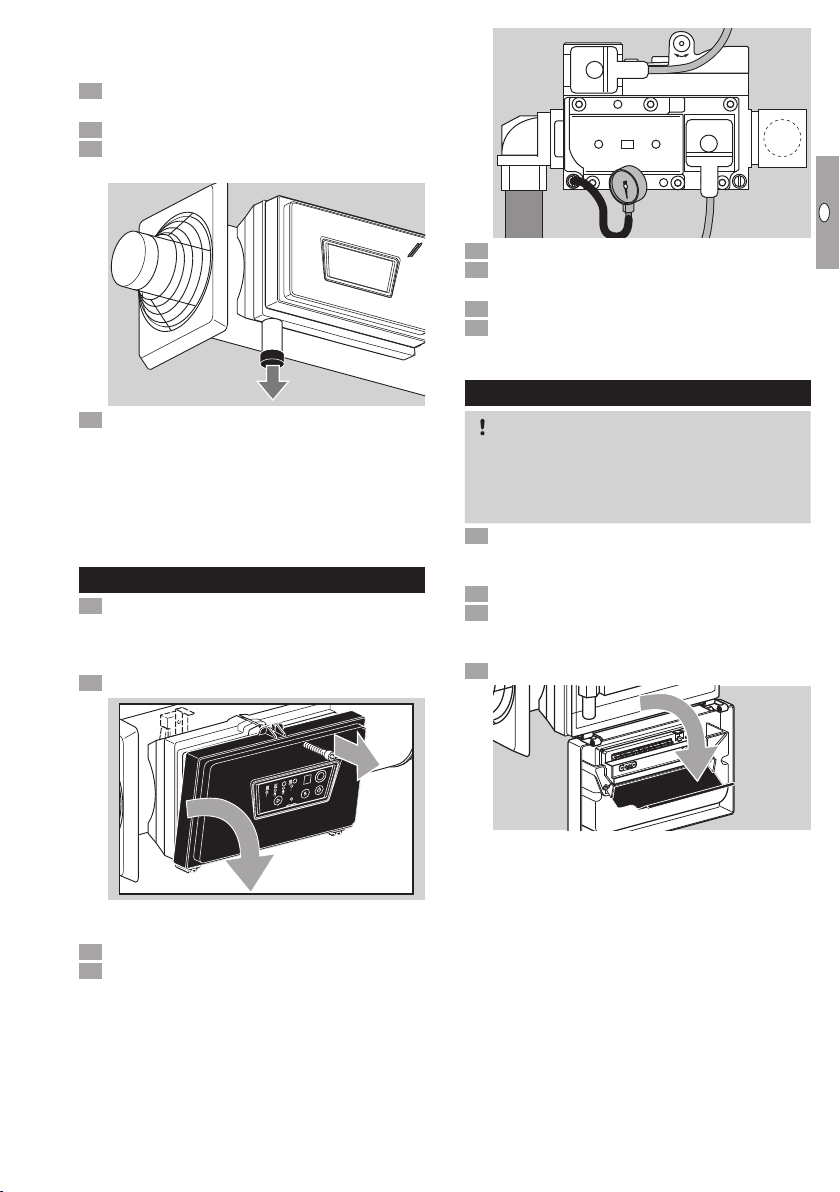

Installation position

▷ To ensure that the vane functions faultlessly, in-

stall the unit in the horizontal position.

▷

Note the safety distance to walls and inflam-

mable materials.

> 1m

> 0,8m

> 1m

> 3 m> 1m

▷ Ensure sufficient free space around the device.

There must be no obstructions in front of the inlet

and outlet side of the heater.

▷ To avoid overheating, do not cover the electric

motor.

GB-3

D

GB

NL

RUS

PL

F

E

UA

CN

Connecting the gas supply

▷

If the heater is suspended on chains, use an

approved flexible gas hose.

Disconnect the system from the electrical power

supply.

Shut off the gas supply.

Remove the sealing plug at the inlet tube of the

gas combination controlCG.

4 Connect the gas pipe with threaded connec-

tion (R½" external thread) or gas hose, see

page 20 (Accessories), to the inlet tube of

the gas combination control.

▷ Use approved sealing material only.

▷ Note the maximum inlet pressure, see page23

(Technical data).

Tightness test

Disconnect the system from the electrical power

supply. The mains plug may only be pulled out

once the device has been switched off.

▷ The valves are closed when de-energized.

Open the cover of the ACU.

MODE RESET ON/OFF

▷ To do so, turn the cross-head screw anti-clock-

wise several turns so that it can be lifted.

Open the test point for puon the CG.

4 Connect a pressure gauge to test point pu.

+ -

+

-

0

pu

5 Switch on the power supply.

6 Release the gas supply.

▷ Inlet pressure pu max.= 70mbar.

7 Shut off the gas supply.

8 Check the gas pressure on the pressure gauge.

▷ The pressure must not drop.

Wiring

CAUTION

Danger of electric shocks!

– Before working on possible live components,

ensure the unit is disconnected from the power

supply.

Disconnect the system from the electrical power

supply. The mains plug may only be pulled out

once the device has been switched off.

Shut off the gas supply.

Open the housing cover of the ACU.

▷ To do so, turn the cross-head screw anti-clock-

wise several turns so that it can be lifted.

4 Open the cover of the burner control unit.

GB-4

D

GB

NL

RUS

PL

F

E

UA

CN

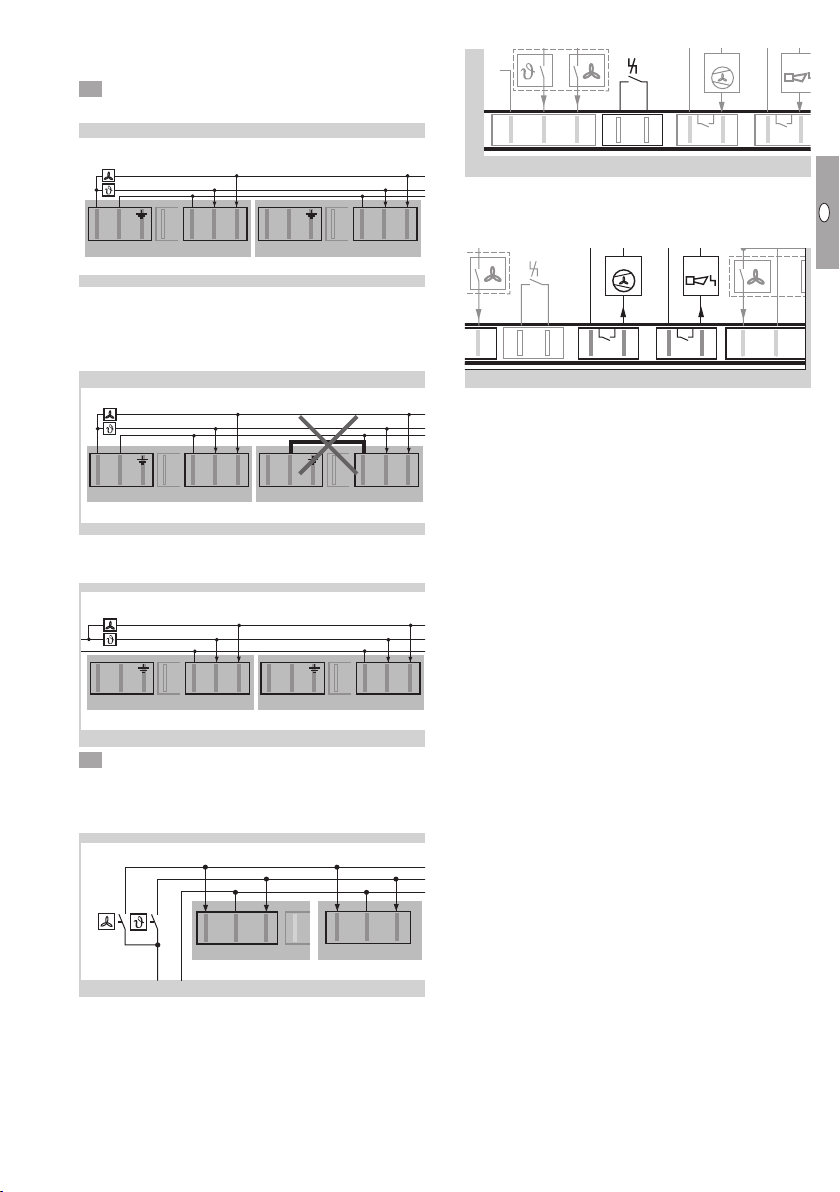

Connection diagram

▷ The burner control unit is fitted with coded con-

nectors to prevent them being mixed up.

