ermaf GP 120 User manual

© 2013 Elster-Instromet B.V.

➔www.docuthek.com

D GB NL RUSPL F E UA

Safety

Please read and keep in a safe place

Please read through these instructions

carefully before installing or operating. Following the

installation, pass the instructions on to the opera-

tor. This unit must be installed and commissioned

in accordance with the regulations and standards

in force. These instructions can also be found at

www.docuthek.com.

Explanation of symbols

• , , , ... = Action

▷= Instruction

Liability

We will not be held liable for damage resulting

from non-observance of the instructions and non-

compliant use.

Safety instructions

Information that is relevant for safety is indicated in

the instructions as follows:

DANGER

Indicates potentially fatal situations.

WARNING

Indicates possible danger to life and limb.

CAUTION

Indicates possible material damage.

Maintenance and repairs may only be carried out by

qualified gas technicians and electrical interventions

may only be carried out by qualified electricians.

Conversion, spare parts

All technical changes are prohibited. Only use OEM

spare parts.

Transport

On receipt of the product, check that the delivery

is complete (see page 2 (Part designations)). Report

any transport damage immediately.

Storage

Store the product in a dry place. Ambient tempera-

ture: see page 17 (Technical data).

Changes to edition .

The following chapters have been changed:

– Checking the usage

– Installation

– Accessories

– Technical data

– Contact

Contents

Operating instructions

Translation from the German

D

GB

F

NL

I

E

GB-1

0558 Edition 06.

Heater GP 0..........................

Contents ..............................

Safety.................................

Checking the usage .....................

Type code .............................2

Part designations ........................2

Type label..............................2

Installation ............................

Tightness test ..........................

Removing the protective caps (optional)....

Wiring ................................

Connecting the room thermostat for “Heating”

and “Controlled air flow” mode..............4

Connecting multiple heaters to a single

room thermostat ........................5

Reset, alarm, external fan..................5

Adjusting the switch-on delay tE............5

Commissioning.........................6

Adjusting the heater.....................6

Installing the protective caps .............7

Cleaning ..............................8

Assistance in the event of malfunction .....9

Maintenance ..........................

Checking the safety functions and

burner operation ......................4

Accessories ..........................4

Spare parts ...........................6

Technical data ........................7

Declaration of conformity ...............7

Goods return form . . . . . . . . . . . . . . . . . . . . . 8

Contact ..............................8

Heater GP 0

Contents

Safety

GB-2

D

GB

F

NL

I

E

Checking the usage

GP 0

Heater with direct, open combustion for agricultural

stables and horticultural greenhouses. Depending

on the type and setting, the heater can be operated

with natural gas or LPG (propane/butane).

This function is only guaranteed when used within the

specified limits – see page17 (Technical data).

Any other use is considered as non-compliant.

Type code

Code Description

GP Heater

0 Capacity 120kW, jet length 50 m

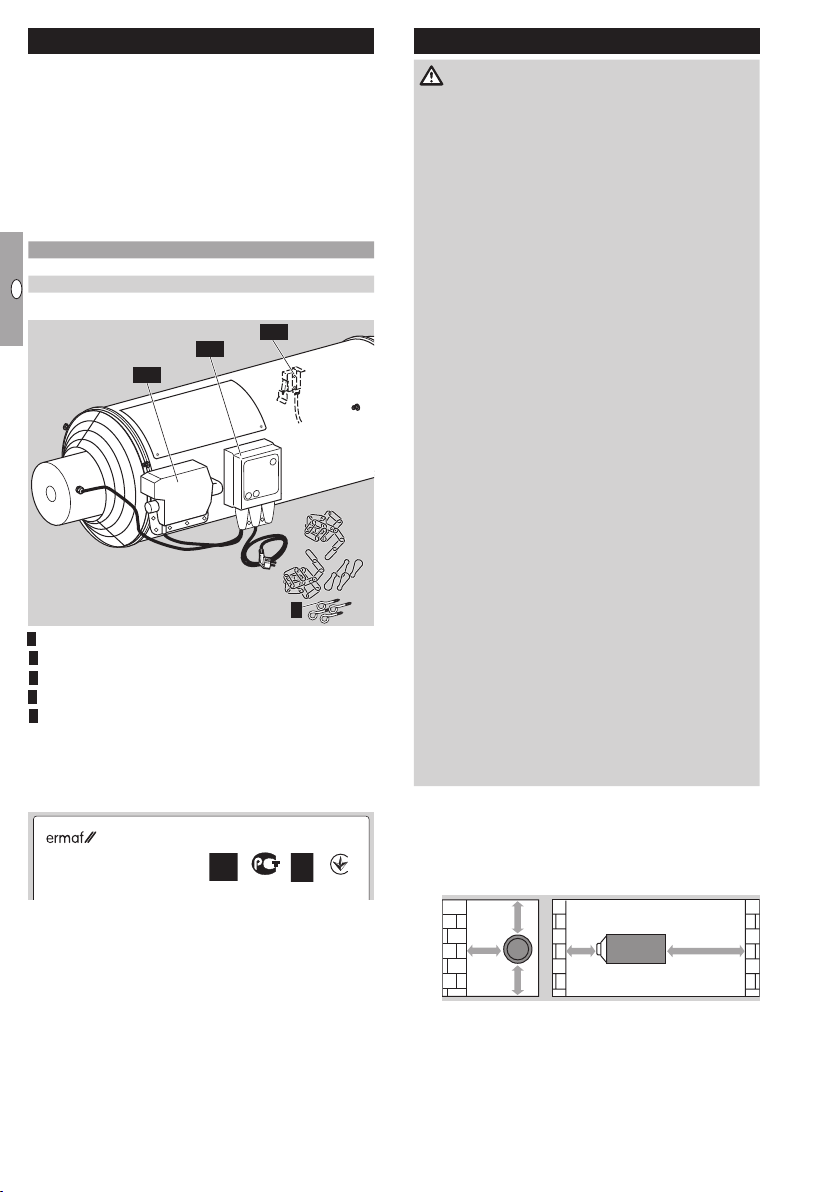

Part designations

4

3, 5

2, 5

1, 5

Burner control unit BCU

Gas combination control CG

Vane

4Assembly accessories

5Protective cap set for use in agriculture (option)

Type label

Air circulation, electrical connection rating, voltage,

rated heat input, gas type, category, supply pressure,

burner pressure, enclosure: see type label.

