EROAD CoreHub Xtreme User manual

Parts and Equipment

Included with the CoreHub Xtreme Install Kit:

CoreHub Xtreme (the “unit”)

Trailer and reefer Smart harness

•

•

•

•

•

•

Remote Start Stop (RSS) switch

harness (optional)

External antenna

Bracket

Zip ties, screws

Required tools

10, 12, 13, 14, and 17 mm deep well sockets

and wrenches

Diagonal flush cutters

Impact driver and 5/16ths bit for self-tapping

screws

18/20ga butt splice crimping tool

Propane torch

Platform to reach the top of the reefer safely

•

•

•

Pre-prep

Start the reefer to ensure it’s working with no

console alarms.

Ensure the reefer has its DataTrak/CarrierShot

firmware updated and operating.

Use the Safety Lockout Procedure; disconnect

any AC power source and battery NEGATIVE

terminal.

A ladder is fine for heights up to 2 m (7

ft) but should not be considered safe

for reaching the top of a reefer. Where

possible, use a scissor-lift, forklift

basket or similar stable, load-bearing

platform.

•

•

•

Mount the unit

Attach the unit to a flat surface half-way up the

inside of the reefer, such as above the APX

Control System display.

Use the holes in the mounting bracket to mark

the drilling points on the reefer, attach the

bracket accordingly, and mount the unit.

Keep the unit and the cables away from hot or

moving parts and high voltage lines (usually

colored orange).

Bracket

APX

Advance

Vector 6500

Vector 8600

Mount the antenna

Attach the antenna to the top of the reefer or the

side front of the trailer. To function properly, it

must directly see the sky.

•

•

•

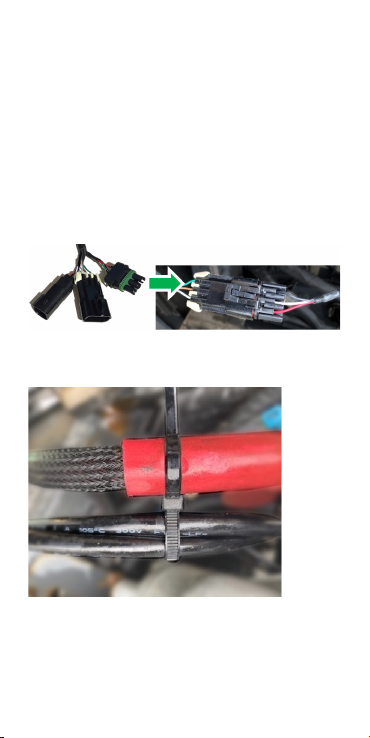

Plug the unit into the DataTrak

connector

Run the CoreHub Carrier harness cables to the

DataTrak connector by the APX display,

following the reefer frame or low-voltage lines

underneath. Do not zip-tie the harness to the

high-voltage (orange) power lines.

The main harness has connectors for reefer

data (Satcomm1), fuel sensor, and the J1

jumper and/or optional RSS switch.

Use the provided zip ties to space the cables.

Reefer data to CoreHub Xtreme

harness

•

•

Loop ties

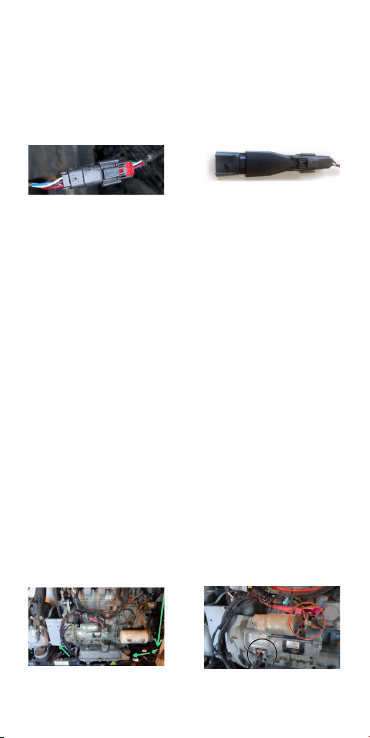

Attach the unit to J1 through

the adapter

Take the cap off the J1 and attach it to the

adapter.

Optional: Attach the unit to J1 with an

optional RSS switch

If you’re using the RSS switch for remote

controlling the unit, you do not need the adapter.

To install the switch, use the start/run toggle

switch nut and a self-drilling screw. If a few

switch threads are exposed, pull the switch to

start the nut.