LN LN NLT LV +T –+VmA V12

LLiN 12 +

0 V

D – 49018 Osnabrück, Germany

ACU

Connecting the room thermostat

CAUTION

To avoid damage to the heater, please observe

the following:

– Provide post-cooling for the heater. The heater

requires a continuous supply of 230 VAC,

50Hz.

– In case of a power failure, an emergency power

supply unit should automatically take over the

power supply. Emergency power supply units

with a cardan shaft drive for tractor attachment

are also suitable.

▷

Use a room thermostat with a hysteresis of ±1°C.

It switches on if the room temperature is 1°C

less than the set temperature and switches off

again once the room temperature is 1°C more

than the set temperature.

▷ The floating connectors X4 (230V) or X8 (24V)

are used to connect the room thermostat.

▷

If the room thermostat is connected to the mains

supply of other connectors (connector X1 orX3),

the heater will be damaged.

Connecting a single heater to a room

thermostat

5 Connect a room thermostat for 230VAC.

▷ 1. Power supply via the heater.

230 V AC

230 V AC

+V – +T

X8

mV

10-24 V AC/DC

X2

230 V AC

L

N

L N

X1 Gas

NLT LV

X4

X2

L N

X1 Gas

NLT LV

X4

X2

L N

X1 Gas

NLT LV

X4

▷

2. Power supply via the environmental control

computer.

230 V AC

230 V AC

+V – +T

X8

mV

10-24 V AC/DC

X2

230 V AC

L

N

L N

X1 Gas

NLT LV

X4

X2

L N

X1 Gas

NLT LV

X4

X2

L N

X1 Gas

NLT LV

X4

5 Connect a room thermostat for 24VDC/AC to

connectorX8.

▷ The 24V power supply must always be from an

external source.

230 V AC

230 V AC

+V – +T

X8

mV

10-24 V AC/DC

X2

230 V AC

L

N

L N

X1 Gas

NLT LV

X4

X2

L N

X1 Gas

NLT LV

X4

X2

L N

X1 Gas

NLT LV

X4

eBus

Burner Chip

Card (BCC)

Potentiom-

eter

(switch-on

delay)

MFA 2

MFA 1

Remote

reset

0 – 10 V

0 – 20 mA

10 – 24 V

Thermostat

Controlled air

flow

230 V

Thermostat

Controlled

air flow

Mains con-

nection

Mains filter

Mains filter

Mains con-

nection

GB-5

D

GB

NL

RUS

PL

F

E

UA

CN

Connecting multiple heaters to a room

thermostat or an environmental control

computer

5 Connect a room thermostat for 230VAC.

▷ 1. Power supply via the heater.

GP 2

X2

GP 2

– +T

X8

+V

L N

X1 Gas

NLT LV

X4

GP 2

X2

L N

X1 Gas

NLT LV

X4

GP 2

X2

L N

X1 Gas

NLT LV

X4

GP 1

GP 1

GP 1

GP 1

230 V AC

230 V AC

+V – +T

X8

mV

10-24 V AC/DC

X2

230 V AC

L

N

L N

X1 Gas

NLT LV

X4

X2

L N

X1 Gas

NLT LV

X4

X2

L N

X1 Gas

NLT LV

X4

▷ Only one bridge may be connected in a single

heater between connectors X1 andX4. “N” may

be connected to all successive heaters between

connectorsX4 only.

GP 2

X2

GP 2

– +T

X8

+V

L N

X1 Gas

NLT LV

X4

GP 2

X2

L N

X1 Gas

NLT LV

X4

GP 2

X2

L N

X1 Gas

NLT LV

X4

GP 1

GP 1

GP 1

GP 1

230 V AC

230 V AC

+V – +T

X8

mV

10-24 V AC/DC

X2

230 V AC

L

N

L N

X1 Gas

NLT LV

X4

X2

L N

X1 Gas

NLT LV

X4

X2

L N

X1 Gas

NLT LV

X4

▷

2. Power supply via the environmental control

computer.

GP 2

X2

GP 2

– +T

X8

+V

L N

X1 Gas

NLT LV

X4

GP 2

X2

L N

X1 Gas

NLT LV

X4

GP 2

X2

L N

X1 Gas

NLT LV

X4

GP 1

GP 1

GP 1

GP 1

230 V AC

230 V AC

+V – +T

X8

mV

10-24 V AC/DC

X2

230 V AC

L

N

L N

X1 Gas

NLT LV

X4

X2

L N

X1 Gas

NLT LV

X4

X2

L N

X1 Gas

NLT LV

X4

5 Connect a room thermostat for 24VDC/AC to

connectorX8.

▷

The 24 V power supply must be from an external

source.

GP 2

X2

GP 2

– +T

X8

+V

L N

X1 Gas

NLT LV

X4

GP 2

X2

L N

X1 Gas

NLT LV

X4

GP 2

X2

L N

X1 Gas

NLT LV

X4

GP 1

GP 1

GP 1

GP 1

230 V AC

230 V AC

+V – +T

X8

mV

10-24 V AC/DC

X2

230 V AC

L

N

L N

X1 Gas

NLT LV

X4

X2

L N

X1 Gas

NLT LV

X4

X2

L N

X1 Gas

NLT LV

X4

Remote reset

L

N

Reset

MFA

1M

FA

2

max. 5 A

max. 264 V

max. 2 A

max. 264 V

NLT LV

X4

12

X6X5

Li

12

X7

▷ An external remote reset may be connected to

connectorX5.

Multi-functional outputs (MFA)

Reset

MFA 1MFA 2

max. 5 A

max. 264 V

max. 2 A

max. 264 V

AC/DC

10-24 V

LV +V –

+

X8

12

X6X5

Li 12

X7

0 V

▷ Floating multi-functional outputs can be param-

eterized using connectors X6 andX7. There are

two methods of completing this parameteriza-

tion:

The PC software for burner control units BCSoft

can be used via the optical interface on the burn-

er control unit, see page20 (Accessories).

The “Setting mode” menu can be opened us-

ing the MODE selection button (heater OFF)

and used for parameterizing the outputs, see

page8 (Setting mode).

▷ MFA , external fan (max. 5 A)

For improved air circulation in the room, an addi-

tional fan can be connected. The external fan can

be actuated with an adjustable delay (BCSoft) for

switching it on and off. The exact time relates to

the operation of the integrated fan.

▷ Possible parameterization options:

– Inactive: the external fan is not actuated.

– Integrated fan active: the external fan is actuated

at the same time as the integrated fan.

– Integrated fan inactive: the external fan is ac-

tuated when the integrated fan of the heater

switches off.

– Modulation enable: the external fan is not actu-

ated until the heater starts modulating operation.

GB-6

D

GB

NL

RUS

PL

F

E

UA

CN

▷ MFA , status signal (max. 2A)

Possible parameterization options:

– Fault NO (default setting):

For example, the input for a horn can be set to

NO.

– Fault NC:

The input on an environmental control computer

can be set to NC (e.g. to indicate a cable dis-

continuity).

– Operation

– Standby

Burner Chip Card (BCC)

▷

All the data relevant to the device are saved

on the BCC and the internal device memory

(EEProm). In addition, the parameters are saved

on the BCC.

WARNING

Danger of electric shocks!

– Before working on possible live components,

ensure the unit is disconnected from the power

supply.

– If the BCC is removed from the burner control

unit, the heater will be non-functional.

▷ In the event of faults which cannot be rectified

by authorized trained personnel, contact the

supplier.

▷

The BCC can be removed from the burner control

unit and submitted for diagnostic purposes by

agreement with the supplier.

B

CC

+

Delay

▷ If no other fault is active, the heater can be read-

ied for use again by inserting a new BCC. The

BCC must be compatible with the heater, the

version and the gas type used.

Setting the switch-on delay

▷

If multiple heaters switch on at the same time,

there can be a gas and/or power shortage on

individual devices. To avoid this happening, ad-

just the switch-on delay using the potentiometer

on the burner control unit.

▷ The potentiometer is set to 0s at the factory.

– +

▷ If necessary, a switch-on delay of 5 to 10s can

be set between the devices.

6 After completing the wiring, close the cover

and the housing cover on the burner control

unit again.

7 Switch on the power supply.

▷

If a switch-on delay has been programmed, a

circulating dash will be displayed when the volt-

age supply is switched on to indicate that the

switch-on delay is running.