Elster s.r.o.

Dr. A. Schweitzera 194

SK-91601 Stará Turá

UA.TR012-13AИ 50

● Before installation, check whether the device is

suitable for the regional gas type and the specified

limits, see type code and page 17 (Technical

data).

Installation

DANGER

Danger of death! Gases are generated during the

storage of slurry which remain partly dissolved in

the liquid. If the slurry is strongly agitated during

mixing and purging, poisonous, explosive gases

such as hydrogen sulphide and methane are re-

leased. If an ignition source is present, the released

gas can explode.

To avoid damage during operation, please observe

the following:

– Switch off the heater before mixing and purging

the slurry.

– Close the slide valves when storing slurry out-

side.

– The fan for the air supply must not be part of a

closed pipe system.

– The space to be heated must be adequately

ventilated.

For mechanical extraction equipment: at least

10m3/h of air per installed capacity.

In the case of natural ventilation, the structure

must have two apertures with a free opening

area of 60x B in cm2. “B” is the installed capac-

ity in kW. Replacement of the full air volume per

hour is thus ensured.

– In the case of natural ventilation, the maximum

allowable total capacity of the heater is 1kW

per 20m3of volume.

– Respect the safety distance of the heater to

inflammable materials, see “Installation position”.

– Consult your fire insurance provider and/or local

fire protection engineer to assess the foresee-

able, general risk of fire.

– For cleaning, care and maintenance, note the

applicable national regulations and directives.

– No condensation permitted. Check the ambient

temperature, see page 17 (Technical data).

Installation position

▷ To ensure that the vane functions faultlessly, in-

stall the unit in the horizontal position.

▷

Note the safety distance to walls and inflam-

mable materials.

> 1m

> 0,8m

> 1m

> 3 m> 1m

▷ Ensure sufficient free space around the device.

There must be no obstructions in front of the inlet

and outlet side of the heater.

▷ To avoid overheating, do not cover the electric

motor.

GB-3

D

GB

F

NL

I

E

Connecting the gas supply

▷

If the heater is suspended on chains, use an

approved flexible gas hose.

Disconnect the system from the electrical power

supply.

Shut off the gas supply.

Remove the screw plug at the inlet tube of the

gas combination controlCG.

4 Connect the gas pipe with threaded connection

(Rp¾" internal thread) or gas hose, see page14

(Accessories), to the inlet tube of the gas com-

bination control.

▷ Use approved sealing material only.

▷ Note the maximum inlet pressure, see page17

(Technical data).

Tightness test

▷ The system is disconnected from the electrical

power supply. The valves are thus closed.

N2

= max. 100 mbar

1 2

Removing the protective caps

(optional)

▷ For agricultural use, the burner control unit, gas

combination control and vane switch are mostly

protected against ingress of dirt and moisture

by a cap.

▷ To wire the burner control unit and to start and

adjust the heater, the protective caps are to be

removed as described below.

▷ Do not remove the protective cap on the vane

switch.

Burner control unit

Slowly pull apart the ends of the protective cap

on the back of the burner control unit until the

rivets come undone.

ON/OFF

(RESET)

MODE

OFF

AUTO

+AUTO

Pull the opened edges of the protective cap out

fully so that the edges are pulled out from between

the burner control unit and the mounting plate.

ON/OFF

(RESET)

MODE

OFF

AUTO

+AUTO

Remove the opened protective cap from the

burner control unit by pulling it upwards.

ON/OFF

(RESET)

MODE

OFF

AUTO

+AUTO

Gas combination control

Slowly pull apart the ends of the protective cap

on the underside until all the rivets come undone.

Starting on the right-hand side, pull the opened

protective cap upwards over the gas outlet.

Remove the protective cap completely by pulling

over the left-hand side of the gas inlet.

Wiring

CAUTION

Danger of electric shocks!

– Before working on possible live components,

ensure the unit is disconnected from the power

supply.

Disconnect the system from the electrical power

supply. The mains plug may only be pulled out

once the device has been switched off.

Shut off the gas supply.

▷ If there is a protective cap on the burner control

unit, this must first be removed.

▷ When opening the burner control unit, do not in-

cline the upper housing section during its removal

to prevent the plug connectors from being bent.

4

3

GB-4

D

GB

F

NL

I

E

Burner control unit BCU connection diagram

12345678910111213141516

17 18 19 20 21 22 23 24 25 26 27 28 29 30 31 32

PE

N (L2)

L1 (L1)

F1

F2

V2V1

WF

24 V

0 V

ϑ

ϑ

IZ

PE

BCU 300:THP-G

DG

max. 2 A,

253 V

max. 5 A,

253 V

N

F1 T 8A H

F2 T 3,15A H

IEC 60127-2/5

N

AC/DC

ϑ

35453625

▷ In order to ensure post-cooling, the heater con-

stantly requires 230 V AC.