Run the switch cable to the rear of the APX

display to avoid interference with doors and

compartment covers.

•

•

•

•

•

•

Tie the double-fuse holder near the APX display

for future use.

Plug the switch cable into the J1 and also into

the main harness.

Zip tie the old J1 jumper next to its connector

for possible future use (in case it’s needed for

emergency bypass).

Switch - Xtreme

harness

Adapter –

discard this if

using the RSS

switch

A thicker switch nut is included to replace the

existing one for easier tightening with a 14 mm

box wrench. Older models like the Advance have

the pushbutton mounted vertically with a machine

screw, sealing washer, and lock.

Connect reefer power

Connect reefer power and ground at the starter

solenoid ring studs.

The power cable is usually tied along a battery

feed to the solenoid using double-loop zip ties

or can follow the low-voltage cables under the

reefer.

The power fuse cover should be tied up with

wires coming out the bottom.

•

•

•

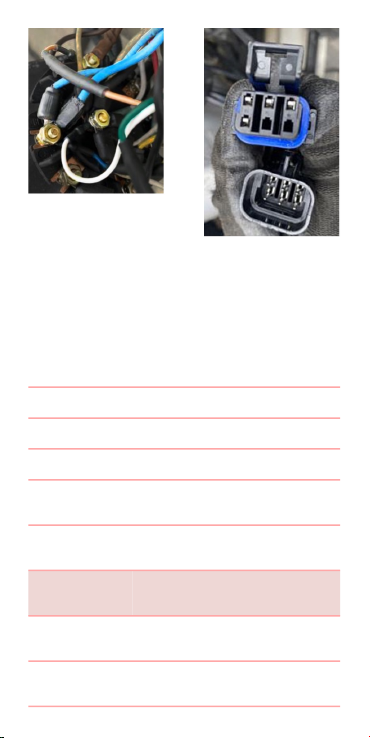

Optional: Connect to trailer ABS

module from the 7-way

connector

This step refers to using the optional trailer ABS

harness (part number HHXTR7) if each axel’s

odometer reading will be gathered for

maintenance purposes.

The unit receives data from the 7-way

connector.

Push the wires through the grommet. To help

this – especially if the rings are already

terminated – loosen the housing to

decompress the grommet, and then loop a wire

through the rings to pull them through.

Connect the blue, brown, and white wires on the

harness to the corresponding blue, brown, and

white power studs on the 7-way. Deep 3/8-inch

sockets can help tighten the nuts. Do not over-

tighten as the studs can break.

•

•

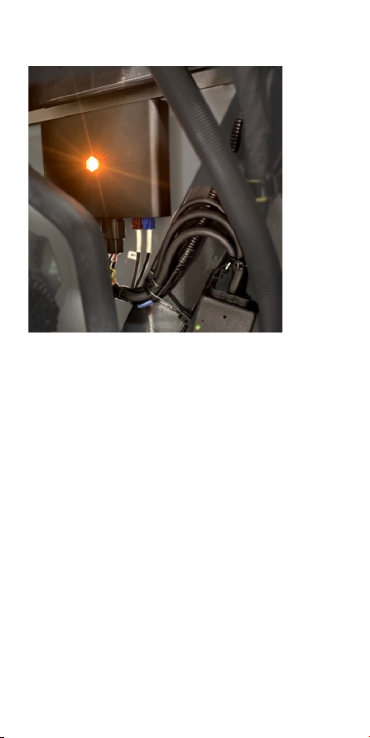

Reefer on; look for a solid red

light

Reconnect the battery.

Use the displayed table to troubleshoot the

unit’s status.

LED Color Flash Pattern Description

Light Pink Solid Bootup

Blue Solid Starting Services

Green Solid/ Ignition

On

Disconnected

from Cloud

Red Flashing/

Ignition Off

Connecting to

Cloud

Red Solid/ Ignition

Off

Connected to

Cloud

Orange Flashing/

Ignition On

Connecting to

Cloud

Orange Solid/ Ignition

On

Connected to

Cloud

•

•

•

•

•

•

Use the Installer app to activate

the unit and any wireless

sensors

Scan the QR code to download or search for

the Unit in Google Play or Apple’s App store.

You can also find the QR code in the box

the unit came in and on the back of the

unit itself. For convenience, place the QR

code on the inside of the APX display door.

Log in to the app using your 360 credentials.

Turn on the reefer and verify that the unit’s

status LED is solid red and that you are within

close Bluetooth range of the unit.

On the home screen, select Install.