8 Release the gas supply.

9 Commission the heater.

Commissioning

WARNING

To avoid damage to the heater, please observe

the following:

– Ensure that the heater, gas pipes, mains voltage

supply and room thermostat have been installed

by authorized trained personnel according to

the regulations.

– The Burner Chip Card (BCC) must be compat-

ible with the heater, the version, the gas type

used and the factory default parameters.

– The heater may only be operated with the gas

type specified on the type label.

– If the device needs to be converted to be oper-

ated with a different gas type:

1. Use the correct nozzle, see page22 (Spare

parts).

2. Set the appropriate pressure on the burner,

see table on page8 (Adjusting the heater),

and then seal the gas pressure setting.

GB-7

D

GB

NL

RUS

PL

F

E

UA

CN

ACU control panel

MODE RESET ON/OFF

MODE RESET ON/OFF

MODE RESET ON/OFF 1

3

5

7

4

2

6

ON/OFF

OFF 1

2

3

4

5

AUTO

+AUT

MODE

(RESET)

ON/OFF

O

LEDs

MODE selection button

4RESET button

5Status indicator light

6Optical interface

77-segment display

Description of function

ON/OFF

OFF 1

2

3

4

5

AUTO

+AUT

MODE

(RESET)

ON/OFF

O

:

To switch the heater on and off

LEDs:

To indicate the chosen operating mode

Operating

mode Explanation

The burner control unit waits for the

signals for controlled air flow or heating

(automatic)

Continuous heating

(manual)

Controlled air flow in continuous op-

eration

(manual)

Controlled air flow in continuous op-

eration and heating when a thermostat

signal is applied

(automatic)

MODE selection button:

Setting mode can be accessed by pressing and

holding the MODE selection button when the

heater is switched off, see page8 (Setting

mode). The multi-functional outputs can be as-

signed and the eBus address specified in this

mode.

4RESET button:

To reset the device after the occurrence of a fault

5Status indicator light:

red: fault

yellow: standby/ready for operation

green: in operation

6Optical interface:

The PC software BCSoft can be used with the PC

opto-adapter via this interface, see page20

(Accessories).

77-segment display:

To display error codes, the flame signal or the

number of operating cycles. The decimal point

indicates that another figure follows.

Error code

RESET button

Flame signal

Operating cycles

> 3 s RESET button

ON

Error code: an error is displayed immediately

in the form of an alternating letter and number

indicating a warning or fault, see page12 (As-

sistance in the event of malfunction).

Flame signal: pressing the RESET button displays

the flame signal, see page9 (Flame signal).

Operating cycles: press and hold the RESET

button for more than 3s to show the number

of operating cycles in changing displays, see

page18 (Maintenance).

▷

Press the RESET button to exit the display of

the flame signal or operating cycles.

Switching on

• Press ON/OFF

OFF 1

2

3

4

5

AUTO

+AUT

MODE

(RESET)

ON/OFF

O

.

▷

The LED for the last selected operating mode will

flash. A different operating mode can be selected

within 2s. If you retain the selection, the flash-

ing light will change to permanently lit after 2s.

▷ The heater will start once the thermostat signal

has been applied and the set switch-on delay

elapsed, see page6 (Setting the switch-on

delay).

▷

The burner starts up and operates in the last

selected operating mode.

Switching off

• Press ON/OFF

OFF 1

2

3

4

5

AUTO

+AUT

MODE

(RESET)

ON/OFF

O

.

▷

The burner control unit display and the burner

will switch off immediately. Mains voltage is still

supplied however. The display indicates “–”.

▷

The main fan cools the heater down until it

reaches switch-off temperature.

CAUTION

– Do not disconnect the heater from the electrical

power supply until the post-cooling process has

been completed.

▷ The display “–” will go out.