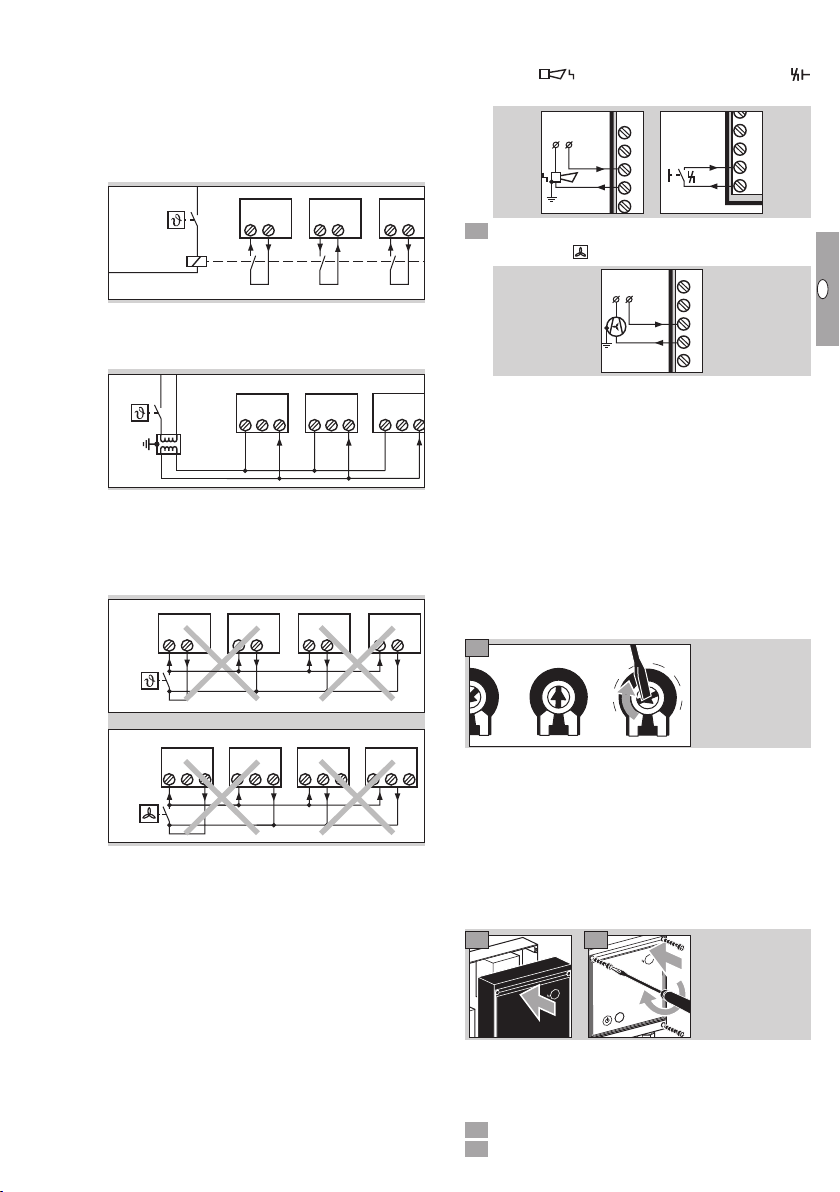

Connecting the room thermostat for “Heating”

and “Controlled air flow” mode

▷

Use a room thermostat with a hysteresis of ±1°C.

It switches on if the room temperature is 1°C

less than the set temperature and switches off

again once the room temperature is 1°C more

than the set temperature.

▷ Do not directly connect the room thermostat to

terminals1 and3.

5 Connect the terminals for Controlled air flow

ϑ

and Heating

ϑ

.

31 3229 3028

31 3229 3028

0

26 27

28

24 2523

0

26 27

28

24 2523

230 V ~ 230 V ~

+24 V =/~

+24 V =/~

+24 V =/~

+24 V =/~

GB-5

D

GB

F

NL

I

E

Connecting multiple heaters to a single room

thermostat

▷ Phase reversal will result in a short-circuit.

▷ Do not install different phases of a three-phase

current system at the inputs if the voltage be-

tween the phases exceeds 230V (+10%).

▷

Multiple heaters must be wired to the thermostat

via a relay.

29

K3/1

K3

24 V=/230 V~

230 V~

230 V~

230 V~

30

1. GP

29 30

2. GP

29 30

3. GP

K3/2K3/3

▷

At 24VDC/AC, multiple heaters can be con-

trolled in parallel.

▷ Note the polarity!

230 V~

24 V=/~

1. GP

26 2725

2. GP

26 2725 26 2725

3. GP

▷

Do not directly connect the thermostat to mul-

tiple heaters.

▷

Do not connect terminals28, 29 and30 directly

to the next heater. A short-circuit can occur due

to different phases and polarities.

29 30

1. GP

29 30

2. GP

29 30

3. GP

29 30

3. GP

28 29

1. GP

30 28 29

1. GP

30 28 29

1. GP

30 28 29

1. GP

30

Reset, alarm, external fan

▷

For external fault signalling, an external

alarm

ϑ

and an external reset button

ϑ

can be connected.

22 2320 2119

NL1

31 3229 30

28

230 V ~

max. 2 A

230 V ~

6 For improved air circulation in the room, an ad-

ditional fan

ϑ

can be connected.

24 25 2622 2321

NL1

253 V AC

max. 5A

▷ In case of a power failure, an emergency power

supply unit should automatically take over the

power supply. Emergency power supply units

with a cardan shaft drive for tractor attachment

are also suitable.

Adjusting the switch-on delay tE

▷

If multiple heaters switch on at the same time,

there can be a gas and/or power shortage on in-

dividual devices. To avoid this happening, adjust

the switch-on delaytEusing the potentiometer

in the upper housing section of burner control

unitBCU.

▷ The potentiometer is set to 0s at the factory.

tN

tM

0

1

0

2

0

3

0

4

0

5

0

6

0

tE

7

▷ We recommend using a switch-on delaytEof 5

to 10s between each device.

▷

The post-cooling timet

N

is set to 50s at the

factory and the minimum burner on timetMto

0s. These values must not be changed.

▷

Once the wiring is complete, close the BCU

again. Ensure that the upper housing section is

not inclined when being replaced on the lower

housing section.

98

▷

To guarantee that the burner control unit com-

plies with enclosure IP54, make sure that the

screws are tightly secured after wiring and that

the cable glands are closed.

0 Switch on the power supply.

Release the gas supply.

GB-6

D

GB

F

NL

I

E

Commissioning

▷ The heater may only be commissioned once it

has been ensured that the heater, gas pipes,

mains voltage supply and room thermostat have

been installed by authorized, trained personnel

according to the regulations.

Switch on the power supply.

Release the gas supply.

Part designations

ON/OFF (RESET)

MODE

OFF

AUTO

+AUTO

3

4

5

2

1

MODE/RESET selection button

BCU On/Off switch

Red lamp lights up if a fault is pending

4Operating mode LED: Off

5LEDs for selectable operating modes

▷

The BCU is operated using two buttons:

using the ON/OFFbutton

OFF 1

2

3

4

5

AUTO

+ AUT

MODE

(RESET)

ON/OFF

O

, the heater is

switched on and off. By pressing the MODE

selection button for >1s, it is possible to switch

between the different operating modes.

Operating

mode Explanation

OFF 1

2

3

4

5

AUTO

+ AUT

MODE

(RESET)

ON/OFF

O

BCU waits for the signals for controlled

air flow or heating.

OFF 1

2

3

4

5

AUTO

+ AUT

MODE

(RESET)

ON/OFF

O

Heating (continuous operation)

OFF 1

2

3

4

5

AUTO

+ AUT

MODE

(RESET)

ON/OFF

O

Controlled air flow (continuous opera-

tion)

OFF 1

2

3

4

5

AUTO

+ AUT

MODE

(RESET)

ON/OFF

O

Controlled air flow (continuous opera-

tion) and heating when thermostat sig-

nal is applied

Switching on

Switch on the burner control unit. Press ON/OFF

OFF 1

2

3

4

5

AUTO

+ AUT

MODE

(RESET)

ON/OFF

O

until an LED lights up.