Use the QR code to identify the unit to the app.

Enter the trailer and reefer information.

•

•

•

•

•

•

Add sensors one at a time by scanning their QR

codes. Each sensor has diagnostics.

Optionally, photo-document your work as

described below.

Photo verification

Installers are encouraged to photo-document their

work to assist in supporting work order

documents.Any digital camera may be used for 2

or 3 images per site, but images must:

Show the device clearly, mounted in place,

oriented appropriately.

Show connections and wiring secure and tidily

managed.

Indicate the environment in which the device is

installed (its position in the cab, or on the

asset).

You may also wish to note the vehicle make/

model for future reference.

1.

2.

3.

4.

a.

b.

5.

a.

Addendum: Migrating from a

TMU to CoreHub Xtreme

Unplug the TMU unit from all cabling.

Take photos of the installation beyond this

step. Any digital camera may be used.

Record/confirm the serial number of the TMU

before moving on.

Except for the fuel sensor and its cabling,

remove the antenna and any connected TMU-

related hardware (harnesses, door sensors,

etc.).

If installed, carefully remove the old TMU

switch attached to the Carrier controller unit.

This controller houses delicate components,

and some plastics become brittle with age.

Avoid forcing or prying the TMU switch from

the controller.

Once removed, fill holes with appropriate

grommets, and weatherproof with silicone.

Mount CoreHub Xtreme. Follow the steps

detailed in this guide, with the following call-

outs:

If using the same TMU locations for the

CoreHub Xtreme and its antenna: re-use the

Photos are evidence of a

compliant install. They protect

EROAD’s and the Installer’s

liability, should a future 3rd party

or incident affect compliance

integrity.

b.

c.

existing site as much as possible. Holes,

braces/supports, etc.

Be mindful of alterations to the reefer since

the TMU’s installation: additional

peripherals, special structures, etc., that

may affect CoreHub Xtreme’s installation,

its performance, or its structural integrity.

If using a door sensor, a new wireless door

sensor will need to be installed. (Wired door

sensors are no longer supported.)

Specifications

Cellular 4G LTE

WiFi 2.4 & 5 GHz 802.11 a/b/g/

n, 150 Mbps

Bluetooth Classic+BLE 4.2

GPS GPS, BEIDOU, GLONASS,

Galileo

Power 12 V, 0.5 A

24 V, 0.25 A

Int. Battery Lion rechargeable, or

Li-hybrid Supercap

(Optional)

Dimensions 160 x 90 x 25 mm (6.3 x

3.5 x 1 in)

250–400 g (0.5–0.8 lb)

Temperature -40 — +70°C

IP Rating IP66K

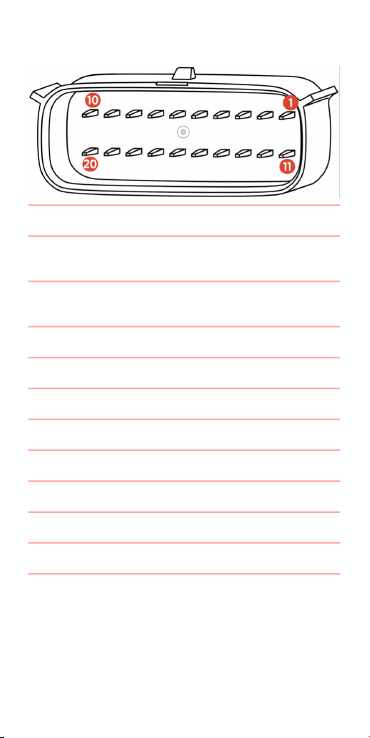

Pinout

PIN Function PIN Function

1 RX2 (normally

debug)

11 ADIO 5

2 TX2 (normally

debug)

12 ADIO 4

3 RX1 (shared J1708) 13 ADIO 3

4 TX1 (shared J1708) 14 ADIO 2

5 CAN LOW 15 ADIO 1

6 CAN HIGH 16 GND

7 1708-/ CAN1 LOW 17 1-Wire

8 1708+/ CAN1 HIGH 18 EXT 5/ 5V SW

9-VIN/ Solar Panel- 19 EX 12/ 12V SW

10 +VIN 20 Solar Panel+

Health and safety

There are no user-serviceable parts.

This device was designed to track land-based

Assets that may be subjected to rain, light

impacts and general mud and dust. Installation in

or on water-borne equipment is not

recommended and is not covered by EROAD's

warranty.