GB-8

D

GB

NL

RUS

PL

F

E

UA

CN

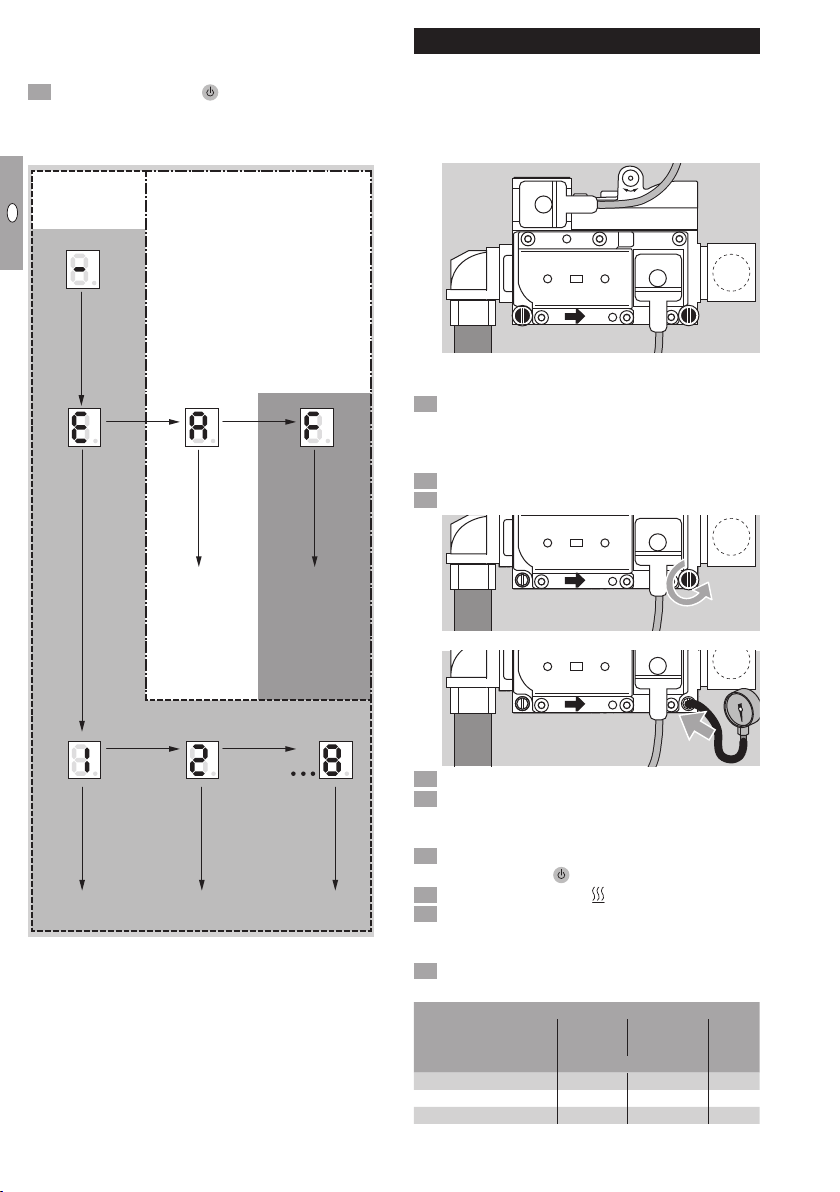

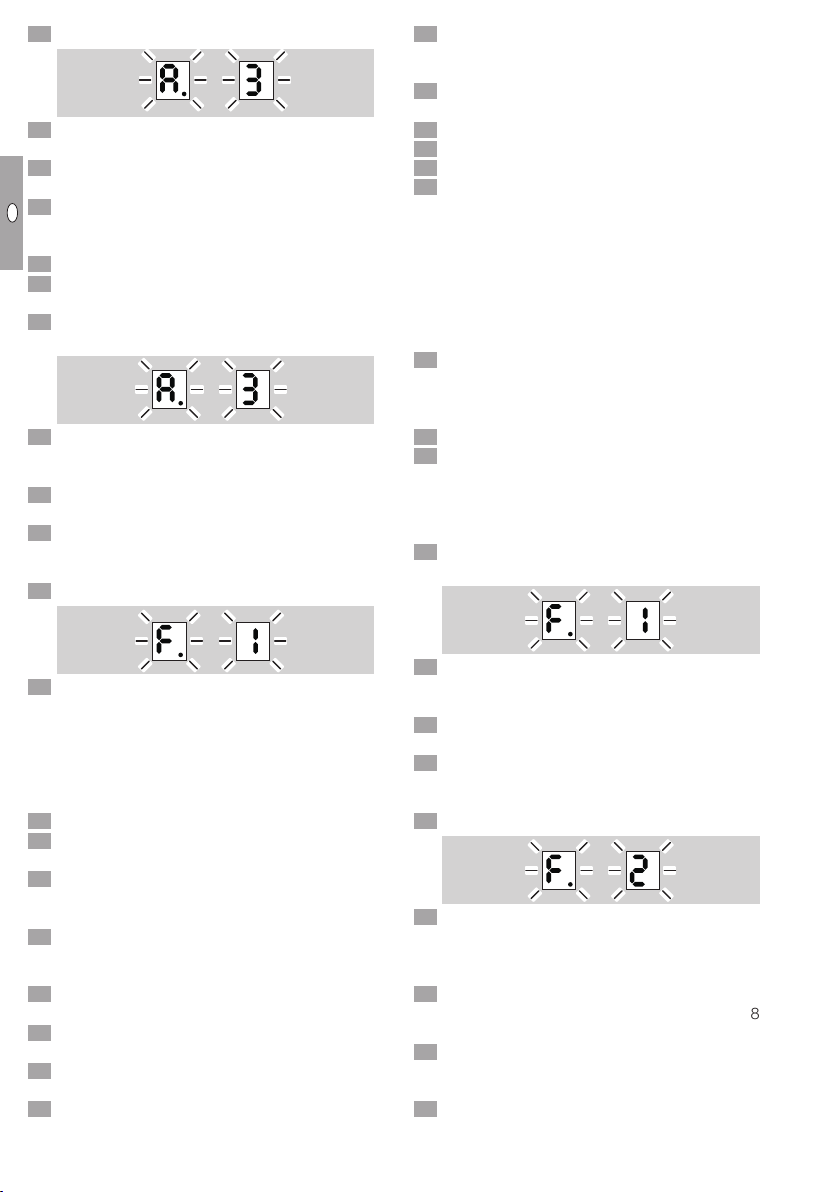

Setting mode

▷

Press and hold the MODE selection button when

the heater is switched off to go to Setting mode.

• Switch off the heater

OFF 1

2

3

4

5

AUTO

+AUT

MODE

(RESET)

ON/OFF

O

.

▷ Mode E: eBus addresses can be saved.

Mode A/F: multi-functional outputs can be pa-

rameterized.

MFA 2 MFA 1

eBus address

Mode E

Mode A/F

MODE

button

MODE

button

MODE

button

MODE

button

eBus adddress 1 ... eBus address 8

Save eBus address

0 Inactive

1 Fault (NC)

2 Fault (NO)

3 Operation

4 Standby

0Inactive

1 Main fan

active

2 Main fan

inactive

3 Modulation

enable

> 2 s MODE button

> 2 s MODE button

> 2 s MODE button

> 2 s MODE button

> 2 s MODE button

> 2 s MODE button

> 2 s MODE button

OFF

▷

Press the RESET button to return to the previ-

ous menu.

▷

After a timeout of 20s, the display will auto-

matically return to the initial mode. The display

indicates “–”.

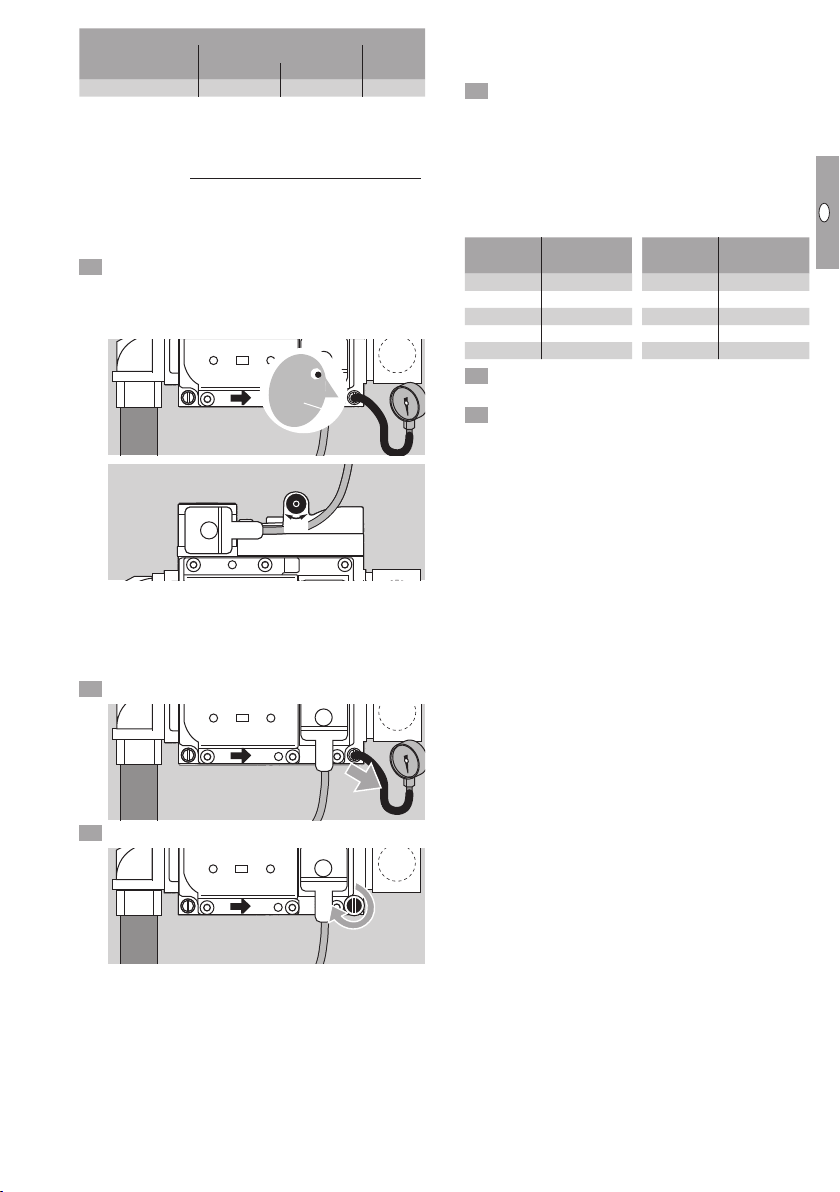

Adjusting the heater

Burner gas pressure pG

pu= Inlet pressure

pG= Gas pressure on the burner

▷

The gas pressure on the burner is adjusted using

pGon the combination control.

+ -

+

-

pupG

▷ For this, the outlet pressurepGmust be meas-

ured on the combination control.

Disconnect the system from the electrical power

supply. The mains plug may only be pulled out

once the device has been switched off and post-

cooling is complete.

Shut off the gas supply.

Open pressure test point pG.

+ -

+

-pG

+ -

+

-

0

p

G

4 Switch on the power supply.

5 Release the gas supply.

▷

The inlet pressurep

u

must comply with the tech-

nical data, see page23 (Technical data).

6 Switch on the burner control unit. Press the

ON/OFF button

OFF 1

2

3

4

5

AUTO

+ AUT

MODE

(RESET)

ON/OFF

O

until an LED lights up.

7 Select the Heating2operating mode.

8 Let all heaters burn for at least 20s.

▷

The required gas pressure on the burner depends

on the heating value/Wobbe index.

9 Select the required gas pressure on the burner

from the tables:

Natural gas, LPG

Gas type

Heating

value

Wobbe

index [mbar]

[MJ/m3]

Natural gas L G25 32.49 41.53 13.5

Natural gas H G20 37.78 50.71 9.5

LPG G 30 125.81 87.34 19.5

GB-9

D

GB

NL

RUS

PL

F

E

UA

CN

G+ K gas*

Gas type Wobbe index [MJ/m3][mbar]

min. max.

G+ K gas 43.46 45.3 13.5

* see page23 (The Netherlands)

▷

Converting the heating value/Wobbe index to

kWh/m3:

kWh/m3=

Heating value/Wobbe index [MJ/m3]

3.6

▷

Always use a pressure gauge to adjust the burner

gas pressure. The white scale on the adjusting

screw may differ.

0 If all heaters are heating at the same time, com-

pare the required gas pressure on the burner

with the gas pressurepGread off the pressure

gauge, adjust it and monitor the pressure gauge.

+ -

+

-

0

pG

+ -

+

-

pG

+ -

+-

▷ The flame must be blue and must remain inside

the device.

▷

Check and adjust the burner pressurep

G

and

flame signal on all devices so that the system

operates correctly.

Remove the pressure gauge from the test point.

+ -

+

-

0

pG

Close the pressure test point.

+ -

+

-pG

Flame signal

▷

The flame signal can be displayed while the

burner is operating.

Press the RESET button to display the flame

signal.