▷

The BCU switches on in the last operating mode

selected.

▷ The heater starts once the set switch-on delay

timetEhas elapsed, see page5 (Adjusting the

switch-on delay tE).

▷ The burner starts after the safety time of 5s has

elapsed and operates in the selected operating

mode.

▷ The operating mode can be changed using the

MODE selection button. The selected operating

mode is only activated once the device has been

in this position for at least 3s. It is thus possible

to “scroll” through the different operating modes.

Switching off

4 Switch off the heater. Press ON/OFF

OFF 1

2

3

4

5

AUTO

+ AUT

MODE

(RESET)

ON/OFF

O

. The LED

next to “

OFF 1

2

3

4

5

AUTO

+ AUT

MODE

(RESET)

ON/OFF

O

” lights up and the burner switches off

after 3s. Mains voltage is still supplied however.

▷

The fan cools the heater down until it reaches

switch-off temperature.

Faults

▷

Flashing LEDs signal the cause of a fault, see

page9 (Assistance in the event of malfunction).

▷

In the first 4s after switching on the power supply

or pressing the ON/OFFbutton

OFF 1

2

3

4

5

AUTO

+ AUT

MODE

(RESET)

ON/OFF

O

, an operating

mode is not yet active. Within these 4s, a new

operating mode can be selected. As soon as

the MODE selection button has been pressed

and a new operating mode has been selected,

the 4s are extended accordingly.

▷

If a fault has occurred, it is displayed immediately,

but 4s are also available here during which a

new operating mode can be selected.

Adjusting the heater

Burner gas pressure pG

pu= Inlet pressure

pG= Gas pressure on the burner

▷

The gas pressure on the burner is adjusted using

pGon the combination control.

p

G

0

pG

pG

pG

pG

pu

2,5 mm

0

pG

▷ For this, the outlet pressurepGmust be meas-

ured on the combination control.

Disconnect the system from the electrical power

supply. The mains plug may only be pulled out

once the device has been switched off and post-

cooling is complete.

Shut off the gas supply.

Open the test nipple.

p

G

0

pG

pG

pG

pG

pu

2,5 mm

0

pG

4 Connect a pressure gauge with display range

10to 50mbar.

p

G

0

pG

pG

pG

pG

pu

2,5 mm

0

pG

5 Switch on the power supply.

6 Release the gas supply.

GB-7

D

GB

F

NL

I

E

▷

The inlet pressurep

u

must comply with the tech-

nical data, see page17 (Technical data).

7 Switch on the burner control unit. Press the

ON/OFFbutton

OFF 1

2

3

4

5

AUTO

+ AUT

MODE

(RESET)

ON/OFF

O

until an LED lights up.

8 Select the Heating

OFF 1

2

3

4

5

AUTO

+ AUT

MODE

(RESET)

ON/OFF

O

operating mode.

9 Let all heaters burn for at least 20s.

▷

The required gas pressure on the burner depends

on the lower calorific value/Wobbe index.

0 Select the required gas pressure on the burner

from the table.

Lower

calorific

value

Wobbe

index [mbar]

[MJ/m3]

Natural gas L G25 32.49 41.53 9.2

Natural gas H G20 37.78 50.71 6.3

LPG G 30 125.81 87.34 24.0

▷

Converting the lower calorific value/Wobbe index

to kWh/m3:

kWh/m3=

Lower calorific value/Wobbe index [MJ/m3]

3.6

▷

Always use a pressure gauge to adjust the burner

gas pressure. The white scale on the adjusting

screw may differ.

If all heaters are heating at the same time, com-

pare the required gas pressure on the burner

with the gas pressurepGread off the pressure

gauge, adjust it and monitor the pressure gauge.

p

G

0

pG

pG

pG

pG

pu

2,5 mm

0

pG

Flame signal

▷ The flame signal is displayed for 20s.

Check the flame signal.

▷

For adjustment and maintenance work, the flame

signal can be displayed.

▷

Display of the flame signal starts when the se-

lection button is pressed and within 1s (almost

simultaneously), ON/OFF

OFF 1

2

3

4

5

AUTO

+ AUT

MODE

(RESET)

ON/OFF

O

is pressed, too.

●= LED is constantly lit

○= LED flashes

µA

2 3 4 6 8 10 12 14 16 18 20

OFF 1

2

3

4

5

AUTO

+ AUT

MODE

(RESET)

ON/OFF

O

○ ●

○●●●

○●●●●●

○●●●●●●●

○●●●●●●●●●

▷

The flame signal is sufficient when 2LEDs are

constantly lit and the third LED flashes.

▷

If the flame signal is not sufficient, see page9

(Assistance in the event of malfunction).

Monitor combustion.

▷ The flame must be blue and must remain inside

the device.

▷ If the burner pressurepGand flame signal have

been checked and adjusted on all devices, the

system operates correctly.

4 Remove the pressure gauge.

p

G

0

pG

pG

pG

pG

pu

2,5 mm

0

pG

5 Close the test nipple.

p

G

0

pG

pG

pG

pG

pu

2,5 mm

0

pG

Installing the protective caps

Burner control unit

Pull the opened protective cap from the top over

the burner control unit. In doing so, pull the edges

of the protective cap apart.

ON/OFF

(RESET)

MODE

OFF

AUTO

+AUTO

Slide the opened edges of the protective cap into

the gap between the burner control unit and the

mounting plate.

ON/OFF

(RESET)

MODE

OFF

AUTO

+AUTO

▷

When it becomes difficult to move the edges

of the protective cap, this means the material

has turned cold and hard. The protective cap

will become soft again when it is heated briefly.

Hold the ends of the protective cap on the back

of the burner control unit together and close the

push-in rivets.

ON/OFF

(RESET)

MODE

OFF

AUTO

+AUTO

GB-8

D

GB

F

NL

I

E

Gas combination control

First, pull the opened protective cap over the

gas inlet on the gas combination control.

Then pull the right-hand side of the protective

cap over the gas outlet.

Hold together the ends of the protective cap on

the underside and close all the rivets.