This device is factory-sealed; tampering will void

the warranty.

Before installing EROAD equipment in a vehicle

you must be, in Australia, an approved EROAD

installer and, in New Zealand, an accredited

EROAD installer. EROAD expects installers and

contractors to understand and follow all relevant

health and safety regulatory requirements.

The installer must wear appropriate Personal

Protective Equipment (PPE) for the install risk and

customer requirements. PPE may include safety

glasses, safety shoes, work gloves, hard hat, high

visibility vest, sun cream, sun hat and coveralls.

You must understand and comply with the safety

requirements of customers or third parties.

Avoid fitting EROAD equipment in locations that

could impede or cause injury to people. This

includes potential head strike zones on the

windshield or dashboard, airbag deployment

locations, seatbelts, and other safety-relevant

devices.

The vehicle must be parked and level, with the

parking brake engaged.

Before installation, check that other safety-

relevant equipment is working properly and report

any issues to the customer.

Before installers are permitted to work under or

around suspended equipment – held aloft with

slings, hoists, or jacks – ensure the equipment is

secured to prevent collapse or falls.

Other manuals for CoreHub Xtreme

1

Table of contents

Other EROAD Automobile Accessories manuals

Popular Automobile Accessories manuals by other brands

Southwing

Southwing SF-505 quick start guide

Cruz

Cruz Evo Rack Alu A30-140 Assembly instructions

TOP VEHICLE TECH

TOP VEHICLE TECH GRKVX04 installation manual

Fiamma

Fiamma LICENCE PLATE CARRIER Installation and usage instructions

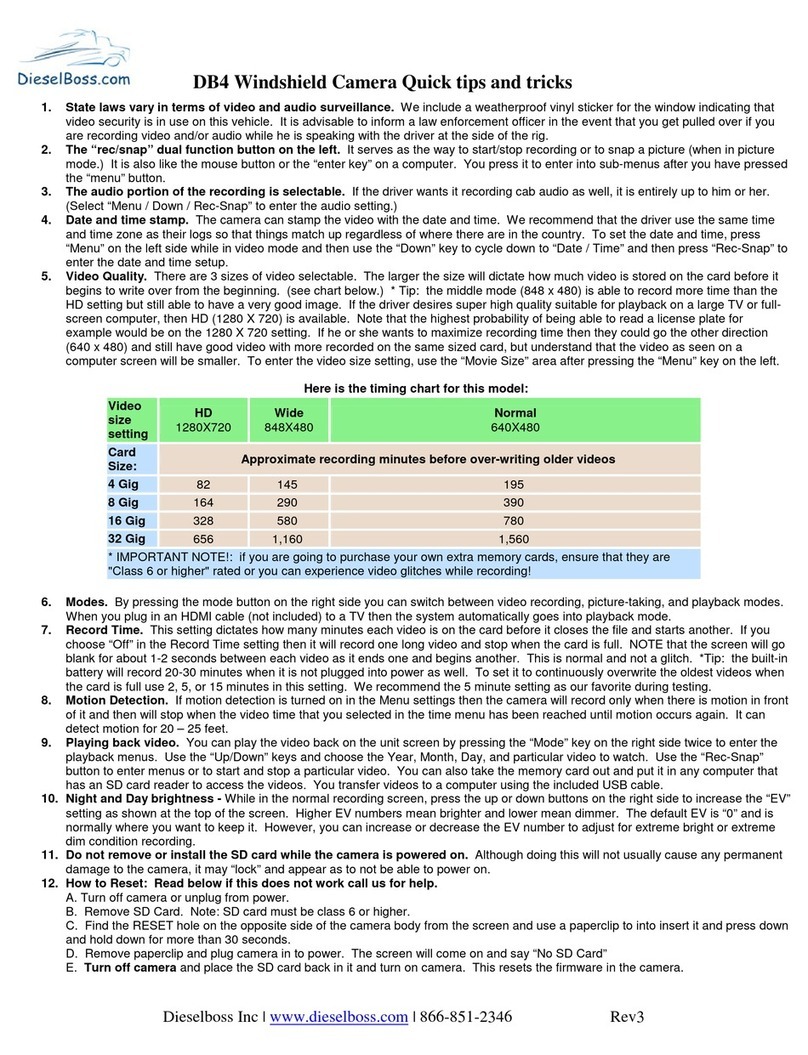

DieselBoss

DieselBoss DB4 Quick tips and tricks

TAUBENREUTHER

TAUBENREUTHER 2086-03 manual