▷

The flame signal is shown in coded form as a

number from 0 to9.

This number must be multiplied by a factor of2.

The result of this multiplication is the level of the

flame signal inµA. Example: the number 3 cor-

responds to a flame signal of 6–8µA.

Display Flame

current [µA] Display Flame

current [µA]

00 – 2 510 – 12

12 – 4 612 – 14

24 – 6 714 – 16

36 – 8 816 – 18

48 – 10 918...

Check the flame signal.

▷ The flame signal is displayed for 20s.

Press the RESET button to exit the flame signal

display.

GB-10

D

GB

NL

RUS

PL

F

E

UA

CN

Cleaning

CAUTION

To ensure that no damage occurs during operation

and cleaning, please observe the following instruc-

tions. Otherwise, injuries or damage to the device

may occur and/or the function of the device may

be impaired, and the manufacturer’s warranty will

be cancelled.

– Sharp-edged metal sheets. Always wear protec-

tive gloves.

– After cleaning, check that the components on

and in the heater are in good condition. The

device may only be restarted if all safety devices

have been installed and the safety functions

have been checked.

– Clean the heater once a year when used in

horticulture and at regular intervals as well as

after each fattening period when used in ag-

riculture, as described below. Inadequate or

irregular cleaning can cause damage to the

device or lead to fire damage. For example, dirt

particles can catch fire and can be blown out

of the heater.

Switch off the burner control unit ACU.

Disconnect the system from the electrical power

supply.

▷ The mains plug may only be pulled out once the

device has been switched off and post-cooling

is complete.

Shut off the gas supply.

4 Check the cover on the burner control unit and

the housing cover to ensure they are both tightly

closed.

▷

The GP is made of high-quality stainless steel

and is resistant to external influences such as

dirt and moisture.

▷

The GP can be cleaned carefully both inside and

outside with a high-pressure cleaner.

▷

The water jet from the high-pressure cleaner can

cause serious damage to the heater compo-

nents. For example, the blade can be bent or

other parts such as the spark plug or rubber

seals can be displaced. Avoid direct contact.

▷ Do not direct the water jet straight at electrical

components such as the vane.

▷

Do not spray water or chemical cleaning agents

directly into the space between the fan shaft/

impeller wheel and motor. Do not clean the fan

shaft/impeller wheel with a high-pressure cleaner.

▷

The housing cover and cable glands on the ACU

must be closed during the cleaning process.

▷

The electrical components are protected from

moisture by additional water drip edges on the

housing cover. Direct water influence on the

edges of the housing cover should be avoided.

▷

A downward slope inside the device ensures

that dirty water drains out.

▷

Never direct the nozzle of the high-pressure

cleaner at the heater when the cleaner is set to

“water jet”. Always use the spray setting.

▷

The distance between the nozzle and the surface

to be cleaned must be at least 50cm. Placing

the high-pressure cleaner at too short a distance

can cause serious damage to the device.

> 50 cm

▷

To facilitate cleaning of the components inside the

housing, the maintenance cover on the casing

can be opened.

56

7 Clean the grille from the outside using a cloth.

▷ Clean the fan, vane and plates for the air intake

using a cloth only.

8 9 10

Clean the interior of the device carefully using air.

▷ The vane must not be bent.

Check that the vane switch is functional.

GB-11

D

GB

NL

RUS

PL

F

E

UA

CN

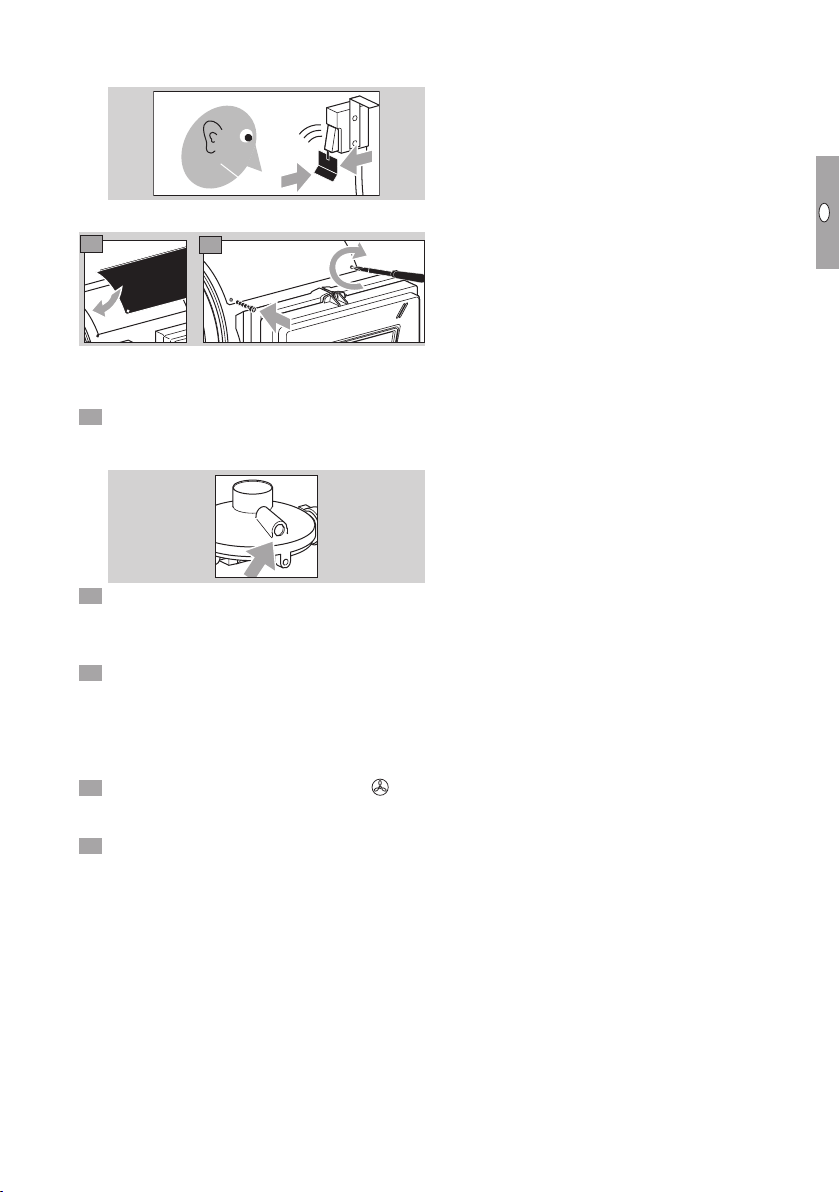

▷

If the vane is moved a little in the direction of the

arrow, a quiet click can be heard. This means

that the switching path is correct.

klick

Assembly

14

13

▷

Check the burner is functioning faultlessly in nor-

mal operation, see page 20 (Checking the

safety functions and burner operation).

5 When operating with propane, check that the

breather orifice of the pressure reducer on the

connection kit is clean.

6 After cleaning, check that all the parts on and

in the heater are in the correct positions, for ex-

ample whether the rubber seals between the

electrodes and terminal boots are fitted correctly.

7 Chemical cleaning agents, disinfectants and/or

pesticides contain corrosive substances which

can even corrode stainless steel. Always rinse

the devices with water after cleaning using such

agents to remove any residue of these agents

from the surface.

8 After cleaning, select operating mode 3Con-

trolled air flow so that the interior of the device

can dry properly.

9 After cleaning the heater, check it is functioning

faultlessly in normal operation, see page20

(Checking the safety functions and burner opera-

tion).

GB-12

D

GB

NL

RUS

PL

F

E

UA

CN

Assistance in the event of

malfunction

WARNING

To avoid harm to persons and animals or damage

to the heater, please observe the following:

– Electric shocks can be fatal! Before working

on possible live components, ensure the unit

is disconnected from the power supply.

– Fault-clearance must only be undertaken by

authorized trained personnel!

– Repairs to components, e.g. the burner control

unit ACU or the combination control CG, may

only be carried out by the manufacturer. Other-

wise, the guarantee will be cancelled. Unauthor-

ized repairs or incorrect electrical connections,

e.g. the connection of power to outputs, can

cause gas valves to open and the burner control

unit to become defective. In this case, fail-safe

operation can no longer be guaranteed.

– (Remote) resets may only be conducted by

authorized trained personnel with continuous

monitoring of the devices concerned.

▷

In the event of an installation fault, the burner

control unit closes the gas valves and the status

indicator light will be red at the latest after a

restart has been unsuccessful.