Cleaning

CAUTION

To ensure that no damage occurs during operation

and cleaning, please observe the following instruc-

tions. Otherwise, injuries or damage to the device

may occur and/or the function of the device may

be impaired, and the manufacturer’s warranty will

be cancelled.

– Sharp-edged metal sheets. Always wear protec-

tive gloves.

– After cleaning, check that the components on

and in the heater are in good condition. The

device may only be restarted if all safety devices

have been installed and the safety functions

have been checked.

– Clean the heater once a year when used in

horticulture and at regular intervals as well as

after each fattening period when used in ag-

riculture, as described below. Inadequate or

irregular cleaning can cause damage to the

device or lead to fire damage. For example, dirt

particles can catch fire and can be blown out

of the device.

Switch off the burner control unit BCU.

Disconnect the system from the electrical power

supply. The mains plug may only be pulled out

once the device has been switched off and post-

cooling is complete.

Shut off the gas supply.

▷ If the burner control unit and the gas combina-

tion control are not equipped with protective

caps, we recommend cleaning the heater with

compressed air or a damp cloth only.

▷ Equipping the burner control unitBCU and the

gas combination controlCG with a protective

cap allows the devices to be cleaned carefully

with a water jet/high-pressure cleaner during

cleaning/disinfection of the animal shed.

▷

To guarantee that the burner control unit com-

plies with enclosure IP54, make sure that the

screws are tightly secured after wiring and that

the cable glands are closed.

▷

The distance between the nozzle and the surface

to be cleaned must always be at least 50cm.

> 50 cm

▷ Do not direct the water jet straight at electrical

components such as the vane.

▷

The water jet from the high-pressure cleaner can

cause serious damage to the components in

the heater. For example, the vane can be bent

or other parts such as the spark plug or rubber

seals can be displaced. Avoid direct contact.

▷

Do not spray the edges of the protective cap

which are closed using push-in rivets only or

the connection between the burner control

unit and the mounting plate directly with water,

high-pressure cleaning equipment or chemical

cleaning agents.

▷

Do not spray water or chemical cleaning agents

directly into the space between the fan shaft/

impeller wheel and motor and do not clean with

high-pressure cleaners.

▷ Chemical cleaning agents, disinfectants and/or

pesticides contain corrosive substances which

can even corrode stainless steel. Always rinse

the devices with water after cleaning using such

agents to remove any residue of these agents

from the surface.

GB-9

D

GB

F

NL

I

E

▷

To facilitate cleaning of the components inside the

housing, the maintenance cover on the casing

can be opened.

Z

I

45

10

911

7

68

6 Clean the grille from the outside using a cloth.

▷ Clean the fan, vane and plates for the air intake

using a cloth only.

7 8 9

0 Clean the interior of the device carefully using air.

▷ The vane must not be bent.

Check that the vane switch is functional.

▷

If the vane is moved a little in the direction of the

arrow, a quiet click can be heard. This means

that the switching path is correct.

klick

Assembly

13

12

▷

Check the burner is functioning faultlessly in nor-

mal operation, see page14 (Checking the safety

functions and burner operation).

4 When operating with propane, check that the

breather orifice of the pressure reducer on the

connection kit is clean.

Assistance in the event of

malfunction

WARNING

To avoid harm to persons and animals or damage

to the heater, please observe the following:

– Electric shocks can be fatal! Before working

on possible live components, ensure the unit

is disconnected from the power supply.

– Fault-clearance must only be undertaken by

authorized, trained personnel!

– Repairs to components, e.g. the burner control

unit BCU or the combination control CG, may

only be carried out by the manufacturer. Other-

wise, the guarantee will be cancelled. Unauthor-

ized repairs or incorrect electrical connections,

e.g. the connection of power to outputs, can

cause gas valves to open and the burner control

unit to become defective. In this case, fail-safe

operation can no longer be guaranteed.

– (Remote) resets may only be conducted by au-

thorized personnel with continuous monitoring

of the devices concerned.

▷

In the event of an installation fault, the burner

control unit closes the gas valves and the red

LED on the burner control unit lights up. Then,

the fault is indicated by a combination of flashing

yellow LEDs which are numbered from 1 to 5.

▷ Faults may be cleared only using the remedies

described below.

Press the reset button on the BCU to reset it.

The unit then reverts to the last operating mode

selected.

▷ Faults marked with an * are warnings. Provided

that a restart has been programmed, they are

no longer displayed if the cause of the fault has

been remedied. It is not necessary to press the

reset button when these messages are displayed.

If the burner control unit does not respond even

though all faults have been remedied, remove

the unit and return it to the supplier.

GB-10

D

GB

F

NL

I

E

? Fault

! Cause

• Remedy

Possible faults and suggested solutions

? LED flashes.

OFF

AUTO

+AUTO

1

2

3

4

5

! Pressure switch does not switch.

• Check inlet pressure pu.

! Gas pressure on the burner too low.

• Readjust gas pressurep

G

on the combination

control, see page6 (Adjusting the heater).

! Fuse F2 defective.

• Replace fuse (3.15 A, slow-acting, H). Ensure

that only one heater is directly wired to the ther-

mostat, see page3 (Wiring).

? LED flashes.

OFF

AUTO

+AUTO

1

2

3

4

5

! Vane switch does not switch off during the “no

flow” state check on burner start-up.

• Check that the vane switch is functional, see

page12 (Maintenance).

? LED flashes.

OFF

AUTO

+AUTO

1

2

3

4

5

! The vane switch has not switched on 25s after

the fan has been switched on.

• Vane, fan or grille are dirty. Clean, see page12

(Maintenance).

• Fuse F1 defective (8 A, slow-acting, H). Check

the function of the fan and replace fuseF1 if

necessary.

! Motor defective.

• Remove the device and return it to the supplier.

? LED 4 flashes.*

OFF

AUTO

+AUTO

1

2

3

4

5

! On burner start-up, the BCU has not detected

a flame during the safety time. In the parameter

“Number of start-up attempts”, it is possible to

program up to three start-up attempts. If one of

the further start-up attempts is successful, fault

signalling stops automatically once the post-

purge time has elapsed.

• Ignition is not working properly.

Clean the ignition electrode and check for correct

distance, see page12 (Maintenance).

Check the connection of the ignition cables for

damage or moisture.

The spark plug must be fitted correctly.

Check the ignition spark optically and acoustically

from the fan side during the 4-second ignition

time.

• Poor flame signal due to incorrect burner ad-

justment. Readjust gas pressurep

G

, see page6

(Adjusting the heater).

• Poor flame signal due to dirty/badly connected

ionization electrode.

Clean the ionization electrode and check for cor-

rect distance, see page12 (Maintenance).

Check the cable connection, cable and plug for

damage or moisture. The plug must be fitted

correctly.

Check the yellow and green burner ground cable

for corrosion and to ensure it is firmly connected.

• Air in the gas pipe. Vent the gas pipe.

• Valves do not open. Remove the valve plug on

the combination controlCG and measure the

voltage betweenL1 andN during the safety time.

If the voltage is not adequate, first replace the

CG and return it to the supplier.

Attention! Only commission the new BCU once

the short-circuit or fault on the valve output of

the CG has been remedied. Otherwise, the new

BCU will be damaged.

• If the fault continues to be signalled, there may

be a short-circuit on the valve output. Return

the burner control unit to the manufacturer for

inspection.

• Short-circuit on ignition output. Replace fine-wire

fuse F2: 3.15A (slow-acting, H) and check the

safety function, see page14 (Checking the safety

functions and burner operation).

GB-11

D

GB

F

NL

I

E

? LED 5 flashes.

OFF

AUTO

+AUTO

1

2

3

4

5

! Signal from safety temperature limiter (STL).

Temperature has been exceeded.

• No fan run-on due to soiling. Clean, see page12

(Maintenance).

! Fan defective.

• Check function of fan.

? LEDs 4 and 5 flash.*

OFF

AUTO

+AUTO

1

2

3

4

5

! Signal from safety temperature monitor (STM).

Temperature has been exceeded.

• Leave heater to cool down for longer.

• No fan run-on due to soiling. Clean, see page12

(Maintenance).

? LEDs and 5 flash.*

OFF

AUTO

+AUTO

1

2

3

4

5

! During three consecutive restarts, the gas pres-

sure switch has tripped during the safety time

or flame proving period (gas pressure switch

oscillates).

• Inlet pressure fluctuates. Establish stable gas

supply.

• Gas pressure pGtoo low. Readjust gas pres-

surepG, see page6 (Adjusting the heater).

? LEDs and 5 flash.

OFF

AUTO

+AUTO

1

2

3

4

5

! Incorrect flame signal through conductive ce-

ramic insulation, e.g. surge via PE wire, possible.

• Remedy incorrect flame signal. Replace ionization

electrode and, if necessary, the BCU as well.

? LEDs and 5 flash.*

OFF

AUTO

+AUTO

1

2

3

4

5

! Temperature sensor is not functioning correctly.

• Check the temperature sensor connection.

• Temperature sensor is below -20°C.

! Temperature sensor defective.

• Replace the temperature sensor.

? LEDs and 4 flash.*

OFF

AUTO

+AUTO

1

2

3

4

5

! The time (cycle lock) between two starts is too

short.

• The BCU ensures there is a pause of 15s be-

tween the starts. This warning is displayed during

this time.

? LEDs and 4 flash.*

OFF

AUTO

+AUTO

1

2

3

4

5

! The flame has gone out during operation. If a

restart has been programmed, an automatic re-

start is carried out provided that the burner has

been in operation for at least 2s beforehand.

• Poor flame signal due to incorrect burner ad-

justment. Readjust gas pressurep

G

, see page6

(Adjusting the heater).

• Poor flame signal due to dirty or badly connected

ionization electrode. Clean the ionization elec-

trode and check for correct distance, see page12

(Maintenance).

• Check the cable connection for damage or mois-

ture. The plug must be fitted correctly.

• Check the yellow and green burner ground cable

for corrosion and to ensure it is firmly connected.

GB-12

D

GB

F

NL

I

E

? LEDs and 4 flash.*

OFF

AUTO

+AUTO

1

2

3

4

5

! A signal is applied for longer than 10s to the

remote reset input (terminals 31 and32) (per-

manent remote reset).

• Remote reset must only be used to reset the

device.

? LEDs and flash.

OFF

AUTO

+AUTO

1

2

3

4

5

! The flame has not gone out within 5s of the

burner being switched off. The gas valve does

not close correctly.

• Shut off the gas supply to the device. Check

the burner and gas valves for correct function,

see page14 (Checking the safety functions and

burner operation).

? LEDs and flash.*

OFF

AUTO

+AUTO

1

2

3

4

5

! The power supply has suffered a fault.

• Ensure there is sufficient mains voltage, see

page17 (Technical data).

? LEDs , 4 and 5 flash.

OFF

AUTO

+AUTO

1

2

3

4

5

! While a fault was pending, more than 5attempts

were made within 15minutes to reset the de-

vice using the remote reset input (terminals31

and32).

• Reset is only possible using the reset button on

the BCU.

Maintenance

CAUTION

To ensure that no damage occurs during operation

and maintenance, please observe the following

instructions. Otherwise, injuries or damage to the

device may occur and/or the function of the device

may be impaired. The supplier/manufacturer cannot

accept liability for damage resulting thereof.

– Have the heater cleaned at least once a year

by qualified maintenance personnel.

– Have the safety functions checked at least once

a year by qualified maintenance personnel, see

page14 (Checking the safety functions and

burner operation).

– Sharp-edged metal sheets. Always wear protec-

tive gloves.

– After cleaning or repair work, check that the

components on and in the heater are in good

condition. The device may only be restarted

if all safety devices have been installed and

the safety functions have been checked, see

page14 (Checking the safety functions and

burner operation).

Switch off the burner control unit BCU.

Disconnect the system from the electrical power

supply. The mains plug may only be pulled out

once the device has been switched off and post-

cooling is complete.

Shut off the gas supply.

▷

To facilitate cleaning of the components inside the

housing, the maintenance cover on the casing

can be opened.

Z

I

45

10

911

7

68

I = Ionization electrode

Z = Ignition electrode

Z

I

45

10

911

7

68

GB-13

D

GB

F

NL

I

E

Check the burner head (nozzle and baffle plate)

and the electrodes for dirt and if necessary, clean

using a cloth. Remove stubborn dirt on the elec-

trode rod using fine abrasive paper.

Check electrodes and porcelain insulators for

cracks and replace the electrodes in case of

damage.

▷ Replace the electrodes if necessary.

74 mm

Z

I

3 mm

ZI

1514

16

17

▷ Ensure correct positioning of the electrodes.