▷ The 7-segment display will show an error code

in the form of a letter with a decimal point and

a number alternately indicating a warning. To-

gether with the red status indicator light, this

then constitutes a fault.

▷ Warnings and faults may be cleared only using

the remedies described below.

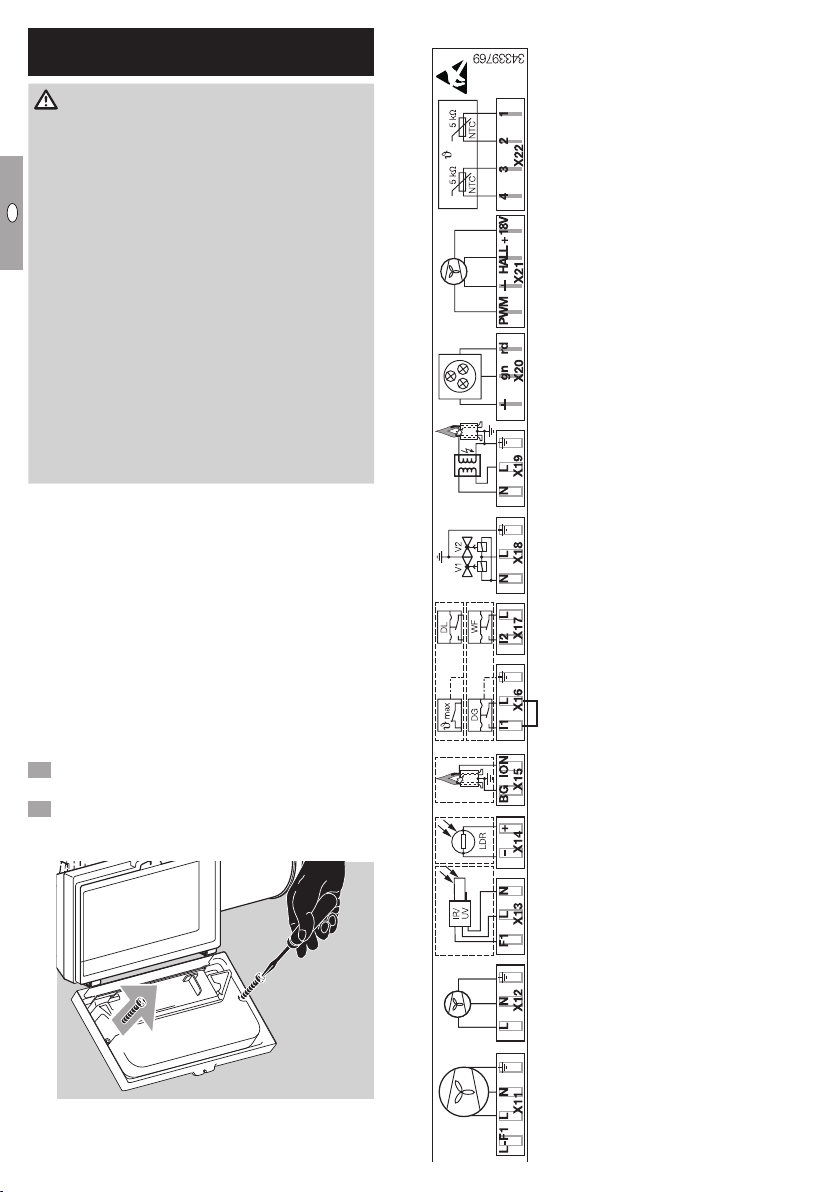

Internal wiring

▷

To rectify a fault, it is sometimes necessary to

check the internal wiring.

Open the housing cover of the burner control

unit.

Undo the two screws (M3) using a Phillips screw

-

driver and remove the complete plastic cover

from the burner control unit.

Internal connection diagram

LN LN NLT LV +T –+VmA V12

LLiN 12 +

0 V

D – 49018 Osnabrück, Germany

ACU

Main fan

Not used

Not used

Not used

Ionization

Gas pressure switch

Vane

Valves

Ignition

Not used

Not used

Safety temperature limiter (STL)

GB-13

D

GB

NL

RUS

PL

F

E

UA

CN

Press the RESET button to reset. The unit then

reverts to the last operating mode selected.

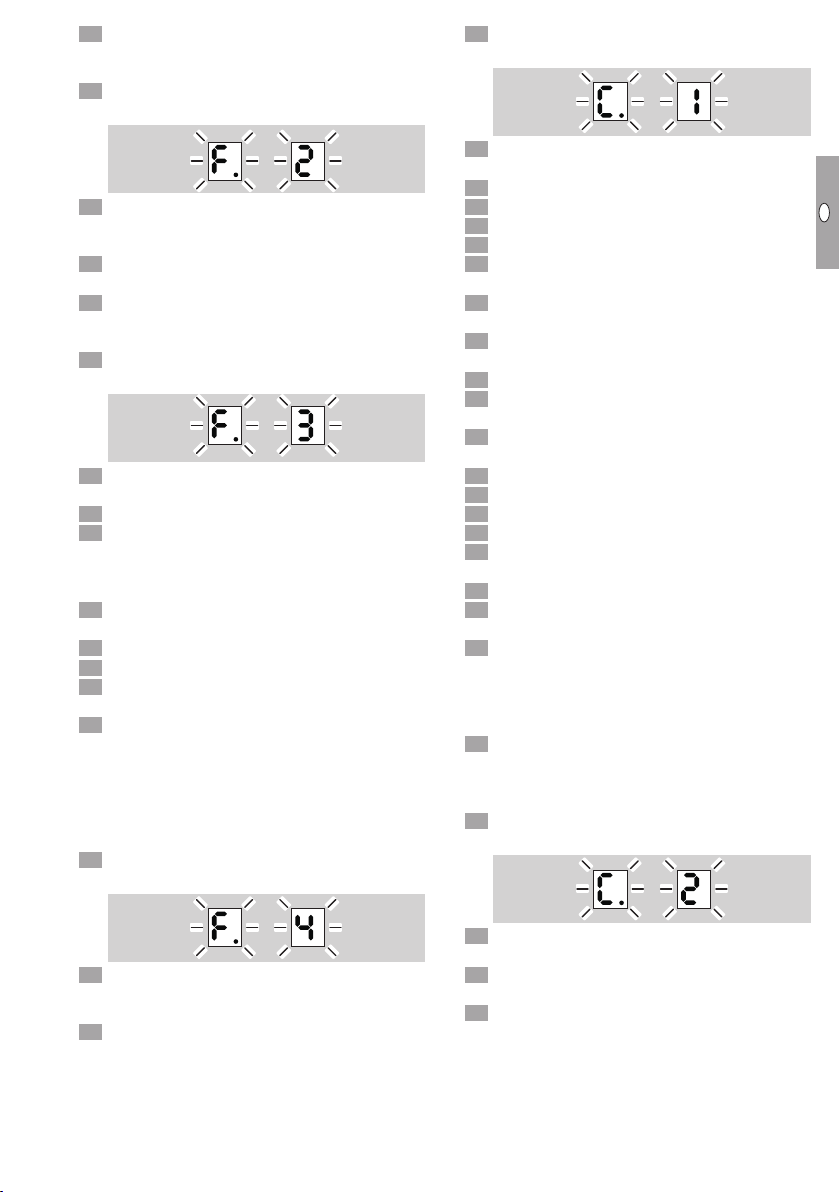

▷ Possible faults:

Display Fault type

FFlame fault

AAir fault

CTemperature fault

EElectronics fault

UOther possible faults

PGas-related faults

4 If the burner control unit does not respond even

though all the possible faults have been rectified

as described below, contact your supplier.

? Fault

! Cause

• Remedy

? The 7-segment display has gone out despite

the voltage supply being OK?

! Fuse F2 is defective.

• Check the fuse contacts.

There is a spare fuse directly next to the fuse

holder.

Attention! Fit the correct fuse for 4A.

LN LN NLT LV +T –+VmA V12

LLiN 12 +

0 V

D – 49018 Osnabrück, Germany

ACU

? Error code P. and 1flash alternately and the

light is red?

! Pressure switch does not switch.

• Check inlet pressure pu.

! Gas pressure on the burner too low.

• Readjust gas pressurep

G

on the combination

control, see page8 (Adjusting the heater).

! Fuse F2 defective.

• Replace fuse (3.15 A, slow-acting, H). Ensure

that only one heater is directly wired to the ther-

mostat, see page3 (Wiring).

? Error code P. and 2flash alternately and the

light is red?