74 mm

Z

I

3 mm

ZI

1514

16

17

▷

When replacing the ionization electrode, the por-

celain insulator must be flush with the ignition

electrode insulator.

▷ Clean the grille and fan using a cloth only.

19

18

▷

Clean the vane and plates for the air intake using

a cloth only.

2120

Clean the interior of the device carefully using air.

▷ The vane must not be bent.

Check that the vane switch is functional.

▷

If the vane is moved a little in the direction of the

arrow, a quiet click can be heard. This means

that the switching path is correct.

klick

Assembly

Z

I

24 25 26

31

28 29

30

27

▷

Connector with conical sealing surfaces must

be screwed tight. Otherwise, gas can escape.

Z

I

24 25 26

31

28 29

30

27

▷ Ensure that the rubber seals between the elec-

trodes and the electrode plugs are fitted correctly.

Z

I

24 25 26

31

28 29

30

27

Check the safety functions before commission-

ing.

GB-14

D

GB

F

NL

I

E

Checking the safety functions and

burner operation

WARNING

If these checks are not carried out, the gas valves

might remain open allowing non-combusted gas

to escape. Risk of explosion!

Safety functions

Switch off the heater during operation. Press

ON/OFF

OFF 1

2

3

4

5

AUTO

+ AUT

MODE

(RESET)

ON/OFF

O

.

▷ The flame goes out <1s.

▷

The fan cools the heater down until it reaches

switch-off temperature.

Remove the valve plug on the combination con-

trol during operation.

▷ The gas valves close <1s.

▷ The flame goes out.

▷

The burner control unit BCU displays the fault

message “The flame has gone out during opera-

tion”. LEDs2 and4 flash.

▷

If a restart has been programmed, the burner

control unit will initially attempt to restart and will

then perform a fault lock-out. LED4 flashes and

displays the fault message “No flame has been

detected during the safety time”.

Shut off the inlet pressure during operation.

▷ The pressure switch in the combination control

switches because the supply pressure is too low.

▷

The burner control unit performs a safety shut-

down: the gas valves are disconnected from the

electrical power supply.

▷ The flame goes out.

▷

The burner control unit BCU displays the fault

message “Supply pressure too low”. LED1

flashes.

▷ If the burner control unit responds in a different

way to that described, a fault has occurred, see

page9 (Assistance in the event of malfunction).

CAUTION

The fault must be remedied before the system may

be operated.

Checking burner operation

Switch on the BCU.

Select the Heating

OFF 1

2

3

4

5

AUTO

+ AUT

MODE

(RESET)

ON/OFF

O

operating mode.

Allow the burner to burn for 15minutes.

4 During this time, monitor the flame pattern.

▷ The flame must be blue.

▷ No dirt particles must come out of the heater.

Accessories

Room thermostat

Use a room thermostat with a hysteresis of ±1°C,

230V, Type TH215.

35

30

25

2015

10

5

0

°C

TH215

Order No.: N50260145

Pressure reducer

Pressure reducer for LPG.

RECA 1.5 bar to 50 mbar, 2 x ½" internal thread

connection, 10 kg/h, Order No.: N52600023.

Manual valve

2 x ½" internal thread connection,

Order No.: N50260019.

½" internal and external thread connection,

Order No.: N50260027.

GB-15

D

GB

F

NL

I

E

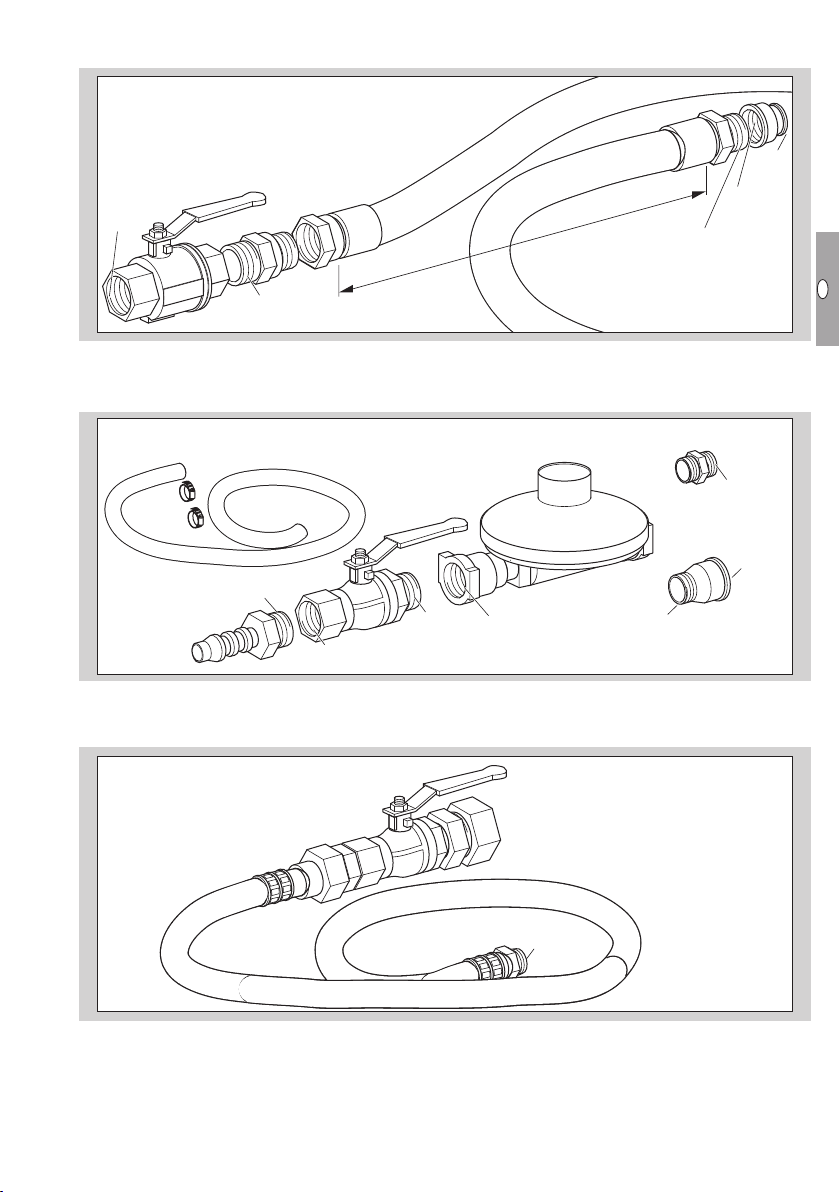

Connection kit for natural gas

Manual valve and gas hose to connect the gas combination control CG to the gas supply.

R 1"

Rp ¾"

Rp 1"

1,40 m

Rp 1"

R 1"

Connection kit: R 1" threaded connection, total length = 1.50m + reducing socket Rp1 – Rp¾",

Order No.: N52600071

Connection kit for propane

Rp ¾"

R ½"

R ½"

R ½"

ø 6 mm

R ½" Rp ½"

Rp ½" GP 70/GP 95/GP 120

GP 14/GP 40

Pressure reducer, manual valve, hose (length = 2m), 2 hose clamps, R½" double nipple for GP14/GP40,

R½ – Rp¾" reducing fitting for GP70– GP120, to connect the gas combination controlCG to the gas sup-

ply, OrderNo.: N52600025

R 3/8"

R ½"

ø 15 mm

Manual valve and hose (DVGW certified, length = 2m) to connect the gas combination controlCG to the gas

supply, OrderNo.: N52990209

GB-16

D

GB

F

NL

I

E

Spare parts

▷ When ordering spare parts, please quote the order number along with the designation and item no. of

the spare part as well as the heater serial number.

▷ When ordering spare parts which are not listed here below, please quote the edition of these operating

instructions and the heater serial number.

▷ Use original spare parts only to ensure the replacement complies with the requirements stipulated by the

manufacturer.

20

21 16

14, 15

13

19

5

22

4

22, 23

1

17

3

18

4

10

12 11 6

7, 8

9

5

Item

Order No. Designation

1N50400012 Multifan fan for GP 120, incl. impeller wheel, 4E-50-8PP

2N50400032 Safety grille for GP 120 fan, black

3N50260173 Pipe 178 mm, galvanized, R ¾"

4N50260144 Vane switch, complete, universal for all devices, incl. 2-core cable

5N52600008 Electrode holder for GP 95/GP 120

6N50260167 Burner baffle plate for GP 95/GP 120/RGA, Ø 48 mm

7N50400066 LPG nozzle for GP 120, 12 x Ø 1.8 mm

8N50400069 Natural gas nozzle for GP 120, 12 x Ø 3.3

9N50390005 Ignition electrode for GP 95/GP 120

10 N50260213 Ignition cable kit for GP 40 – GP 120, complete with plug and cap

11 N50390006 Ionization electrode for GP 95/GP 120

12 N50500080 Ionization cable kit for GP series, incl. plug and seal

13 N50260101 BCU 300 upper housing section, incl. electronics, Kromschröder THP-GW 84636001

14 N50260102 BCU 300 lower housing section, incl. ignition transformer

15 N50260109 Ignition transformer for gas, Eichhof E4718/55, 1-pin

16 N50260097 Temperature sensor for STM/STL, 6 x 45, L = 290 mm, TSK 1056 NTC (5 kΩ/25°C)

17 N50260171 90° male/female elbow, galvanized, R ¾"/Rp ¾"

18 N50400004 Pipe 300 mm, galvanized, R ¾"

19 N50280123

Gas combination control CG 220 for GP 70– GP 120, Kromschröder CG 220R01-DT2WF1Z

20 N50260119 Plug for pressure switch, grey

21 N50260118 Plug for valves, black

22 N50400200 Natural gas burner for GP 120, complete

23 N50400201 LPG burner for GP 120, complete

24 N50400102 Burner chamber for GP 120

25 N50260147 Protective cap for BCU, PVC, black, with viewing window

26 N50260148 Protective cap for gas combination control CG 220, PVC, black

GB-17

D

GB

F

NL

I

E

Technical data

Inlet pressure pu:

natural gas: 20 – 25 mbar,

propane: 35 – 50 mbar.

Setting of the gas pressure switch pW:

natural gas: 10 mbar,

propane: 30 mbar.

Gas connection: R ¾" external thread.

Material:

casing: stainless steel 430,

burner chamber: stainless steel 430,

BCU: PPE.

Ambient temperature:

-10 to +60°C. No condensation permitted.

Cycle lock: 15 s.

Capacity: 120kW.

Gas consumption:

natural gas L: ± 11.7 m3/h,

natural gas H: ± 9.9 m3/h,

propane: ± 8.6 kg/h.

Connection rating:

230VAC, -15/+10%, 50/60Hz, 735W.

Power consumption: IA/IN: ± 8 A/3.2 A.

Air circulation:

Controlled air flow: ± 6650 m3/h,

Heating: ± 8000 m3/h.

Jet length: 50 m.

Housing:

length: 1450 mm,

width (total): 650 m,

height/diameter: 532 mm,

weight: 45 kg.

Declaration of conformity

We, the manufacturer, hereby declare that the prod-

uctGP complies with the requirements of the listed

Directives and Standards.

Directives:

– 2009/142/EC

– 2004/108/EC

– 2006/42/EC

– 2006/95/EC

Standards:

– DIN 3362, EN 298

– EN 60730

– EN 1643, EN 525:2009

The relevant product corresponds to the type tested

by the notified body 0085.

The production is subject to the surveillance proce-

dure pursuant to Directive 2009/142/EC according

to annex II paragraph 3.

Elster-Instromet B.V.

Scan of the Declaration of conformity (D, GB) – see

www.docuthek.com

GB-18

D

GB

F

NL

I

E

Contact

If you have any technical questions, please

contact your local branch office/agent. The ad-

dresses are available on the Internet or from

Elster-Instromet B.V.

Munstermanstraat 6

7064 KA Silvolde

T +31 315 338-911

F +31 315 338-679

We reserve the right to make technical modifications

in the interests of progress.

orders.ermaf@elster.com,

www.ermaf.nl

Elster-Instromet B.V.

Sales Office

Postfach 2809, 49018 Osnabrück

Strohteweg 1, 49504 Lotte (Büren)

Germany

T +49 541 1214 702

F +49 541 1214 506

Goods return form

Name of the operator

P.O. Box/Street

Postcode and town/city

Tel.

E-mail

Returned by (Mr./Ms.)

Date

Number of returns

Heater serial number

Power supply [V/Hz]

Inlet pressure pu[bar]

Reasons for return

Description of fault

Desired action

Credit note Replacement Repair

Remarks

Date and signature

Please send returns back to your supplier.

Contact

This manual suits for next models

1

Table of contents

Other ermaf Heater manuals