! During three consecutive restarts, the gas pres-

sure switch has tripped during the safety time

or flame proving period (gas pressure switch

oscillates).

• Inlet pressure fluctuates. Establish stable gas

supply.

• Gas pressure pGtoo low. Readjust gas pres-

surepG, see page8 (Adjusting the heater).

? Error code A. and 1flash alternately?

! Vane switch switches off during burner operation.

• Check the function of the vane switch, see

page18 (Maintenance).

• Vane, fan or grille are dirty. Clean, see page18

(Maintenance).

• Fuse F1 defective (8 A, slow-acting, H). Check

the function of the fan and replace fuseF1 if

necessary.

! Motor defective.

• Remove the device and return it to the supplier.

? Error code A. and 2flash alternately?

! Vane switch does not switch off during the “no

flow” state check on burner start-up.

• Check that the vane switch is functional, see

page18 (Maintenance).

? Error code A. and 2flash alternately and the

light is red?

! The fault “Vane switch” could not be rectified.

The programmed number of start-up attempts

having failed, the ACU initiates a fault lock-out.

• Reset using the RESET button on the ACU or

via the remote reset.

• Check that the vane switch is functional, see

page18 (Maintenance).

GB-14

D

GB

NL

RUS

PL

F

E

UA

CN

? Error code A. and 3flash alternately?

! The vane switch has not switched on 15s after

the fan has been switched on.

• Vane, fan or grille are dirty. Clean, see page18

(Maintenance).

• Fuse F1 defective (8 A, slow-acting, H). Check

the function of the fan and replace fuseF1 if

necessary.

! Motor defective.

• Remove the device and return it to the supplier.

? Error code A. and 3flash alternately and the

light is red?

! The fault could not be rectified. The programmed

number of start-up attempts having failed, the

ACU initiates a fault lock-out.

• Reset using the RESET button on the ACU or

via the remote reset.

• Check that the vane switch is functional. Clean

the vane, fan or grille if soiled.

? Error code F. and 1flash alternately?

! On burner start-up, the ACU has not detected

a flame during the safety time. In the parameter

“Number of start-up attempts”, it is possible to

program up to three start-up attempts. If one

of the further start-up attempts is successful,

warning signalling stops automatically once the

post-purge time has elapsed.

! Ignition is not working properly.

• Clean the spark electrode and check for correct

distance, see page18 (Maintenance).

• Check the connection of the ignition cables for

damage or moisture.

▷ The spark plug must be fitted correctly.

• Check the ignition spark optically and acoustically

from the fan side during the 4-second ignition

time.

! Poor flame signal due to incorrect burner adjust-

ment.

• Readjust gas pressurepG, see page 8 (Ad-

justing the heater).

! Poor flame signal due to dirty/badly connected

flame rod.

• Clean the flame rod and check for correct dis-

tance, see page18 (Maintenance).

• Check the cable connection, cable and terminal

boot for damage or moisture. The terminal boot

must be fitted correctly.

• Check the yellow and green burner ground cable

for corrosion and to ensure it is firmly connected.

! Air in the gas pipe.

• Vent the gas pipe.

! Valves do not open.

• Remove the valve plug on the combination con-

trolCG and measure the voltage betweenL1

andN during the safety time. If the voltage is

not adequate, first replace the CG and return it

to the supplier.

Attention! Only commission the new ACU once

the short-circuit or fault on the valve output of

the CG has been remedied. Otherwise, the new

ACU will be damaged.

• If the fault continues to be signalled, there may

be a short-circuit on the valve output. Return

the burner control unit to the manufacturer for

inspection.

! Short-circuit on ignition output.

• Replace fine-wire fuse F2 (3.15A, slow-acting,

H) and check the safety function, see page20

(Checking the safety functions and burner opera-

tion).

? Error code F. and 1flash alternately and the

light is red?

! The fault could not be rectified. The programmed

number of start-up attempts having failed, the

ACU initiates a fault lock-out.

• Reset using the RESET button on the ACU or

via the remote reset.

• Rectify the cause of the fault as described for

warning F.1.

? Error code F. and 2flash alternately?

! The flame has gone out during operation. If a

restart has been programmed, an automatic re-

start is carried out provided that the burner has

been in operation for at least 2s beforehand.

• Poor flame signal due to incorrect burner adjust-

ment. Readjust gas pressurepG, see page8

(Adjusting the heater).

• Poor flame signal due to dirty or badly connected

flame rod. Clean the flame rod and check for

correct distance, see page18 (Maintenance).

• Check the cable connection for damage or mois-

ture. The terminal boot must be fitted correctly.

GB-15

D

GB

NL

RUS

PL

F

E

UA

CN

• Check the yellow and green burner ground cable

for corrosion and to ensure it is firmly connected.

? Error code F. and 2flash alternately and the

light is red?

! The fault could not be rectified. The programmed

number of start-up attempts having failed, the

ACU initiates a fault lock-out.

• Reset using the RESET button on the ACU or

via the remote reset.

• Rectify the cause of the fault as described for

warning F.2.

? Error code F. and 3flash alternately and the

light is red?

! The burner control unit detects a flame signal

during start-up or in fault status.

! A gas valve does not close correctly.

• Shut off the gas supply to the device. Check the

burner and gas valves for correct function, see

page20 (Checking the safety functions and

burner operation).

! Incorrect flame signal due to leakage/creepage

current.

• Check wiring, see page3 (Wiring).

• Check the flame rod.

! Incorrect flame signal through conductive ce-

ramic insulation, e.g. surge via PE wire, possible.

• Remedy incorrect flame signal. Replace the flame

rod and, if necessary, also the complete burner

control unit and housing.

▷

Reset is only possible by pressing the RESET

button on the burner control unit or using the

remote reset if there is one.

? Error code F. and 4flash alternately and the

light is red?

! The flame has not gone out within 5s of the

burner being switched off. A gas valve does not

close correctly.

• Shut off the gas supply to the device. Check the

burner and gas valves for correct function, see

page20 (Checking the safety functions and

burner operation).

? Error code C. and 1flash alternately and the

light is red after 5minutes?

! Signal from safety temperature monitor (STM).

Temperature has been exceeded.

• Leave heater to cool down for longer.

! The main fan does not switch on.

• Check the main fan.

! Wiring fault.

• Check the wiring to actuate the main fan, see

page3 (Wiring).

! The safety temperature monitor (STM) is incor-

rectly aligned.

• Check the position of the safety temperature

monitor(STM).

! Ambient temperature exceeded.

• The temperature is >40°C. Allow the room to

cool.

! The safety temperature monitor (STM) is measur-

ing an incorrect temperature.

• Replace the safety temperature monitor.

! The heater is badly soiled.

• The heater must be cleaned urgently.

! Installation position.

• The heater is too close to other heaters, see

page2 (Installation).

! Device incorrectly set.

• The heater is not set correctly and must be ad-

justed, see page8 (Adjusting the heater).

! In the event of a power failure during operation,

the heater will be switched off without a cool-

ing phase. If the power failure lasts less than

5minutes, the combustion chamber will heat

the device and the STL will issue a signal.

• In this case, Controlled air flow mode is activated.

If the heater has been successfully cooled within

1minute, it will restart.

? Error code C. and 2flash alternately and the

light is red?

! Signal from safety temperature limiter (STL).

Temperature has been exceeded.

! The cause of the fault as described above for

faultC.1 could not be rectified.

• Check the heater for damage, see page18

(Maintenance).

GB-16

D

GB

NL

RUS

PL

F

E

UA

CN

? Error code C. and 9flash alternately and the

light is red?

! Temperature sensor incorrectly connected.

• Check contact at connector X22.

! Temperature sensor is below -30°C.

! Temperature sensor defective.

• Replace temperature sensor.

! Incorrect temperature sensor.

▷ Sensor BCU is not compatible with the ACU.

• Select the correct temperature sensor for the

ACU.

? Error code E. and 1flash alternately?

! The remote reset input is defective.

• If you use the remote reset input, contact your

supplier.

? Error code E. and 2flash alternately and the

light is red?

! An adjustable parameter and the CRC check are

not the same. The parameters are implausible.

• Order a new BCC. Contact your supplier.

▷

Reset is only possible by pressing the RESET

button on the burner control unit or using the

remote reset if there is one.

? Error code E. and 3flash alternately and the

light is red?

! A fixed parameter and the CRC check are not

the same. The parameters are implausible.

• Order a new BCC. Contact your supplier.

▷

Reset is only possible by pressing the RESET

button on the burner control unit or using the

remote reset if there is one.

? Error code E. and 4flash alternately and the

light is red?

! Limits for fixed parameters not observed.

• Order a new BCC. Contact your supplier.

? Error code E. and 5flash alternately and the

light is red?

! The BCC is not connected.

• Connect the BCC to the printed circuit board.

? Error code E. and 6flash alternately and the

light is red?

! An incorrect BCC is connected. The BCC must

be compatible with the GP.

• Remove the BCC and connect the correct BCC

to the printed circuit board, see page6 (Burn-

er Chip Card (BCC)).

? Error code E. and 8flash alternately?

! Programming mode is active.

• As soon as Programming mode has been de-

activated, the display will go out.

? Error code E. and 9flash alternately?

! Internal electronics fault.

• Remove the BCC and return it to the supplier.

? Error code U. and 1 flash alternately and the

light is red?

! Voltage supply is below the limit (programmable

limit, e.g. <160V).

• Ensure that adequate mains voltage is supplied.

GB-17

D

GB

NL

RUS

PL

F

E

UA

CN

? Error code U. and 2flash alternately and the

light is red?

! Voltage supply is above the limit (programmable,

e.g. >260V).

• Ensure that adequate mains voltage is supplied.

? Error code U. and 3flash alternately and the

light is red?

! All start-up attempts in the programmed voltage

range (e.g. 160–180V) were unsuccessful. The

last start-up attempt is not made to prevent a

lock-out.

• Ensure that adequate mains voltage is supplied.

? Error code U. and 5flash alternately and the

light is red?

! While a fault was pending, the unit has been

successfully reset more than 5 times within

15minutes using the remote reset input.

▷

Reset is only possible by pressing the RESET

button on the burner control unit or using the

remote reset if there is one.

? Error code U. and 6flash alternately and the

light is red?

! The unit has been unsuccessfully reset more

than 10times within 15minutes using the remote

reset input.

▷

Reset is only possible by pressing the RESET

button on the burner control unit or using the

remote reset if there is one.

? A circulating dash is displayed rather than

an error code?

▷

After switching on the voltage, a circulating dash

is displayed.

! Switch-on delay time running.

Or

! Cycle lock active. The time (cycle lock) between

two starts is too short.

▷ The display will go out automatically as soon as

the time between two starts is long enough. The

burner control unit will ensure a pause between

start-up attempts on the basis of its parameteri-

zation. This warning is displayed during this time.

Or

! The pressure switch signal does not drop when

the main fan is switched off.

▷ A burner restart is not possible.

▷ After 25s, the display will change to error code

A. 9.

GB-18

D

GB

NL

RUS

PL

F

E

UA

CN

Maintenance

CAUTION

To ensure that no damage occurs during operation

and maintenance, please observe the following

instructions. Otherwise, injuries or damage to the

device may occur and/or the function of the device

may be impaired. The supplier/manufacturer cannot

accept liability for damage resulting thereof.

– Have the heater cleaned at least once a year

by qualified maintenance personnel.

– Have the safety functions checked at least once

a year by qualified maintenance personnel, see

page20 (Checking the safety functions and

burner operation).

– Sharp-edged metal sheets. Always wear protec-

tive gloves.

– After cleaning or repair work, check that the

components on and in the heater are in good

condition. The device may only be restarted

if all safety devices have been installed and

the safety functions have been checked, see

page20 (Checking the safety functions and

burner operation).

Switch off the burner control unit ACU.

Disconnect the system from the electrical power

supply.

▷ The mains plug may only be pulled out once the

device has been switched off and post-cooling

is complete.

Shut off the gas supply.

▷

To facilitate cleaning of the components inside

the housing, the service cover on the casing

can be opened.

45

▷ Alternatively, the fan may be removed.

7

68

10

911

Clean the grille with a cloth.

Clean the interior of the device carefully using air.

▷ The vane must not be bent.

4 Clean the fan and vane using a cloth.

5 Check that the vane switch is functional.

▷

If the vane is moved a little in the direction of the

arrow, a quiet click can be heard. This means

that the switching path is correct.

klick

▷ Check the nozzle and burner baffle plate for dirt

and if necessary, clean using a cloth. Remove

first the burner baffle plate, then the nozzle. To

do this, a special tool is required. Nozzle spanner

size = A/F 36 and A/F 46. The nozzle is secured

via the burner baffle plate by a cross-head screw.

17

16

8 Loosen the A/F 36 nut to detach the gas pipe.

Note the seal.

9 Then loosen the A/F 46 nut.

SW 36

SW 46

▷ Remove the nozzle.

20

▷

The flame rod and spark electrode can be re-

moved without having to dismantle the combus-

tion chamber.

GB-19

D

GB

NL

RUS

PL

F

E

UA

CN

Check the nozzle for signs of damage and dirt

and clean if required.

SW 21

SW 22

242322

272625 SW 21

8 Check the electrodes for dirt and if necessary,

clean using a cloth. Remove stubborn dirt on

the electrode rod using fine abrasive paper.

9 Check electrodes and porcelain insulators for

cracks and replace the electrodes in case of

damage.

▷ Replace the electrodes if necessary.

▷ Fit the electrode seal.

0 Clean the plates for the air intake using a cloth.

Assembly

▷ Ensure that the rubber seals between the elec-

trodes and the terminal boots are fitted correctly.

SW 21

SW 22

31

363534

3332

SW 21

▷

Ensure the electrodes are at the correct distance

from one another and correctly positioned as

regards the nozzle.

2 mm

▷

The device may only be restarted if all safety

devices have been installed.

38

37 39

41

40 42

4 Check the safety functions before commission-

ing, see page20 (Checking the safety func-

tions and burner operation).

GB-20

D

GB

NL

RUS

PL

F

E

UA

CN

Checking the safety functions and

burner operation

WARNING

If these checks are not carried out, the gas valves

might remain open allowing non-combusted gas

to escape. Risk of explosion!

Safety functions

Switch off the heater during operation. Press

ON/OFF

OFF 1

2

3

4

5

AUTO

+ AUT

MODE

(RESET)

ON/OFF

O

.

▷ The flame goes out <1s.

▷

The fan cools the heater down until it reaches

switch-off temperature.

Remove the valve plug on the combination con-

trol during operation.

▷ The gas valves close <1s.

▷ The flame goes out.

▷ The burner control unit ACU displays the warn-

ing message “The flame has gone out during

operation”. Error code F. and 2 flash alternately.

▷

If a restart has been programmed, the burner

control unit will initially attempt to restart and

will then perform a fault lock-out. Error code F.

and 1 flash and indicate the fault message “No

flame has been detected during the safety time”.

Shut off the inlet pressure during operation.

▷ The pressure switch in the combination control

switches because the supply pressure is too low.

▷

The burner control unit performs a safety shut-

down: the gas valves are disconnected from the

electrical power supply.

▷ The flame goes out.

▷

The burner control unit ACU displays the fault

message “Supply pressure too low”. Error code

P. and 1 flash alternately and the light is red.

▷ If the burner control unit responds in a different

way to that described, a fault has occurred, see

page12 (Assistance in the event of malfunc-

tion).

CAUTION

The fault must be remedied before the system may

be operated.

Checking burner operation

Switch on the ACU.

Select operating mode2

OFF 1

2

3

4

5

AUTO

+ AUT

MODE

(RESET)

ON/OFF

O

Heating.

Allow the burner to burn for 15minutes.

4 During this time, monitor the flame pattern.

▷ The flame must be blue.

▷ No dirt particles must come out of the heater.

Accessories

Room thermostat

Use a room thermostat with a hysteresis of ±1°C,

230V, Type TH215.

35

30

25

2015

10

5

0

°C

TH215

OrderNo.: N50260145

Pressure reducer

Pressure reducer for LPG.

RECA 1.5 bar to 50mbar, 2x½" internal thread

connection, 10kg/h, Order No.: N52600023.

Manual valve

2 x ½"internal thread connection,

Order No.: N52600019.

½"internal and external thread connection,

Order No.: N52600027.

Table of contents

Other ermaf Heater manuals

Popular Heater manuals by other brands

Somogyi Elektronic

Somogyi Elektronic Home FK 130/2000 instruction manual

Heat Storm

Heat Storm Tradesman HS-1500-TT User manual and safety instruction

Jobsite

Jobsite CT2142 Original instructions

De Vielle

De Vielle DEF057232 Installation instructions manual

Kenmore

Kenmore 13477900B (0807) Use & care guide

Jata calor

Jata calor C204NT INTRUCTIONS OF USE